Light-leaking-preventing instrument pointer structure

An instrument pointer and anti-light leakage technology, which is applied in the direction of instruments, measurement value indicators, and measuring devices, can solve the problems of light leakage from the pointer 14, increase the man-hours and production costs of the pointer 14, and reduce lateral light leakage and reduce manufacturing costs. Cost, the effect of overcoming light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be exemplified below in detail with reference to the accompanying drawings. Furthermore, the directional terms mentioned in the present invention are, for example, up, down, top, bottom, front, back, left, right, inside, outside, side, surrounding, central, horizontal, transverse, vertical, longitudinal, axial, The radial direction, the uppermost layer or the lowermost layer, etc. are only directions referring to the drawings. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention.

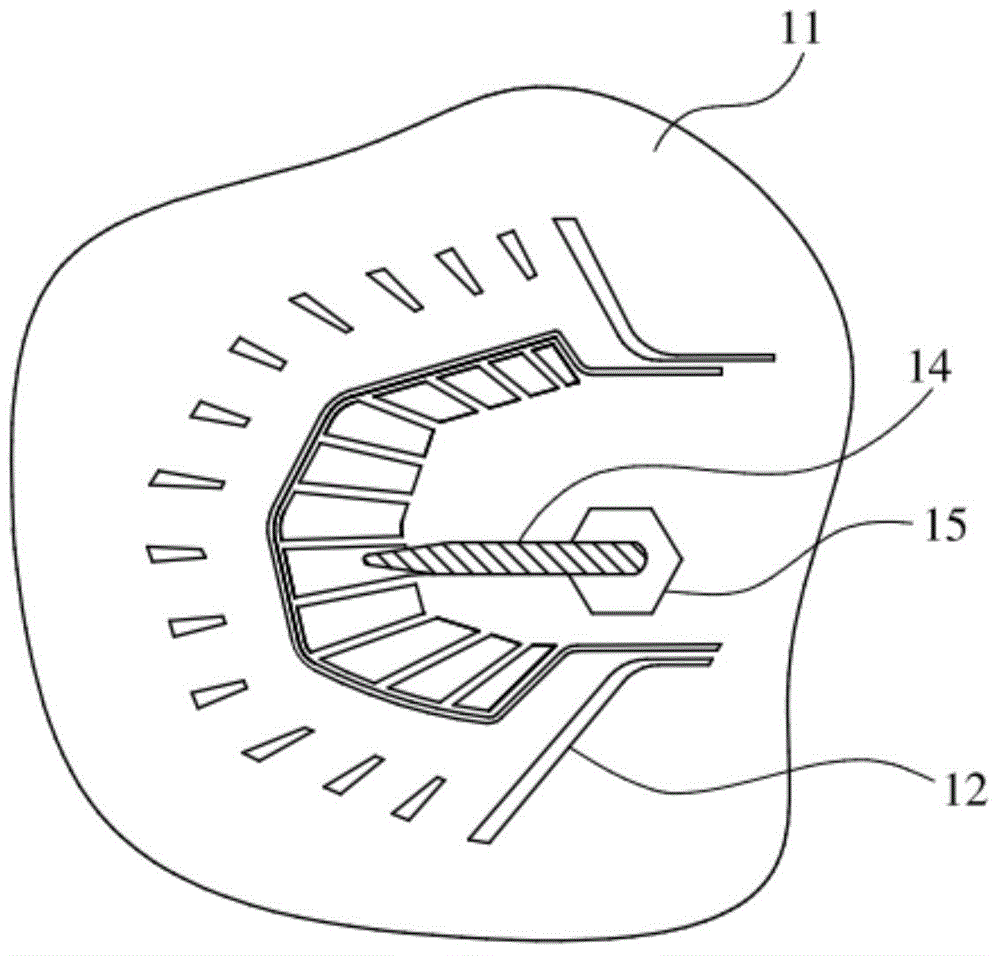

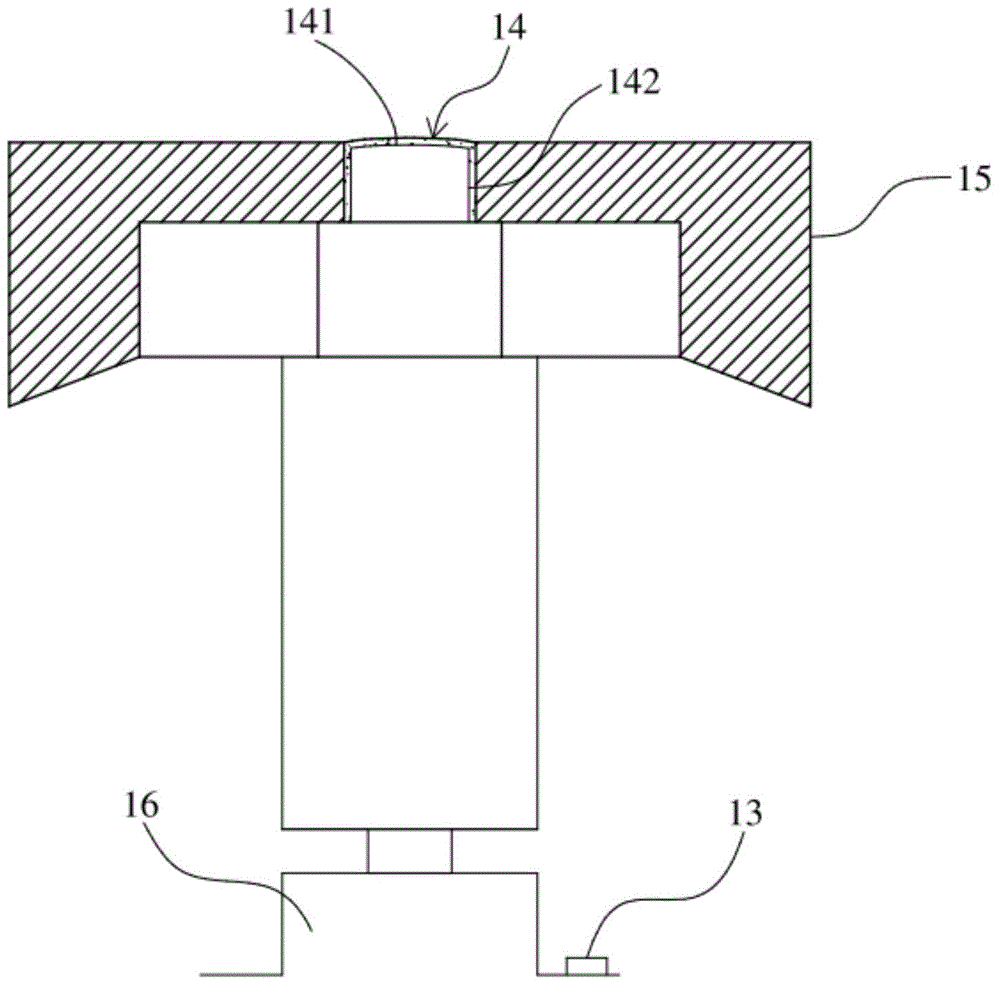

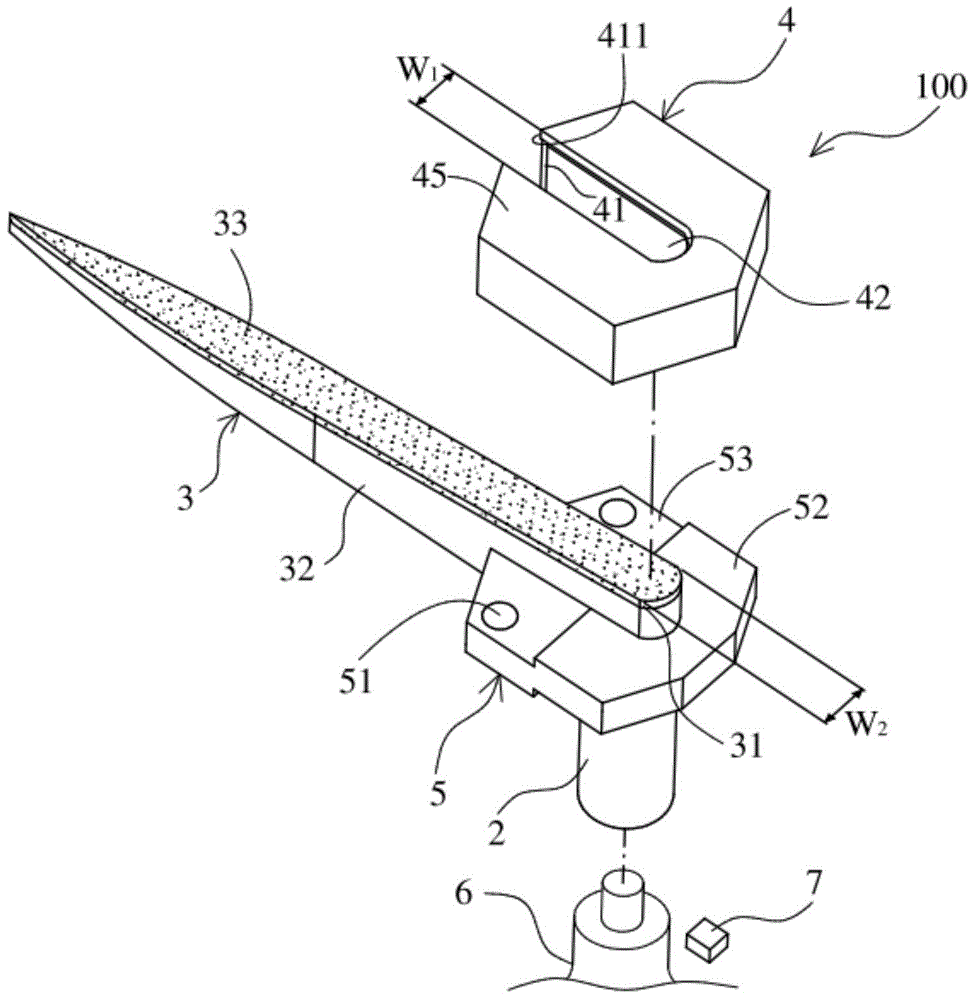

[0026] Please refer to image 3 , 4 As shown, a preferred embodiment of the anti-leakage instrument pointer structure of the present invention is used to be arranged on an instrument panel of a car body (see figure 1 ), the pointer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com