Positioning and pressing tool for fabricating motor iron core

An iron core and pressing plate technology, applied in the field of positioning and pressing tooling, can solve the problems affecting the electromagnetic and electrical performance of the motor iron core, the quality stability of the product yield and the work reliability, the thickness of the punching sheet, the size of the pressing force, the size of the sheet The gap and uniformity restriction, the verticality of the inner hole surface and the outer surface and the overall surface flatness are not ideal, etc., to achieve the effect of reliable bonding, reliable mechanical strength, reasonable structure and scientific effect between punching sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

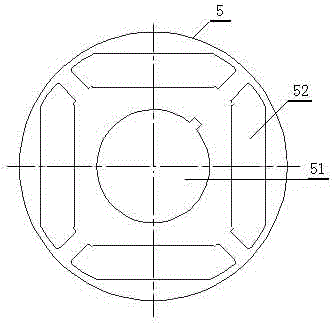

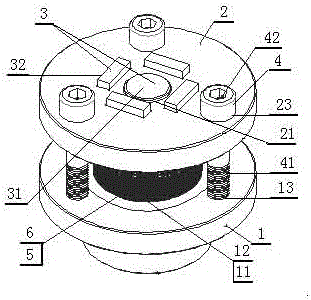

[0015] exist figure 1 and figure 2 Among them, the positioning and pressing tool for making the motor iron core of the present invention includes a lower base plate 1, an upper pressing plate 2, and a limiting member 3 and a fastener 4 arranged between the lower base plate 1 and the upper pressing plate 2, and is characterized in that: The limiting member 3 includes a central axis 31 whose cross section conforms to the shape and size of the central hole 51 on the punching sheet 5 and a side hole limiting strip 32 whose cross section conforms to the shape and size of the peripheral hole 52 on the punching sheet 5; The fastener 4 is composed of a fixed screw rod 41 and a rotatable screw sleeve 42; the lower bottom plate 1 is provided with a central axis mounting hole 11 corresponding to the central hole 51 on the punching piece 5, and is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com