Tail-end casting device for deep-sea cage culture pneumatic conveying feeding system

A technology of deep-sea cages and feeding devices, which is applied in the field of farming machinery, can solve the problems of high price, uneven feeding, poor adaptability to the environment, etc., and achieve the effects of low manufacturing cost, good sealing effect, and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

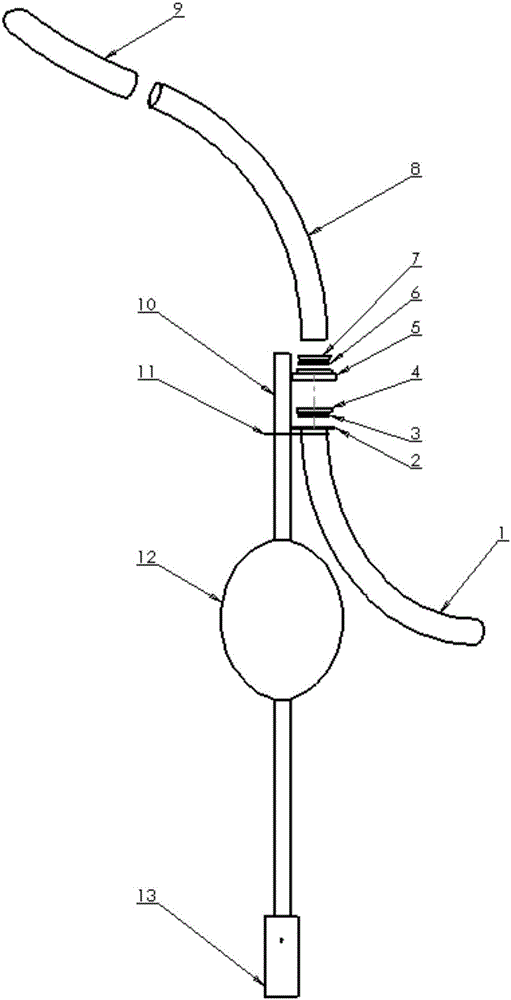

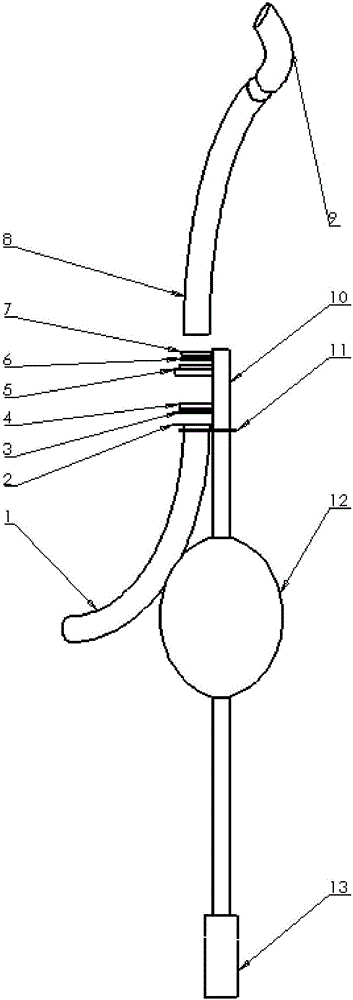

[0026] Such as Figure 5 As shown, the air feeding feeding system for aquaculture includes a fan, a feeder, a remote conveying pipeline and a terminal spreading device.

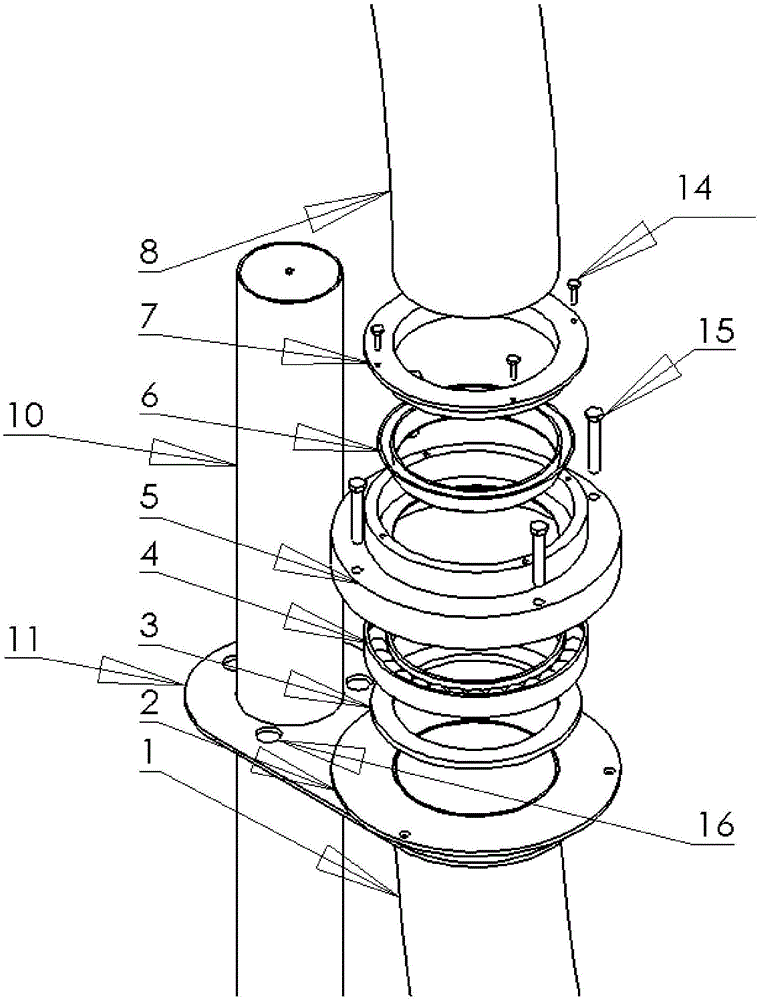

[0027] Such as figure 1 , 3 , shown in 4, a kind of terminal material spreading device that is used for breeding air feeding feeding system, comprises rotating mechanism and fixed floating mechanism; Rotating mechanism comprises lower fixed pipe 1, rotating joint, lower rotating pipe 8, upper rotating pipe 9; One end of the fixed pipe 1 is connected to the end of the remote conveying pipe of the breeding air feeding and feeding system, and the other end is welded with a flange 2. There is a rotary joint between the lower fixed pipe 1 and the lower rotating pipe 8, and the lower fixed pipe 1 is a thin Steel Pipe. The upper rotating tube 9 and the lower rotating tube 8 are nested and sealed connections, which are bonded with metal adhesive glue to make the connection sealed. The upper rotating tube 9 and the...

Embodiment 2

[0032] The principle is the same as in Embodiment 1, except that the floating system consists of vertical rods 10, buoys 12, and weights 13, other floating platforms can also be used, and the shape and structure are not limited to the vertical rod structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com