A device and method for ash hopper material level monitoring and emergency ash unloading for preventing ash accumulation

An ash unloading device and a technology for preventing ash accumulation, which are applied in combustion methods, combustion product treatment, and removal of solid residues, etc., can solve problems such as threats to boiler operation safety, ash accumulation in ash duct flues, and insufficient attention to boiler ash cleaning. and other problems, to achieve the effect of high level of automatic operation, efficient ash unloading, and reducing the difficulty of on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

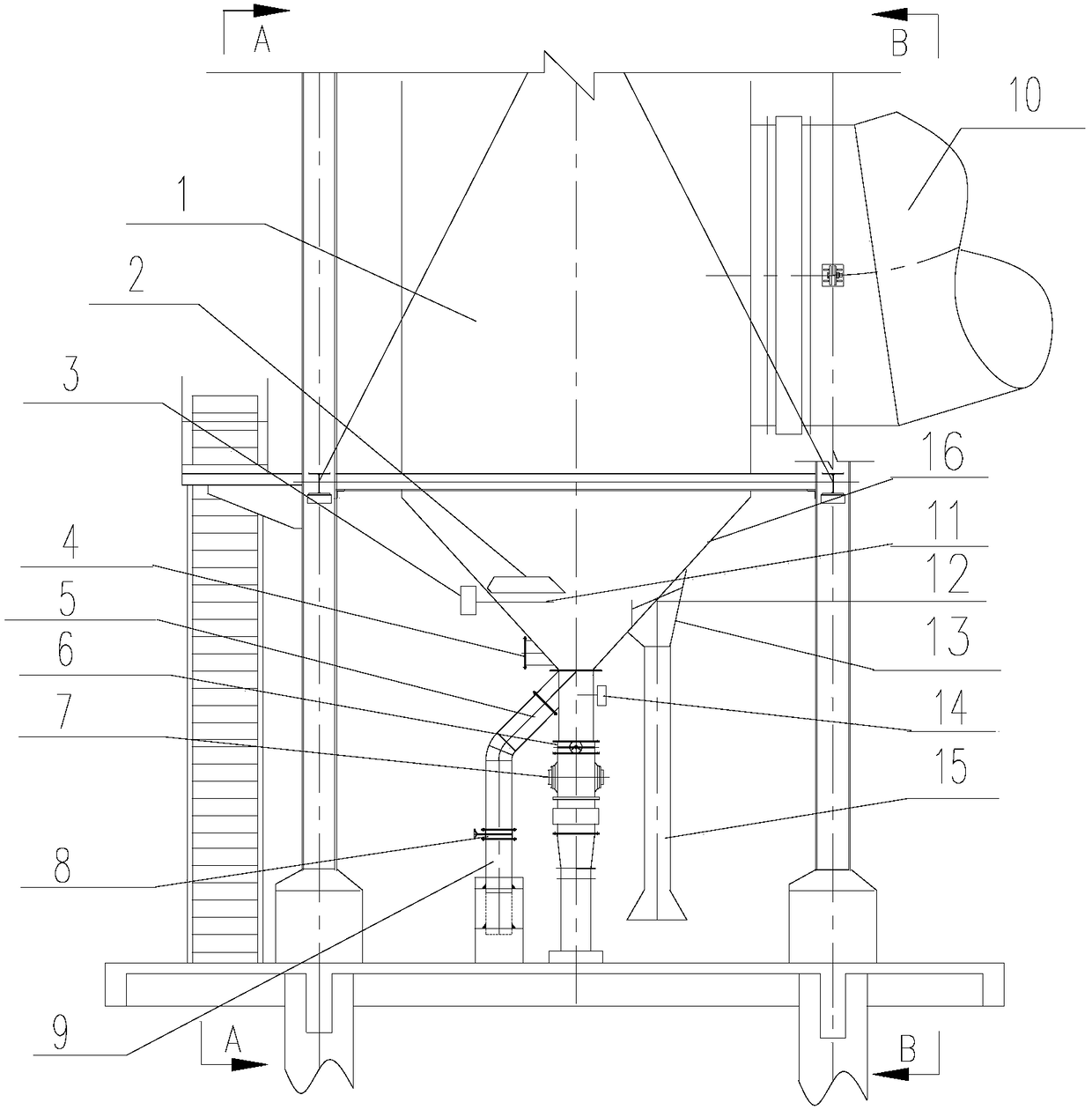

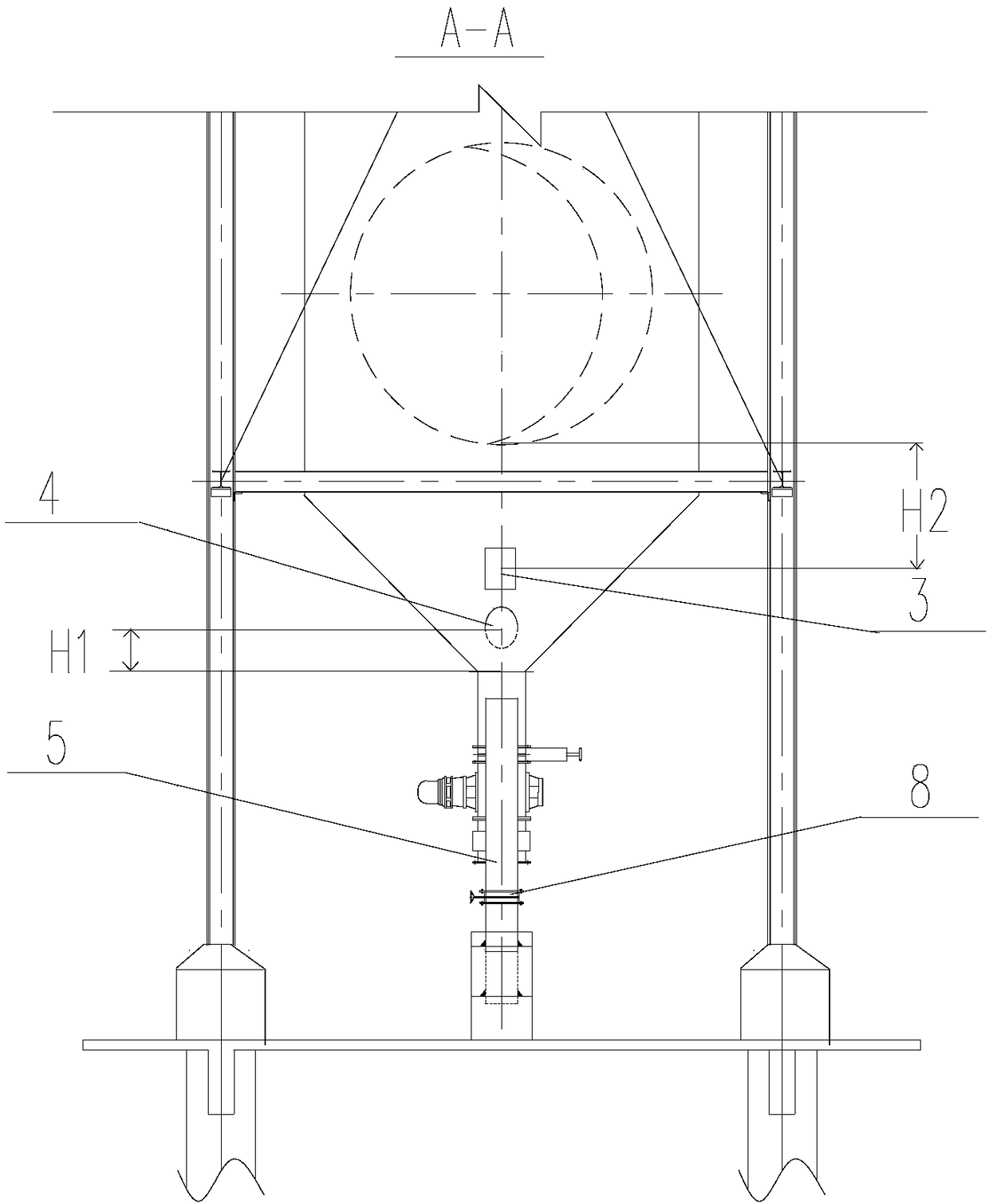

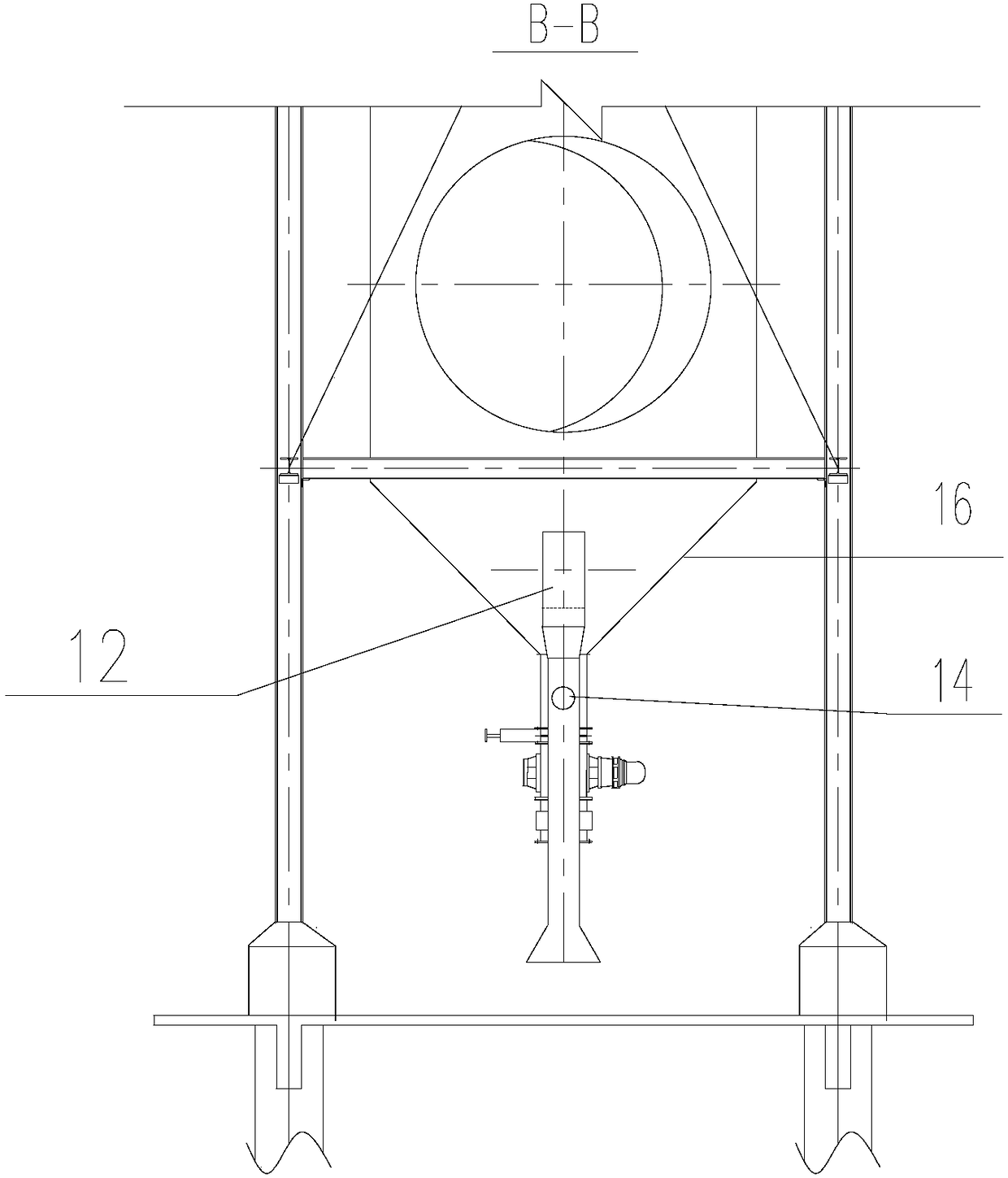

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Such as Figure 1-3 As shown, the ash hopper material level monitoring and emergency ash unloading device for preventing ash accumulation in this embodiment includes a conventional unloading system, a bypass poking ash system, an automatic ash unloading system and an emergency alarm system;

[0022] Among them, the conventional unloading system is connected at the ash outlet directly below the ash hopper 16. The conventional unloading system includes a flat gate valve 6 and a star unloader 7 connected by a pipe, and the flat gate valve 6 is located at the bottom of the star unloader 7. above. The bypass ash removal system includes a bypass ash removal port 4, a thermocouple 14, and a bypass emergency ash release elbow 5 (the angle between it and the vertical direction is 120-140°, which is conducive to the smooth flow and fall of the accumulated...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap