A method and device for detecting fastening force of a low-pressure turbine shaft disk of an aeroengine based on a cylinder-type contact displacement sensor group

A technology of displacement sensor and low-pressure turbine shaft, which can be used to measure the direction of torque/torsional force during tightening, which can solve the problems of low test efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

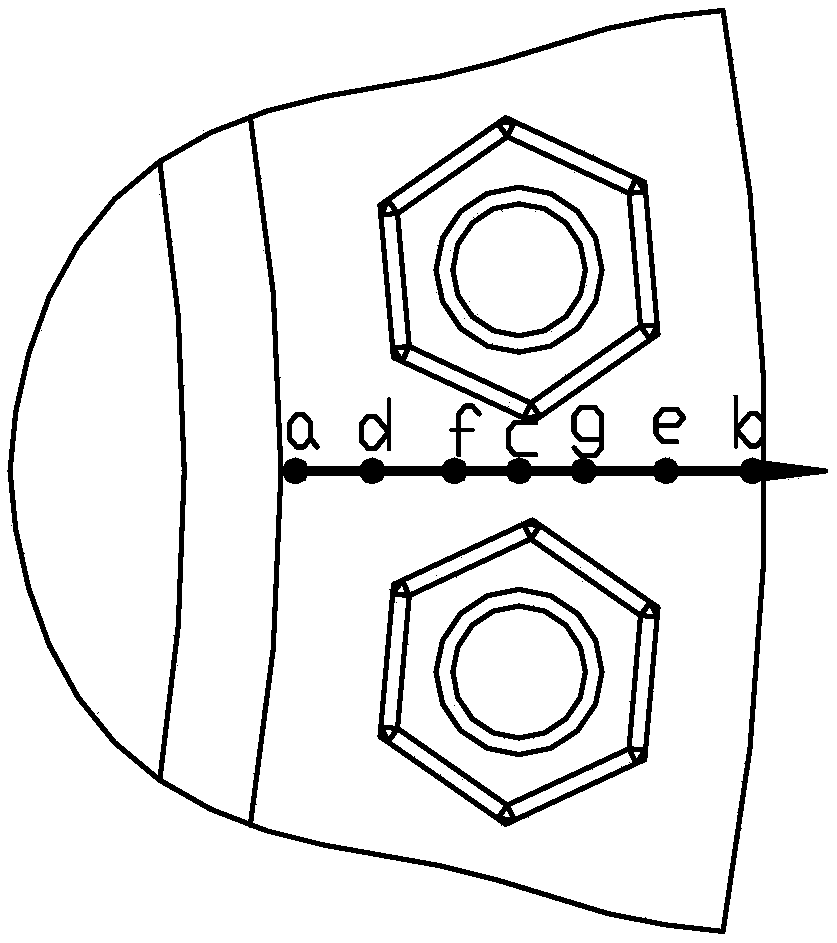

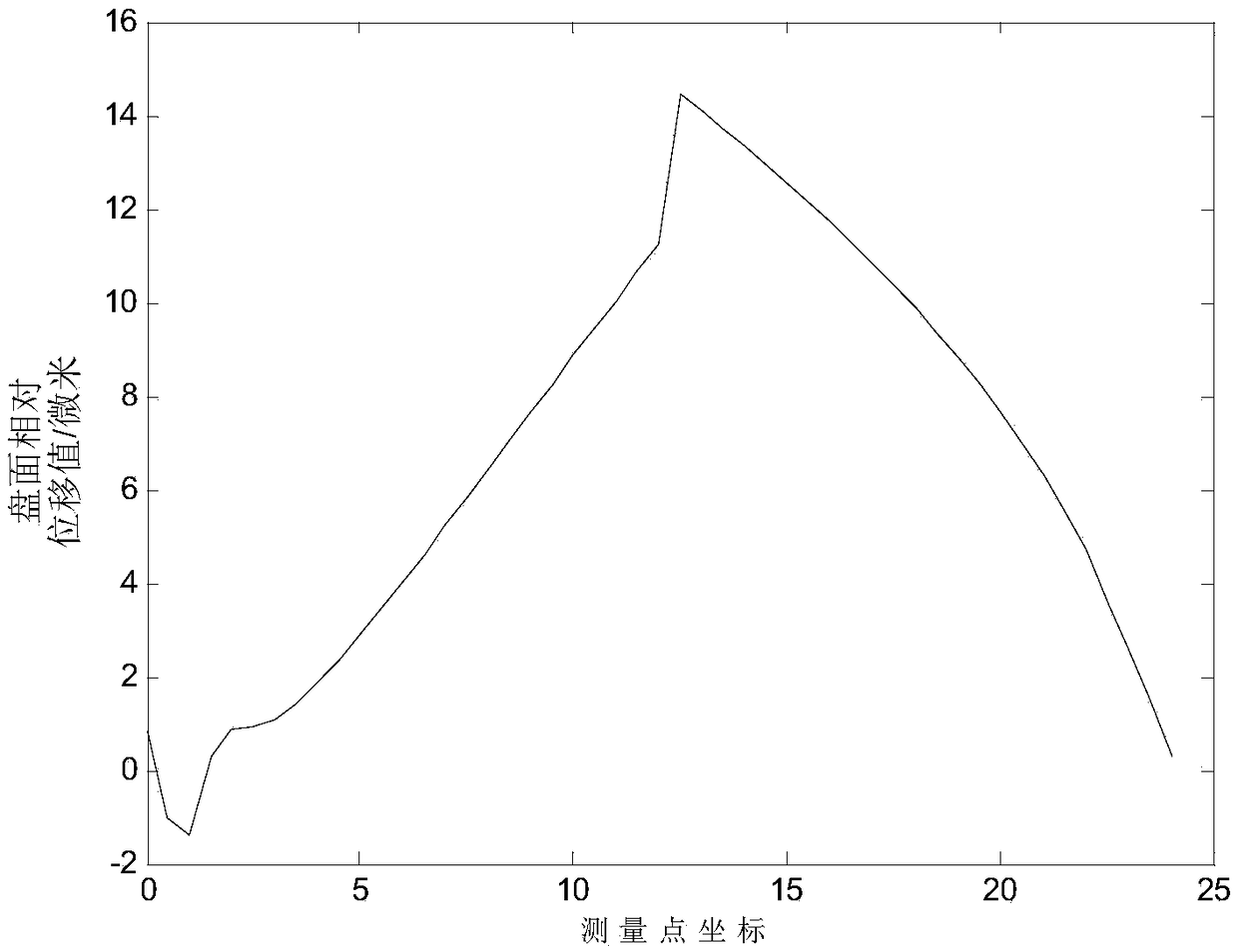

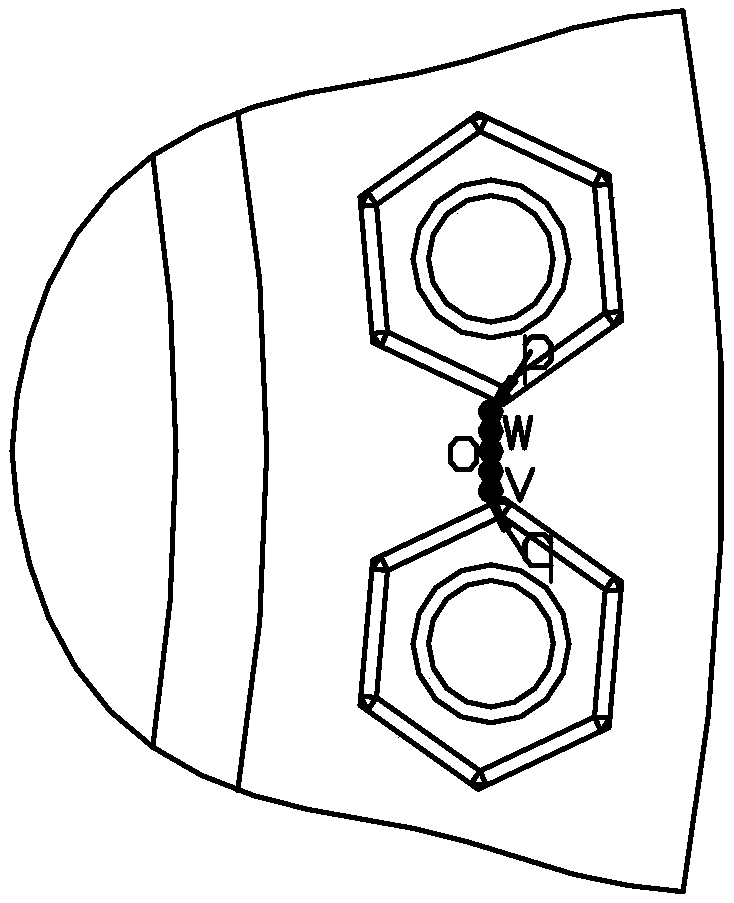

[0061] A method for detecting fastening force of an aeroengine low-pressure turbine shaft disk based on a cylinder-type contact displacement sensor group, the cylinder-type contact displacement sensor group includes a first sensor pair, a second sensor pair and a second sensor pair arranged at equal intervals along a straight line. Three sensor pairs, the distance is equal to the diameter of the circle where the outer edge of the bolt portion on the surface of the low-pressure turbine shaft disk is located and the sum of the distances between two adjacent bolt portions on the surface of the low-pressure turbine shaft disk, the first sensor pair, Both the second sensor pair and the third sensor pair include two cylinder-type contact displacement sensors that are oppositely arranged to detect the relative displacement value of the low-pressure turbine shaft disk, and the axes of the six cylinder-type contact displacement sensors are located in the same plane ,

[0062] The detec...

Embodiment 2

[0090] Such as Figure 5-Figure 7 As shown, an aero-engine low-pressure turbine shaft plate fastening force detection device based on a cylinder-type contact displacement sensor group is characterized in that: an installation platform 1, a headstock 2 and a cylinder-type contact displacement sensor group,

[0091] The spindle box 2 is connected with the installation platform 1 through the base 3, the rear end of the spindle box 2 is provided with a motor 4, and the output end of the motor 4 is connected with the spindle box 2 through the spindle box 2. The front end of the turntable 5 is connected, and the turntable 5 is provided with three claws 7 for connecting the low-pressure turbine disk 6. The three claws 7 are evenly distributed around the axis of the turntable 5. The installation platform 1 is also provided with an auxiliary support frame 8 for supporting the low-pressure turbine disk 6,

[0092] The cylinder-type contact displacement sensor group includes six cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com