Method and device for detecting fastening force of low-pressure turbine shaft disk of aeroengine based on eddy current sensor group

A technology of eddy current sensors and low-pressure turbine shafts, applied to measuring devices, measuring torque/torsion force during tightening, instruments, etc., can solve problems such as low test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A method for detecting fastening force of an aeroengine low-pressure turbine shaft disk based on an eddy current sensor group has the following steps:

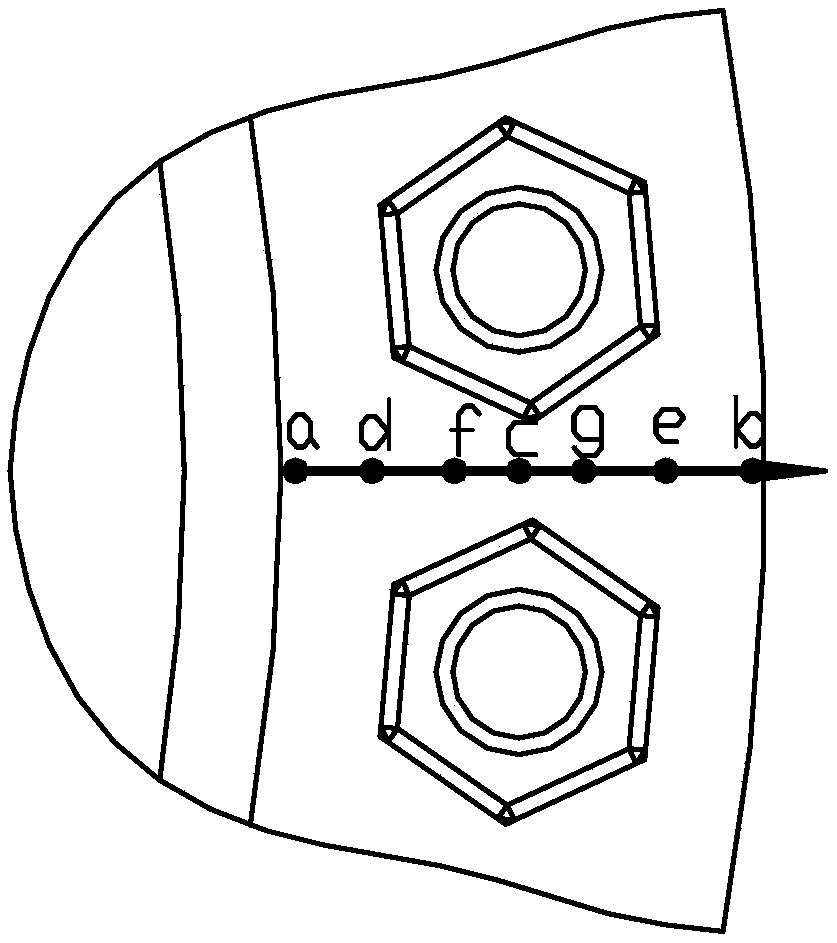

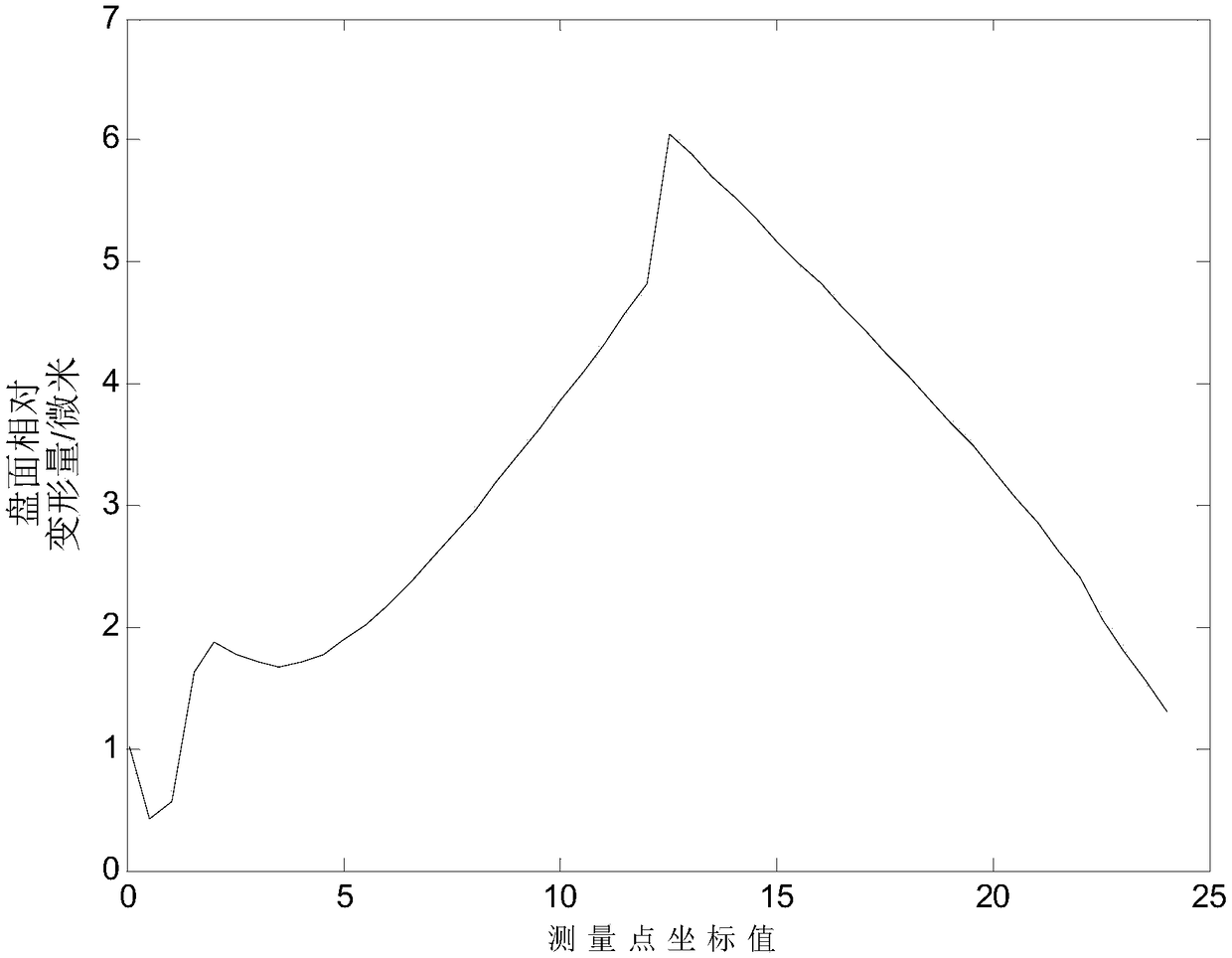

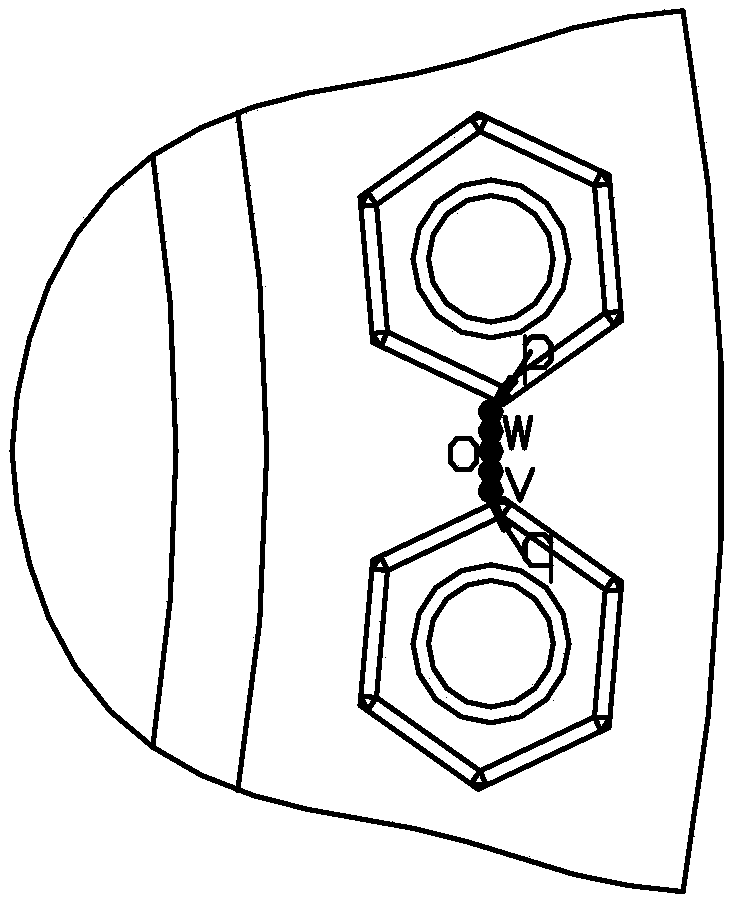

[0102] S1. Obtain the relationship between the pre-tightening force of the low-pressure turbine bolts and the relative displacement and distribution of the upper and lower disk surfaces:

[0103] S11. Use the bolt axial force test system to tighten each bolt more than 3 times, record the relationship between the torque and the axial force after tightening 3 times, and select the bolt with the same end surface friction coefficient, tooth surface friction coefficient and axial force, And record its position on the low-pressure turbine shaft disk;

[0104] S12. Making the same low-pressure turbine shaft disk test piece as the low-pressure turbine shaft disk refers to making the same material as the low-pressure turbine shaft disk, the same inner and outer diameter of the flange, the same flange thickness, the same bolt spaci...

Embodiment 2

[0133] Such as Figure 5-Figure 7 As shown, an aero-engine low-pressure turbine shaft disk fastening force detection test device based on eddy current sensor group, including base 1, eddy current sensor feeding device 2 and V-shaped iron I3, V-shaped iron II4 and V-shaped iron III5, the V-shaped iron I3 is connected to the base 1 through the base 6, and the V-shaped iron II4 is connected to the base 1 through the horizontal feed platform I7 and the lifting platform I8 in turn, The V-shaped iron III5 is sequentially connected to the base 1 through the horizontal feed platform II9 and the lifting platform II10, and the V-shaped iron I3, the V-shaped iron II4 and the V-shaped iron III5 are all provided with pressure plates 11,

[0134] The eddy current sensor feeding device includes an eddy current sensor group connected in sequence, a sensor chuck 12, a radial micro-motion feeding platform 13, an angular position platform 14, a vertical feeding platform 15 and a horizontal feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com