A wire cutting fixture

A wire cutting tooling and fixture technology, applied in the field of tooling and fixtures, can solve the problems of manpower and raw material waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

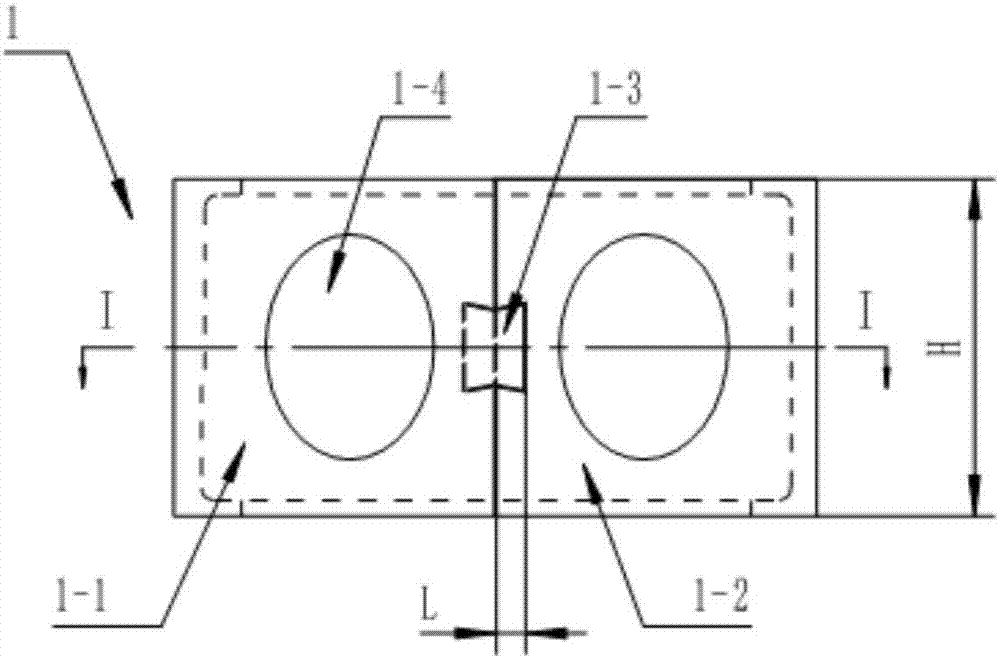

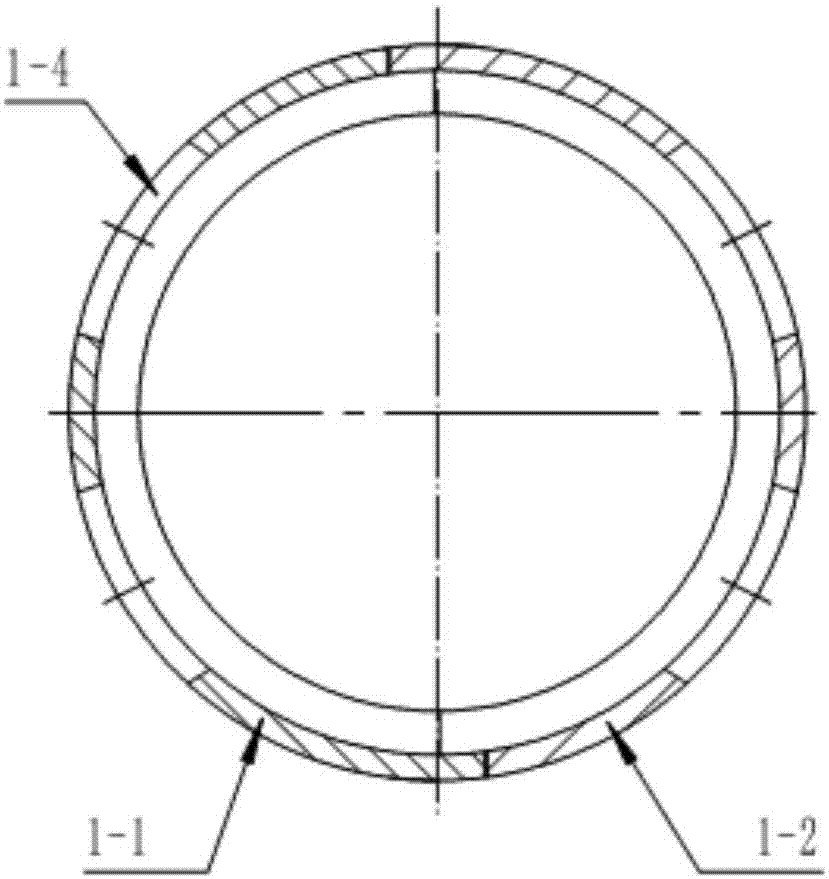

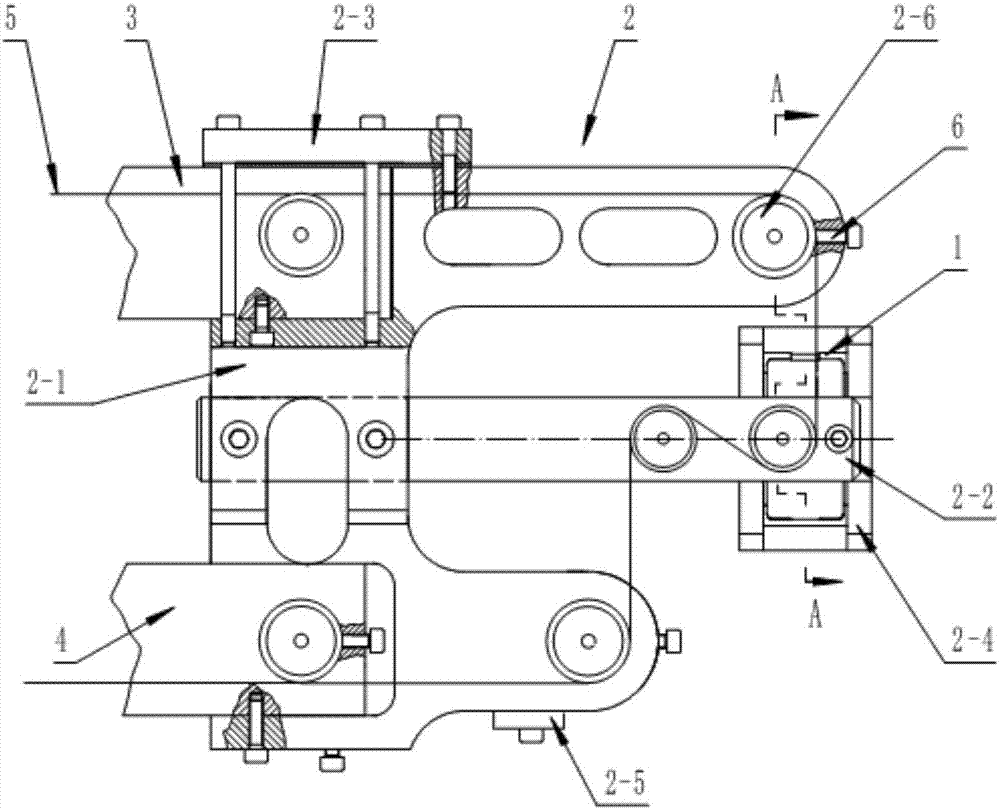

[0031] see image 3 , Figure 4 , Figure 5 , Figure 8 , Figure 9 , Figure 12 , the wire cutting fixture 2 of the present invention includes a tooling bracket 2-1, a middle arm 2-2, a pressing plate 2-3, a workpiece clamping seat 2-4 and a set of guide wheels 2-6; The tooling support 2-1 is fixedly installed on the upper support arm 3 of the wire cutting machine tool through the pressing plate 2-3, and the middle support arm 2-2 is equipped in the middle part of the tooling support 2-1; the middle support arm 2-2 is divided into One-piece structure, consisting of a fixed arm 2-2-1 and a detachable arm 2-2-2 installed on the fixed arm, forming an up and down connection between the fixed arm 2-2-1 and the detachable arm 2-2-2 The guide wheel accommodation cavity 2-2-3, respectively arrange a group of guide wheels 2-6 in the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com