An auxiliary pit structure for automobile chassis maintenance

A technology for automobile chassis and pits, applied in industrial buildings, etc., can solve problems such as harsh working environment, difficulty in cleaning, and affecting normal work of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

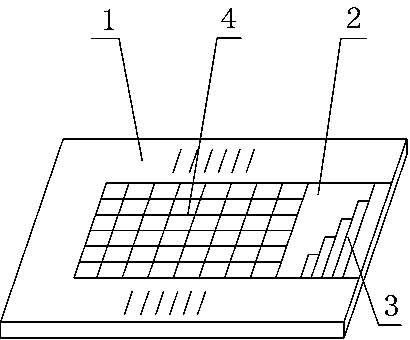

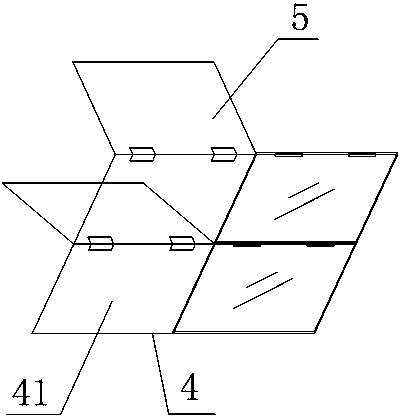

[0022] Such as figure 1 versus figure 2 The illustrated auxiliary pit structure for the overhaul of automobile chassis includes a pit 2 with a step 3 provided on the ground 1. A layer of wire mesh 4 is provided at the upper open end of the pit 2 and the wire mesh 4 is connected to each other Vertical iron wires are arranged in a cross arrangement; no iron wire 4 is provided directly above the ladder 3; the grid 41 on the iron wire 4 is in a square structure, and the side length of the grid 41 is equal to 21 cm; A transparent cover plate 5 that matches the grid 41 is provided. One side of the cover plate 5 is hinged on the iron wire forming the wire mesh 4, and each cover plate 5 is independently hinged; all the cover plates 5 are in their respective The corresponding grid 41 is hinged on the same side; the cover plate 5 is made of PC plastic; the side wall of the groove 2 is uneven; the wire mesh 4 is fixed on the side wall of the groove 2.

[0023] In the working process of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com