A pit structure for motor vehicles

A technology for motor vehicles and pits, used in industrial buildings and other directions, can solve the problems of workers inhaling too much dirt, poor working environment, and difficulty in cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

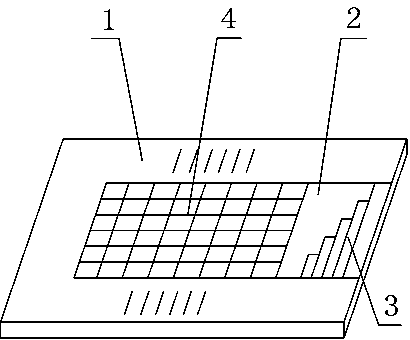

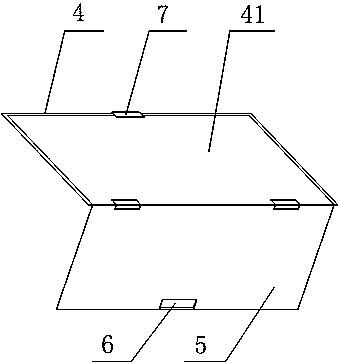

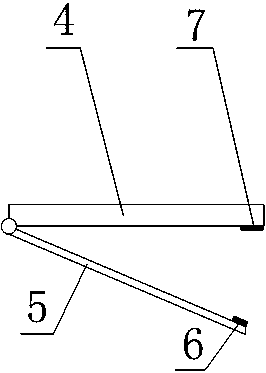

[0023] like Figure 1 to Figure 3 The shown pit structure for motor vehicles includes a pit 2 with a step 3 arranged on the ground 1, the upper open end of the pit 2 is provided with a layer of aluminum alloy mesh 4, and the aluminum alloy The net 4 is composed of aluminum alloy rods arranged perpendicular to each other; the aluminum alloy net 4 is provided with openings directly above the steps; the grid 41 on the aluminum alloy net 4 is a square structure, and the sides of the grid 41 The length is greater than or equal to 20cm; the lower part of each grid 41 is provided with a transparent base plate 5 matching the grid 41, one side of the base plate 5 is hinged on the aluminum alloy mesh 4, and each base plate 5 is independently hinged The upper surface of each base plate 5 is fixed with an iron sheet 6, and the iron sheet 6 is positioned at the side edge facing the hinged edge of the base plate 5; the lower surface of each grid 41 is fixed with the The magnet block 7 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com