A high anti-loosening spin riveting blind rivet

A core blind rivet and mandrel technology, applied in the direction of rivets, etc., can solve the problems of connection plate damage, large external force, falling off, etc., and achieve the effect of avoiding fastening accidents, loosening or even falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with the accompanying drawings.

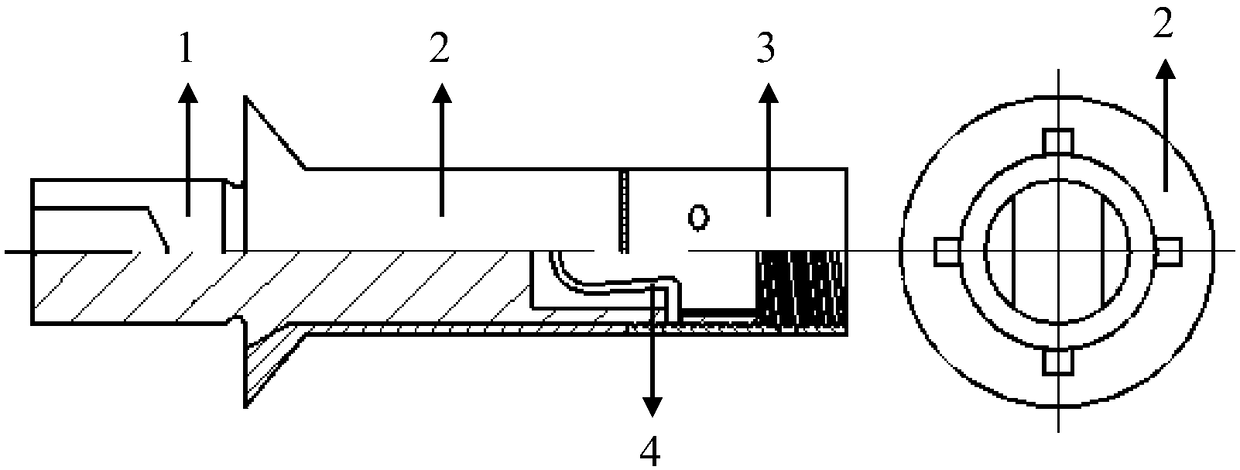

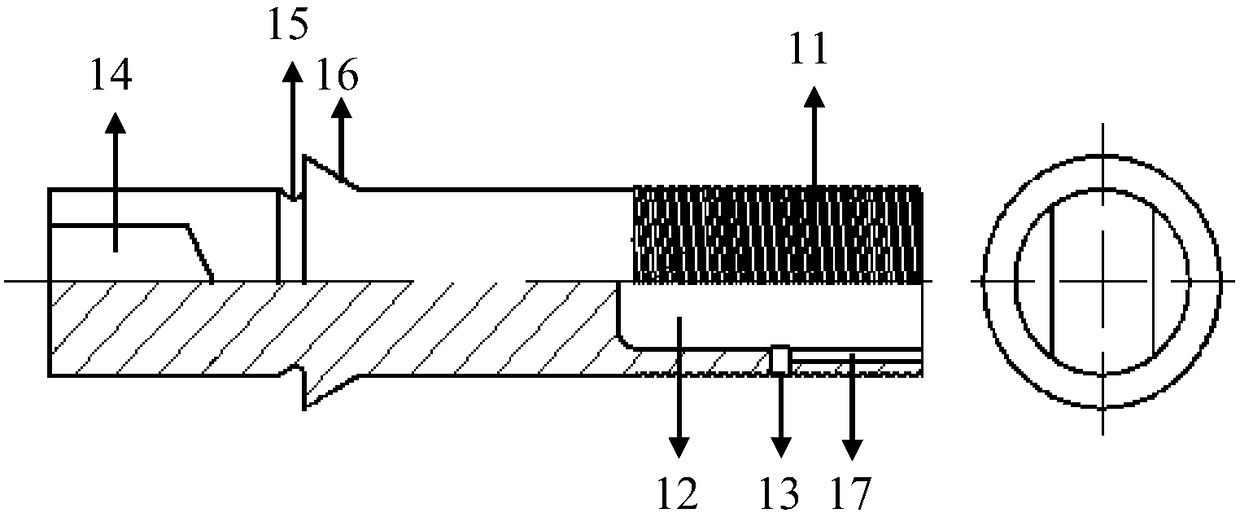

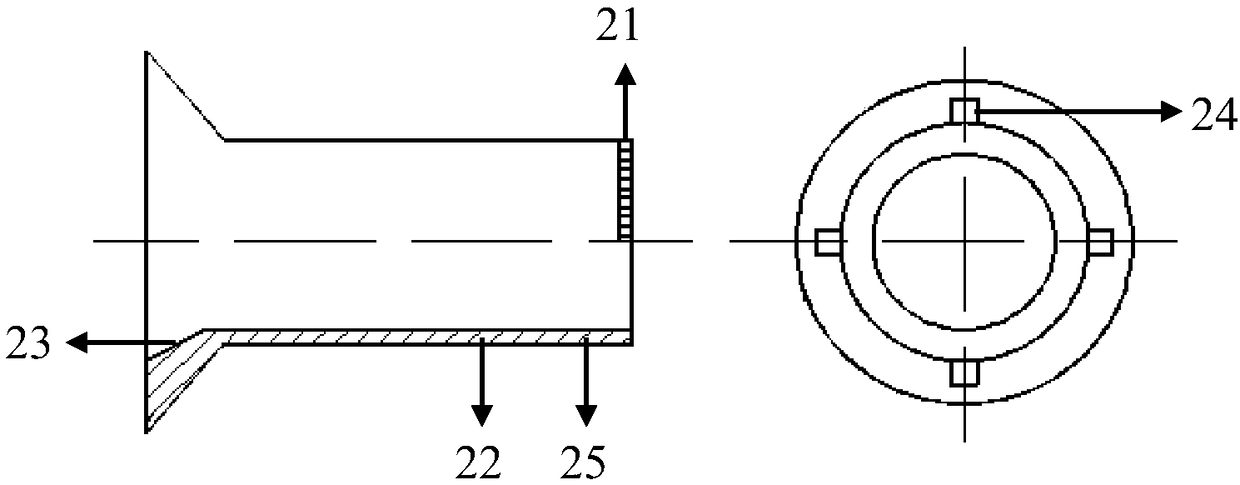

[0023] An embodiment of the inventive structure of the present invention is as figure 1 As shown, it includes a core rod 1, a nail sleeve 2, a nut 3 and a U-shaped spring 4; the outer surface of the tail of the core rod 1 is provided with a threaded section 11, and the tail of the threaded section 11 is covered with all the parts that can be matched and engaged with it. The nut 3; the end surface of the tail part of the core rod 1 is provided with a cavity 12 inwardly along the axial direction, and the inner wall of the cavity 12 is provided with a clamping hole 13 which is connected to the outside symmetrically around the axis, and the U-shaped spring 4 is The compressed state is fixed in the cavity 12, and the two ends of the U-shaped spring 4 are provided with clamping feet 41 outward, and the clamping feet 41 are respectively clamped in the clamping holes 13 of the core ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com