Tunnel energy pipe piece prefabrication and connection method applied to shield construction

A technology of shield segment and connection method, which is applied in the direction of strengthening and forming, can solve the problems of difficult to achieve the expected effect, inconvenient on-site operation, long construction period, etc., to improve the problem of thermal pollution, broaden the scope of application, and ensure the quality of construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

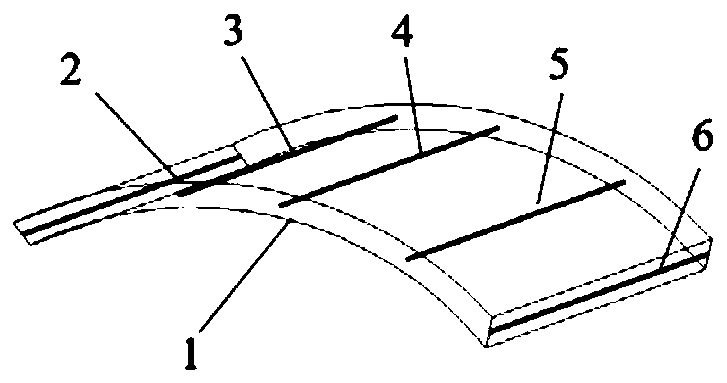

[0041] Attached below Figure 1-Figure 3 The present invention is described in detail, specifically, the structure is as follows:

[0042] This embodiment provides a tunnel energy segment prefabrication method applied to shield tunneling construction. The steps are as follows: First, a plurality of steel bars are evenly added and welded at the set position of the reinforcement cage 1. In this embodiment, as figure 1 As shown, five reinforcement bars are welded on the reinforcement cage 1, that is, the first reinforcement bar 2 welded to the middle position of one end of the reinforcement cage 1, the fifth reinforcement bar 6 welded to the middle position of the other end of the reinforcement cage 1, and the fifth reinforcement bar 6 welded to the inside of the reinforcement cage 1 The second steel bar 3, the third steel bar 4 and the fourth steel bar 5.

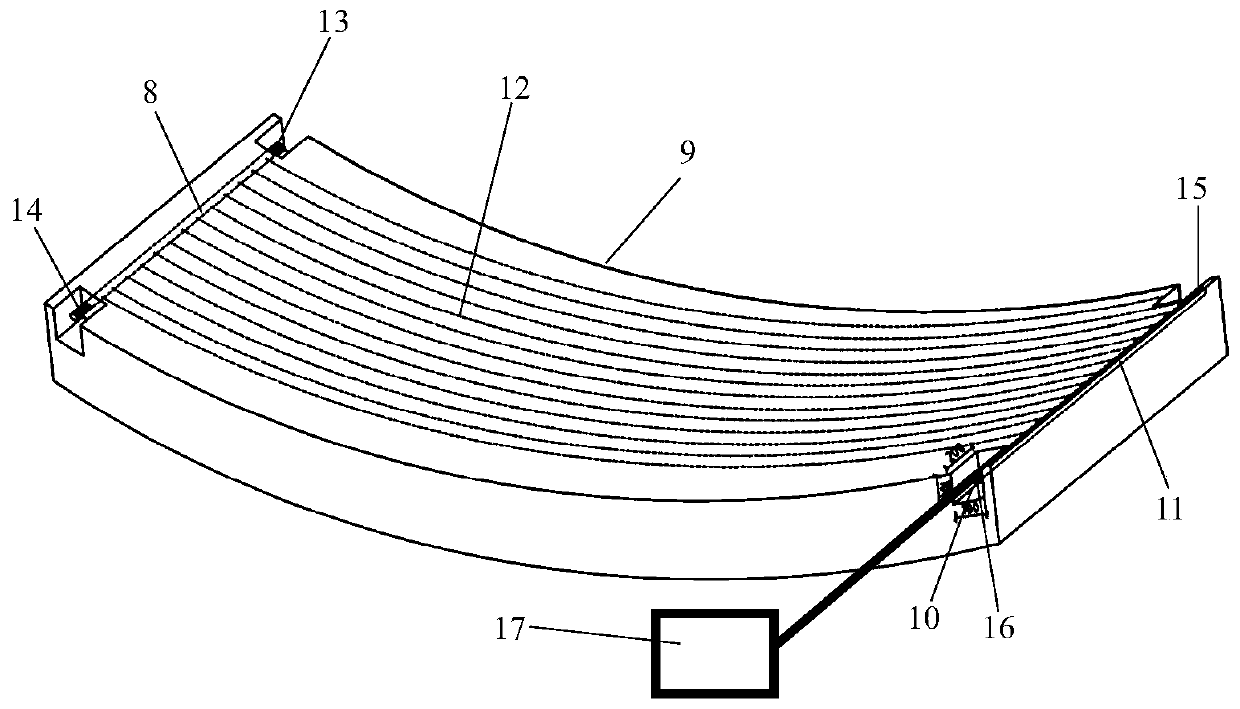

[0043]Select the capillary heat exchanger 12 whose specifications are slightly smaller than the steel cage 1, wherein the ...

Embodiment 2

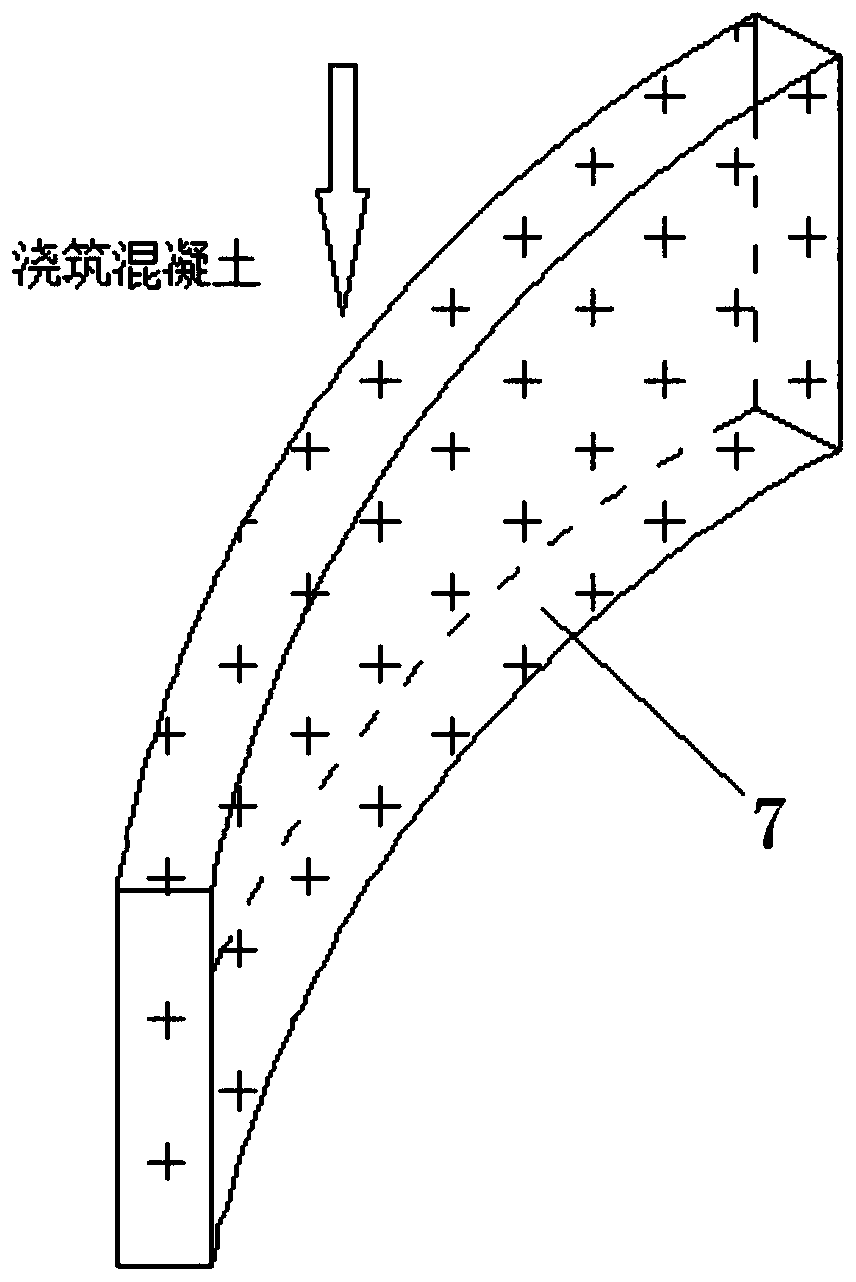

[0050] This embodiment provides a tunnel energy segment prefabrication method applied to shield tunneling construction, such as Figure 4 As shown in Fig. 5, respectively add and weld a reinforcing bar (the sixth reinforcing bar 21, the seventh reinforcing bar 22) at the two ribs of reinforcing cage 1, the main water supply pipe 11 is bound on the sixth reinforcing bar 21, and the return water main pipe 8 is bound on the second Seven steel bars 22 on.

[0051] Before pouring, insert the prefabricated parts, use the shield segment mold 7 to set the second groove 23 that allows the connection of adjacent capillary tubes, the opening side of the second groove 23 is located at the end of the shield segment mold 7, other steps It is the same as the first embodiment, and will not be repeated here.

Embodiment 3

[0053] This embodiment provides a tunnel energy segment connection method applied to shield tunneling construction, as shown in Figure 6(a)-6(b), the capillary trunks between the shield segments 9 are connected by straight seams connected to each other in a way. Before connecting, remove the sealing cover at the dry pipe joint, clean up the cement and other debris on the exposed dry pipe joint, put the adjacent dry pipe joint 20 into the sleeve 19, and use the rubber sealing ring for sealing to avoid There is a leak at the capillary connection 18.

[0054] During construction, every time three shield segments 9 are laid, a pressure test is carried out on the laid capillary. After confirming that there is no leakage at the joint 18, the groove at the joint 18 is filled with concrete to further reduce the joint connection of the main pipe. potential leakage hazards.

[0055] Such as Figure 7(a)-7(b) As shown, after the laying of the shield segment 9 is completed, the return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com