Remote telemetering switch for industrial Internet of Things

An Internet of Things and remote technology, applied in the direction of electromagnetic relay details, relays, electrical components, etc., can solve the problems of only starting, complex structure, loss, etc., to avoid easy damage, strong relaxation resistance, and moderate hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

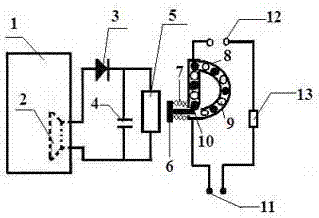

[0018] A remote telemetry switch for the industrial Internet of Things, including a mobile phone module 1 with a mobile phone signal, a ringing connection 2, a diode 3, a capacitor 4, a relay 5, a horizontal T-shaped armature 6, a spring 7, an insulating D-ring 8, and a conductive ball 9. Insulating ball 10, plug 11, and jack 12; the ringing connection 2 is placed in the mobile phone module 1, and is formed by cutting the original ringing connection in a closed circuit. After one end is connected to the diode 3 through a wire, it is connected to the other end The capacitor 4 and the relay 5 are connected in parallel through wires to form a loop, which can directly follow the prior art; the wide part of the horizontal T-shaped armature 6 is close to the relay 5, and the spring 7 and the insulating D-ring 8 are respectively passed through the upper and lower sides. The vertical part is connected, and its thin part is inserted into the lower end gap of the insulating D-shaped ring...

Embodiment 2

[0020] A remote telemetry switch for industrial Internet of Things, the structure of which is the same as that of Embodiment 1. The steel used for the spring 7 includes 0.45%C, 0.68%Si, 0.56%Si, 0.79%Mn, 0.92%Cr, 0.12%Sn, 0.03%Hf, and the remainder is composed of Fe and the total amount. Less than 0.05% impurity element composition. The preparation method of spring steel: Weigh each raw material, put it into a mixer and stir evenly to obtain a mixed material; put the above mixed material into a high-temperature furnace for fusion treatment to obtain a mixed metal liquid; pour the above mixed metal liquid to a designated In the mold, the steel for springs is obtained after cooling and forming.

Embodiment 3

[0022] A remote telemetry switch for industrial Internet of Things, the structure of which is the same as that of Embodiment 1. The steel used for the spring 7 includes 0.45%C, 0.68%Si, 0.56%Si, 0.79%Mn, 0.92%Cr, 0.12%Sn, 0.021%Hf, and the remaining part is composed of Fe and the total amount. Less than 0.05% impurity element composition. The preparation method of spring steel: Weigh each raw material, put it into a mixer and stir evenly to obtain a mixed material; put the above mixed material into a high-temperature furnace for fusion treatment to obtain a mixed metal liquid; pour the above mixed metal liquid to a designated In the mold, the steel for springs is obtained after cooling and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com