Movable clamp block of rope gripper

A technology of movable clips and rope grippers, which is applied in elevators, transportation and packaging, etc., can solve the problems of difficulty in ensuring motion sensitivity and slippage of steel wire ropes, and achieve the effect of simple and convenient installation and positioning, reducing materials and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

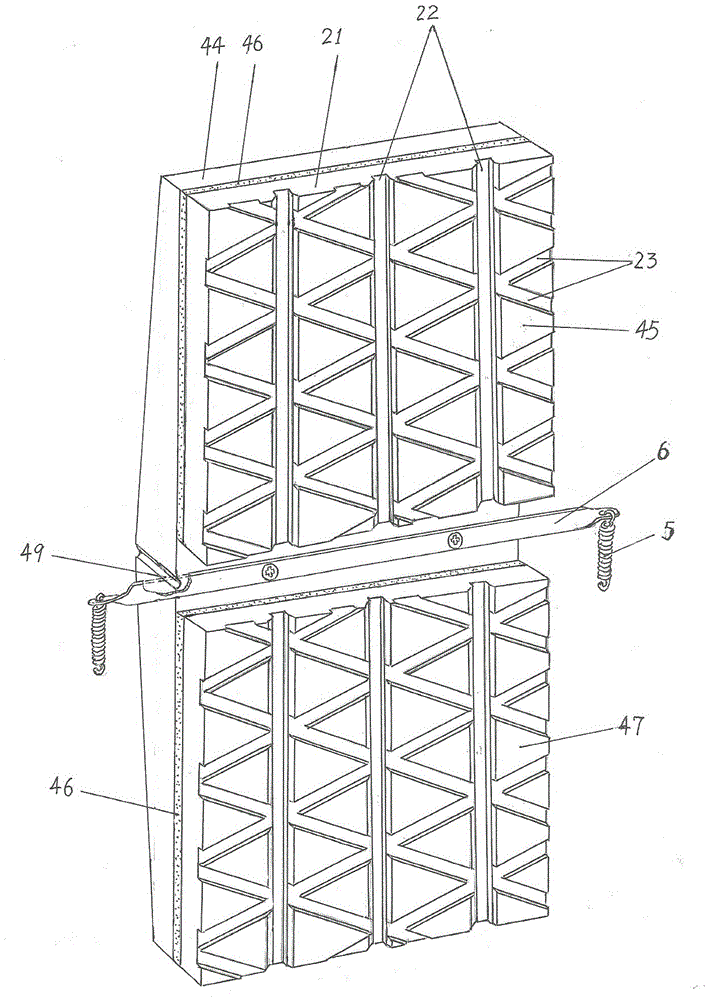

[0012] Such as figure 1 As shown, the present invention includes a clamp body 44 and a friction plate fixed on the clamp body; the friction plate is divided into an upper friction plate 45 and a lower friction plate 47, and the upper friction plate 45 is fixed on the top of the front surface of the clamp body 44, The lower friction plate 47 is fixed on the lower part of the front surface of the clamp body 44, and the friction surface of the upper friction plate 45 and the friction surface of the lower friction plate 47 should be on a vertical plane. The front surface of the clamping block body 44 is an upright surface, and the back side of the clamping block body 44 is a central raised surface formed by two inclined surfaces. There is a gap between the upper friction plate 45 and the lower friction plate 47 , and a pull rod 6 is arranged in the gap, and the pull rod 6 is fixed on the clamp body 44 . The two ends of the pull rod 6 protrude from the side edge of the clamping bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com