Semi-automatic cleaning immersion device

A semi-automatic and equipment technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of continuous water inflow, drainage, post-processing of lenses, no timing, etc., and achieve perfect soaking function. and conditions, reduce the direct labor intensity, and improve the effect of operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

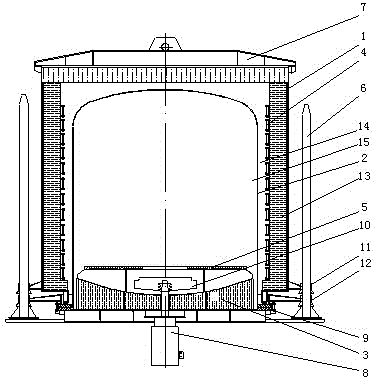

[0013] see figure 1 , the semi-automatic cleaning and soaking equipment of the present invention includes a base, a furnace base 3, an inner cover 2, an annealing cover 1 and a cooling cover 16, the furnace base 3 and the positioning column 6 are fixed on the base, the inner cover 2, the annealing cover 1 and the cooling cover 16 are in the shape of a circular bell jar, and are respectively provided with a positioning sleeve II12, a positioning sleeve I11, and a positioning sleeve III18. The inner cover 2 is inserted from the upper end of the positioning column 6 through the positioning sleeve II12 for positioning. The flange plate provided at the bottom is fixed on the base, the cover is outside the furnace base 3 , and a sealing ring 9 is fixed between the flange plate of the inner cover 2 and the base to form a sealed furnace chamber 15 . In the inner cavity of the furnace base 3, a large air volume circulation fan 10 driven by a sealed motor 8 is also fixed. The furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com