Semi-automatic barrel washing and soaking equipment

A semi-automatic, bucket-washing technology, used in cleaning hollow objects, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems such as injury, time-consuming and laborious, and improve the soaking effect, reduce the direct labor intensity, and improve the soaking function. and the effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

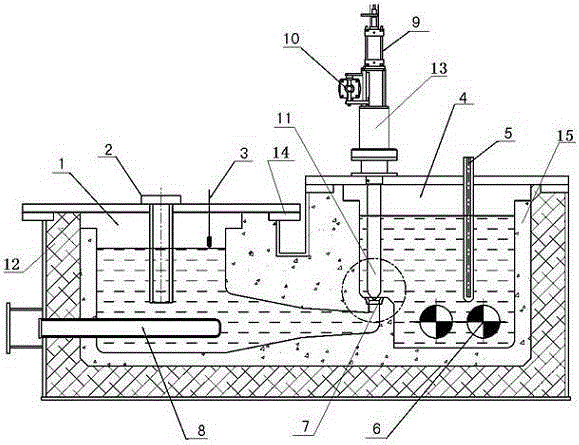

[0009] Such as figure 1 As shown, a semi-automatic bucket washing and soaking equipment is composed of a cleaning tank and an electric box controller 9. The cleaning tank is composed of an outer tank 1, an inner tank 2, a heating pipe 3, a temperature controller probe 4, a water inlet 5, and a drain 6 , overflow port 7 and outer tank double-layer thermal insulation board 15, the electric box controller is composed of heating switch 10, timer switch 11, temperature controller display 12, meter display 13 and alarm 14, cleaning tank and electric The box controller 8 is connected by a bracket 8, the outer tank 1 and the inner tank 2 are double-layered, and insulation cotton is added in the middle, and a water inlet 5 is opened in front of the outer tank 1, and the flow is controlled by the water inlet valve. There are two drains 6, which are drained through the drain valve. There is an overflow port 7 at the upper end of the back of the tank, which is directly connected to the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com