Semi-automatic cleaning and soaking equipment

A semi-automatic, equipment-based technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as inability to adjust the temperature of soaking liquid, low cleaning and soaking efficiency, and difficulty in adding soaking liquid, etc., to achieve perfection Soaking functions and conditions, improving operating efficiency and operating safety, and reducing the effect of direct labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

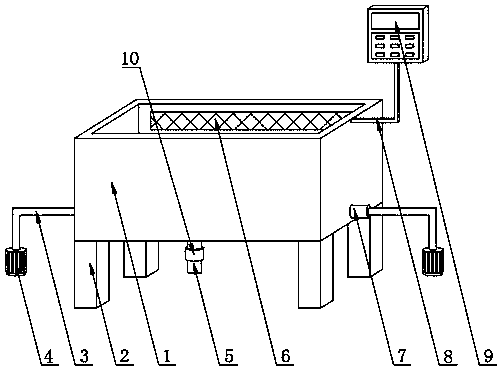

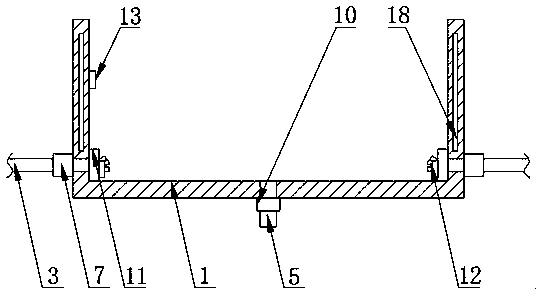

[0018] Embodiment one, by figure 1 , figure 2 with Figure 5 Given, the present invention includes a soaking box 1, the top side of the soaking box 1 is fixed with a control panel 9 through a bracket 8, which facilitates centralized control and effectively improves the convenience of use, and a temperature controller 22 is installed inside the control panel 9 , the center of the bottom of the soaking tank 1 is embedded with a sewage pipe 5, the first electromagnetic valve 10 is installed on the sewage pipe 5, the water injection main pipe 11 is fixed on both sides of the bottom of the soaking tank 1 by bolts, and several water injection main pipes 11 are installed. A high-pressure nozzle 12, the center of one side of the water injection main pipe 11 is connected with the water outlet of the high-pressure water pump 4 by the water inlet pipe 3, and the junction of the water inlet pipe 3 and the soaking tank 1 is equipped with a second electromagnetic valve 7, and one part of ...

Embodiment 2

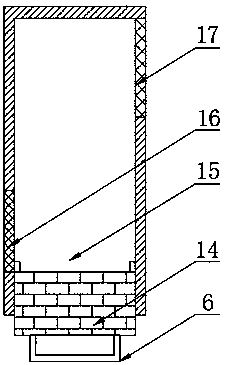

[0019] Embodiment two, on the basis of embodiment one, by figure 1 with image 3 Out, the sewage discharge mechanism 6 comprises a cover 14, a dirt storage tank 15, a second filter screen 16 and a first filter screen 17, the dirt storage tank 15 is fixed on the top side of the soaking tank 1 by bolts, and the soaking tank 1 is connected with the dirt storage tank. The top joint of the tank 15 is embedded with a first filter screen 17, the bottom of the other side of the dirt storage tank 15 is embedded with a second filter screen 16, and the bottom of the dirt storage tank 15 is clamped and fixed with a cover 14. The tumbling of the liquid, the dirt after soaking and cleaning floats, flows into the inside of the dirt storage tank 15 through the first filter screen 17, and makes the soaking liquid flow out after being filtered through the second filter screen 16, so that the dirt remains in the dirt storage tank The inside of 15 is cleaned and dirty by disassembling the cover ...

Embodiment 3

[0020] Embodiment 3, on the basis of Embodiment 2, a seal ring is bonded and fixed around the cover 14, and the seal ring is a rubber material member, which can effectively prevent the soaking liquid from leaking from the cover 14 and the dirt storage tank 15. The overflow at the connection effectively improves the convenience of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com