Excavation rod for installation of heat exchange pipe

A technology of heat exchange tubes and digging rods, which is applied to earth movers/shovels, construction, etc., can solve problems such as low hole digging efficiency, poor silt discharge efficiency, and complex structure, so as to improve hollowing efficiency and quality , Guarantee the effect of construction quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

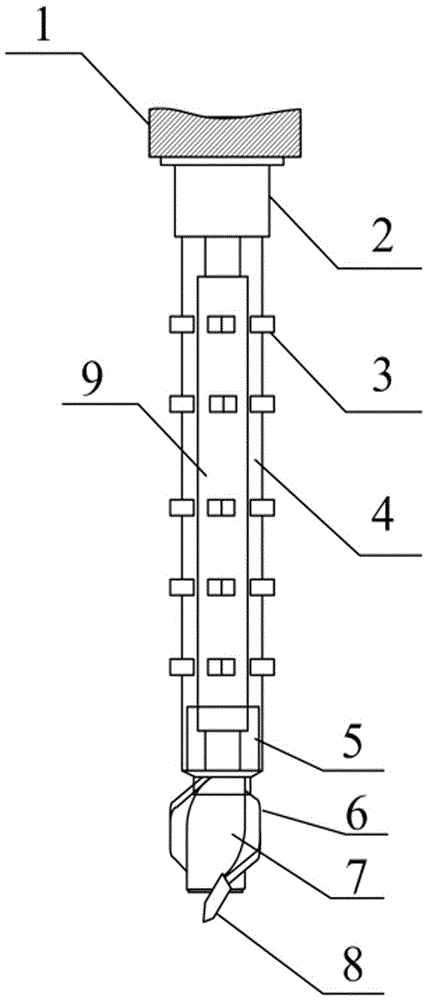

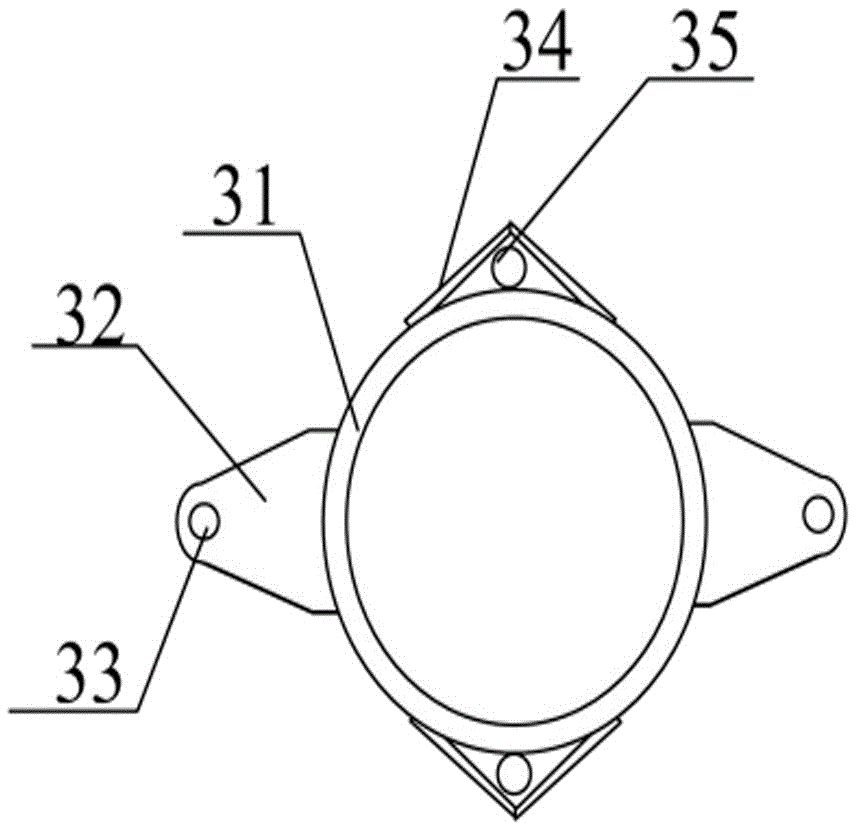

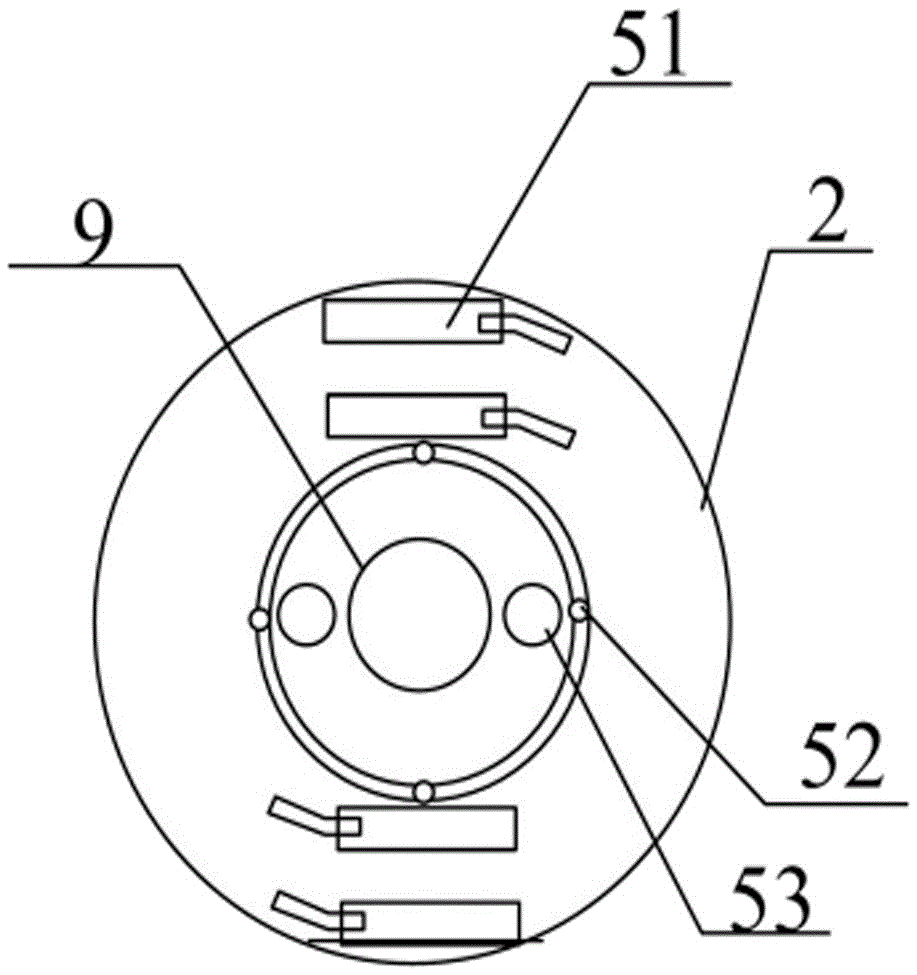

[0025] as attached figure 1 to the attached image 3 shown

[0026] The present invention provides an excavating rod for installing a heat exchange pipe, comprising a driving mechanism 1, an excavating rod 2, a cleaning device 3, a pipe body 4, a tamping device 5, a rotary hole blade 6, a drill bit 7, a spray head 8 and an installation Hole 9, the excavating rod 2 is installed at the lower part of the driving mechanism 1; the cleaning device 3 is installed in the middle of the pipe body 4; the hole tamping device 5 is installed at the bottom of the pipe body 4; the pipe body 4. An installation hole 9 is provided inside; the rotary hole blade 6 is installed on the outer side of the drill bit 7; the spray head 8 is installed on the lower end of the drill bit 7; the cleaning device 3 includes a pipe wall 31, a support plate 32, an end The hole cover 33, the outer covering 34 and the drain pipe 35, two support plates 32 are installed outside the pipe wall 31; the outer end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com