A manipulator used for discharging railway wagon parts

A technology of railway wagons and manipulators, applied in the field of manipulators, can solve the problems of low efficiency and many parts of railway wagons, and achieve the effects of high discharge accuracy, controllable force, and precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

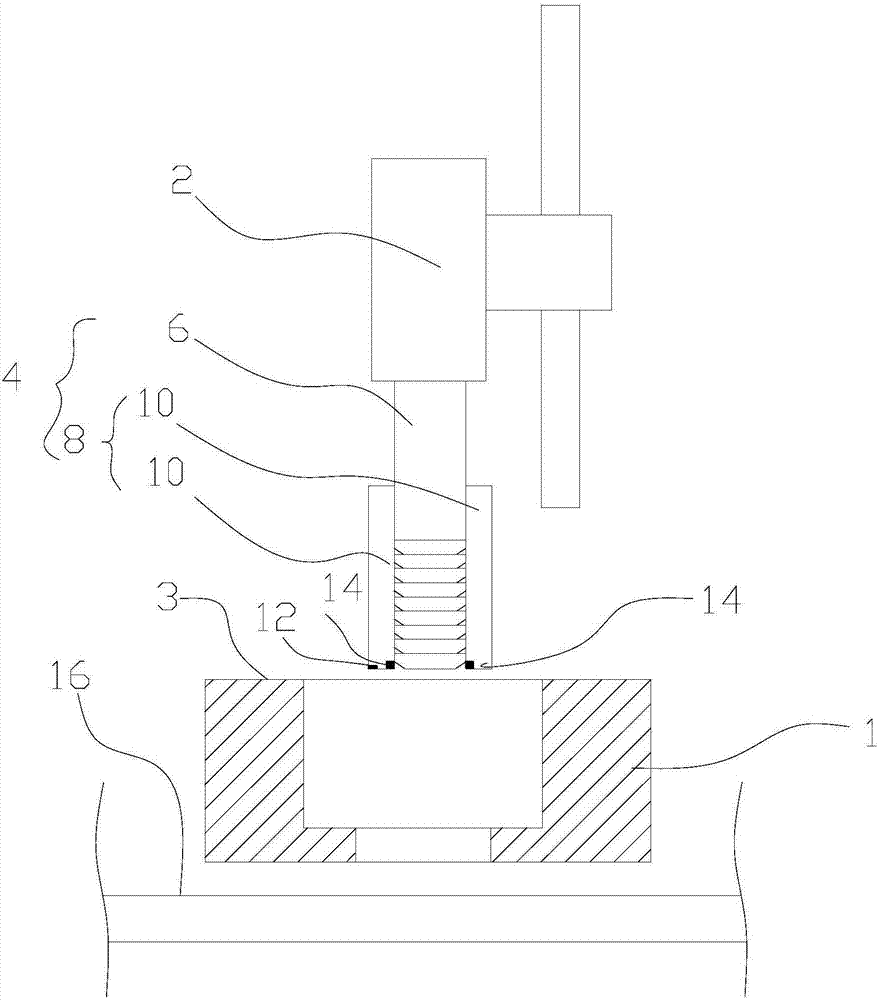

[0016] Such as figure 1 As shown, the present invention includes a lifting mechanism 2 and a manipulator 4 fixed below the lifting mechanism 2 for realizing its lifting. The manipulator 4 includes a cylinder 6 of a cylindrical structure and is connected below the cylinder 6 and is The inner cavity of the cylindrical body 6 is connected, and an open clamping body 8 is provided at the bottom thereof, and several workpieces are superimposed on the inner cavity of the clamping body 8 and the cylindrical body 6 from top to bottom, so that The clamping body 8 is also provided with two clamping split bodies 10 arranged symmetrically along the vertical plane. The clamping split bodies 10 are used to clamp or loosen the workpiece by adjusting the distance between the two clamping split bodies 10 through a horizontal adjustment mechanism. The bottom of the clamping split body 10 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com