Permanent magnetic torsion calibration device

A calibration device and torque technology, applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, instrument, etc., can solve the problems of low test accuracy, affecting service life, easy to wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

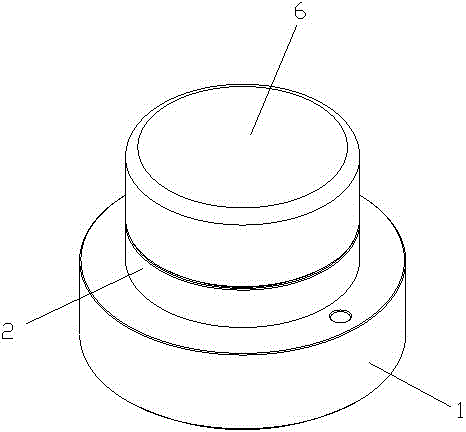

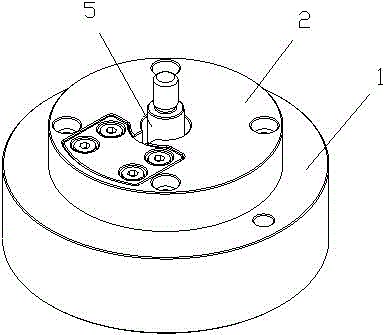

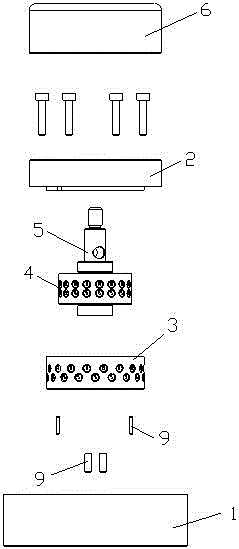

[0023] Such as Figure 1 to Figure 6 A permanent magnet torque calibration device shown includes a base 1, a fixed block 2, an outer magnet fixed block 3, an inner magnet fixed block 4, a rotating rod 5 and a knob 6, and the outer magnet fixed block 3 is arranged in a circular shape structure, the center of the base 1 is provided with a blind hole 31 matching the structure of the outer magnet fixing block 3, the bottom of the blind hole 31 is concentrically provided with a bearing installation hole, and the inner magnet fixing block 4 is installed on the outer magnet fixing block 3. Inside, the inner wall of the magnet outer fixing block 3 is provided with two circles of first magnet mounting holes 32 in a circular array, and the upper and lower adjacent two first magnet mounting holes 32 are alternately arranged, and the magnets are internally fixed T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com