Humidification equipment for spinning

A technology for humidifying equipment and water tanks, which is applied in the fields of textile processing machine accessories, textiles and papermaking, textile materials, etc. It can solve the problems of easy adsorption and deformation of fabrics, property loss, and insufficient device treatment, etc., and achieve low humidification efficiency. , increase the operating area, increase the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

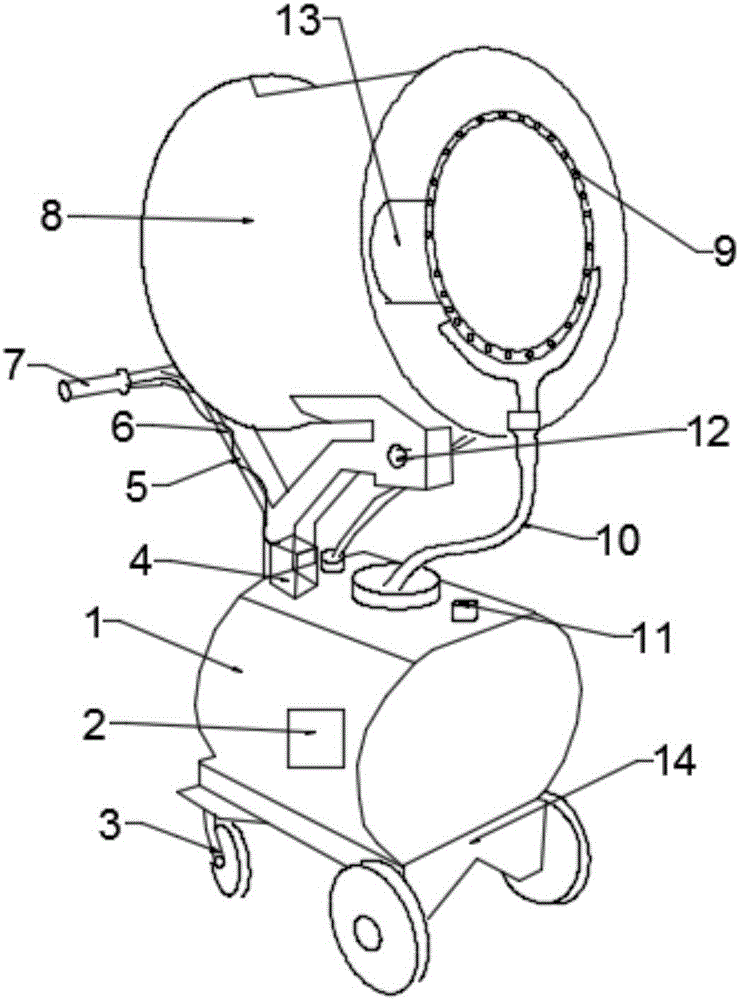

[0016] see figure 1 , the present invention provides a technical solution: a humidification device for textiles, including a water tank 1, a water pump 2 is installed inside the water tank 1, an electric control box 4 is installed above the water tank 1, and beside the electric control box 4 A water pipe 10 is installed, and a water inlet 11 is installed next to the water pipe 10. A support frame 12 is installed above the electric control box 4. The humidification cylinder 8 and the support frame 12 are engaged by gears, and the meshing method is adopted, so that The humidifying cylinder 8 can freely rotate the angle of humidification to facilitate the rotation angle. The humidifying cylinder 8 is installed on the support frame 12, and the atomizing nozzle 9 is installed inside the humidifying cylinder 8, and the atomizing nozzle 9 is installed in a circular shape. And atomizing nozzle 9 is all connected with water pipe 10, adopts circular atomizing nozzle 9, the area of hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com