Common-mode choke coil and manufacturing method therefor

A technology of common mode choke coil and manufacturing method, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, inductor, etc. suppress the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

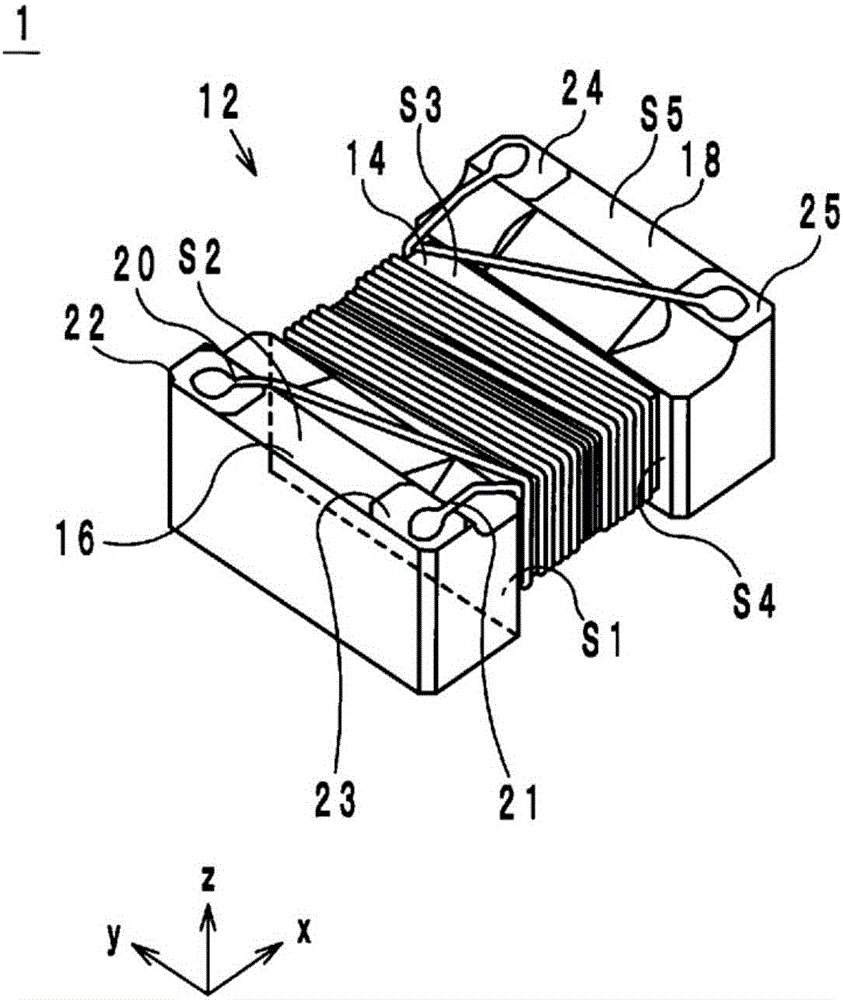

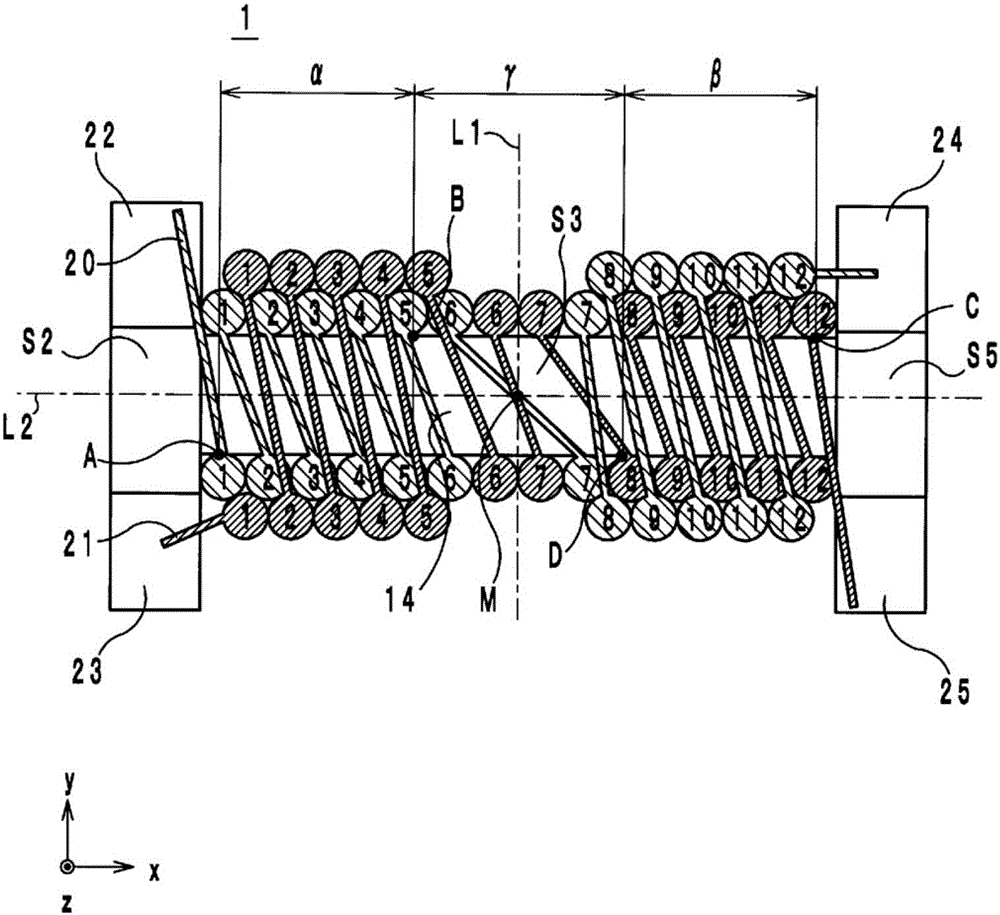

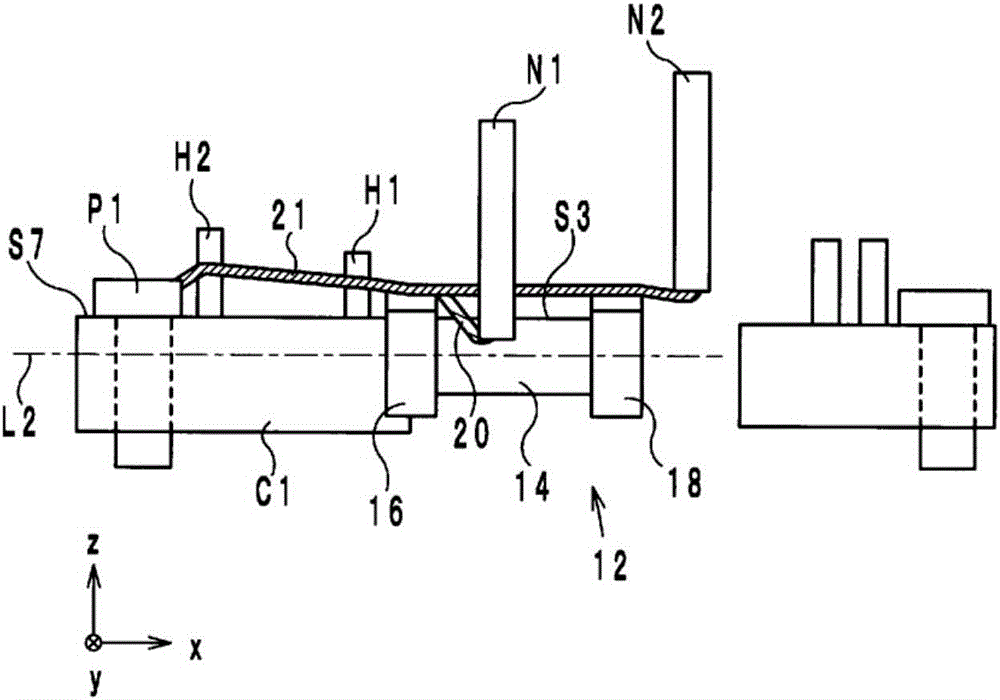

[0051] (For the structure of the common mode choke coil, refer to figure 1 as well as figure 2 )

[0052]A common mode choke coil 1 according to an embodiment will be described with reference to the drawings. Hereinafter, the direction in which the central axis of the winding core portion 14 extends is defined as the x-axis direction. In addition, when viewing the x-axis direction, the direction along the long side of the flange portion 16 is defined as the y-axis direction, and the direction along the short side of the flange portion 16 is defined as the z-axis direction. In addition, the x-axis, y-axis, and z-axis are orthogonal to each other.

[0053] Such as figure 1 As shown, the common mode choke coil 1 includes an iron core 12 , winding wires 20 and 21 , and external electrodes 22 to 25 . Such as figure 2 As shown, the common mode choke coil 1 is roughly divided into the starting line side area α (first area) as the starting winding end of the winding wires 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com