Optical integrated high-power optical energy transmission assembly

A technology for transmitting components and light energy, applied in the field of optical fibers, can solve the problems of low efficiency, low efficiency of optical waveguide and injected light coupling, difficulty, etc., to improve the transmission efficiency and eliminate the reflection and scattering of light energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

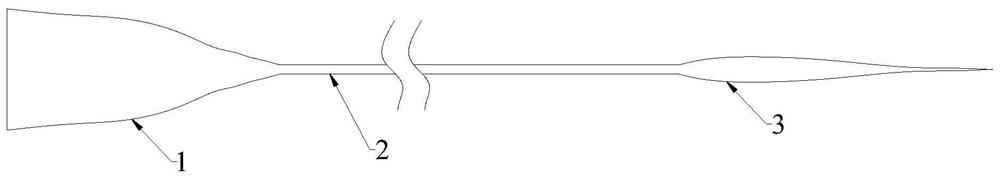

[0040] Such as Figure 1-3 As shown, the present invention provides an optically integrated high-power optical energy transmission component, which is composed of three parts, namely an input coupling part 1, an optical fiber 2 and an output coupling part 3, the input coupling part 1, the optical fiber 2 and the output coupling component 3 are integrated together by optical integration technology to become an optical component.

[0041] The optical fiber 2 is a high-power optical energy transmission optical fiber.

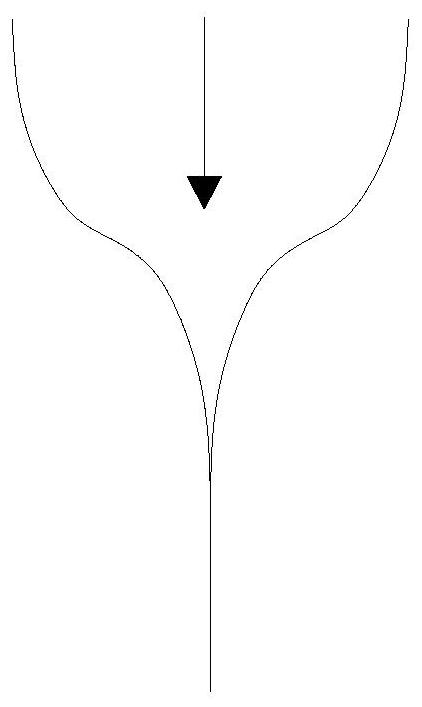

[0042] The outer diameter of the input coupling part 1 gradually decreases from the open end to the end close to the optical fiber, and the outer contour is in the shape of a quadratic function curve, which encourages the injected light to converge into the optical fiber core. Not a simple cone.

[0043] The diameter of the coupling surface of the input coupling part 1 and the light source is 8-12 times of the diameter of the optical fiber 2, and the integration ...

Embodiment approach

[0058] 1. The present invention adopts the optical integration technology to integrate the input coupling part 1, the high-power optical fiber 2 and the output coupling part 3 into a high-power optical energy transmission component for high-power optical energy transmission, eliminating the need for high-power optical fiber input, The refraction, birefringence, reflection and various scattering of the transmitted light on the connection between the output coupling device and the high-power optical fiber or fusion interface greatly reduce the energy loss of the transmitted light.

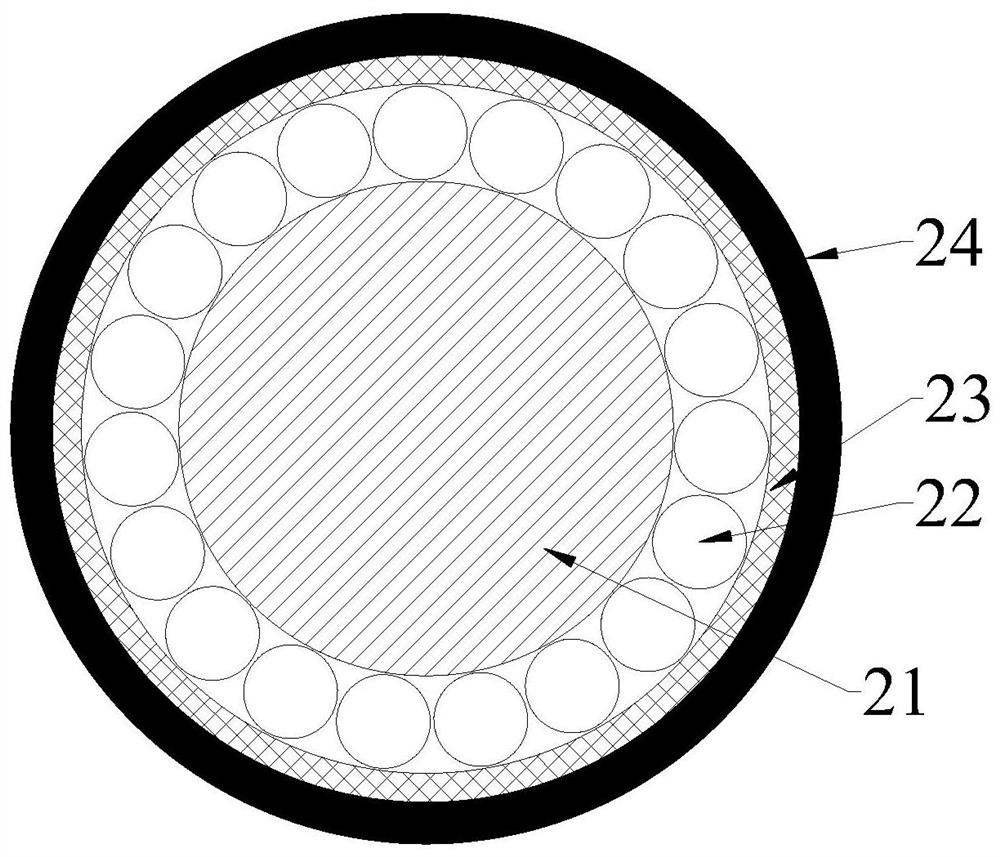

[0059]2. The high-power optical energy transmission part adopts the optical waveguide TIR-PCF with photonic crystal structure. Photonic crystal-structured optical waveguides do not simply rely on total reflection at the interface between the fiber core and the crystal cladding. There are clear interfaces between the fiber core and the gas / vacuum inside and outside the surrounding photonic crystal tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com