Common mode choke coil and manufacturing method thereof

A technology of common mode choke coil and manufacturing method, which is applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, inductor, etc., can solve problems such as mode conversion, and achieve suppression mode conversion, The effect of suppressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

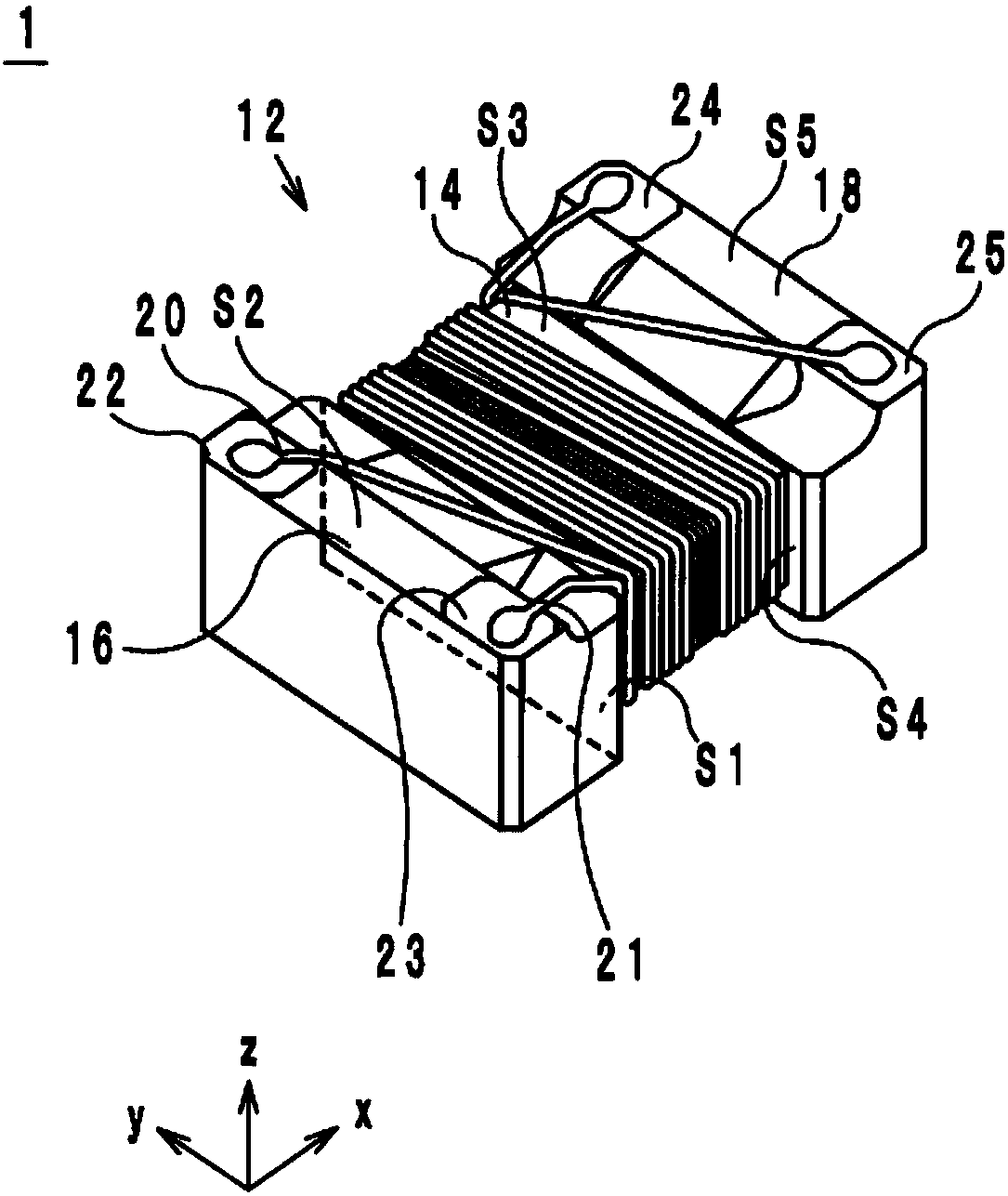

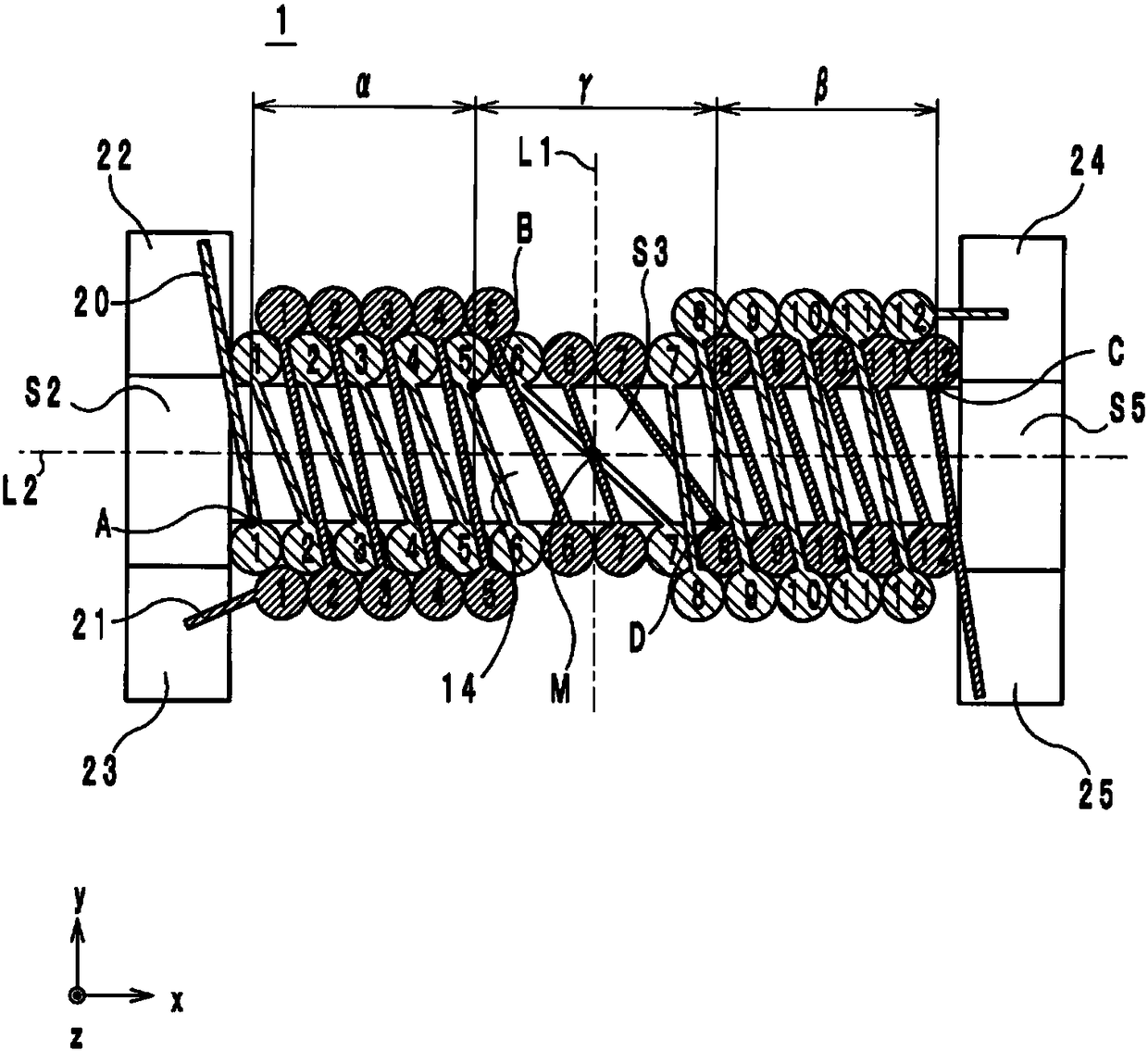

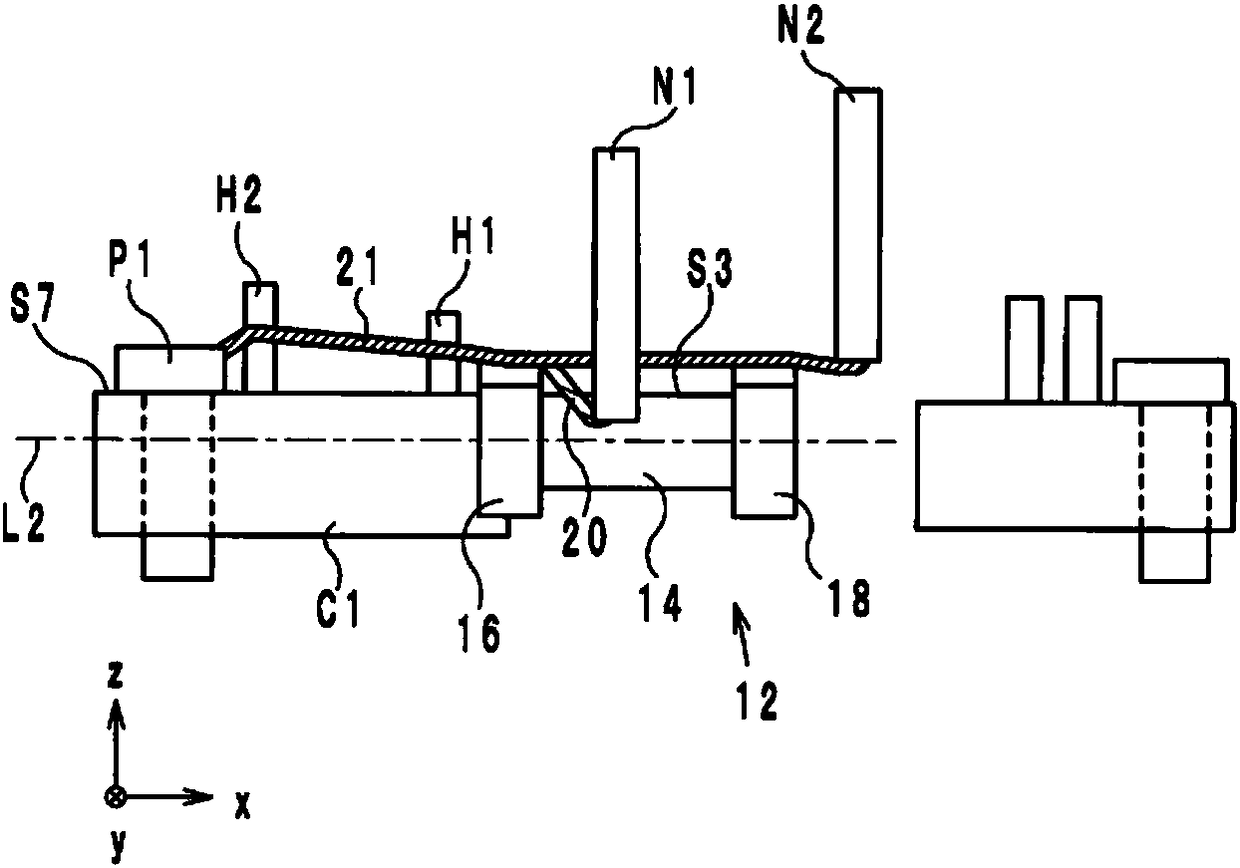

[0051] (For the structure of the common mode choke coil, refer to figure 1 as well as figure 2 )

[0052]A common mode choke coil 1 according to an embodiment will be described with reference to the drawings. Hereinafter, the direction in which the central axis of the core portion 14 extends is defined as the x-axis direction. In addition, the direction along the long side of the flange portion 16 when viewed from the x-axis direction is defined as the y-axis direction, and the direction along the short side of the flange portion 16 is defined as the z-axis direction. In addition, the x-axis, the y-axis, and the z-axis are orthogonal to each other.

[0053] like figure 1 As shown, the common mode choke coil 1 includes an iron core 12 , winding wires 20 and 21 , and external electrodes 22 to 25 . like figure 2 As shown, the common mode choke coil 1 is roughly divided into a starting wire side region α (first region) serving as a starting winding end of the winding wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com