Automatic bottle washer

A bottle washing machine and automatic technology, applied in the field of bottle washing machines, can solve the problems of complex structure and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

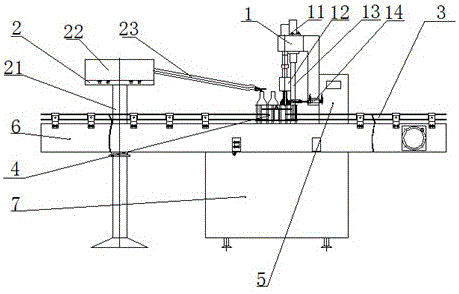

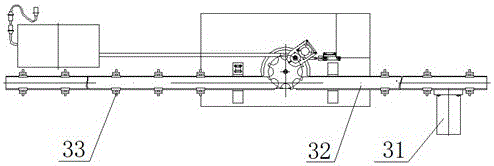

[0023] An automatic bottle washing machine, which consists of: bottle clamping and cleaning mechanism 1, feeding mechanism 2, transmission mechanism 3, turntable mechanism 4, control mechanism 5, characterized in that: the cleaning mechanism 1, feeding mechanism 2. The transmission mechanism 3 and the turntable mechanism 4 are connected to the control mechanism 5 described above.

Embodiment 2

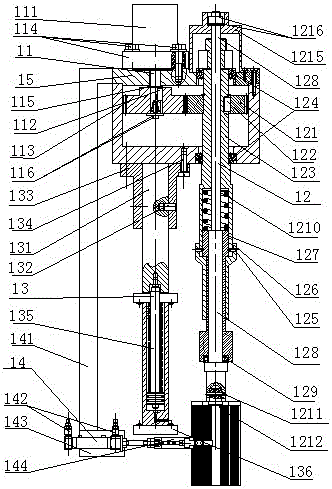

[0025] The clamping bottle and its cleaning mechanism 1 according to Embodiment 1 includes: a power transmission mechanism 11, a bottle washing mechanism 12, a lifting mechanism 13, and a clamping mechanism 14, and is characterized in that: the power transmission mechanism 11 includes a motor one 111 , the motor one 111 is connected with the gear one 113 through the key one 112, and is fixed on the gear box body 15 through the bolt group one 114, and the gear one 113 is connected with the gear two 121 in the bottle washing mechanism 12 meshing, the second gear 121 is connected with the hollow shaft 123 through the second key 122, and the power is transmitted to the bottle washing mechanism 12.

Embodiment 3

[0027] According to Embodiment 2, the shaft end of the first motor 111 is provided with a threaded hole and is equipped with a shaft end retaining ring 115, and the threaded hole cooperates with the second bolt group 116, and the second bolt group 116 and the shaft end The retaining ring 115 fixes the first gear 113 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com