Bottom line detection device

A technology for detecting device and bottom thread, which is applied to bobbin winding in sewing machines, textiles and papermaking, sewing equipment, etc., can solve the problem of inconvenient replacement of bobbins, and achieve the effects of easy adjustment, smooth expansion, and prevention of seam emptiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, an embodiment in which the bobbin thread replacing device according to the present invention performs bobbin thread replacement based on detection of the remaining amount of bobbin thread will be described in detail with reference to the drawings.

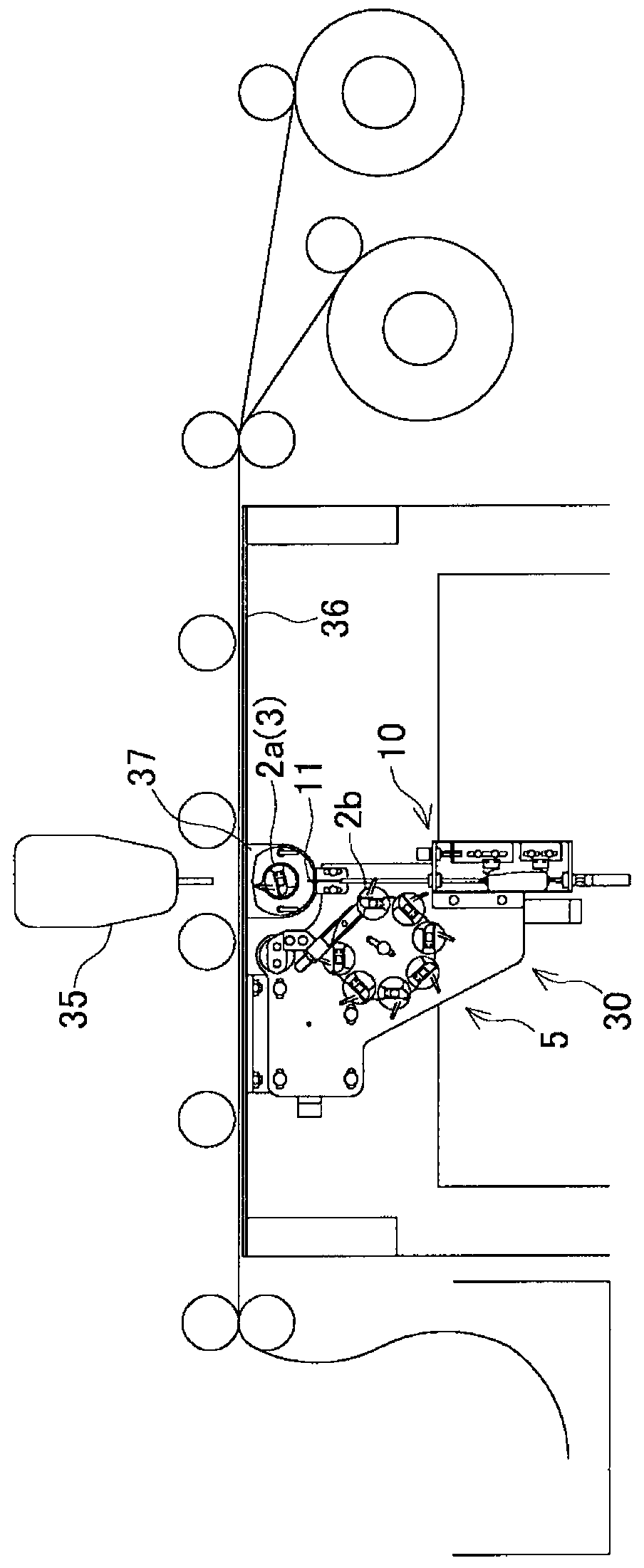

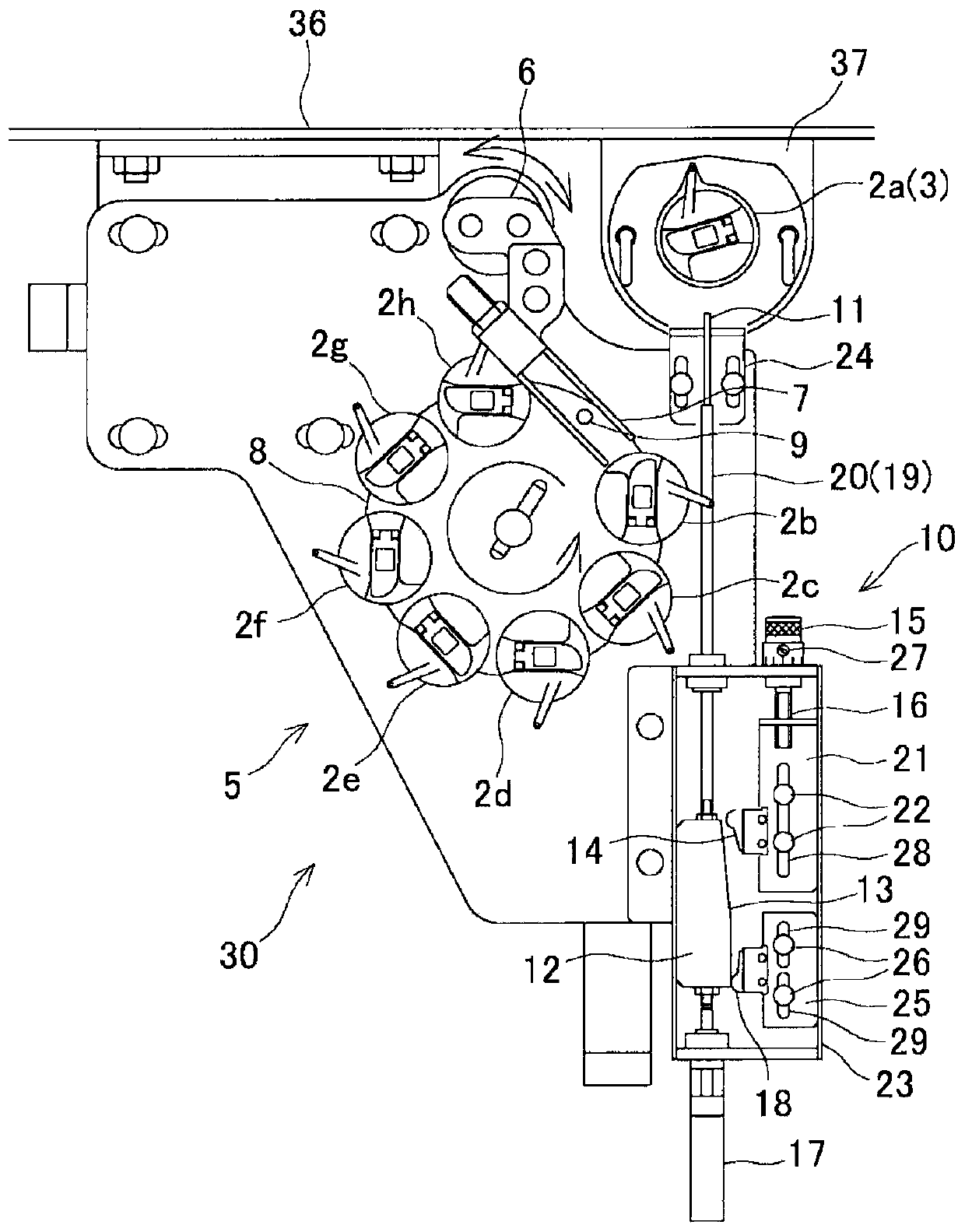

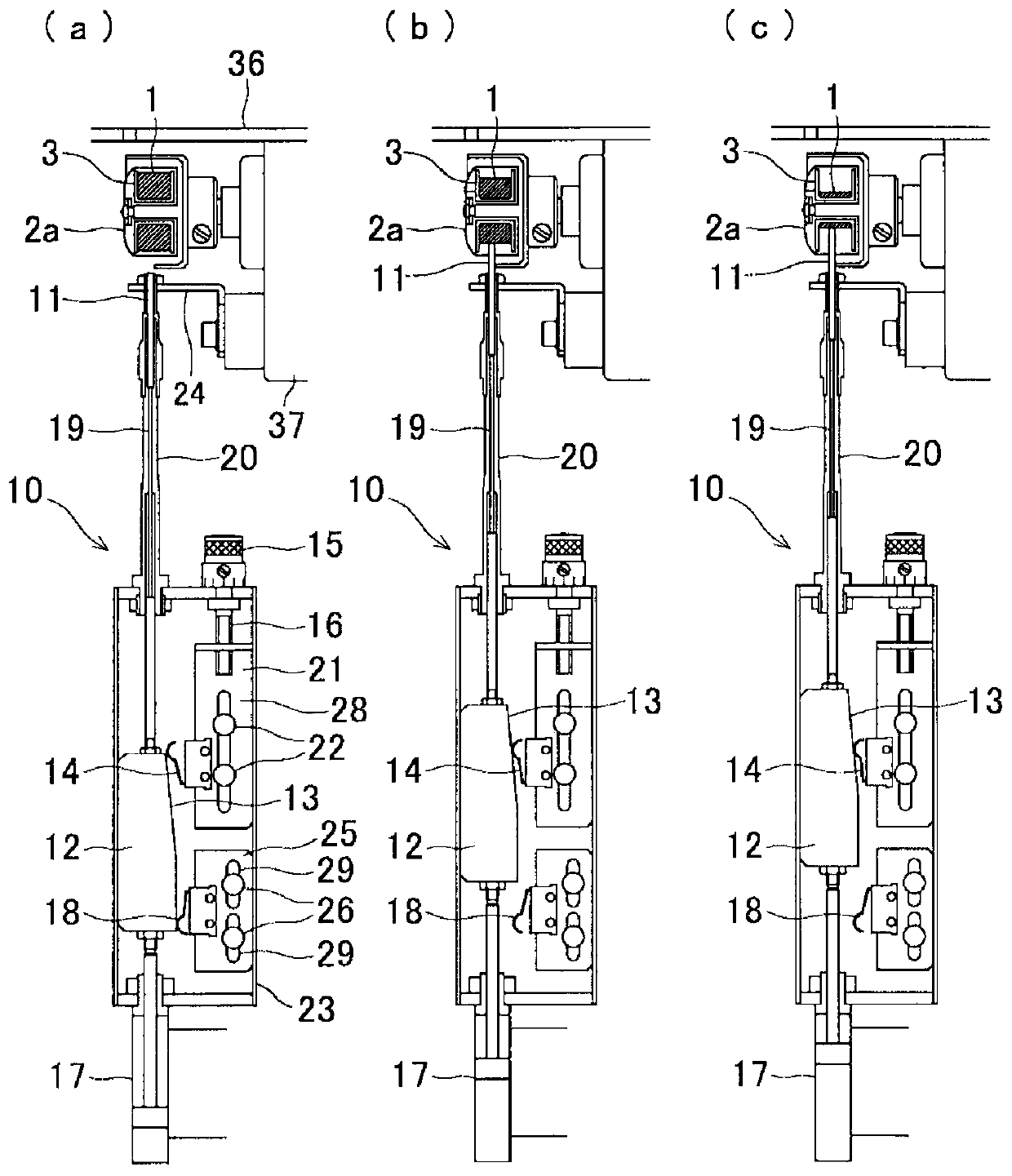

[0037] figure 1 It is an explanatory diagram showing a state where the bobbin thread changing device is installed on the sewing table. figure 2 It is an explanatory diagram showing the bobbin thread changing device. image 3 It is an explanatory diagram showing the input of the contact switch for measuring the stopper by the detection rod. Figure 4 It is an explanatory diagram showing a state in which a detection pin is extended by an air cylinder and an electromagnetic switch. Figure 5 It is an explanatory diagram showing the state where the position adjustment knob is rotated and the contact switch is slid. Figure 6 It is an explanatory diagram showing the relationship between the winding length and the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com