A thin keyboard switch

A keyboard switch, thin technology, applied in electrical switches, contact operating mechanisms, electrical components, etc., can solve problems such as unsmooth use, insufficient elasticity of metal sheets, affecting normal use, etc., to increase the pressing feel, improve user experience, The effect of enhancing balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

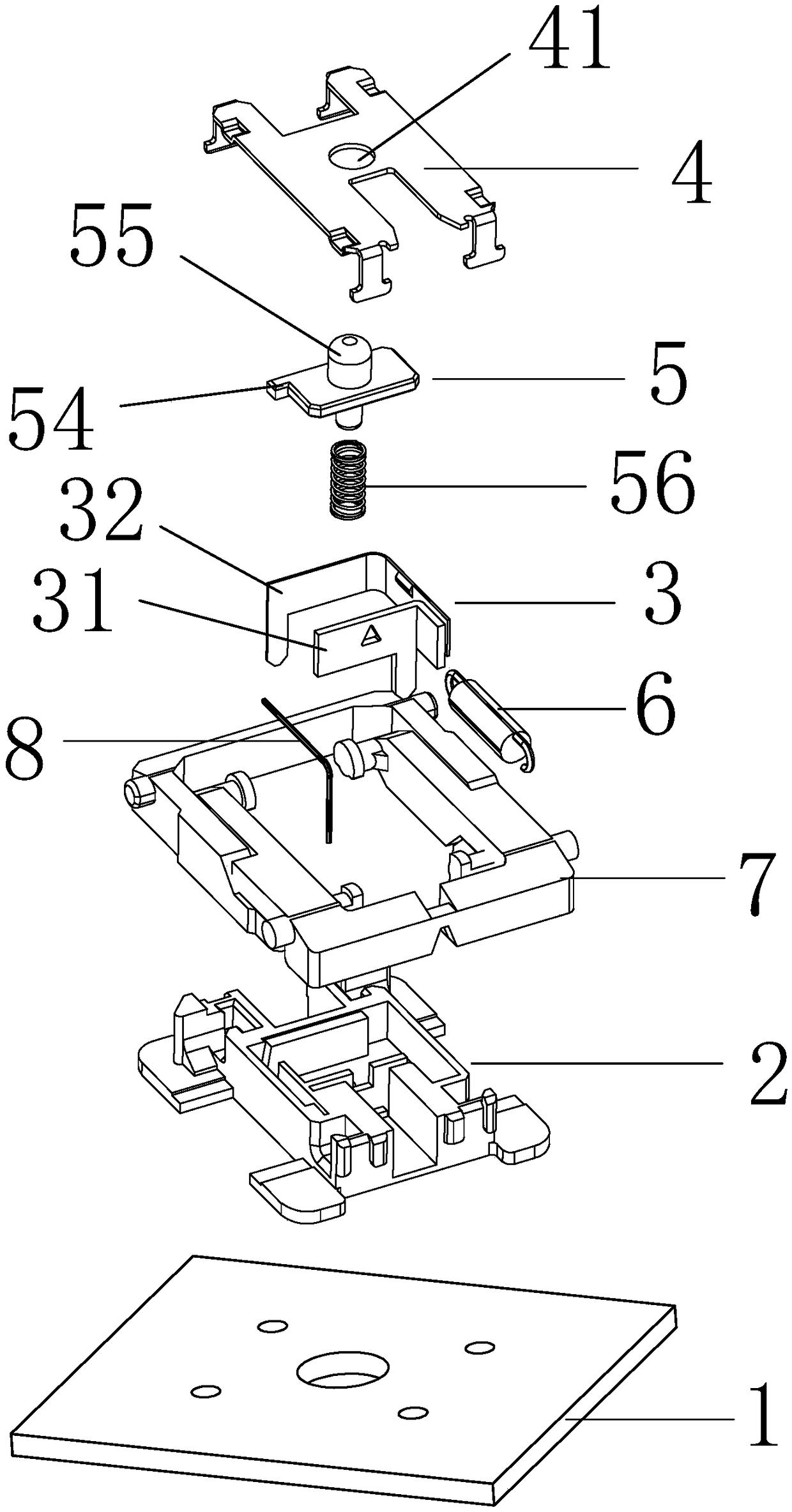

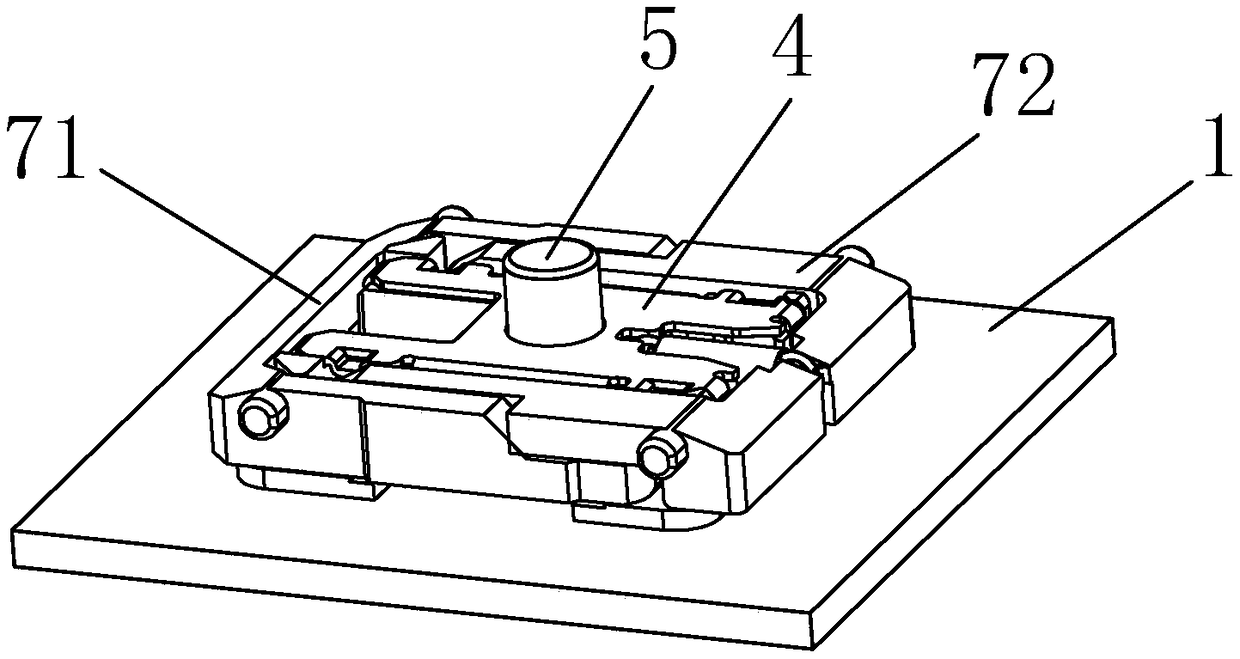

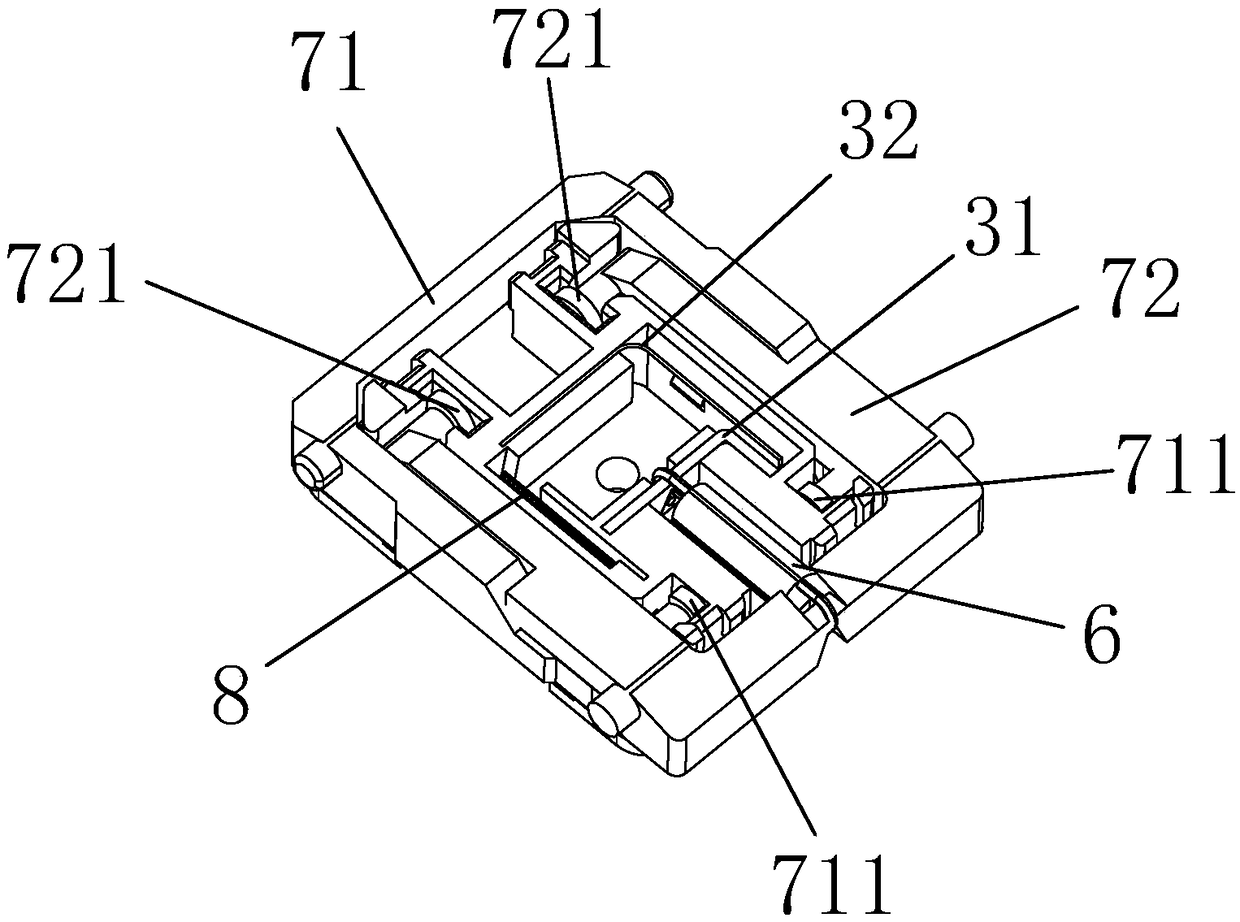

[0024] Please refer to Figure 1 to Figure 5 , the embodiment of the present invention provides a thin keyboard switch, including a PCB board 1, a base 2 arranged on the PCB board 1, and a conduction component 3 and an upper cover 4 respectively arranged on the base 2, and also includes respectively The guide core assembly 5, the extension spring 6 and the X-shaped bracket 7 arranged on the base 2, the base 2 is provided with a first accommodation groove 21 and a second accommodation groove 22, and the extension spring 6 is clamped on the In the first accommodating groove 21, the guide core assembly 5 and the conduction assembly 3 are clamped in the second accommodating groove 22, and the upper cover 4 is provided with an opening 41 for the upper end of the guide core assembly 5 to pass through; The upper edge of the base 2 is provided with a support plate seat 23, the X-shaped bracket 7 is arranged on the support plate seat 23, and is surrounded by the periphery of the base 2...

Embodiment 2

[0033] Please refer to Image 6 and Figure 7 The main difference between this embodiment and Embodiment 1 is that the guide core assembly 5' includes a guide core active part 51 and a guide core follower 52 inserted into the lower end of the guide core active part 51, and the conduction assembly 3 ' is a turtle carrier, which is located at the lower end of the guide core follower 52.

[0034] The working principle of this embodiment is: press the guide core active part 51, apply a downward force to the guide core follower 52, make the guide core follower 52 contact with the turtle carrier, and realize the conduction of the keyboard switch; Pressing the guide core active part 51, the guide core active part 51 drives the guide core follower 52 to return to the initial position upwards, so that the guide core follower 52 is separated from the tortoise carrier, and the keyboard switch is disconnected.

[0035] The key points of the present invention are mainly: by adding extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com