Automobile screw-in shift limiter and method for manufacturing the push rod of the shift limiter

A technology of limiter and push rod, which is applied to other manufacturing equipment/tools, manufacturing tools, components with teeth, etc., can solve the problem of short effective working stroke of the shift limit assembly, and extend the effective working stroke. , Wide application range, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described.

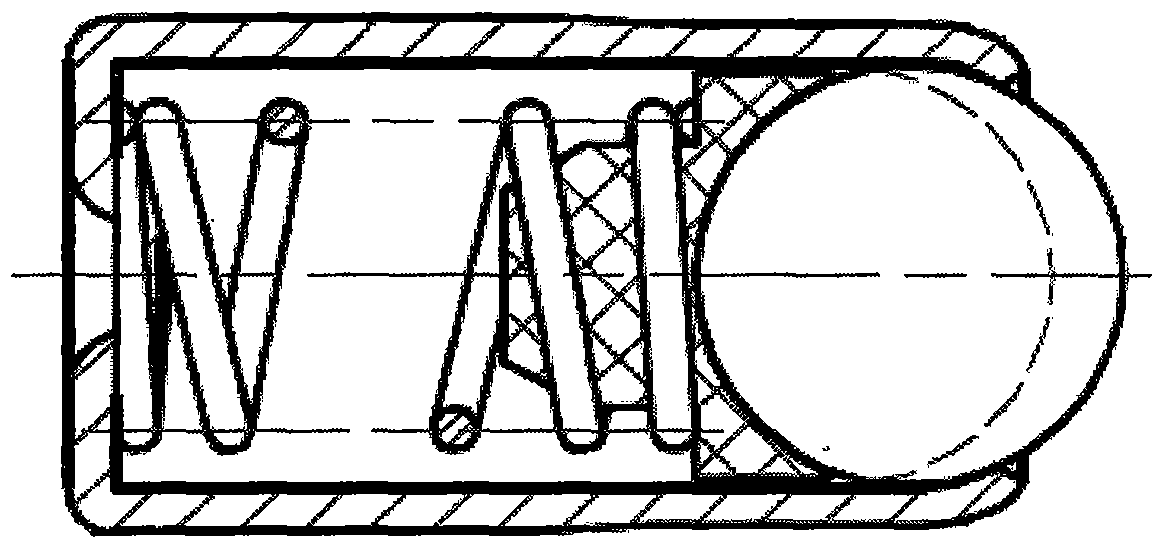

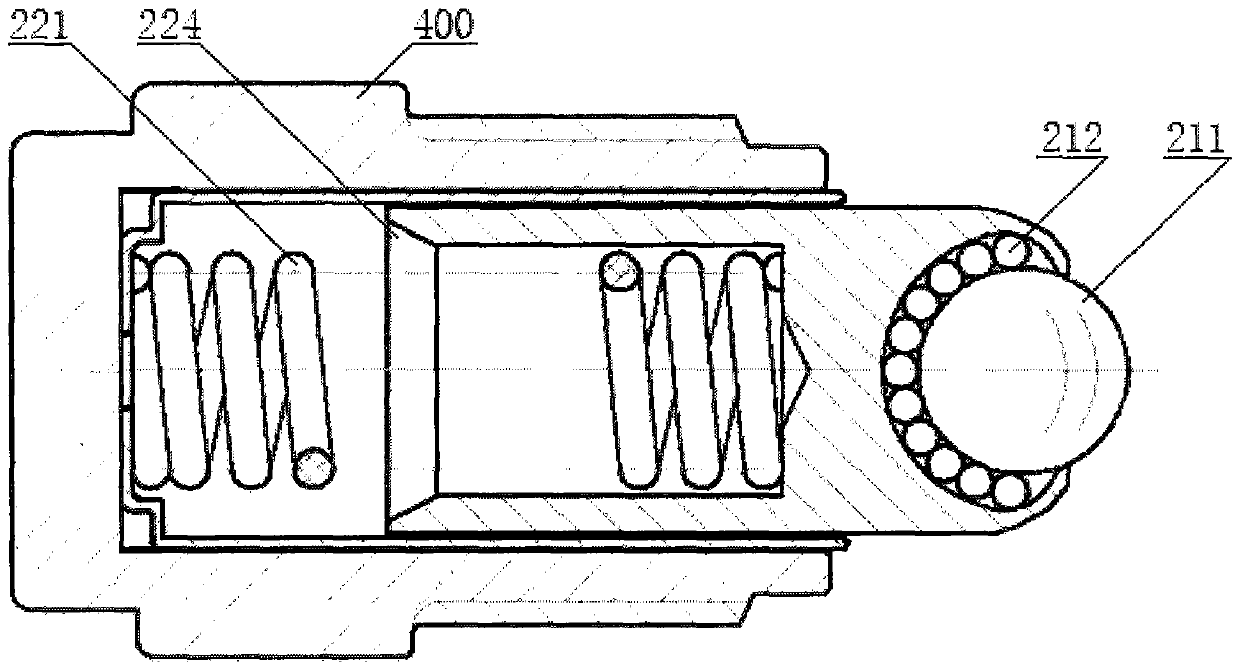

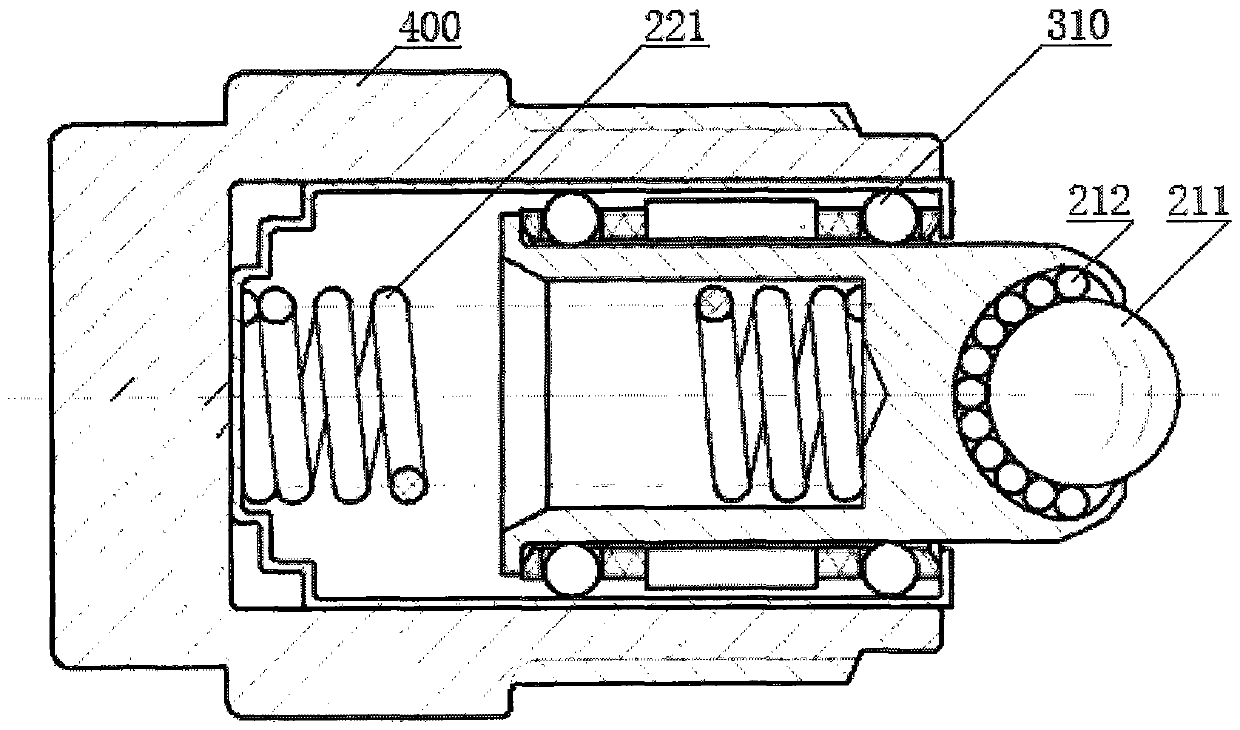

[0031] Such as figure 2 As shown, the schematic diagram of the automobile screw-in shift limiter of the present invention. The automotive screw-in shift limiter includes a shift limiter housing, a shift limiter housing screw-in casing 400 and a shift limiter push rod, and the shift limiter housing is a hollow cylinder body structure, the shift limiter housing is elastically sleeved on the shift limiter push rod in the axial direction, and the outer surface of the shift limiter housing screw-in type jacket 400 is provided with a screw-in thread, and the shift limiter The screw-in casing 400 of the device housing is fixedly sleeved on the shift limiter housing. figure 1 It shows the specific structure of the existing shift limiter. The elastic socket is connected by winding the spring in the shift limiter housing with one end of the limit block. The steel ball at the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com