Slide rail assembly and bracket thereof

A slide rail assembly, bracket technology, applied in the direction of rack/frame structure, etc., can solve the problems of affecting the operation performance, complex structure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

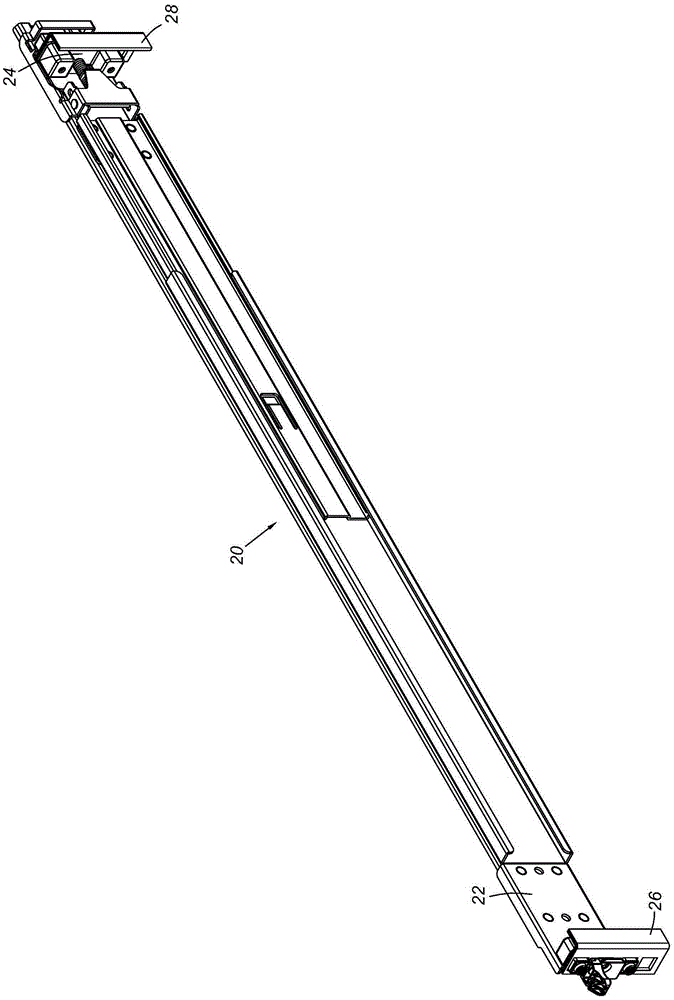

[0029] figure 1 A slide rail assembly 20 showing an embodiment of the present invention is detachably attached to a first column 26 and a first column of a rack (rack) by means of a first bracket 22 and a second bracket 24. Second machine column 28.

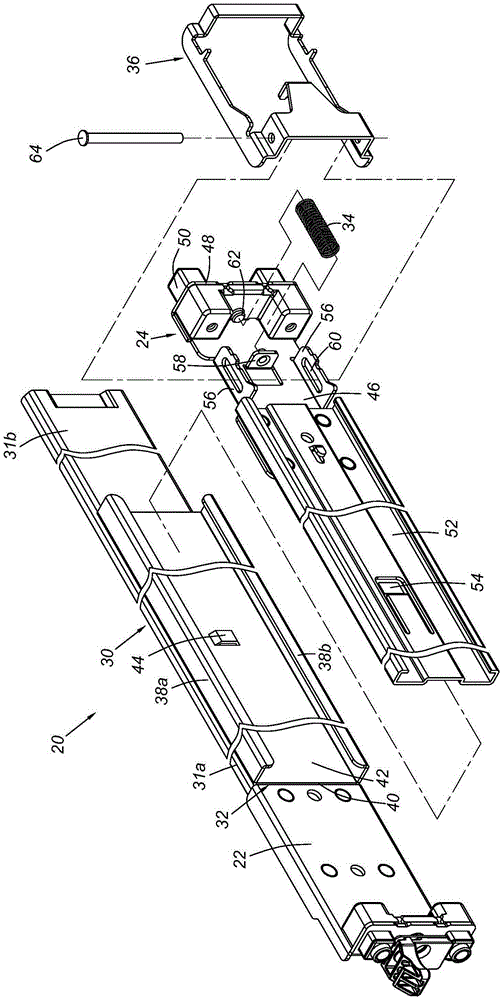

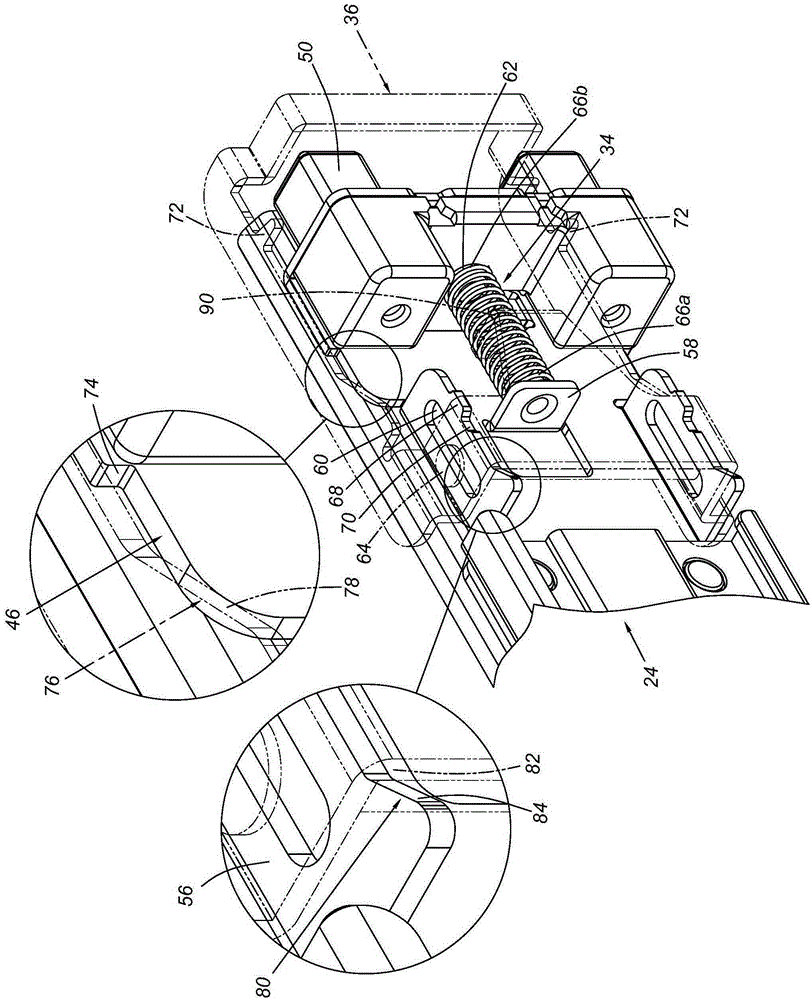

[0030] Cooperate figure 2 As shown, the slide rail assembly 20 further includes a rail member 30 and a support frame 32 . Wherein, the support frame 32 is fixedly connected to the rail 30 and can be regarded as a part of the rail 30 . The supporting frame 32 has an upper wall 38a, a lower wall 38b, and a longitudinal wall 40 connected between the upper wall 38a and the lower wall 38b. The upper wall 38 a , the lower wall 38 b , and the longitudinal wall 40 jointly define a channel 42 . The longitudinal wall 40 includes a first portion 44 (eg, a protruding block) disposed within the channel 42 .

[0031] The first bracket 22 is mounted to a first end portion 31a adjacent to the rail 30, and the second bracket 24 is movably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com