passenger conveyor

A technology for passenger conveyors and frames, used in transportation and packaging, escalators, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

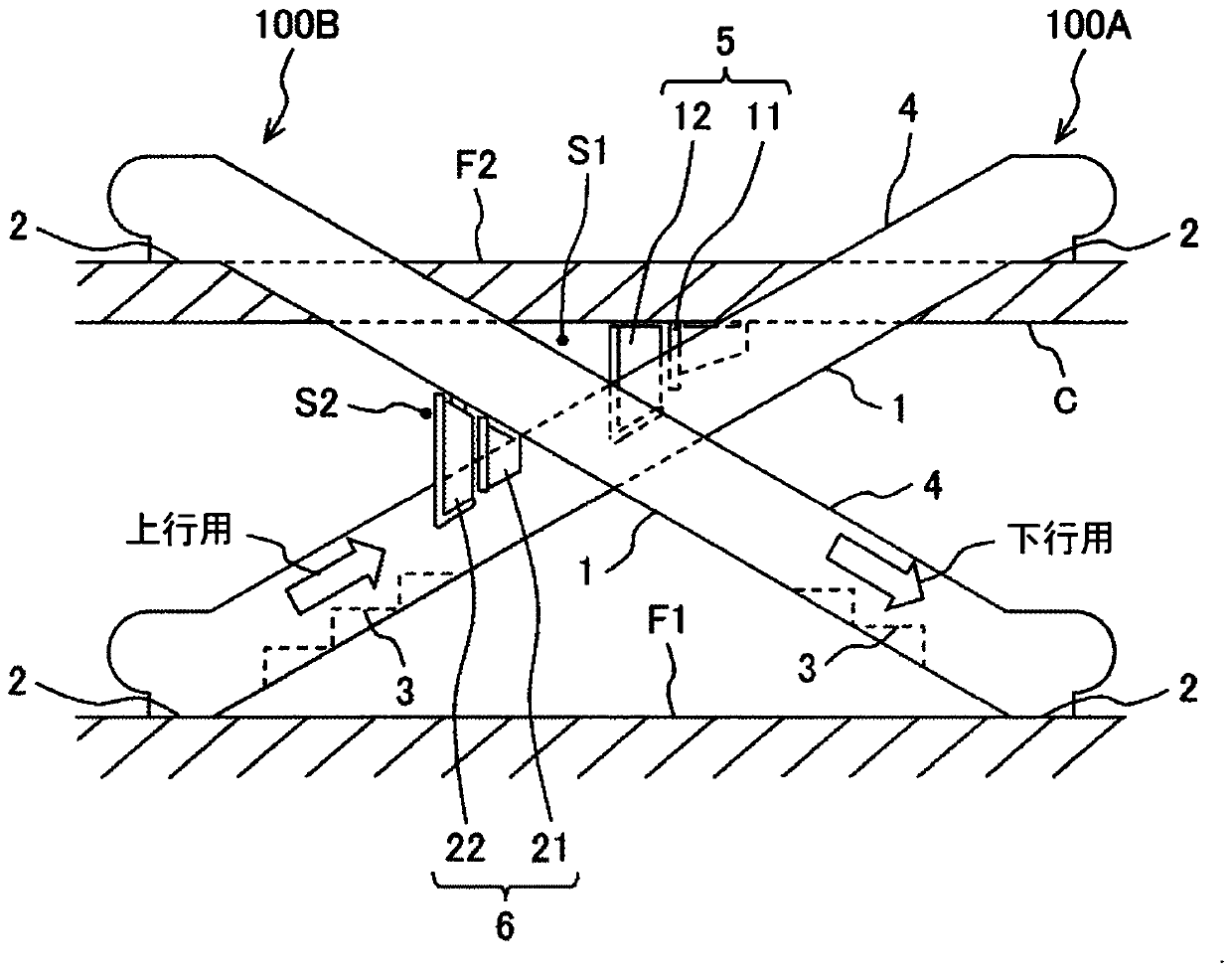

[0027] figure 1 It is a schematic structural diagram related to one embodiment of the passenger conveyor to which the present invention is applied.

[0028] In this embodiment, two passenger conveyors 100A and 100B are arranged in parallel between the floor surface F1 of the lower floor and the floor surface F2 of the upper floor of the building. The passenger conveyor 100A is for upward travel, and the passenger conveyor 100B is for downward travel. Each conveyor 100A, 100B comprises: a frame body 1 erected between the lower floor surface F1 and the upper floor surface F2; passenger upper and lower floors 2 respectively arranged on the lower floor surface F1 and the upper floor surface F2; Steps 3 that are endlessly connected in the frame body 1 and circulate between the upper and lower floors 2 of each passenger; a driving device (not shown) that drives the steps 3; installed in the frame body 1 and arranged along the forward direction of the steps 3 The railings 4 on both...

Embodiment 2

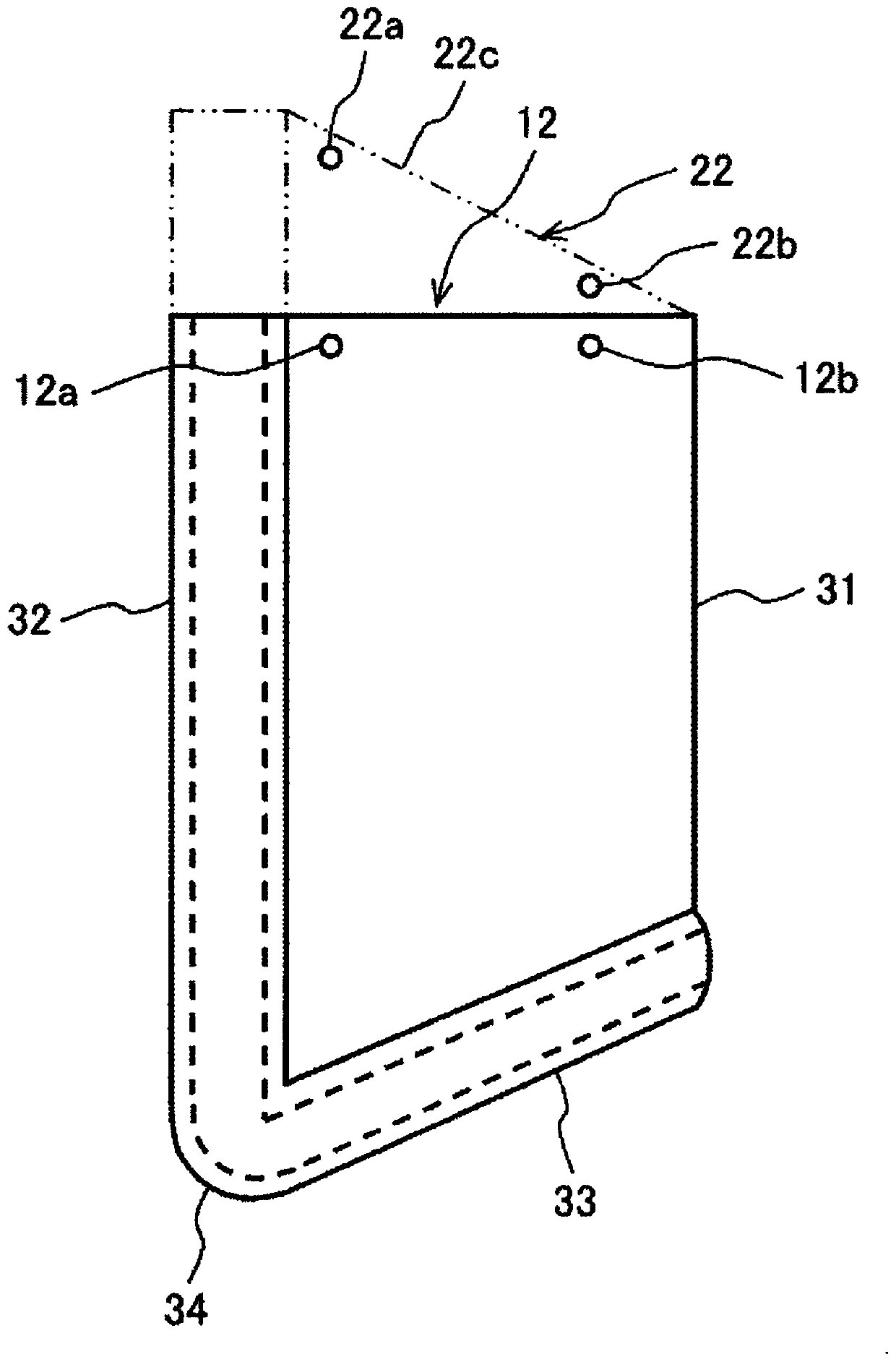

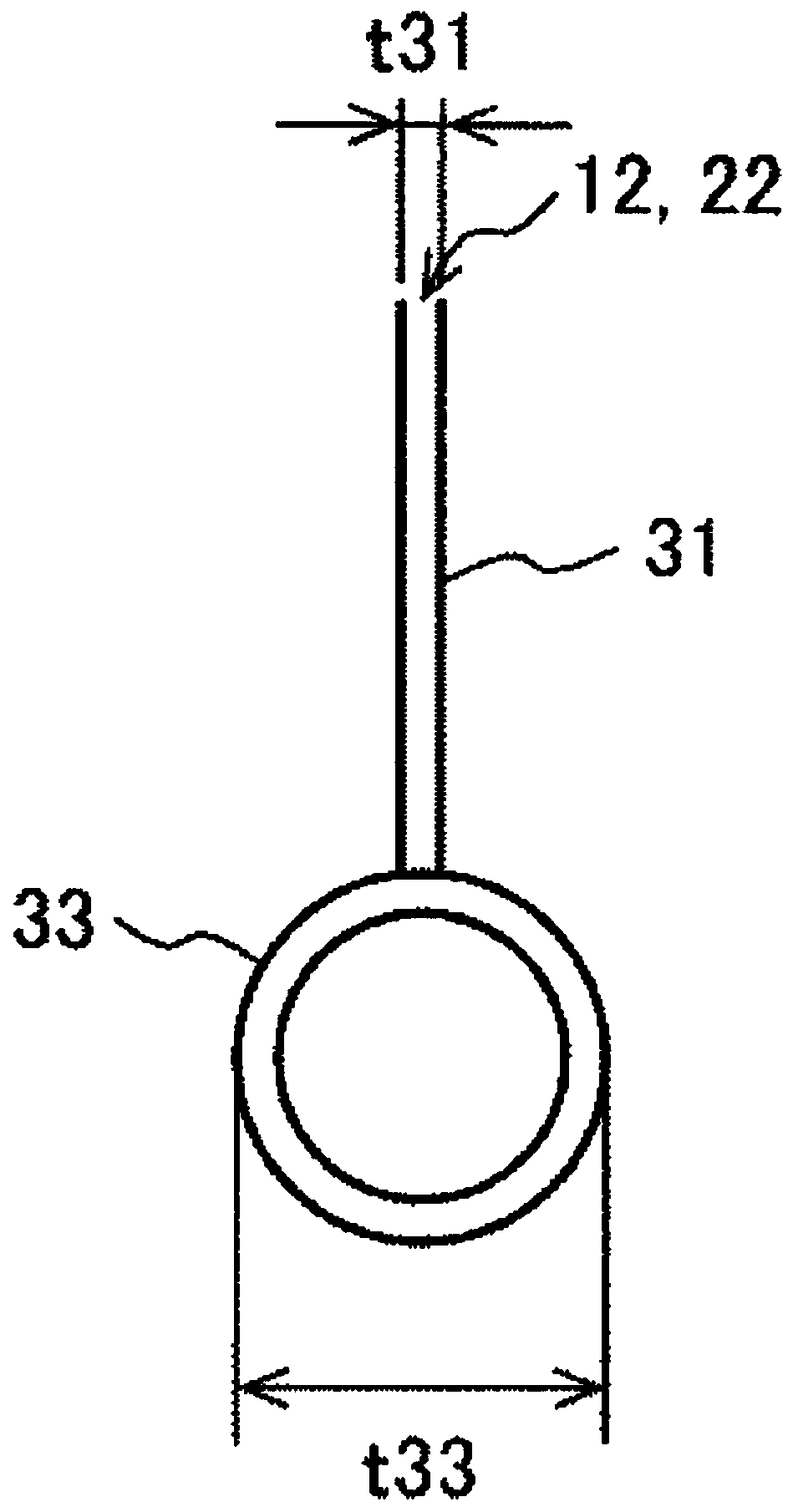

[0042] Figure 5 It is a figure which shows the triangle plate of the passenger conveyor concerning Example 2 of this invention. Image 6 It is a longitudinal cross-sectional view showing an example of the shape of the gusset according to the second embodiment. Figure 7 It is a longitudinal cross-sectional view showing an example of the shape of the gusset according to the second embodiment. Figure 8 It is a longitudinal cross-sectional view showing an example of the shape of the gusset according to the second embodiment. exist Figure 5 in, with figure 2 Similarly, the parts of the movable warning panel 22 that are different from the movable warning panel 12 are indicated by dotted lines.

[0043] The movable warning panels 12 and 22 of the second embodiment are composed of a plate-shaped member 41 and a cylindrical member 42 attached to the front edge of the plate-shaped member 41 . The lower edge portion of the plate member 41 is bent in a curved manner to form a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com