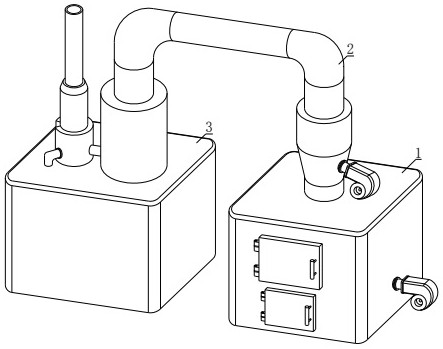

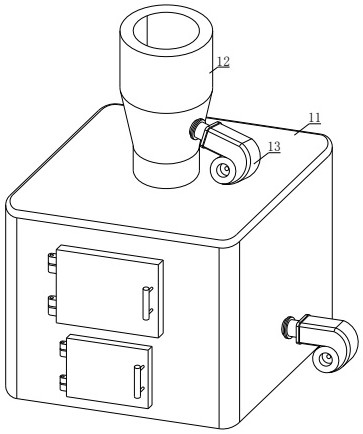

Waste incineration device with smoke pipe cooling structure and implementation method of waste incineration device

A technology of waste incineration and cooling structure, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., which can solve the problems of easy blockage of the filter screen, poor circulation, etc., and achieve the effect of reducing resistance and facilitating pull back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

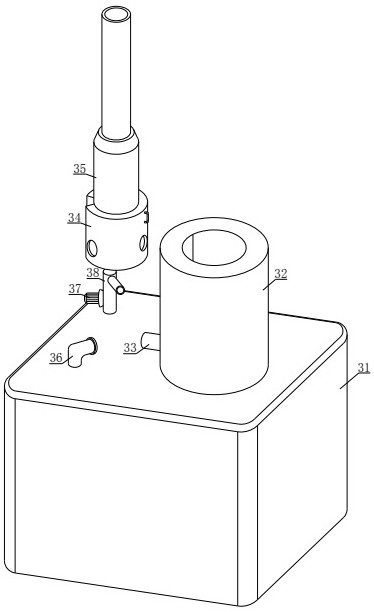

[0036] The present invention provides another technical solution: a method for implementing a waste incineration device with a flue pipe cooling structure, comprising the following steps:

[0037] S01: The incinerator 11 starts to incinerate, the heat of the flue gas heats the aqueous solution in the inner cavity of the steam chamber 346, and the generated steam enters the push chamber 347 through the steam pipe 345, and at the same time, the steam pushes the first rotating wheel 3481, and the rotation of the first rotating wheel 3481 drives the second rotating wheel. One tooth 3483, the first tooth 3483 makes the third gear 3484 rotate, the third gear 3484 pushes the connecting rod 3486 through the crankshaft 3485, and the connecting rod 3486 pushes the water wave assembly 3472;

[0038] S02: The first push plate 34721 installed at the lower end of the water wave component 3472 pushes the water solution in the water solution cooling chamber 349 to generate waves, and the waves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com