How to use the one-way valve for run-flat tires

A one-way valve, run-flat tire technology, applied in tire inflation valve, tire parts, with independent inflation pads and other directions, can solve the problems of motor vehicles prone to partial tire failure, motor vehicle running out of control, traffic accidents, etc. Achieve the effect of avoiding puncture traffic accidents and tire dents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

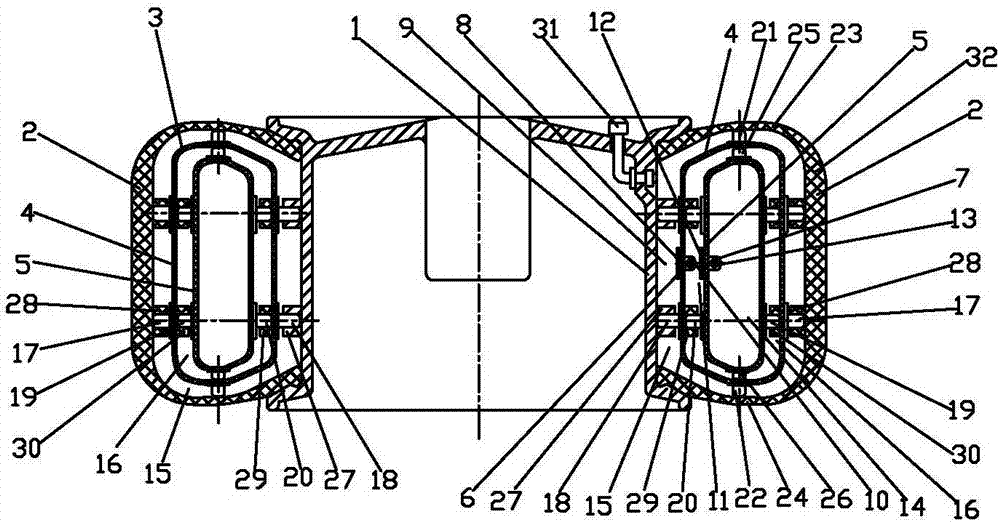

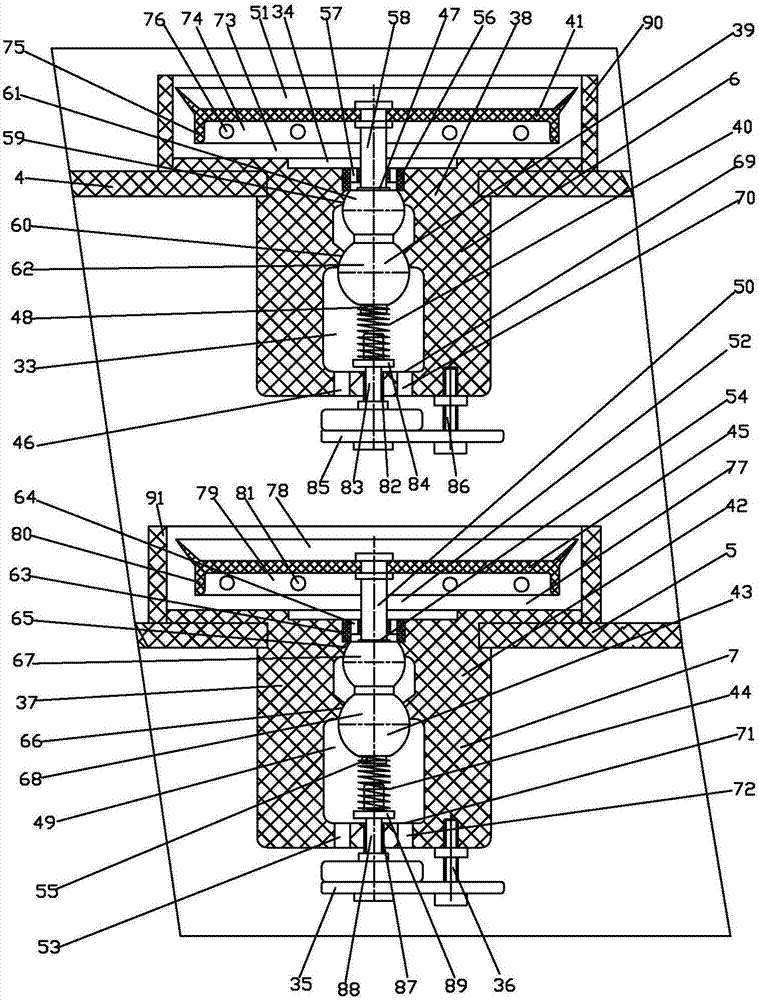

[0012] Below in conjunction with accompanying drawing, the present invention is further described:

[0013] figure 1 The structural schematic diagram of the shown run-flat tire and figure 2 The schematic diagram of the structure of the one-way valve shown, the run-flat tire includes a rim 1, an outer tire 2, an inner tube 3 and a one-way valve 37, and the one-way valve 37 includes a first one-way valve 6 and a second one-way valve 7, and the outer tire 2 is connected with the rim 1, the inner tube 3 is located in the outer tire 2; there are multiple inner tubes 3, the inner tube 3 includes a first inner tube 4 and a second inner tube 5, the first one-way valve 6 is located on the first inner tube 4, the first The one-way valve 6 is sealingly connected with the first inner tube 4, the second one-way valve 7 is arranged on the second inner tube 5, and the second one-way valve 7 is sealingly connected with the second inner tube 5; the first air intake of the first one-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com