Optical imaging lens

An optical imaging lens and imaging technology, applied in optics, optical components, instruments, etc., can solve the problems of short lens length, unfavorable thinning of mobile phones and digital cameras, etc., achieve reduction of field curvature aberration, good optical imaging quality, and promote The effect of system length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

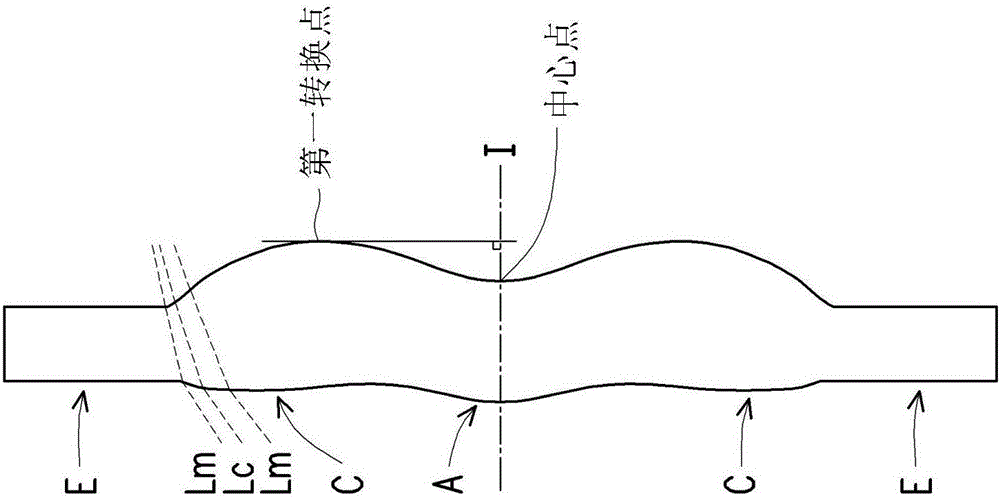

[0063] "A lens has a positive refractive power (or negative refractive power)" mentioned in this specification refers to the positive (or negative) refractive power of the lens on the optical axis calculated by Gaussian optics theory. The image side and object side are defined as the range through which the imaging light passes, where the imaging light includes the chief ray Lc and the marginal ray Lm, such as figure 1 As shown, I is the optical axis and this lens is radially symmetrical to each other with the optical axis I as the symmetry axis. The area where the light rays pass through the optical axis is the area A near the optical axis, and the area where the marginal light rays pass is the area C near the circumference. , In addition, the lens also includes an extension E (that is, the area near the circumference C radially outward), which is used for the lens to be assembled in an optical imaging lens, and the ideal imaging light does not pass through the extension E , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com