Patents

Literature

75results about How to "Shorten system length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

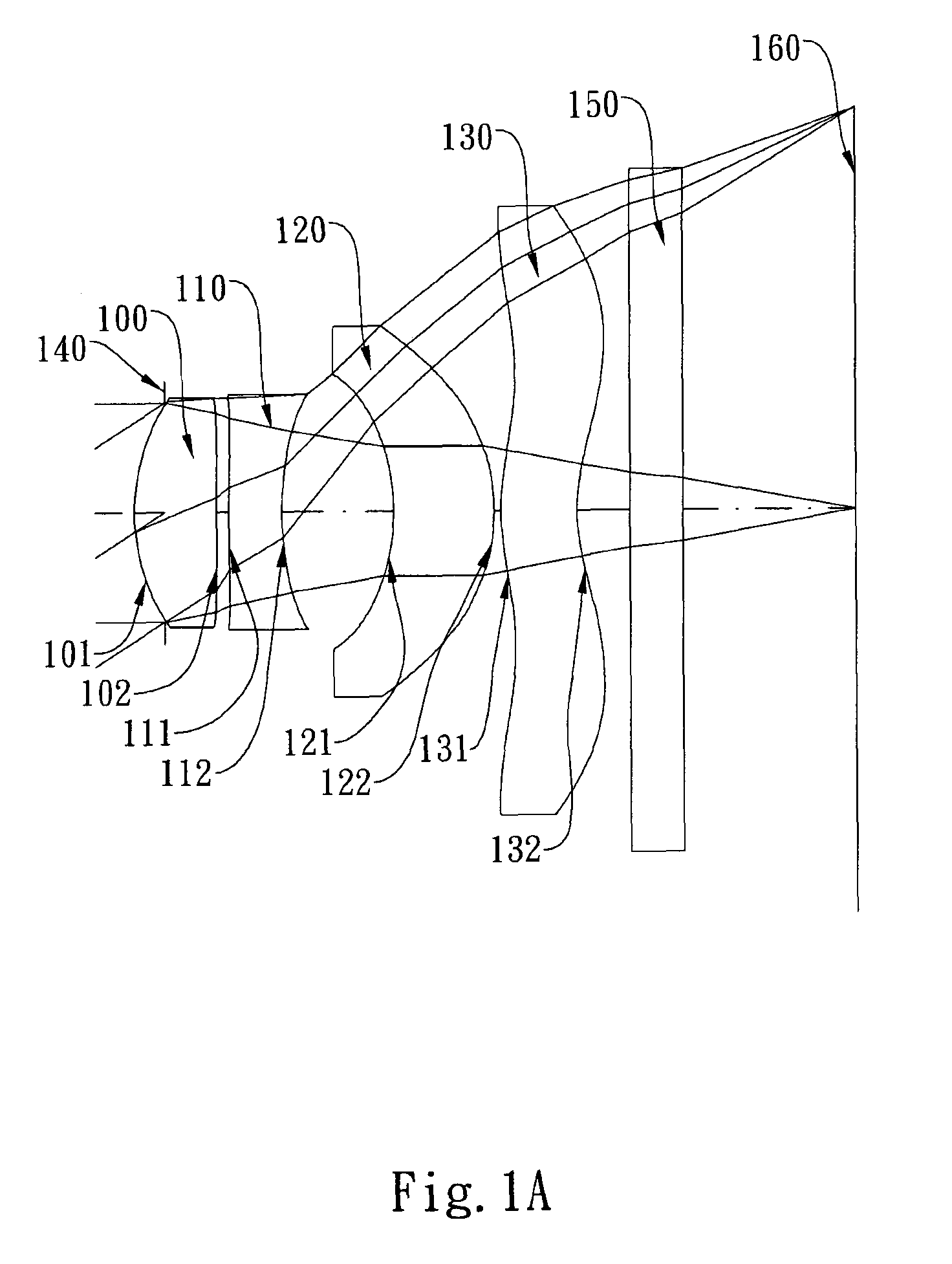

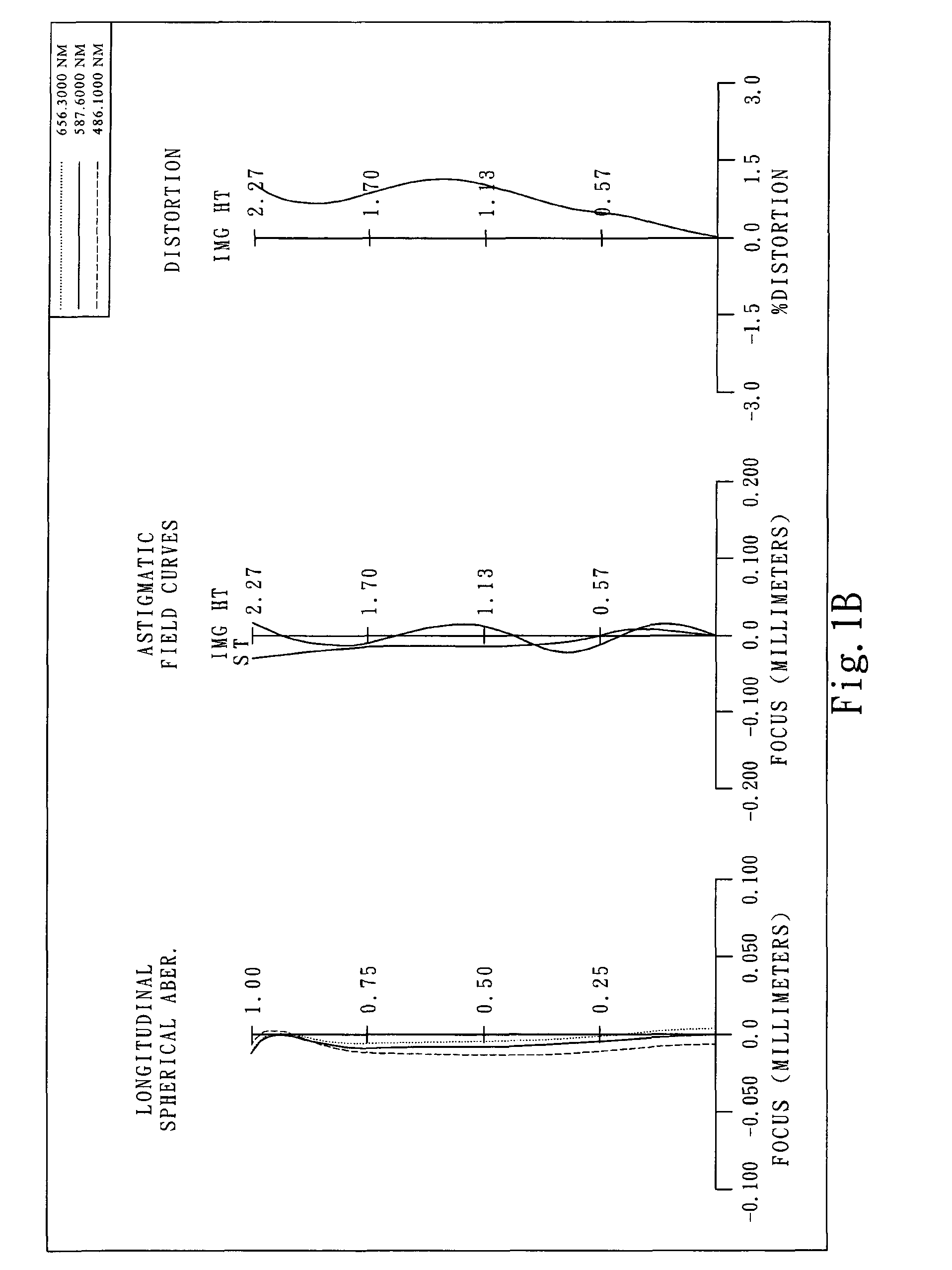

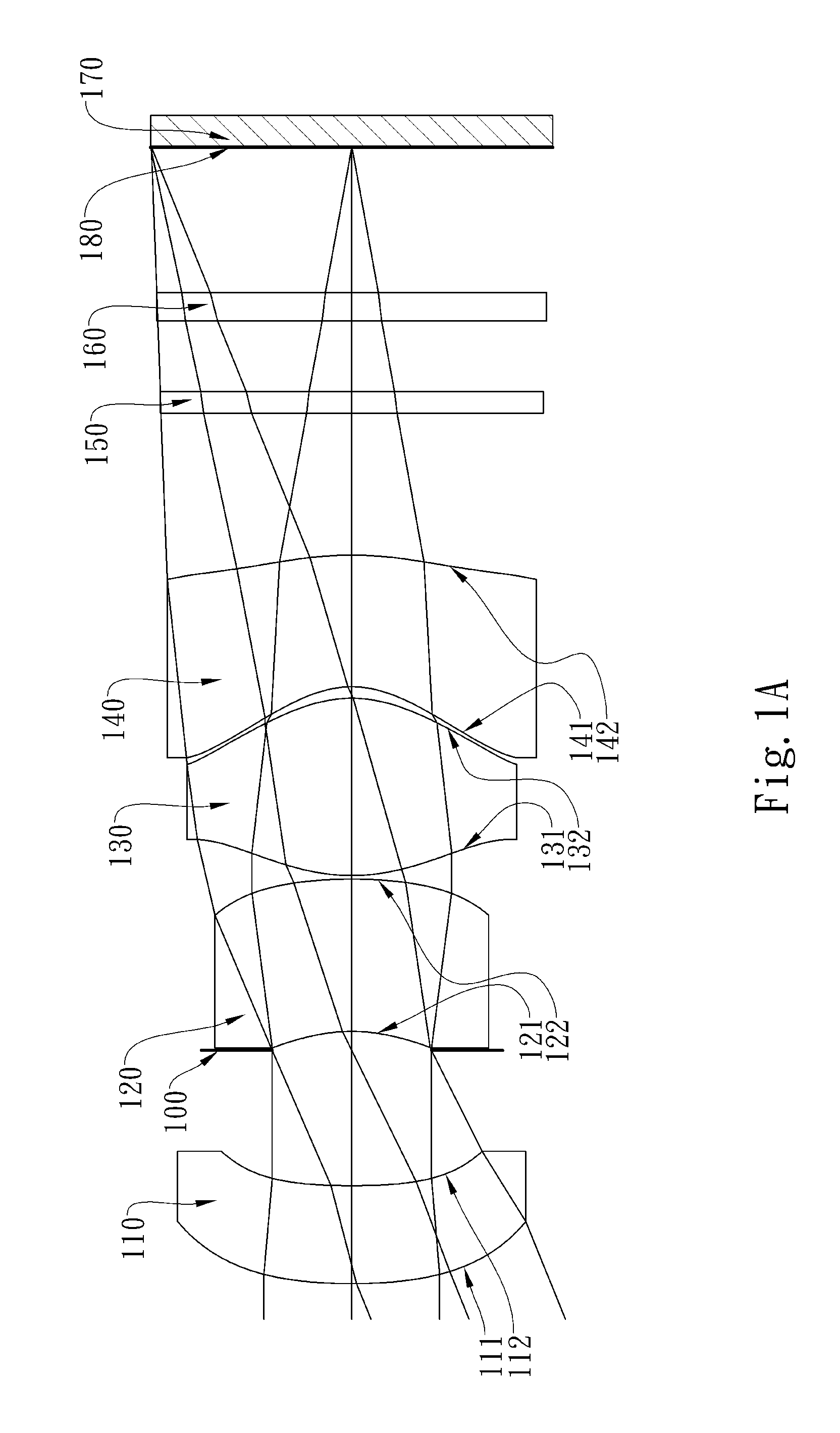

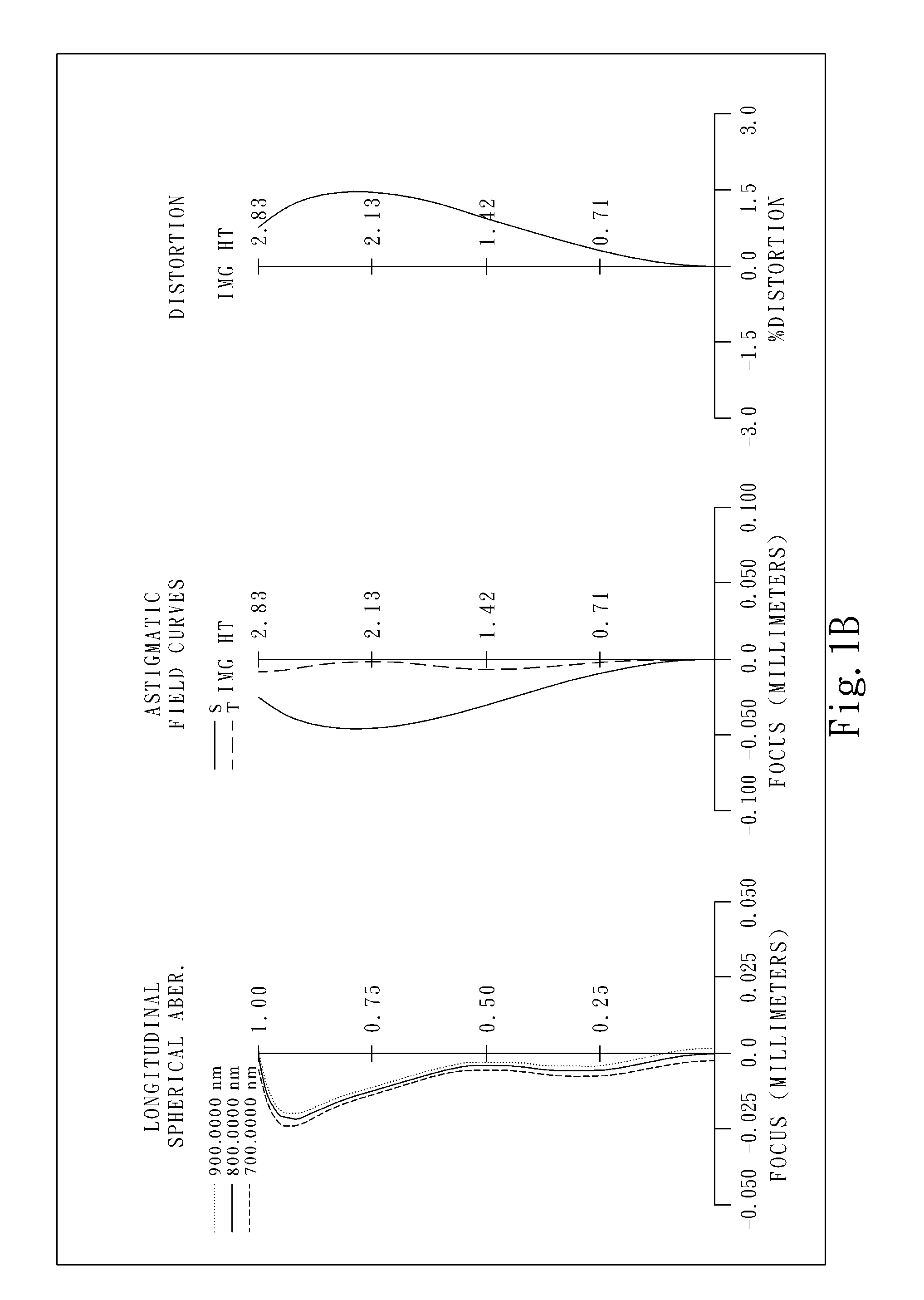

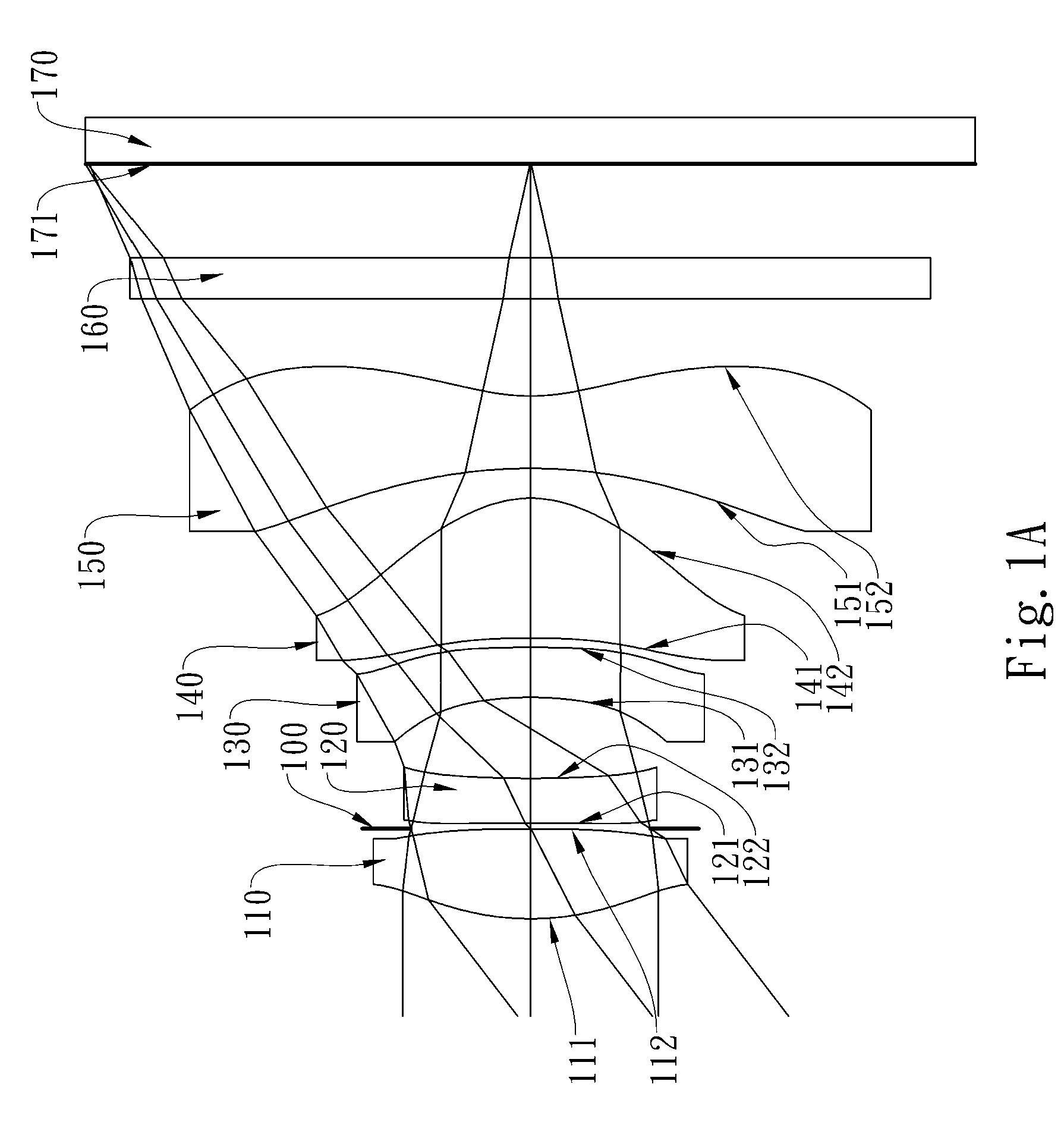

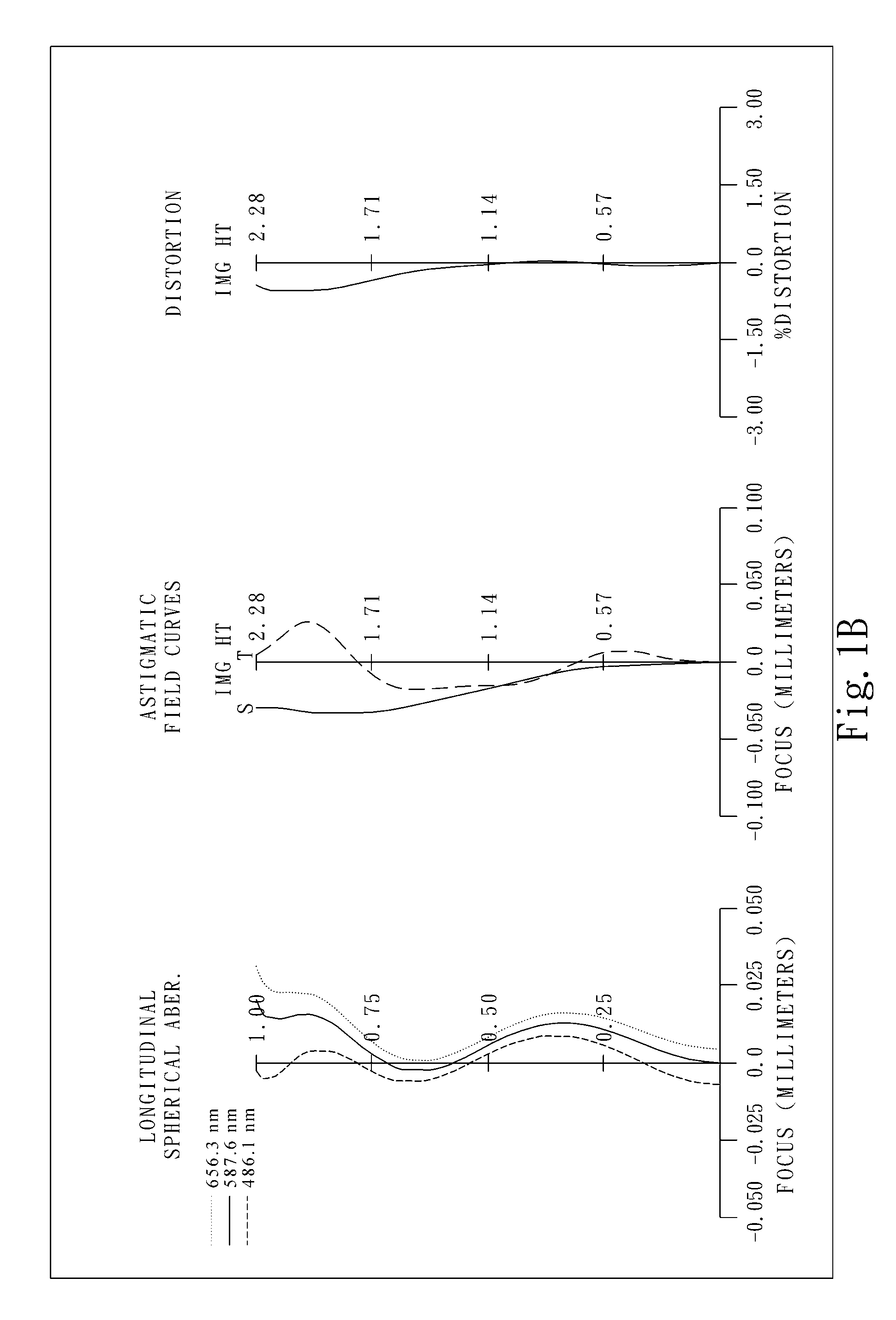

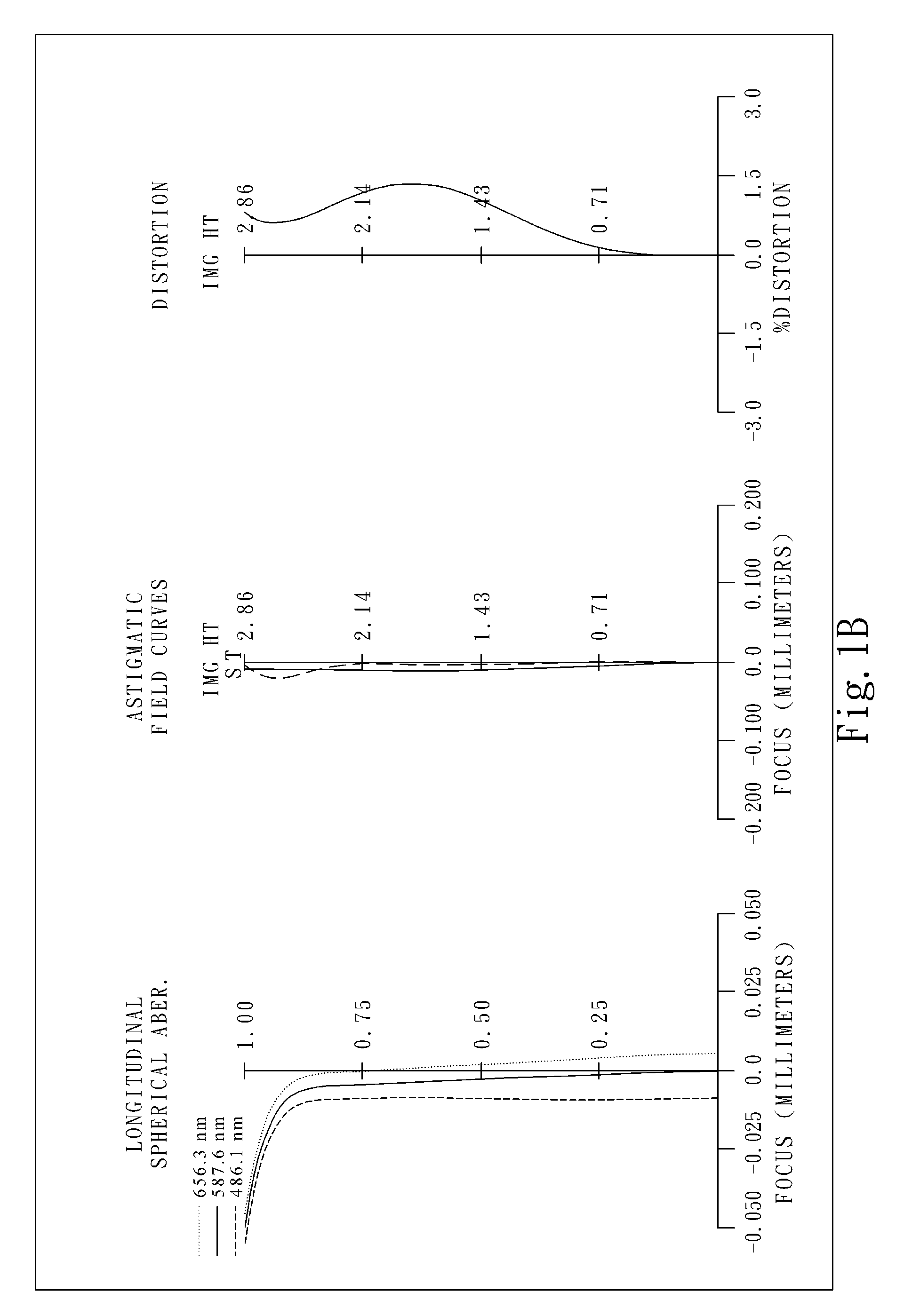

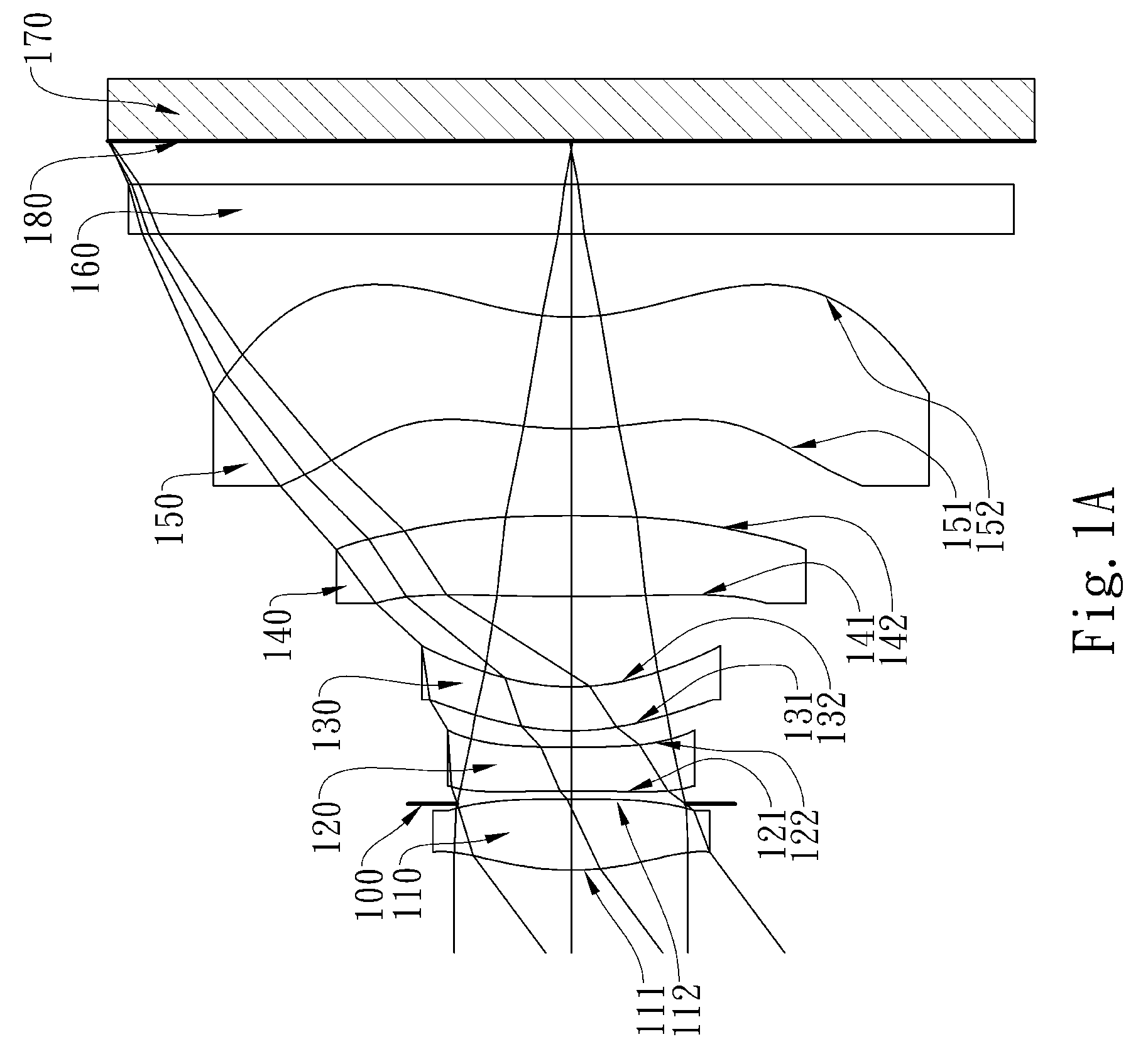

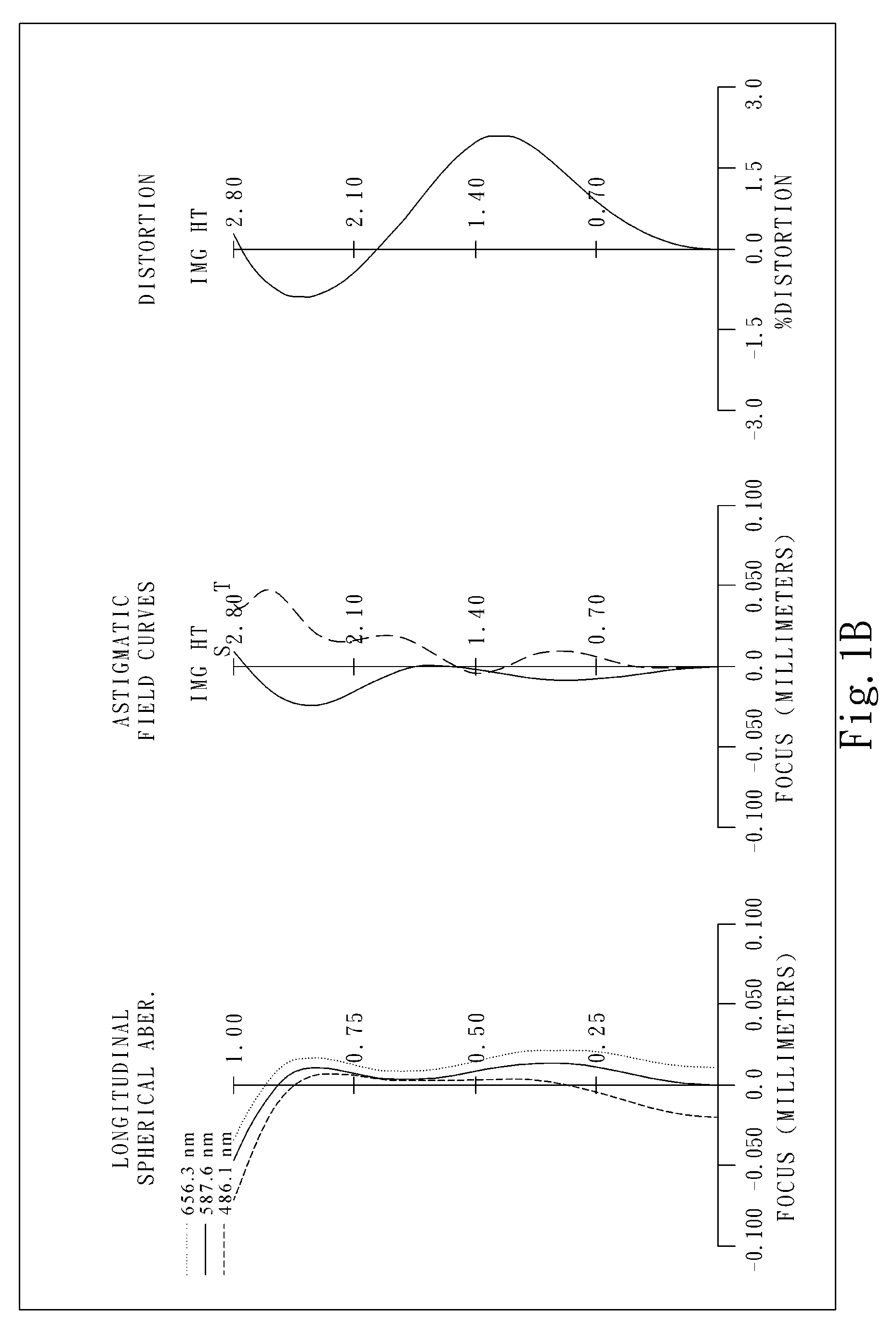

Imaging lens assembly

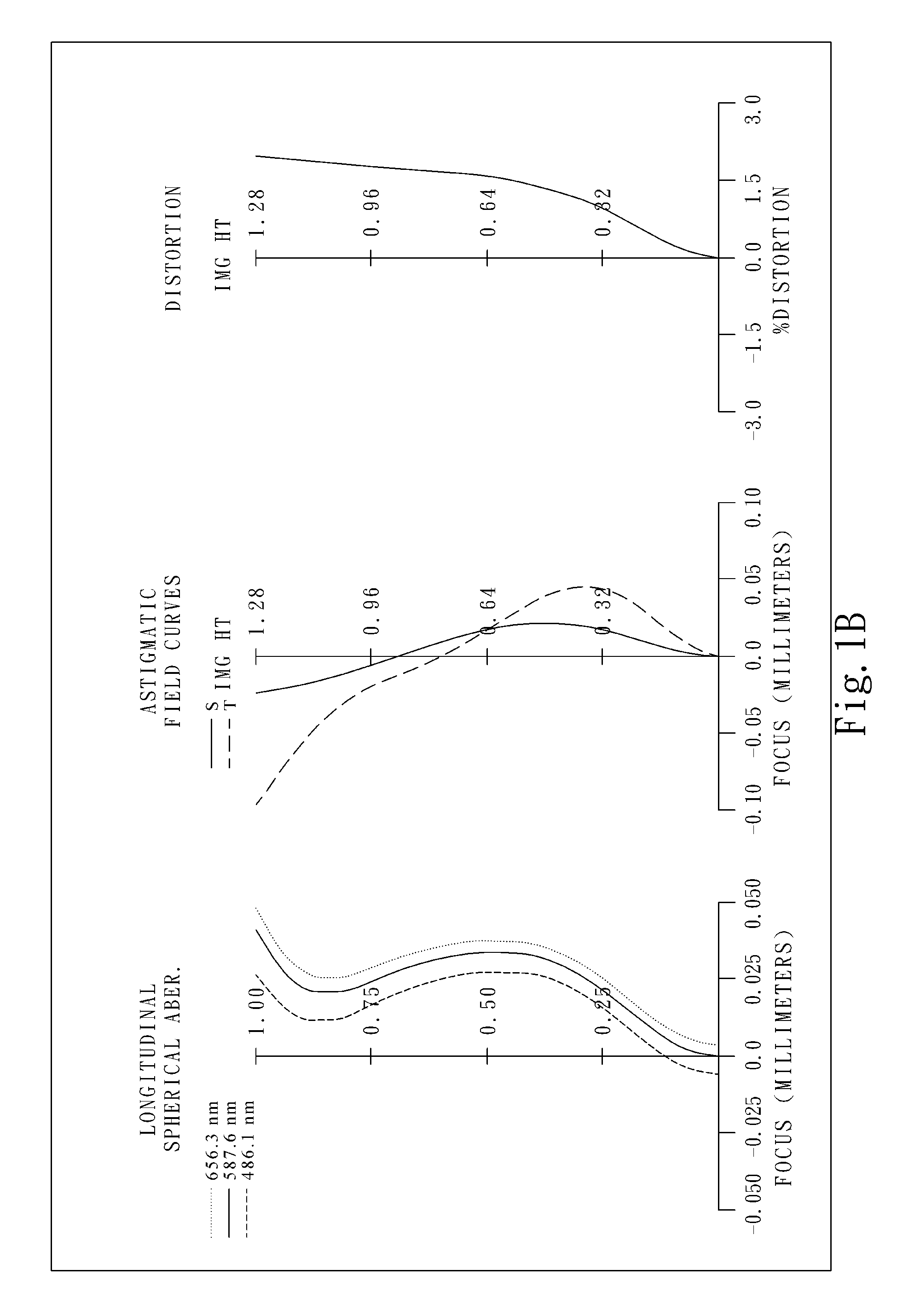

ActiveUS7969664B2Reduce sensitivitySmall sizeTelevision system detailsColor television detailsConvex sideImaging lens

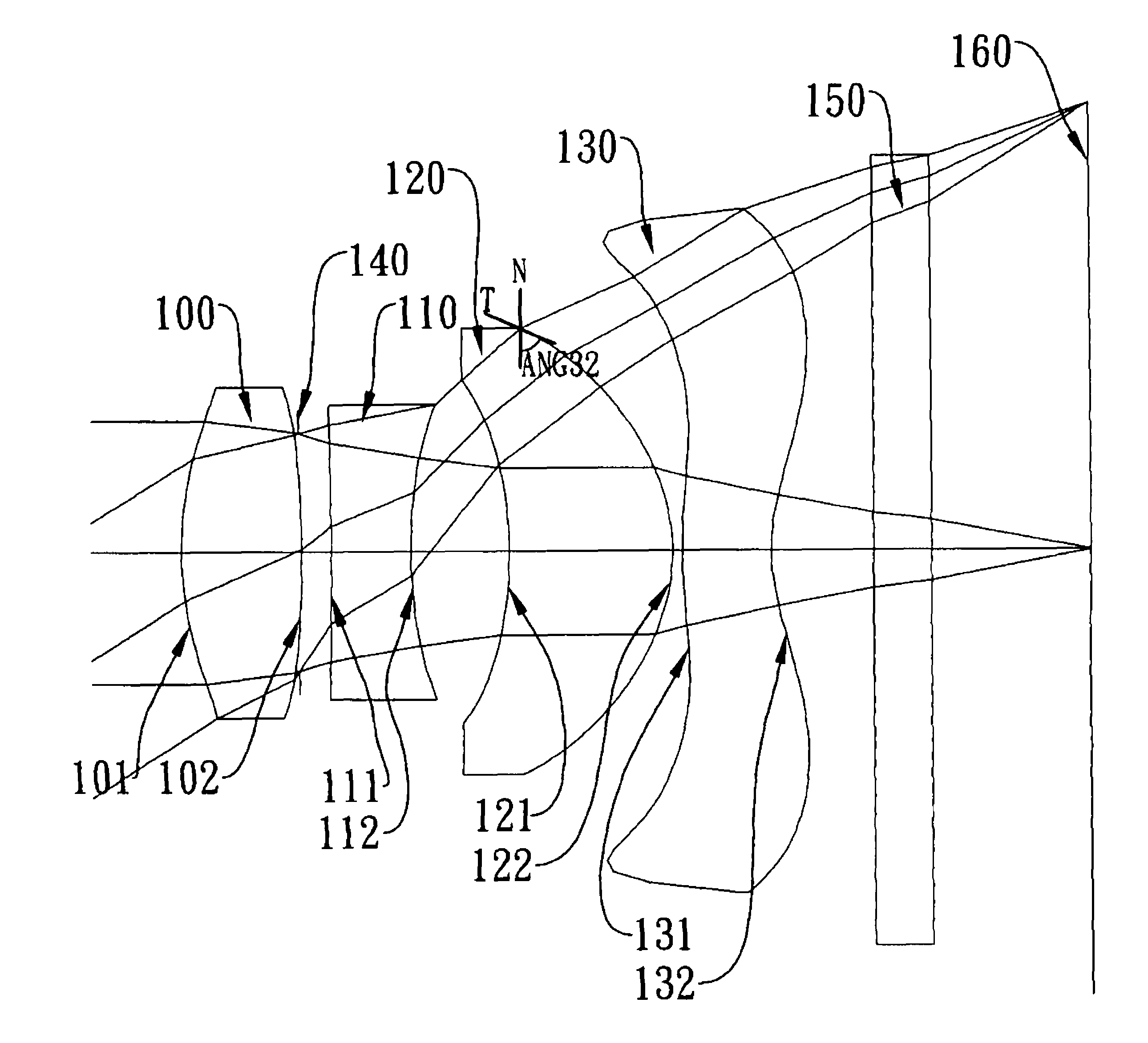

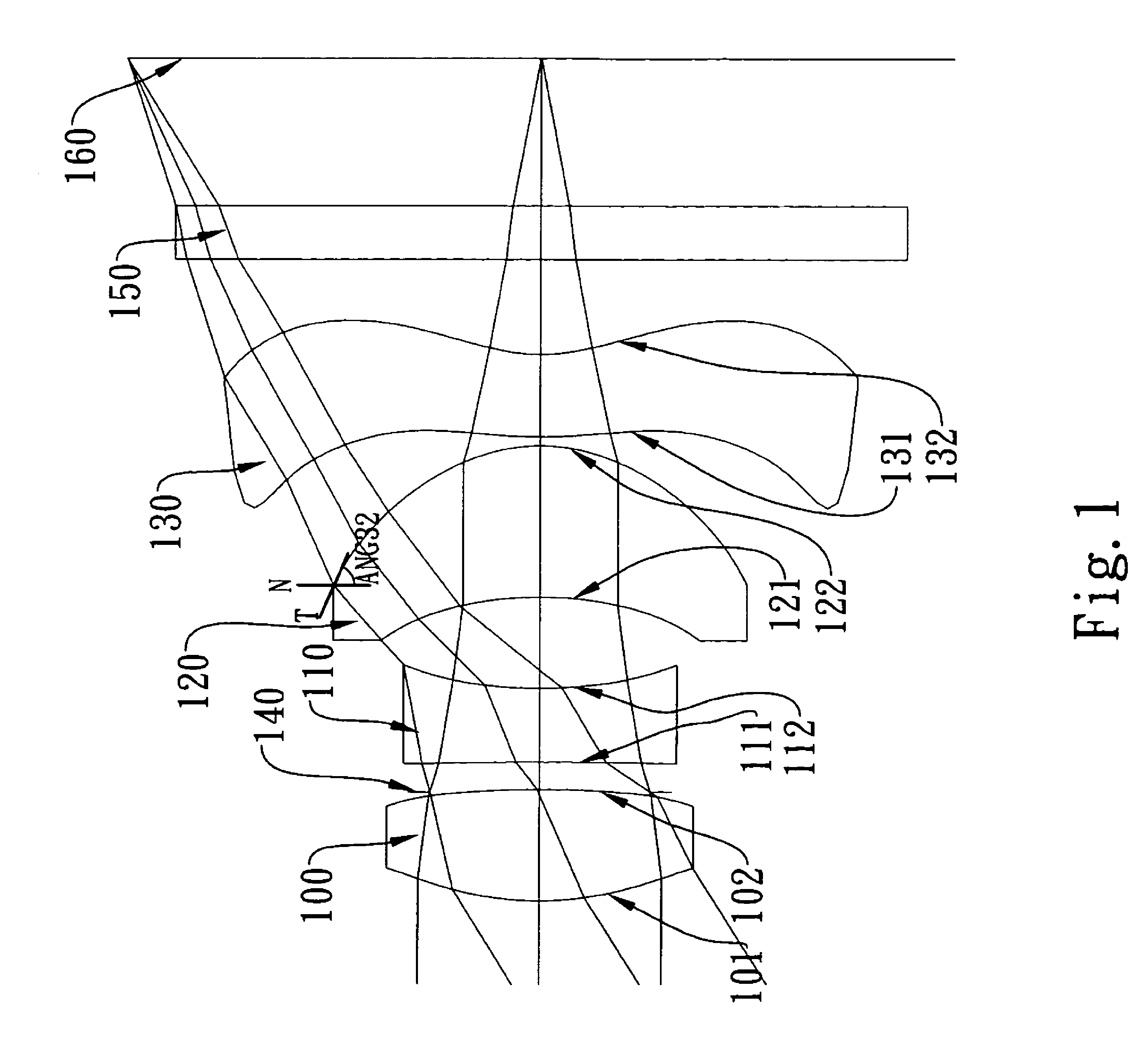

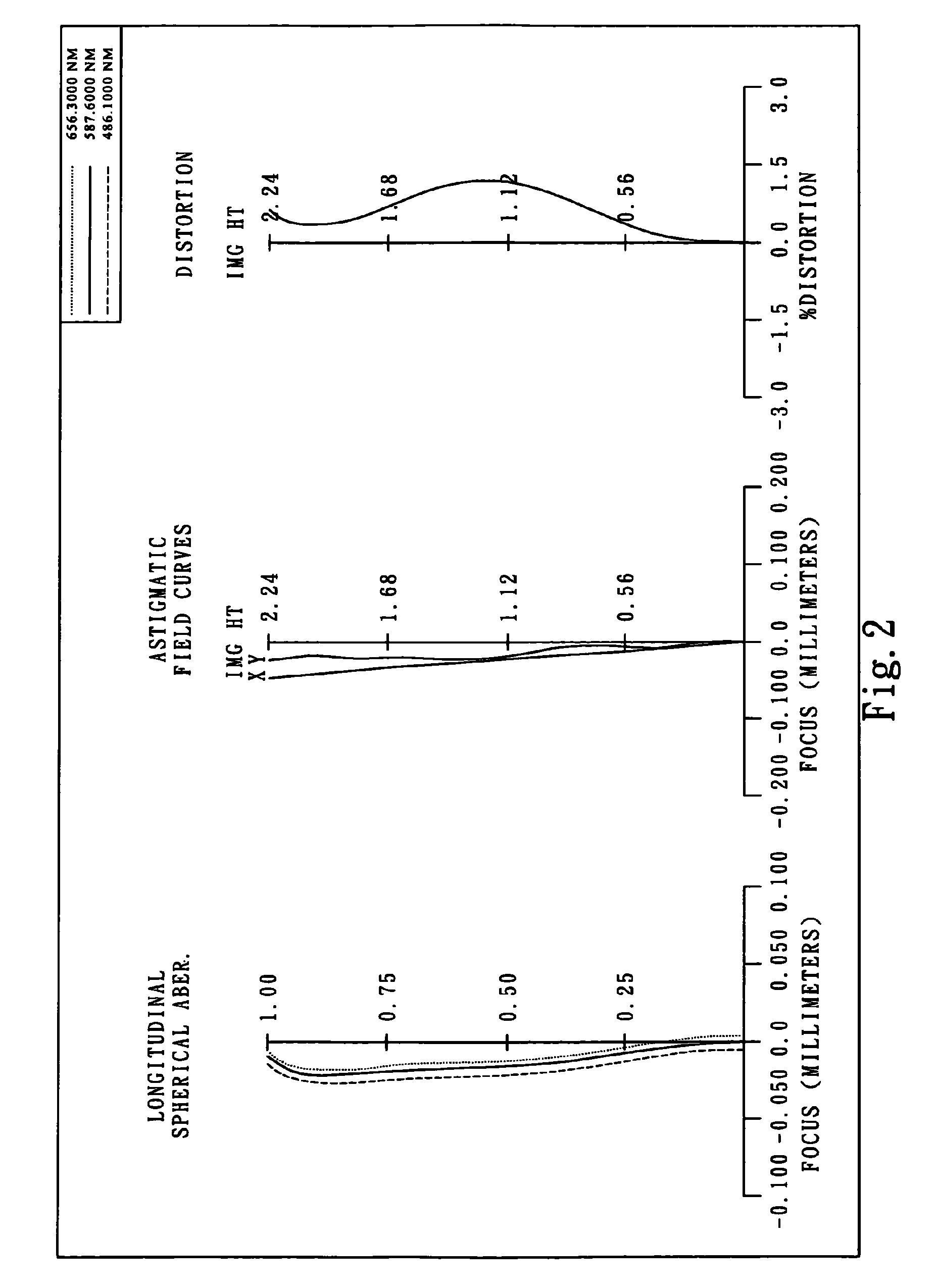

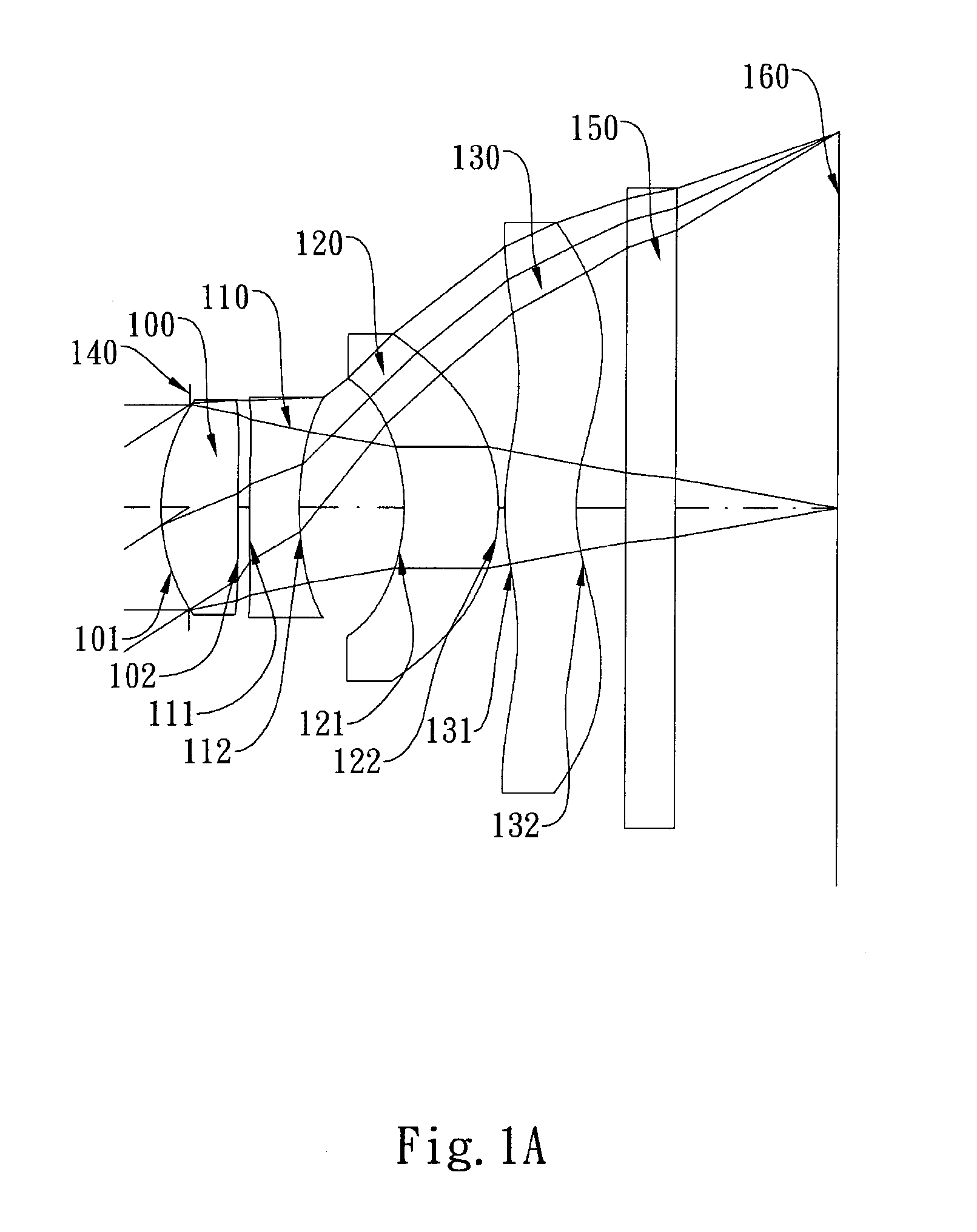

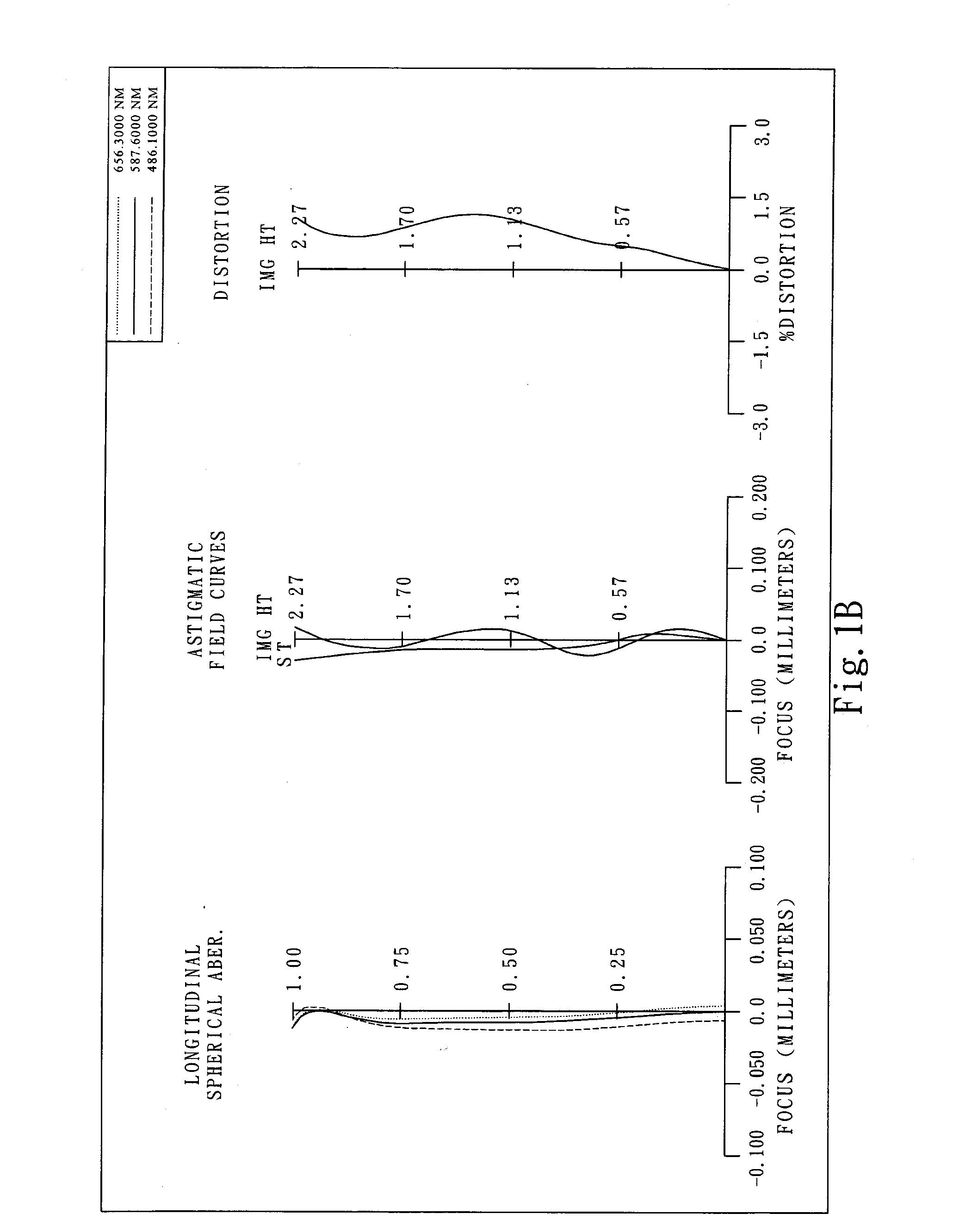

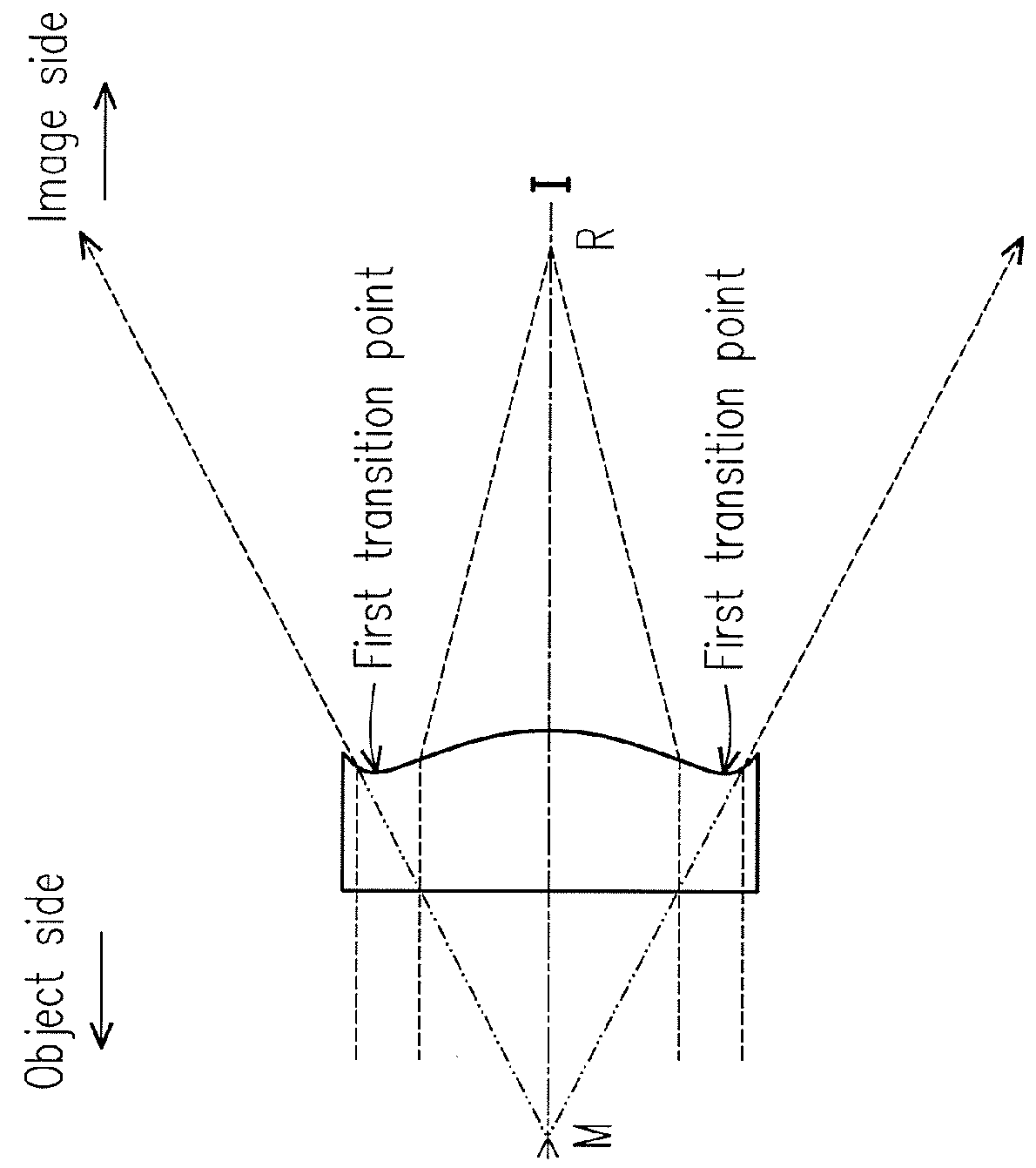

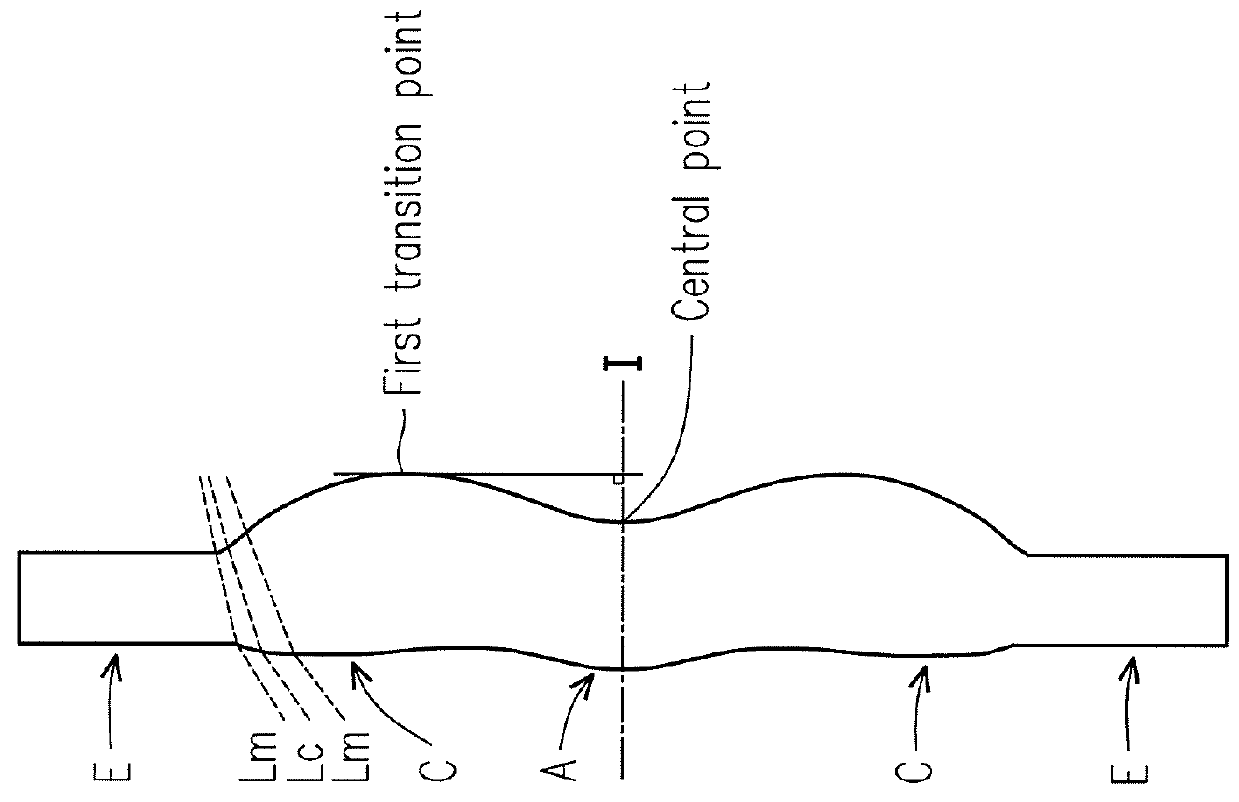

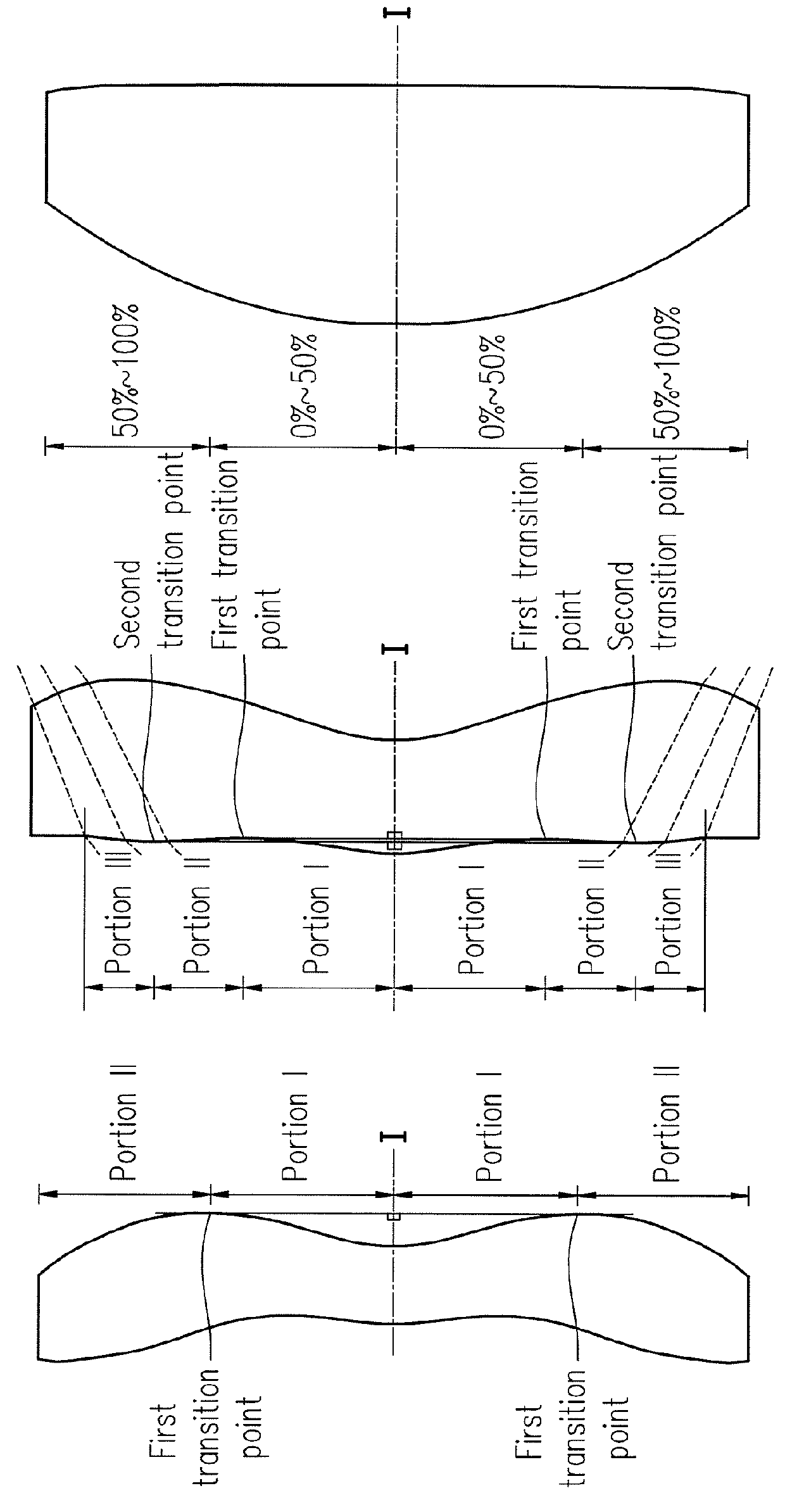

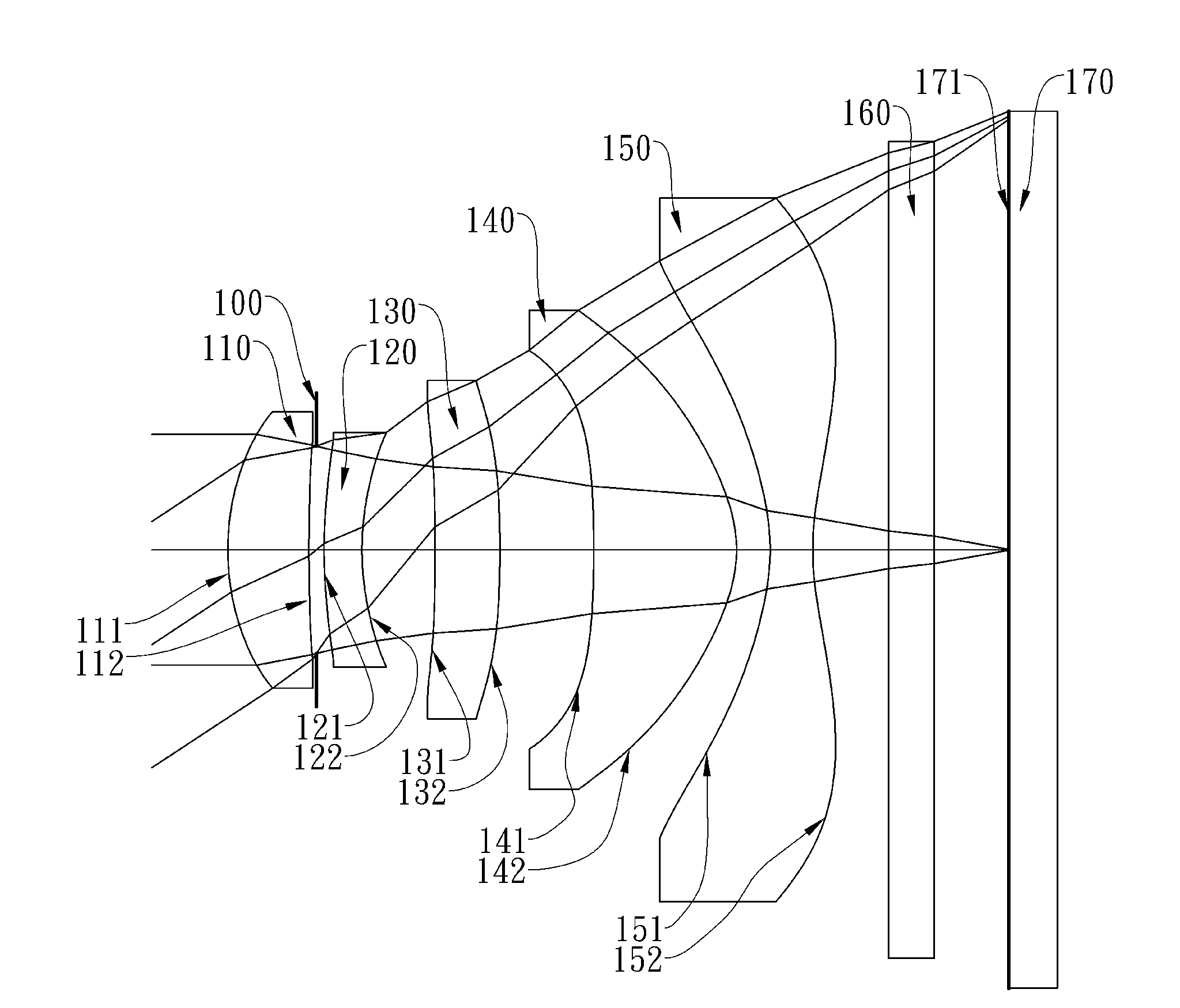

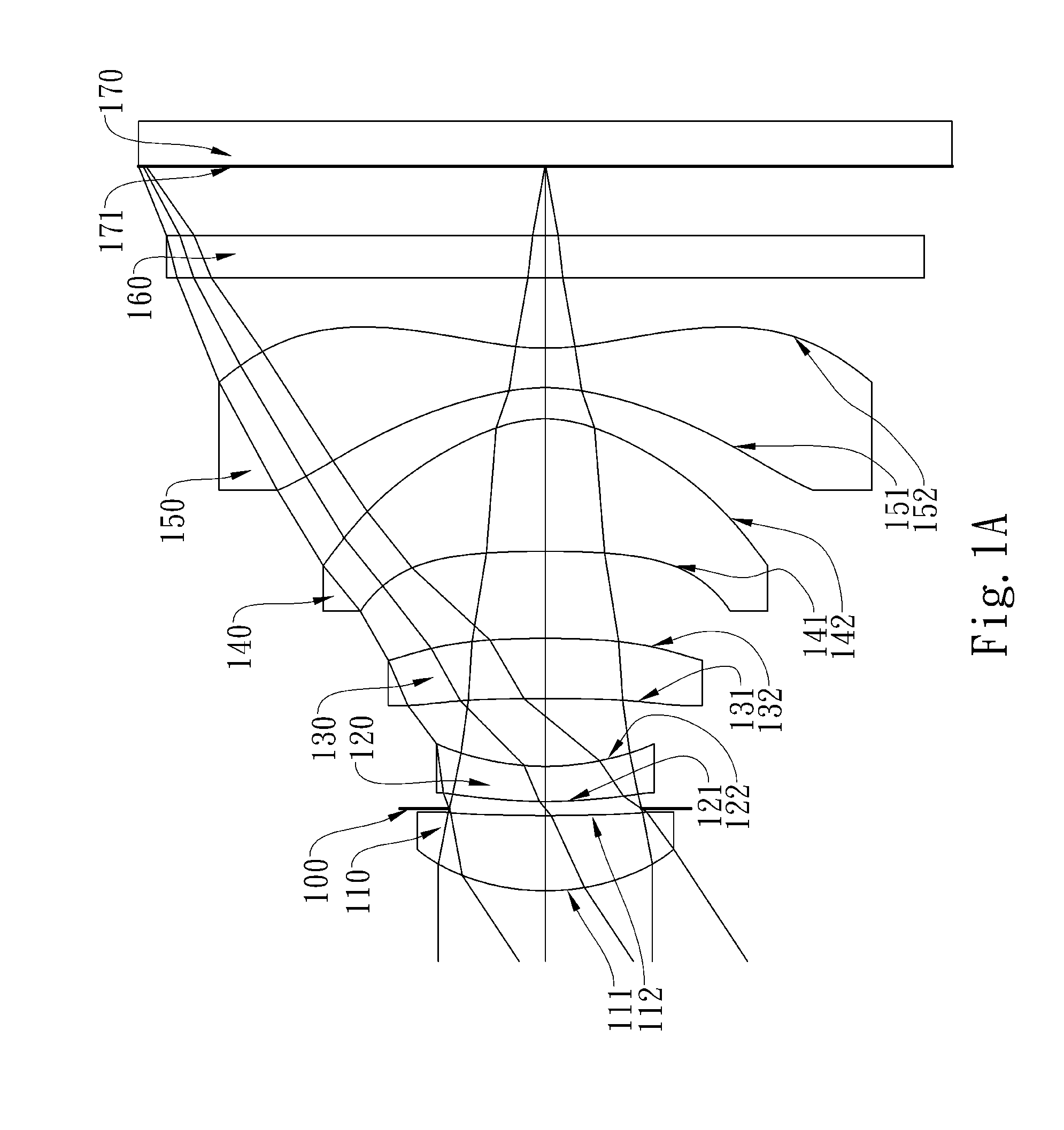

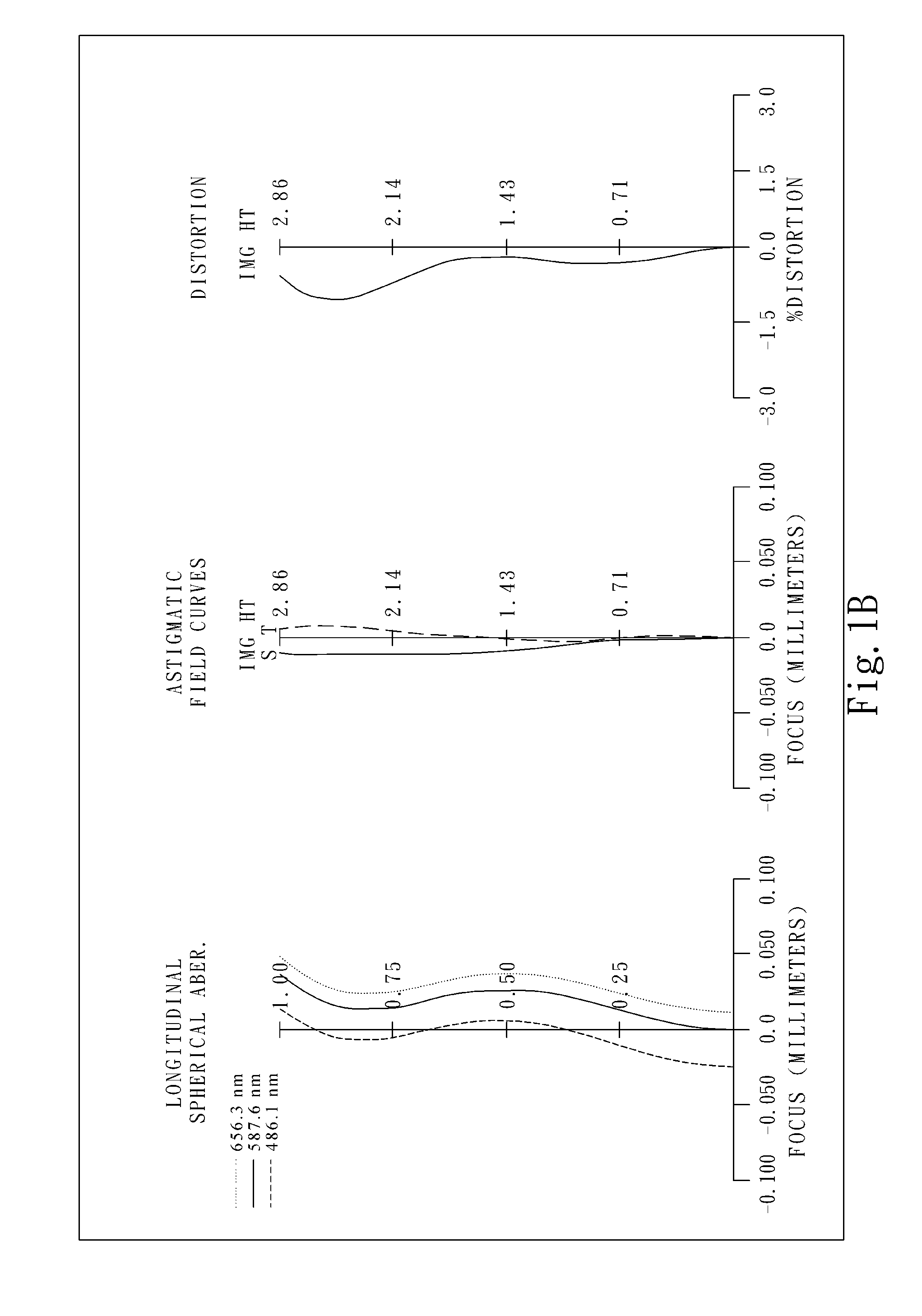

This invention provides an imaging lens assembly comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens with negative refractive power having a concave object-side surface; a third lens with positive refractive power having a convex image-side surface, at least one of both surfaces thereof being aspheric; and a fourth lens with negative refractive power having a convex object-side surface and a concave image-side surface on which at least one inflection point is formed; wherein there are four lenses with refractive power, an on-axis spacing between an aperture stop and an electronic sensor provided therein is SL, an on-axis spacing between the object-side surface of the first lens and the electronic sensor is TTL, they satisfy the relation: 0.75<SL / TTL<0.90.

Owner:LARGAN PRECISION

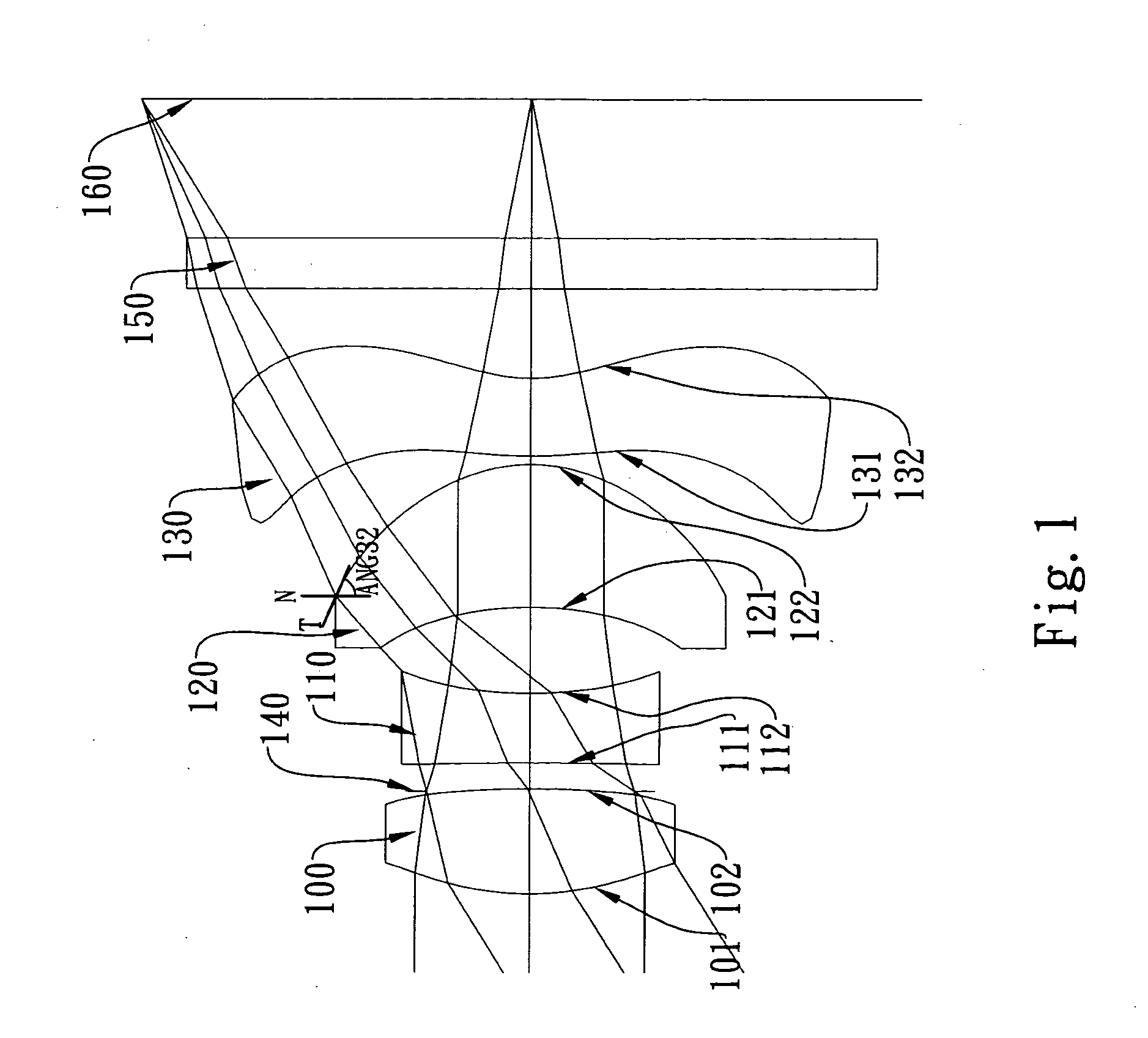

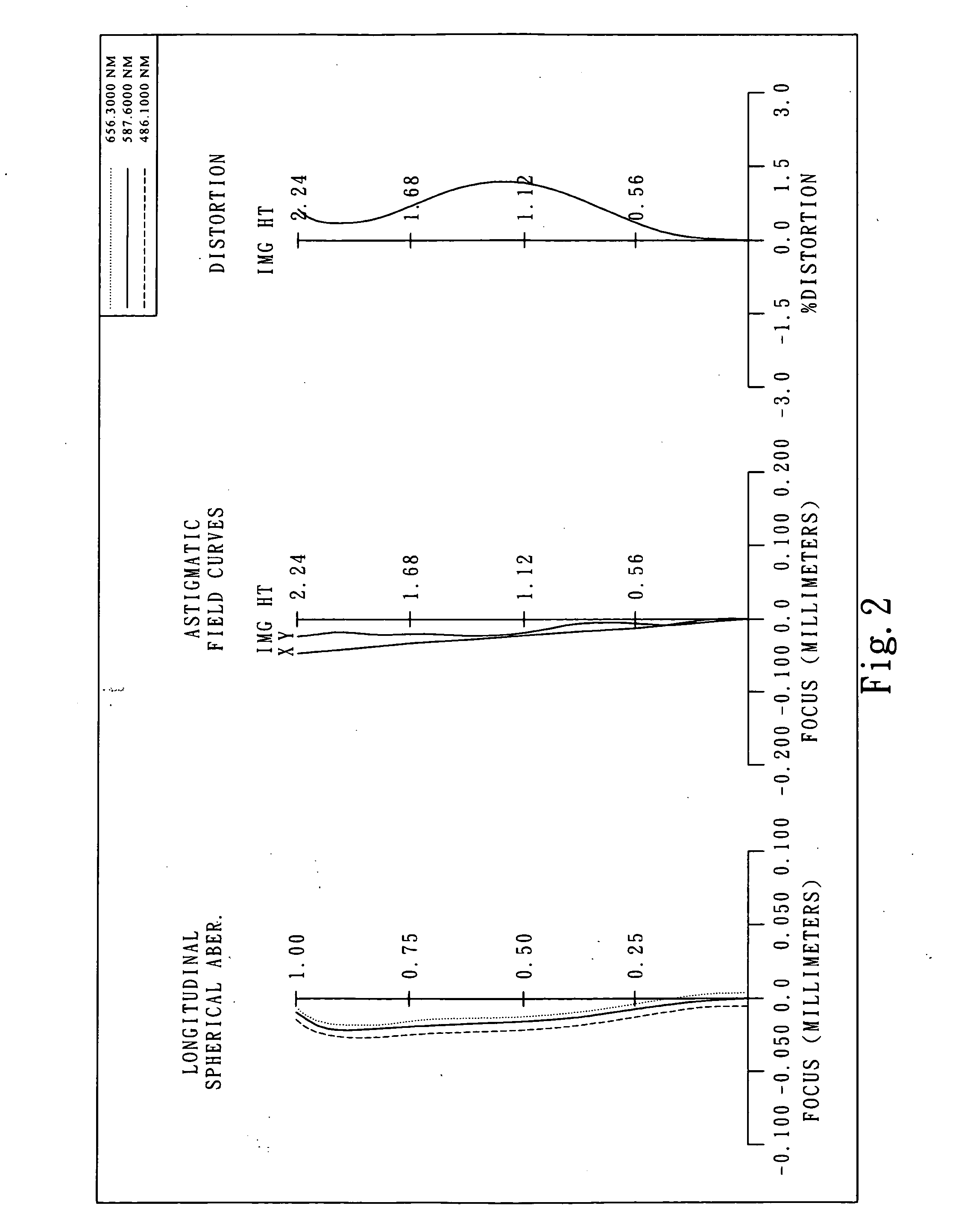

Image-capturing lens assembly

ActiveUS8179470B2Small sizeReduce sensitivityTelevision system detailsColor television detailsImage resolutionImage capture

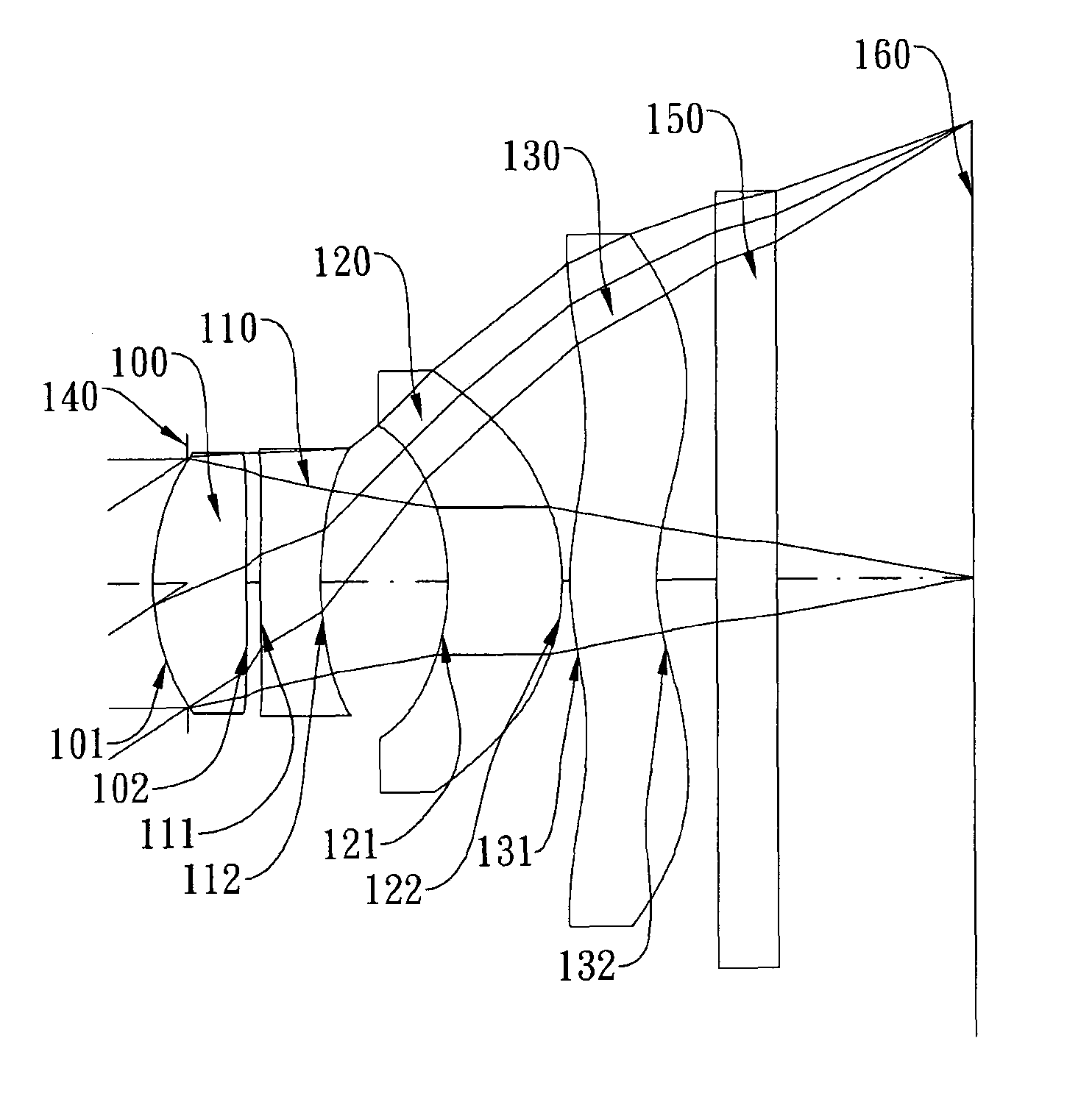

This invention provides an image-capturing lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, the object-side and image-side surfaces thereof being aspheric; a fourth lens element with negative refractive power having a concave image-side surface on which at least one inflection point is formed, the object-side and image-side surfaces thereof being aspheric; and a stop disposed between an imaged object and the first lens element; wherein there are four lens elements with refractive power. Such an arrangement of optical elements can effectively reduce the size of the lens assembly, mitigate the sensitivity of the optical system and enable the lens assembly to obtain a higher resolution.

Owner:LARGAN PRECISION

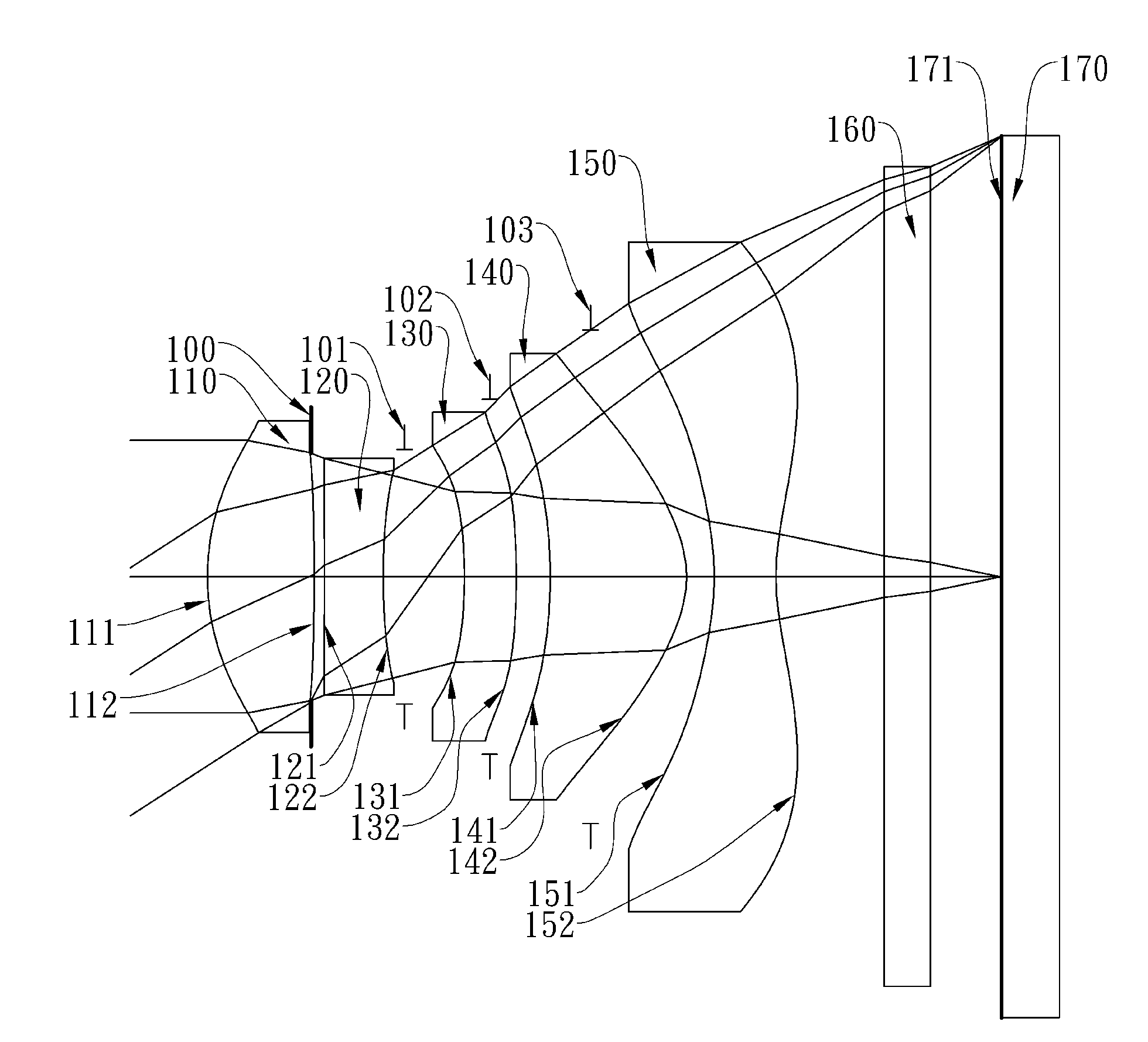

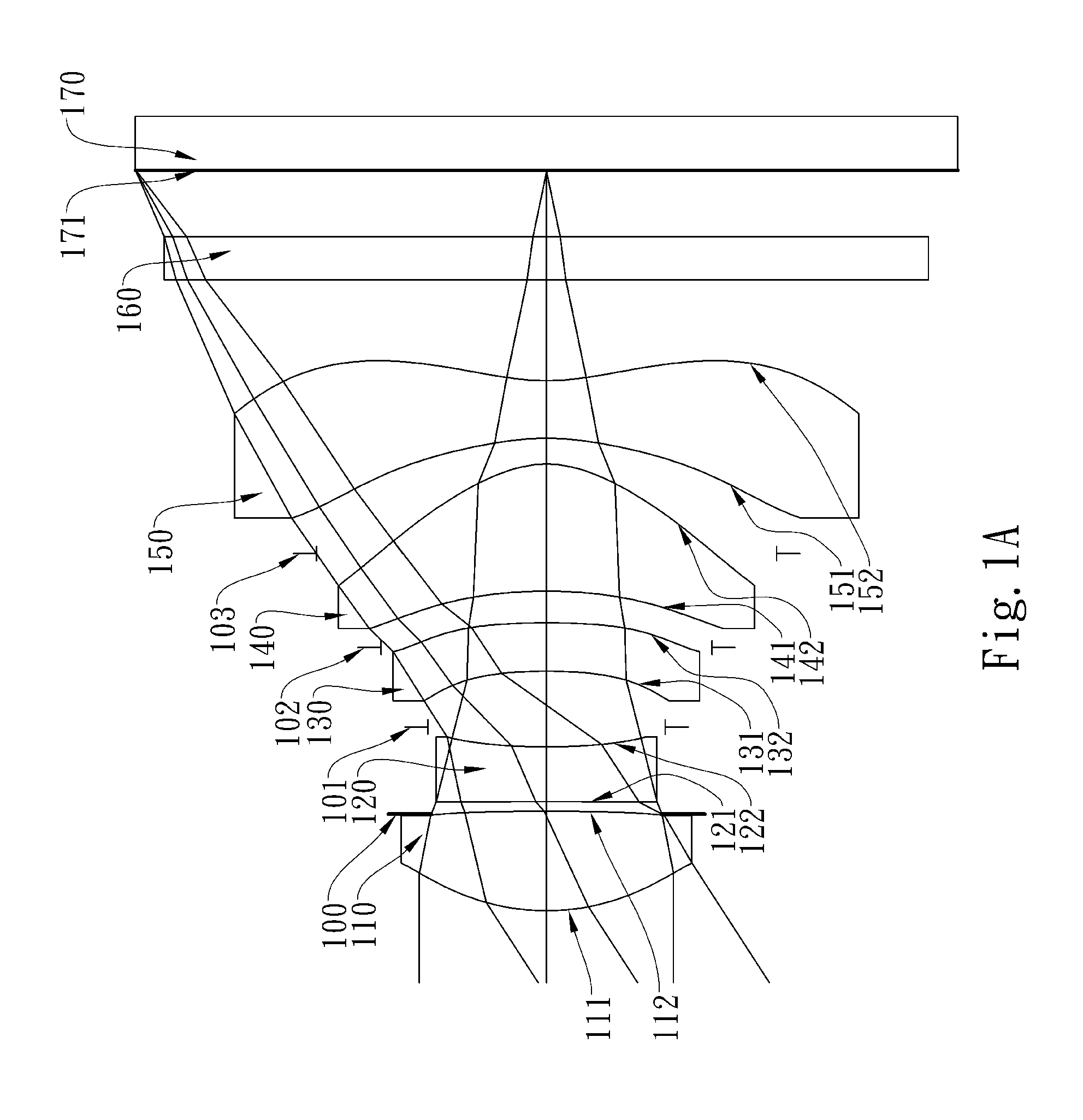

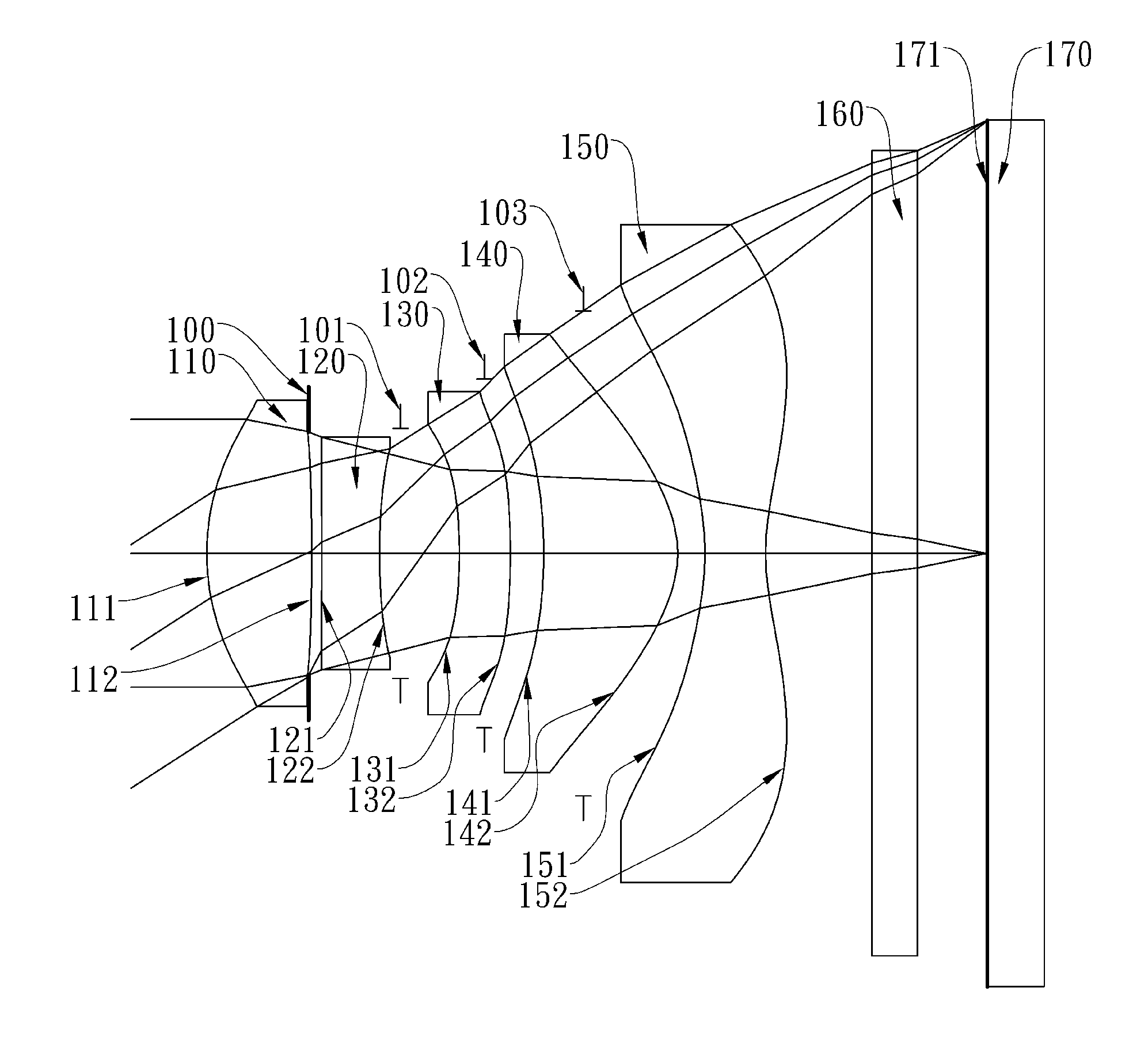

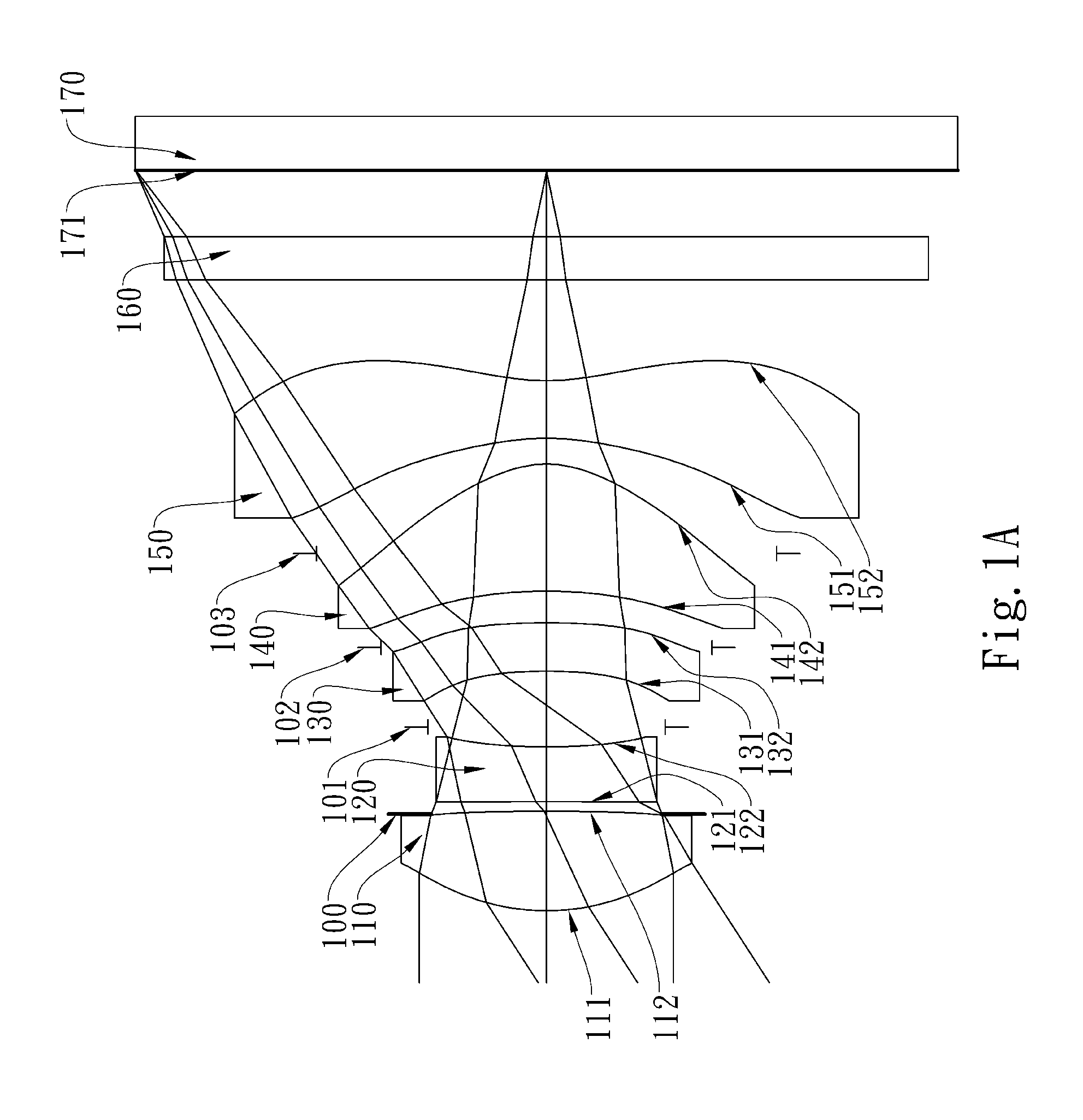

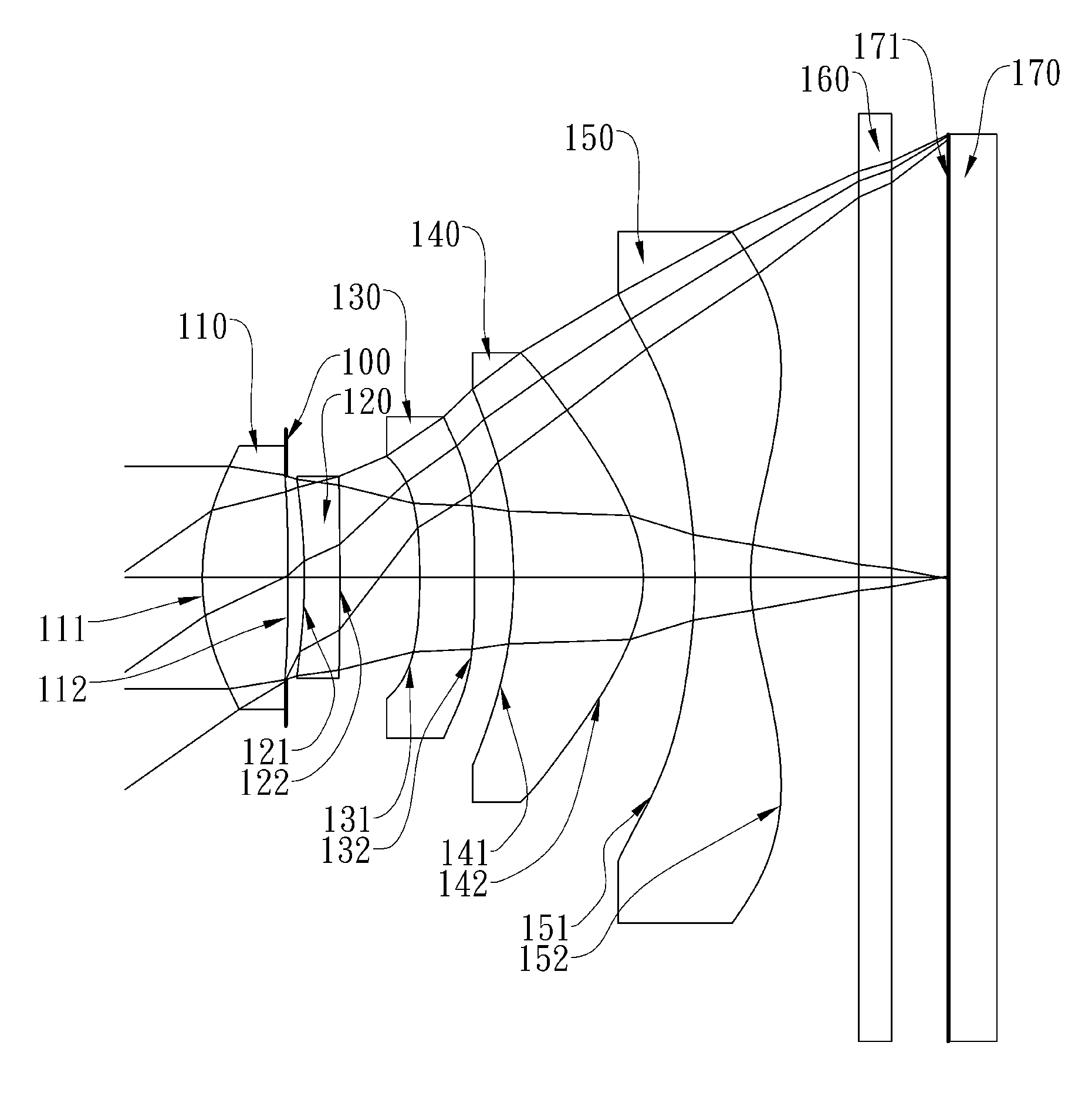

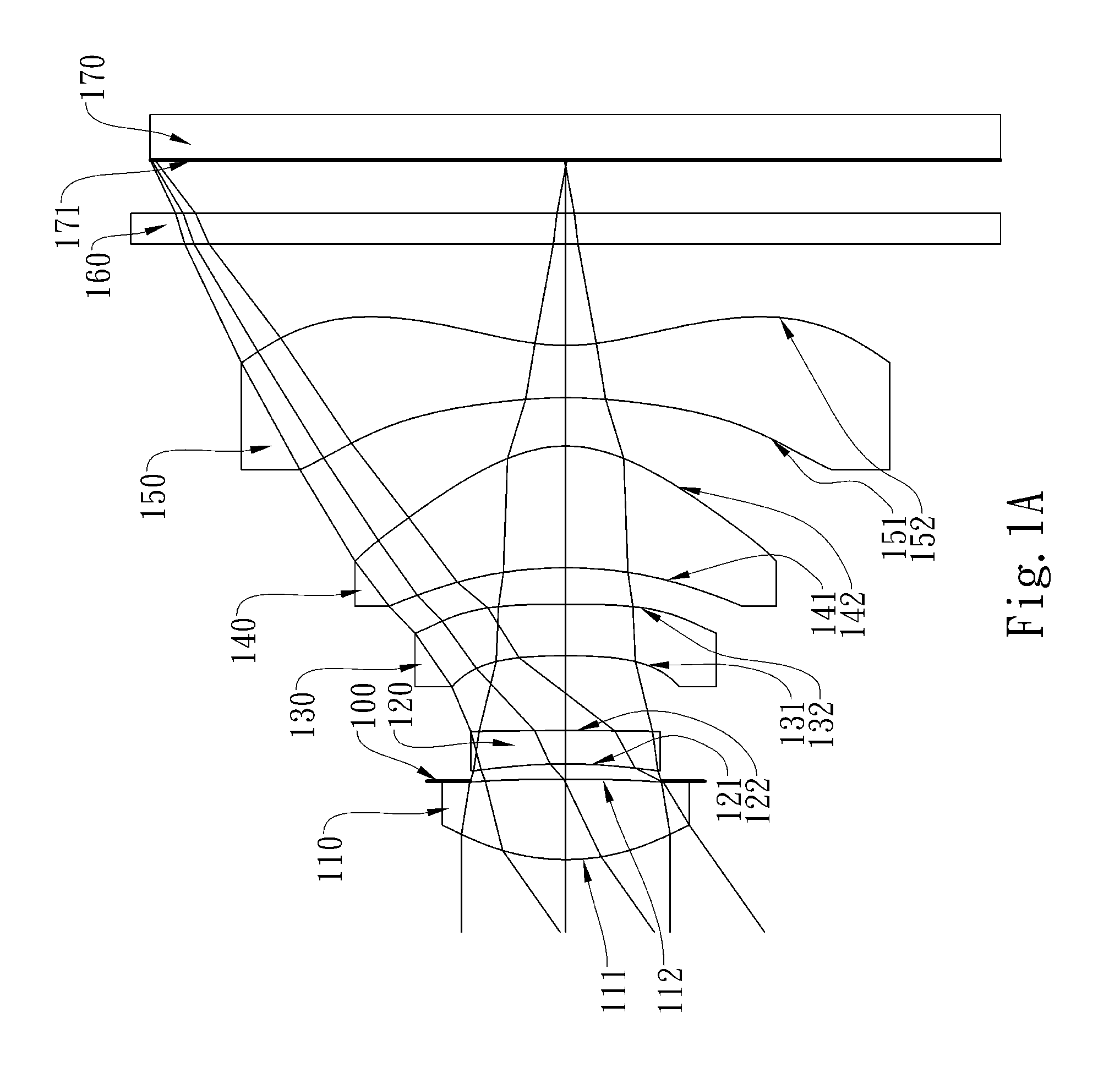

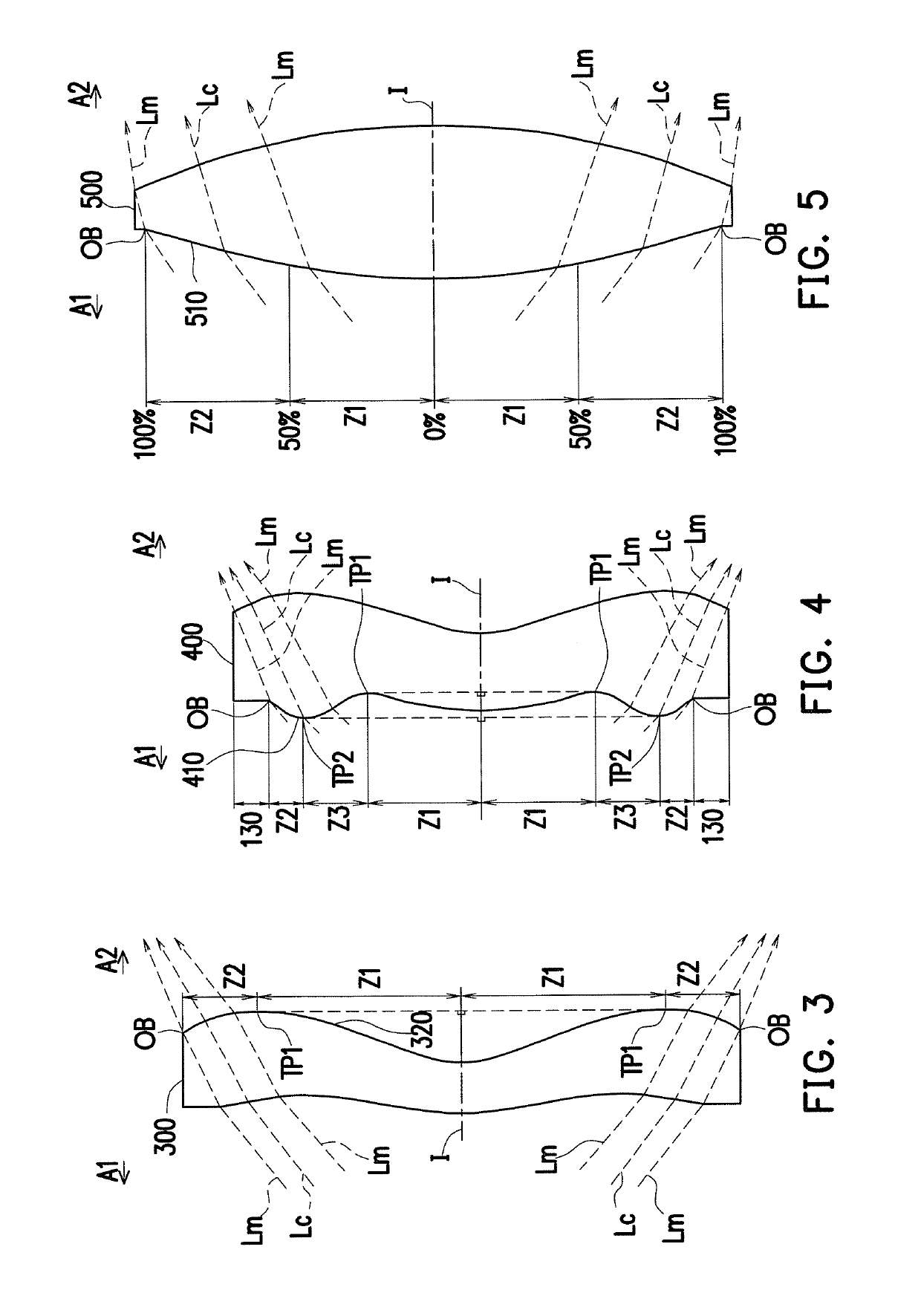

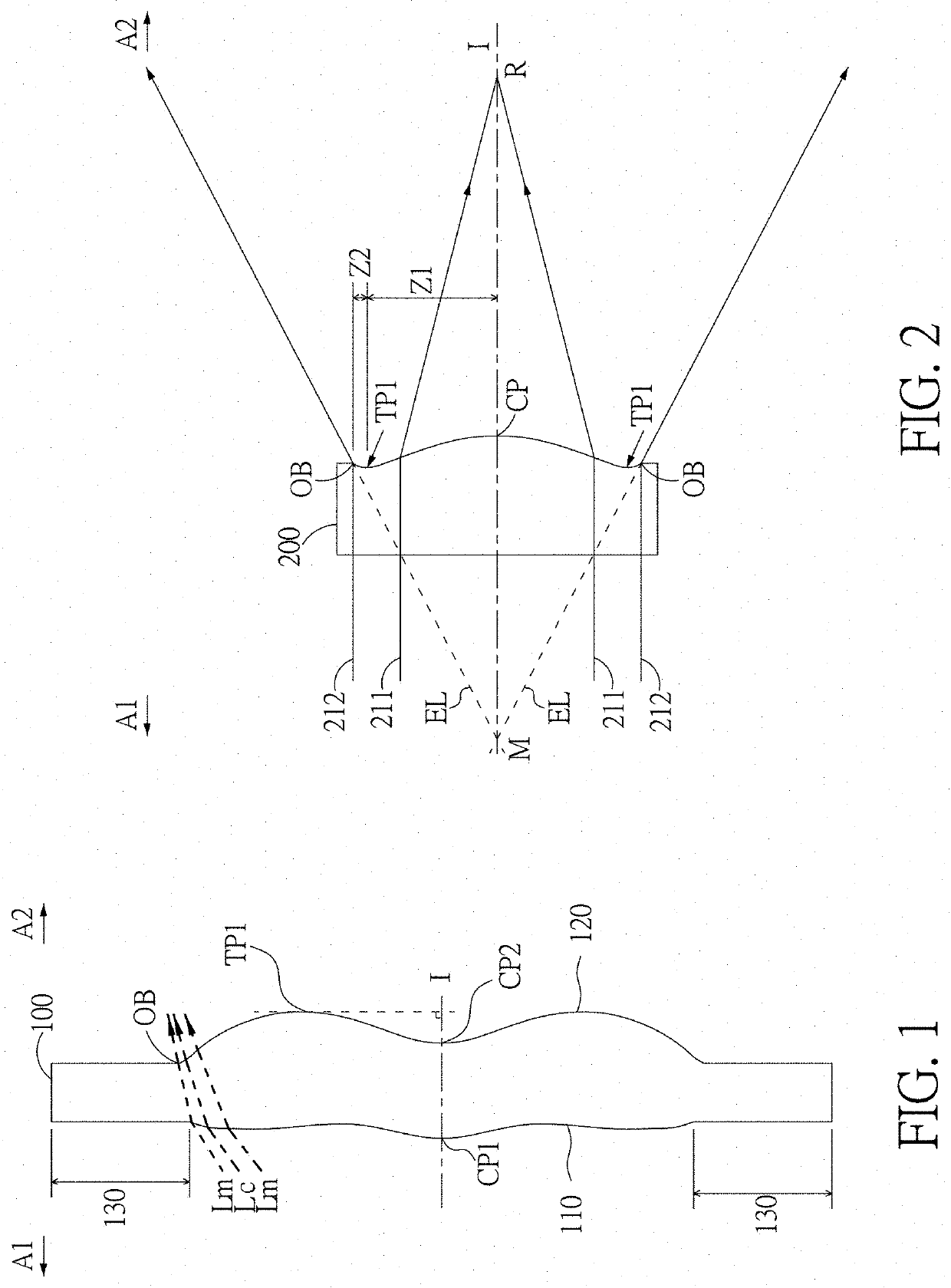

Optical image capturing lens system

This invention provides an optical image capturing lens system comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element; and a fifth lens element with negative refractive power, at least one of the object-side and image-side surfaces thereof being aspheric, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein the system at least has one front stop and one rear stop; which are positioned between an imaged object and the third lens element as well as between the third lens element and the fifth lens element, respectively. By such arrangement, photosensitivity and total track length of the system can be reduced, and the aberration and astigmatism of the system can be effectively corrected. Moreover, the focusing performance thereof can be improved.

Owner:LARGAN PRECISION

Optical image capturing lens system

This invention provides an optical image capturing lens system comprising: a negative first lens element having a convex object-side surface and a concave image-side surface at the paraxial region; a positive second lens element; a negative third lens element; a positive fourth lens element having a convex image-side surface at the paraxial region; and a negative plastic fifth lens element having a convex object-side surface at the paraxial region as well as a concave at the paraxial region and convex at the peripheral region image-side surface, at least one of the object-side and image-side surfaces being aspheric. The optical image capturing lens system of the present invention effectively increases the angle of view to a proper range and suppresses the distortion. In addition, the present invention has a tighter arrangement of the lens elements and a smaller back focal length, and therefore is more appropriate for the compact device.

Owner:LARGAN PRECISION

Optical imaging lens

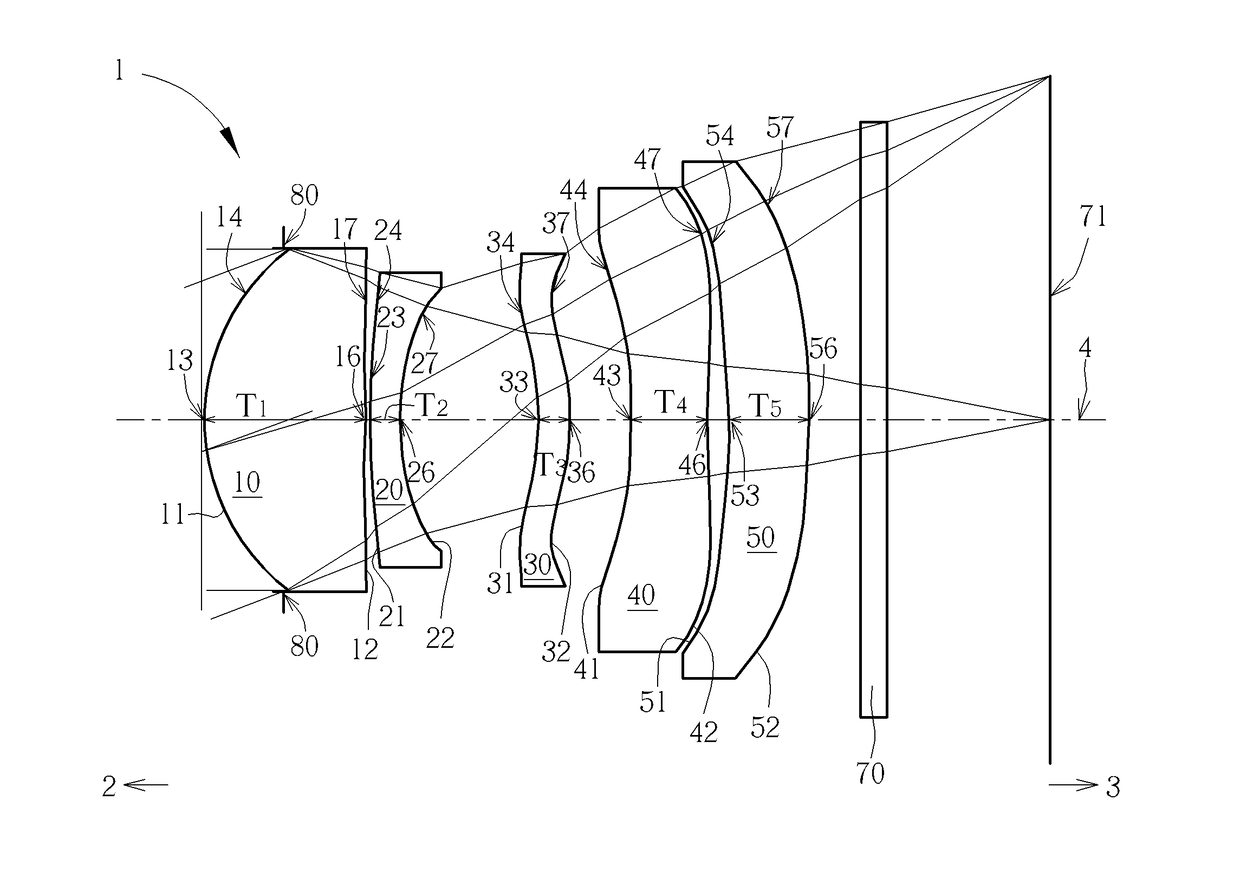

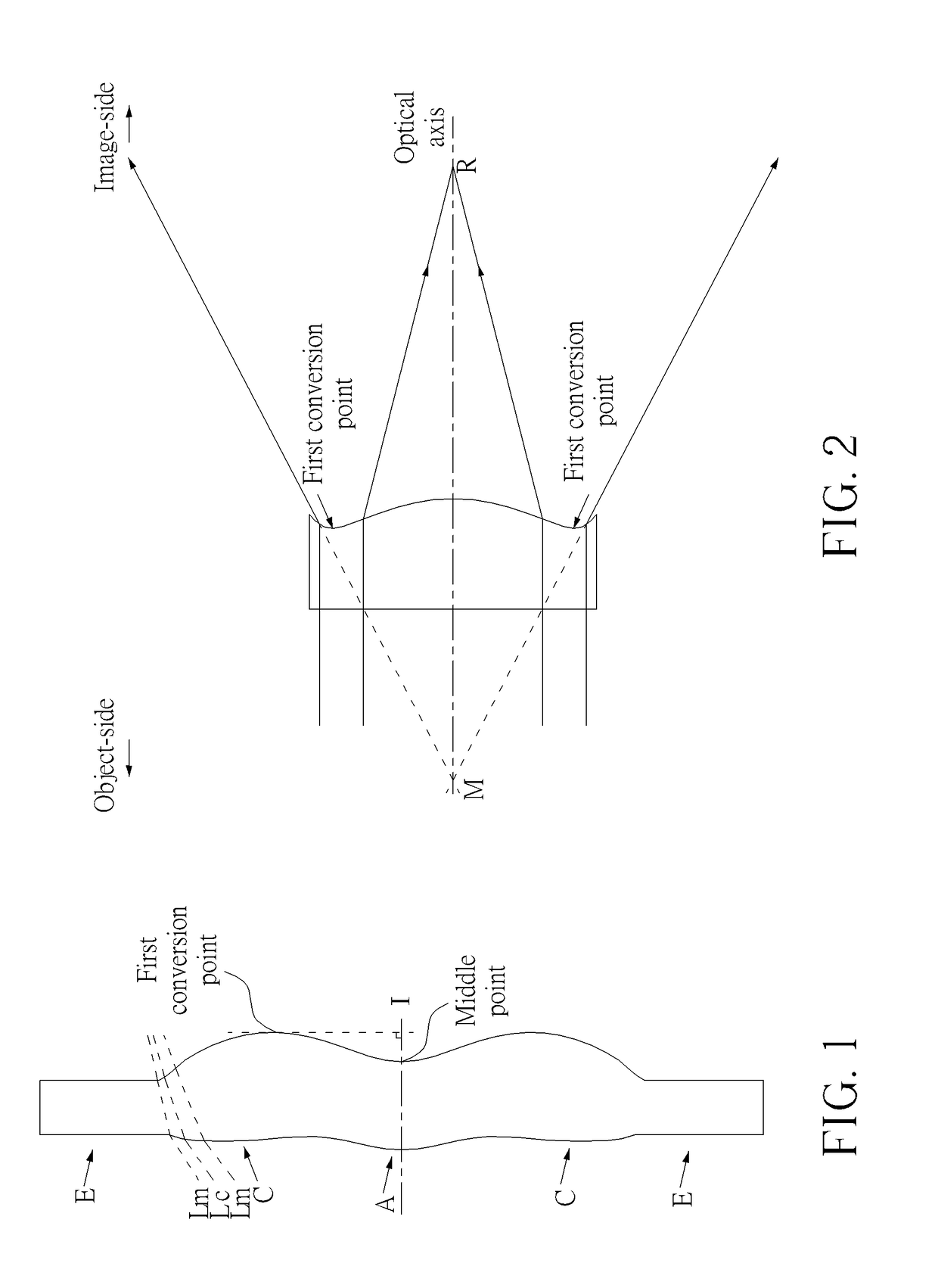

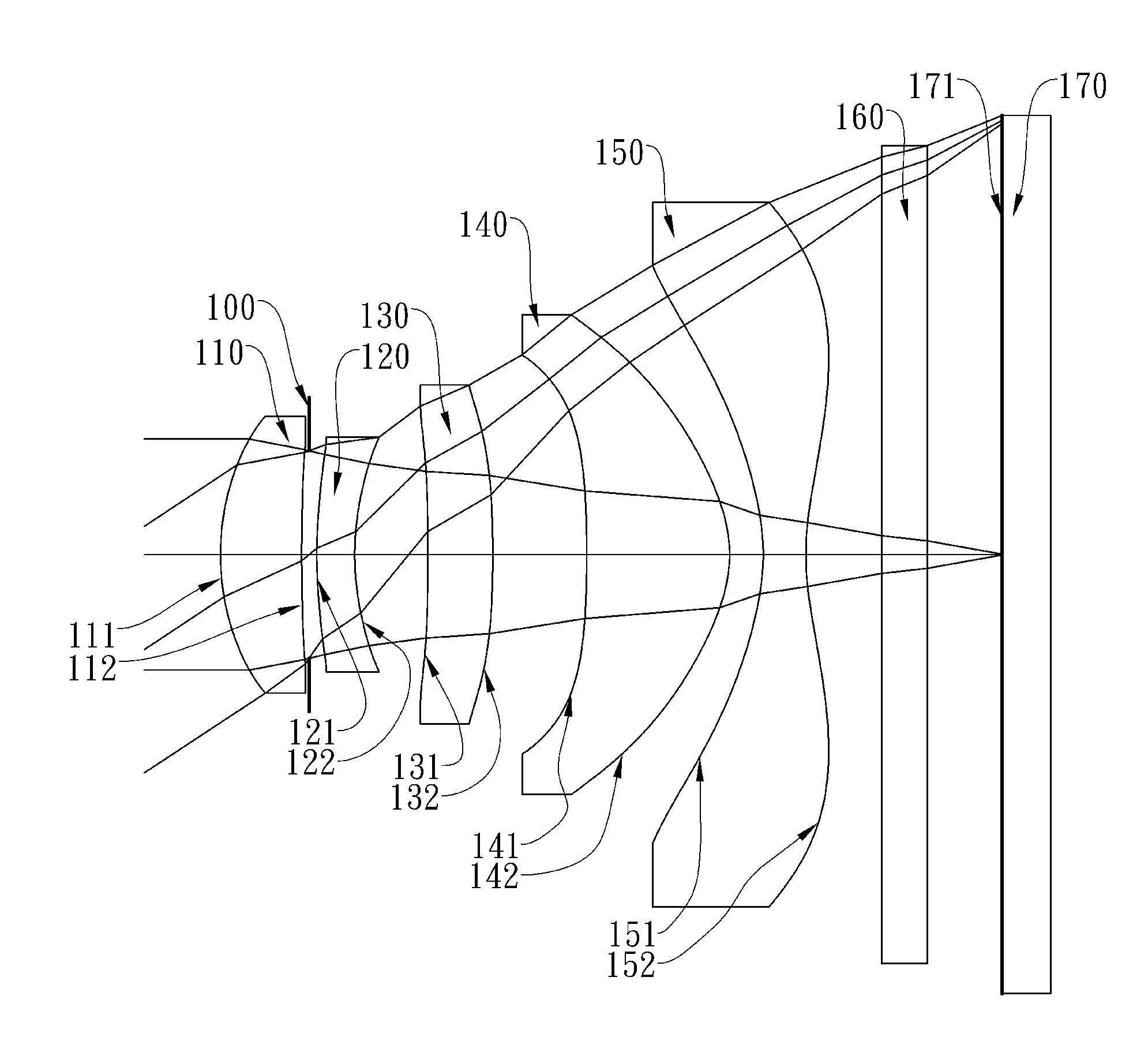

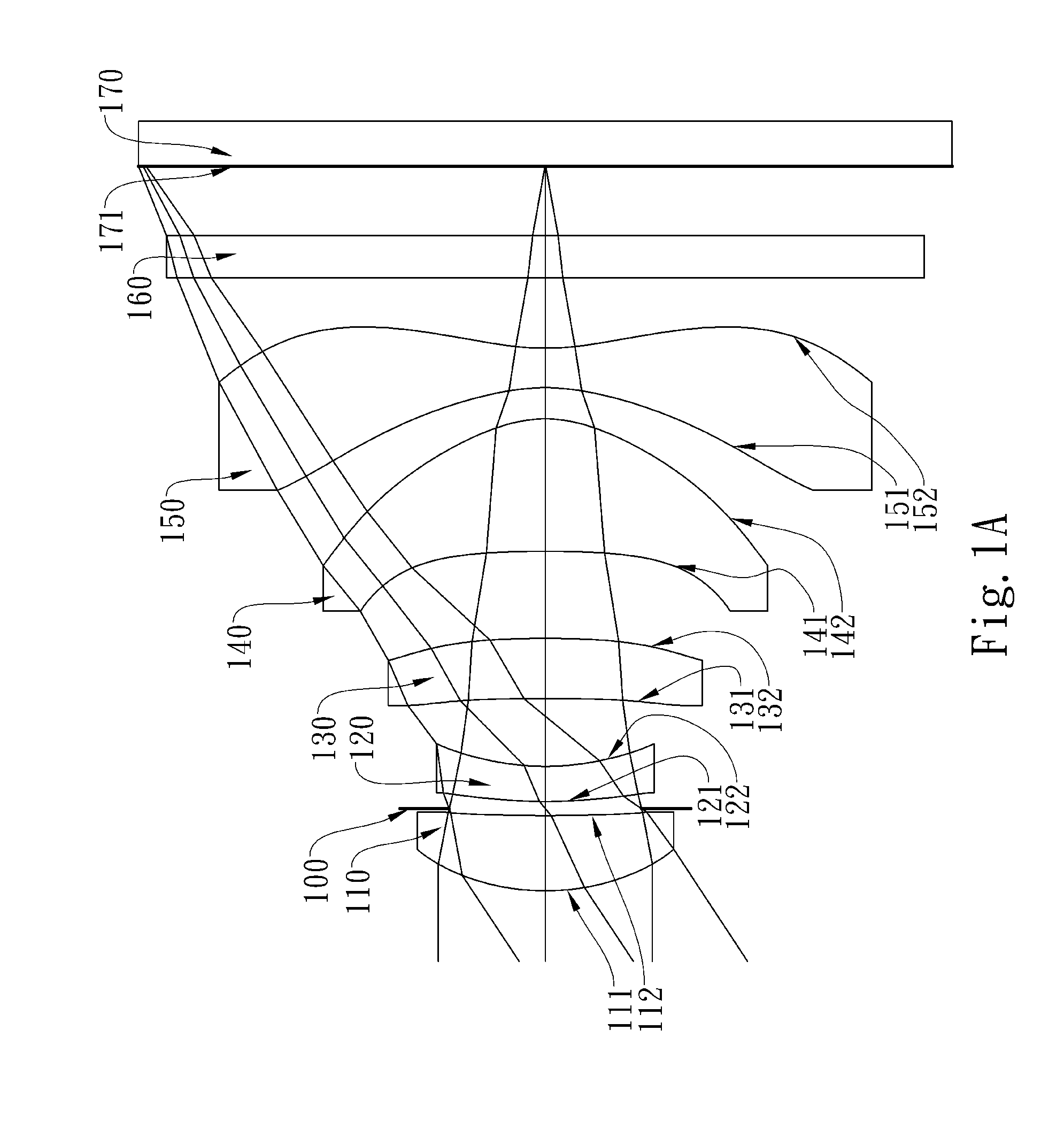

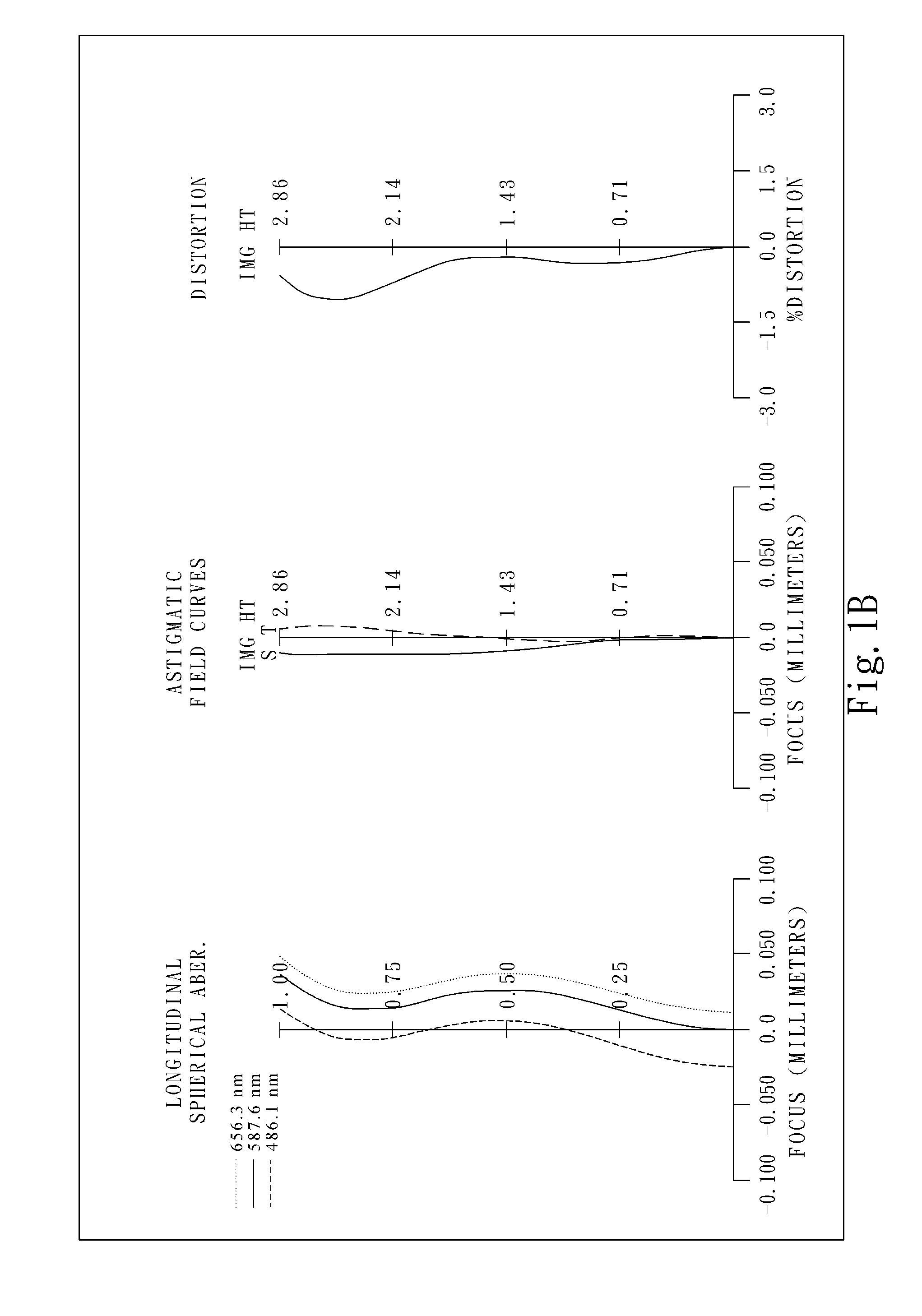

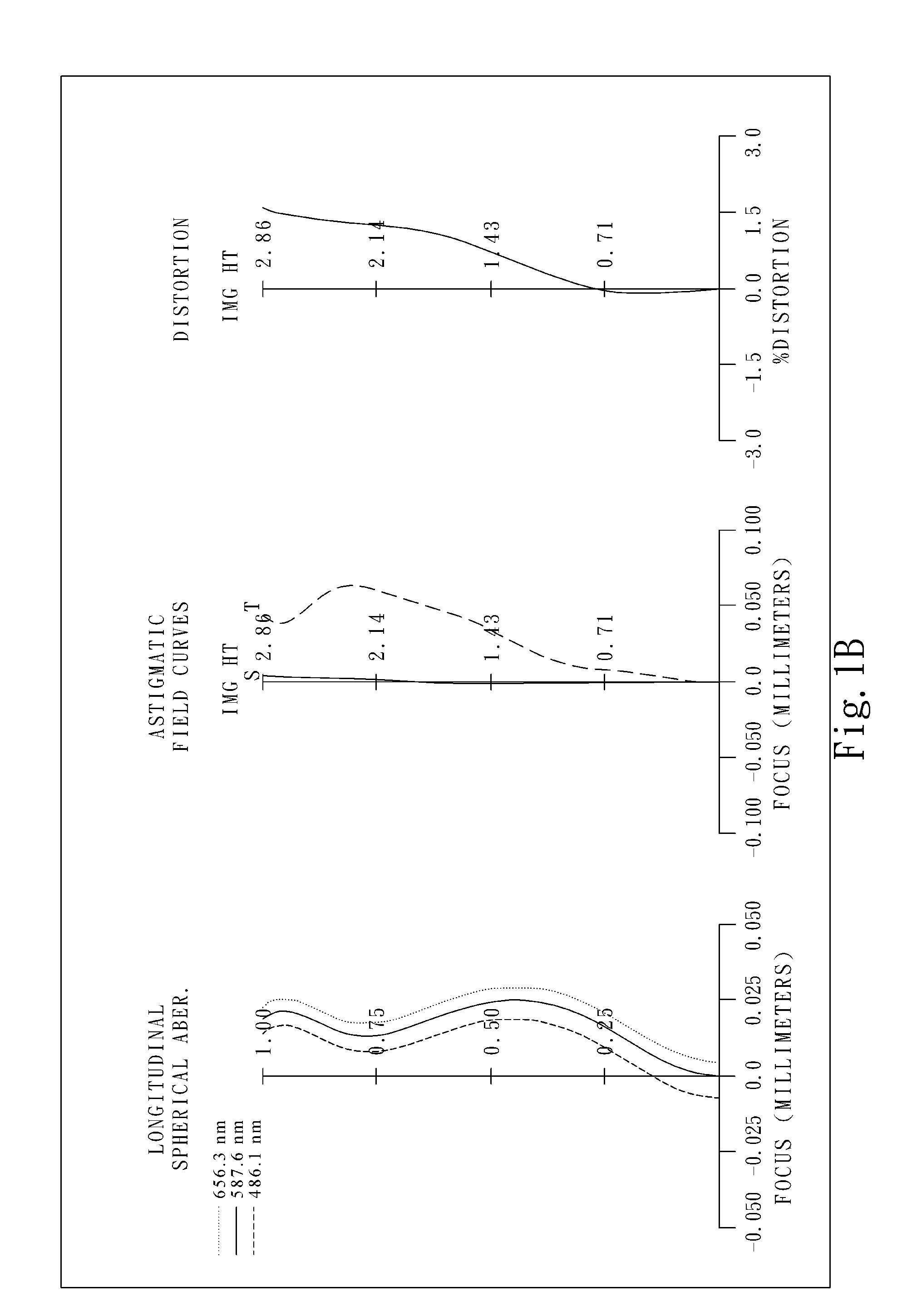

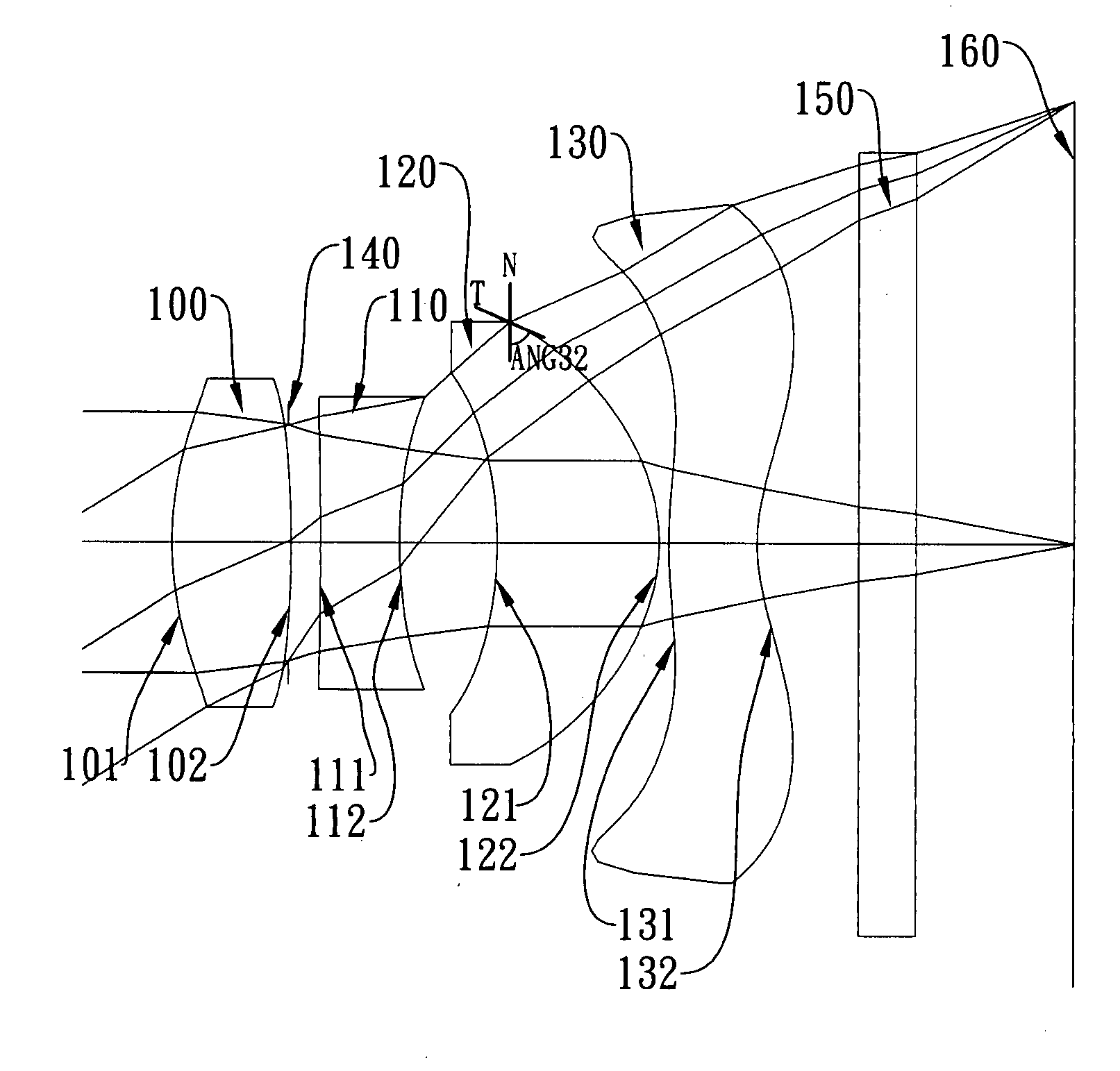

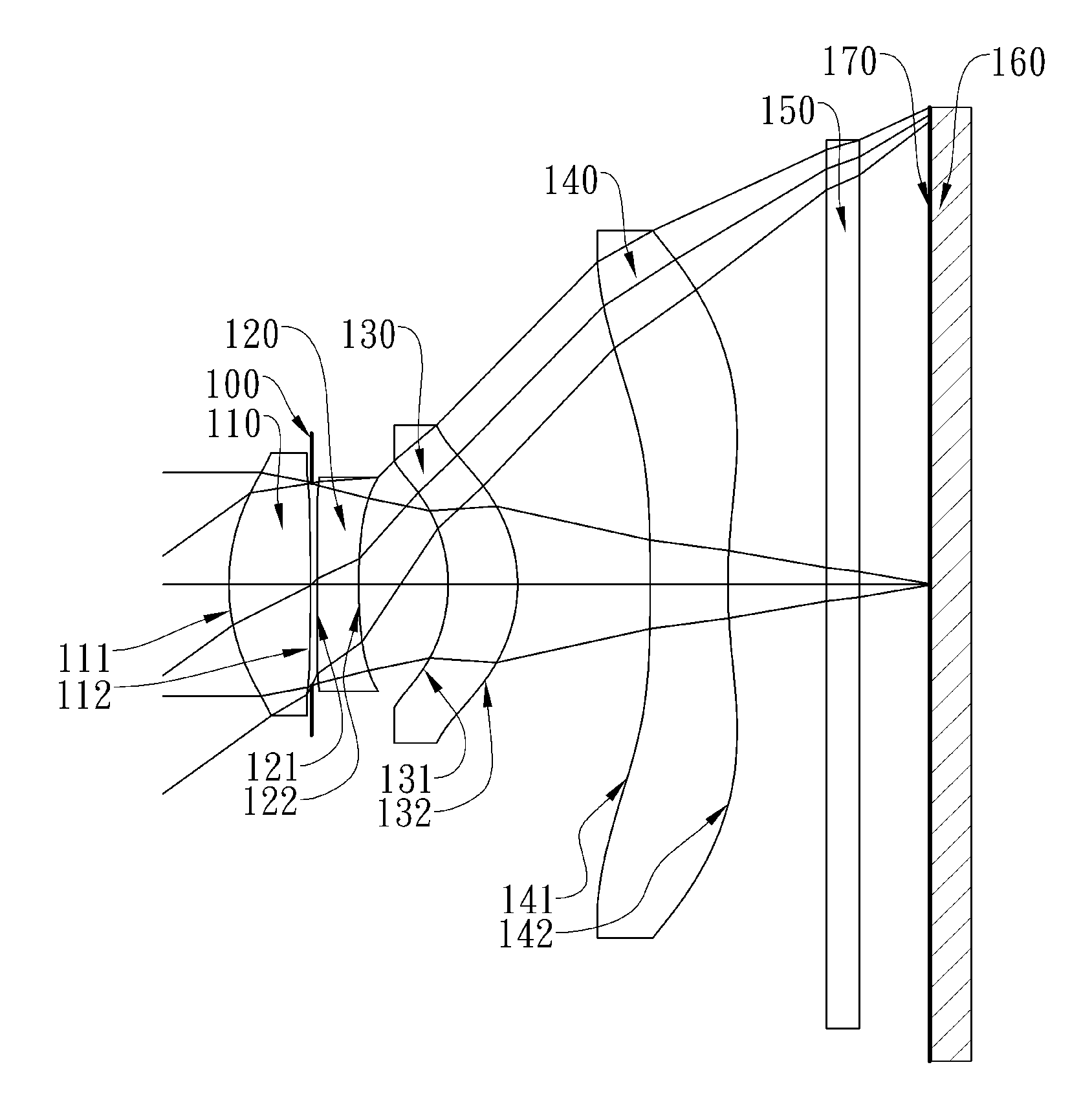

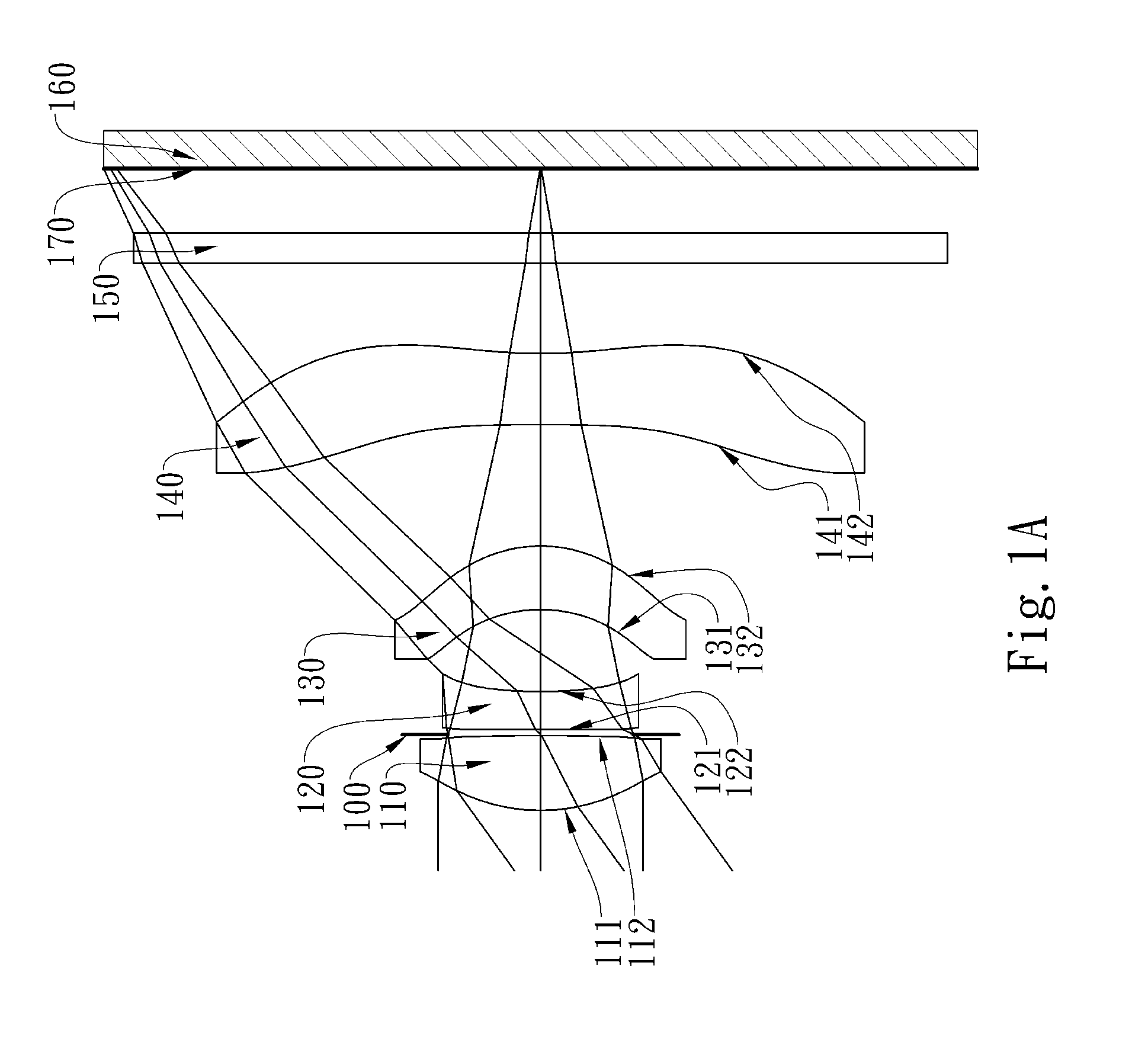

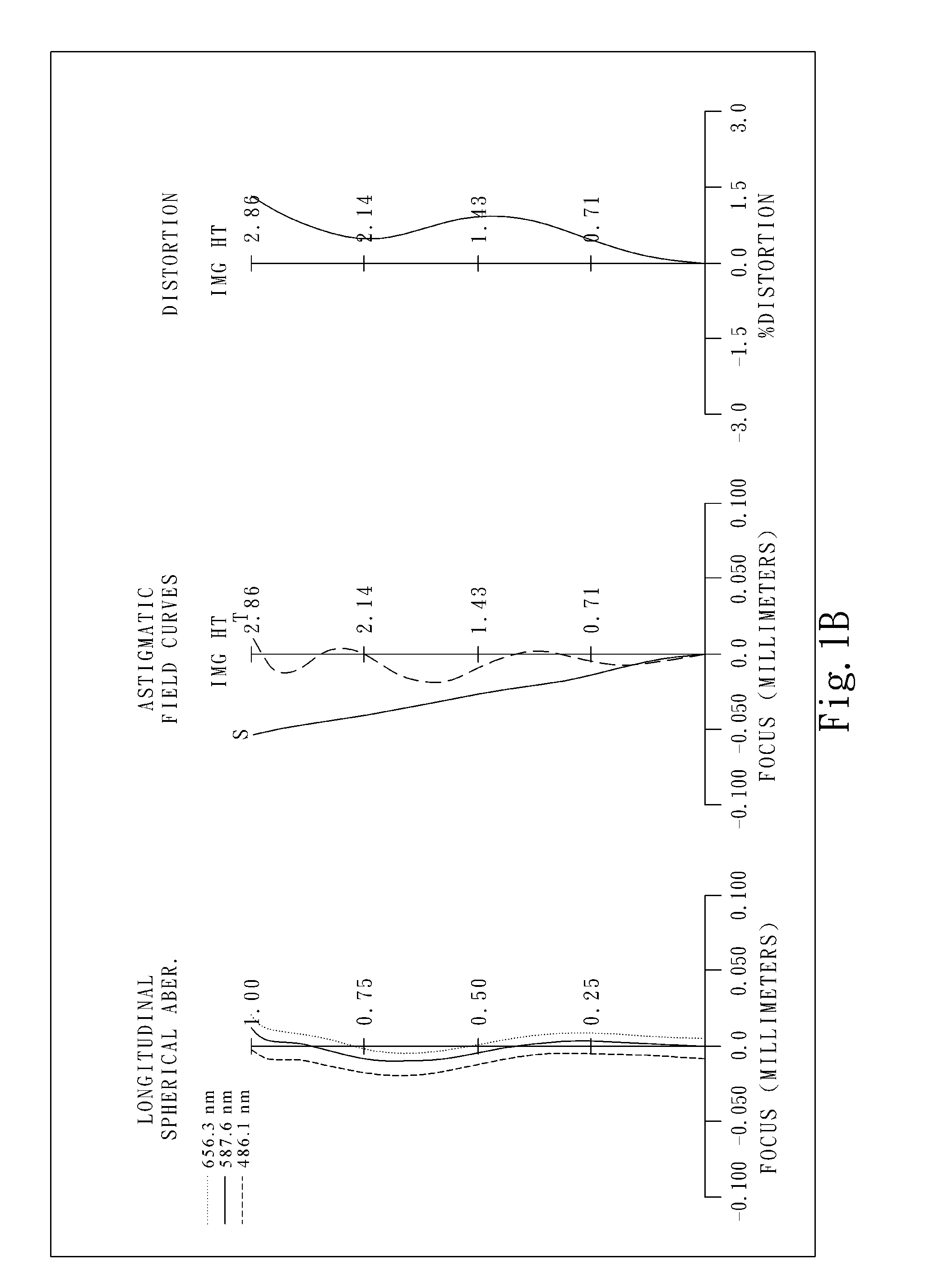

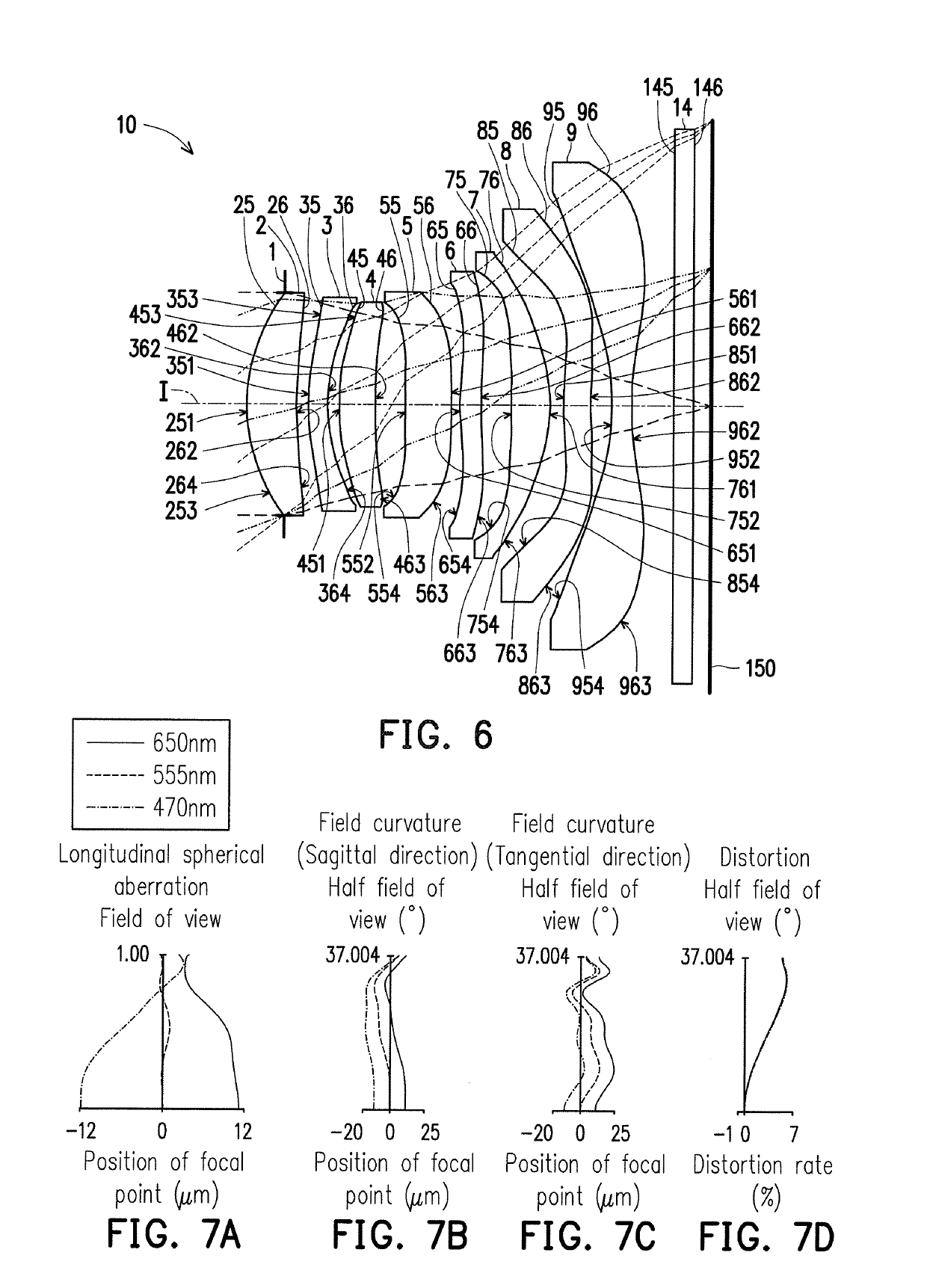

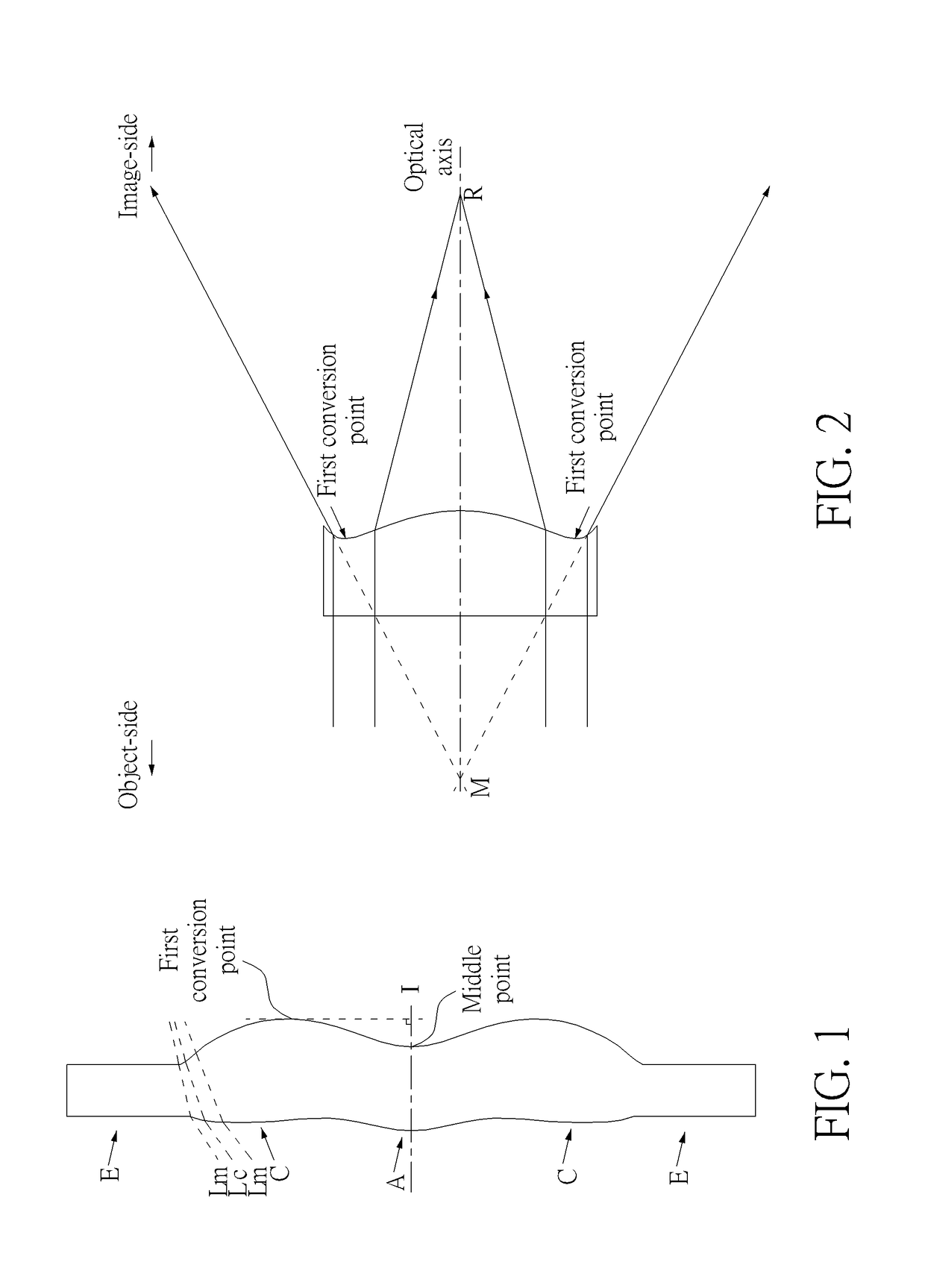

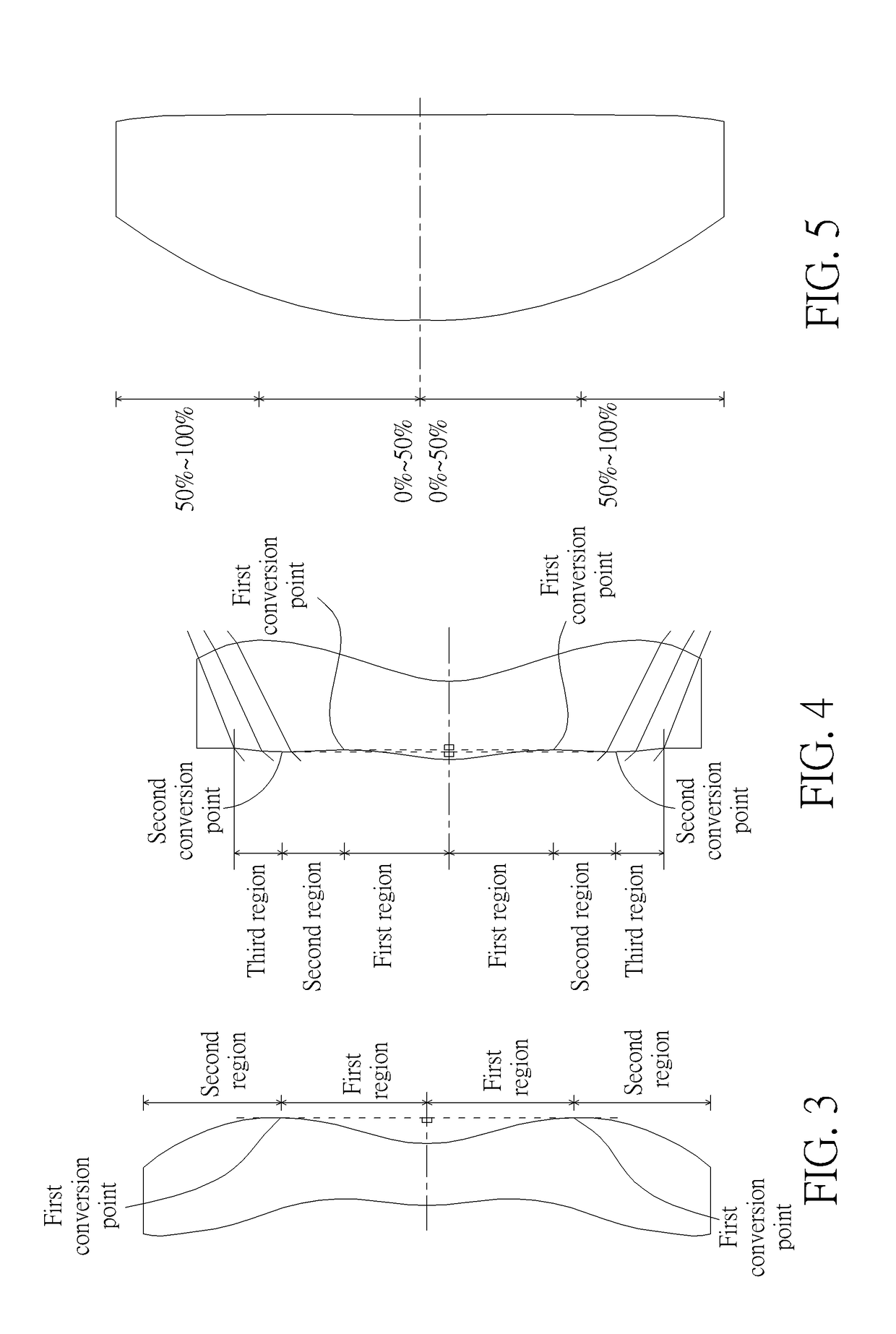

ActiveUS20180059365A1Good optical performanceShorten system lengthOptical elementsCamera lensOptical axis

An optical imaging lens includes a first lens element, a second lens element, a third lens element, and a fourth lens element from an object side to an image side in order along an optical axis. The first lens element to the fourth lens element each include an object-side surface and an image-side surface. The first lens element has positive refracting power. The second lens element has negative refracting power. At least one of the object-side surface and the image-side surface of the third lens element is an aspheric surface. At least one of the object-side surface and the image-side surface of the fourth lens element is an aspheric surface. A maximum distance between the image-side surface of the first lens element and the object-side surface of the second lens element in a direction parallel to the optical axis is less than 0.2 mm.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Image-capturing lens assembly

ActiveUS20110115962A1Small sizeReduce sensitivityTelevision system detailsColor television detailsImage resolutionOptic system

This invention provides an image-capturing lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, the object-side and image-side surfaces thereof being aspheric; a fourth lens element with negative refractive power having a concave image-side surface on which at least one inflection point is formed, the object-side and image-side surfaces thereof being aspheric; and a stop disposed between an imaged object and the first lens element; wherein there are four lens elements with refractive power. Such an arrangement of optical elements can effectively reduce the size of the lens assembly, mitigate the sensitivity of the optical system and enable the lens assembly to obtain a higher resolution.

Owner:LARGAN PRECISION

Optical imaging lens

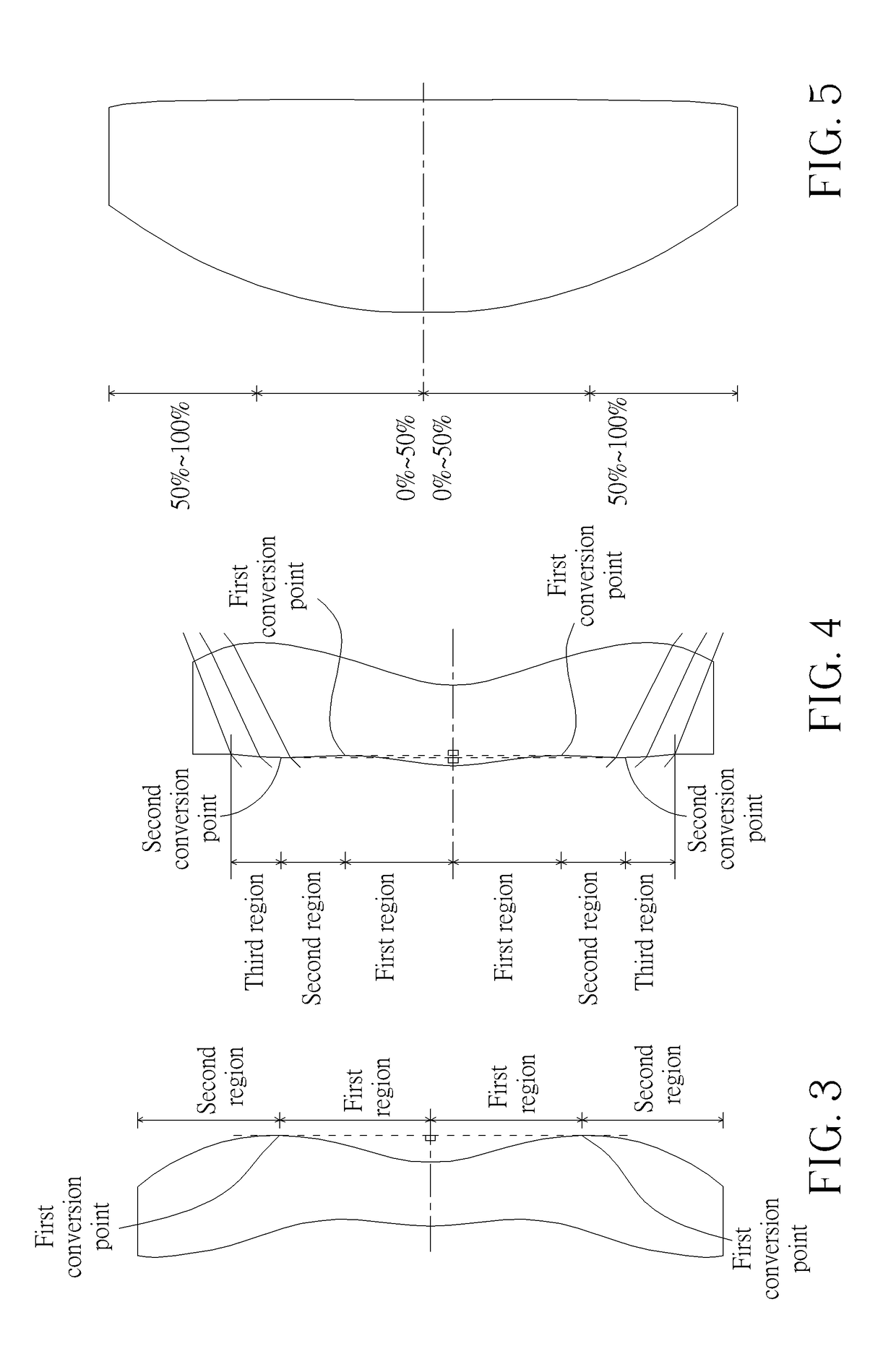

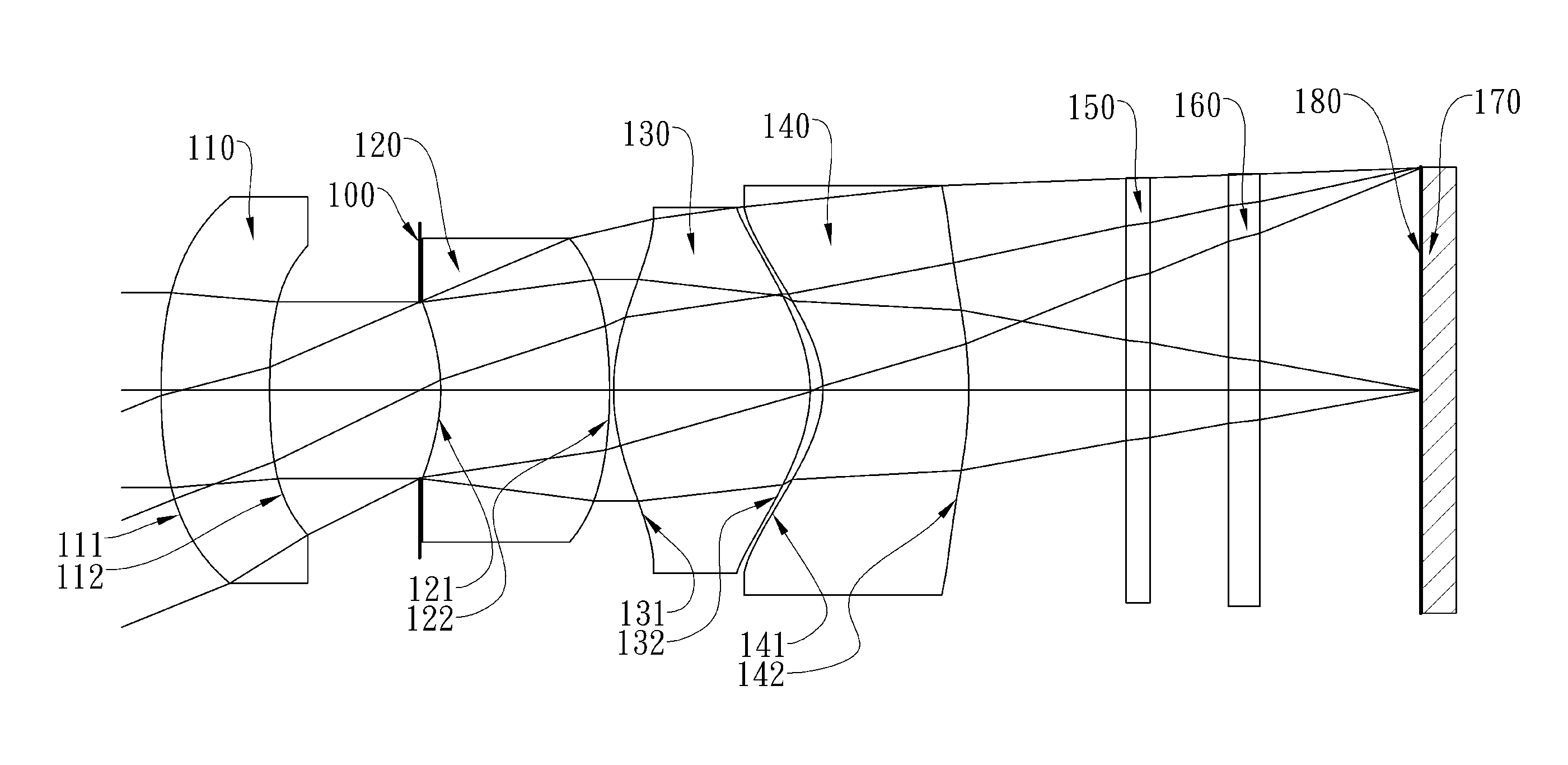

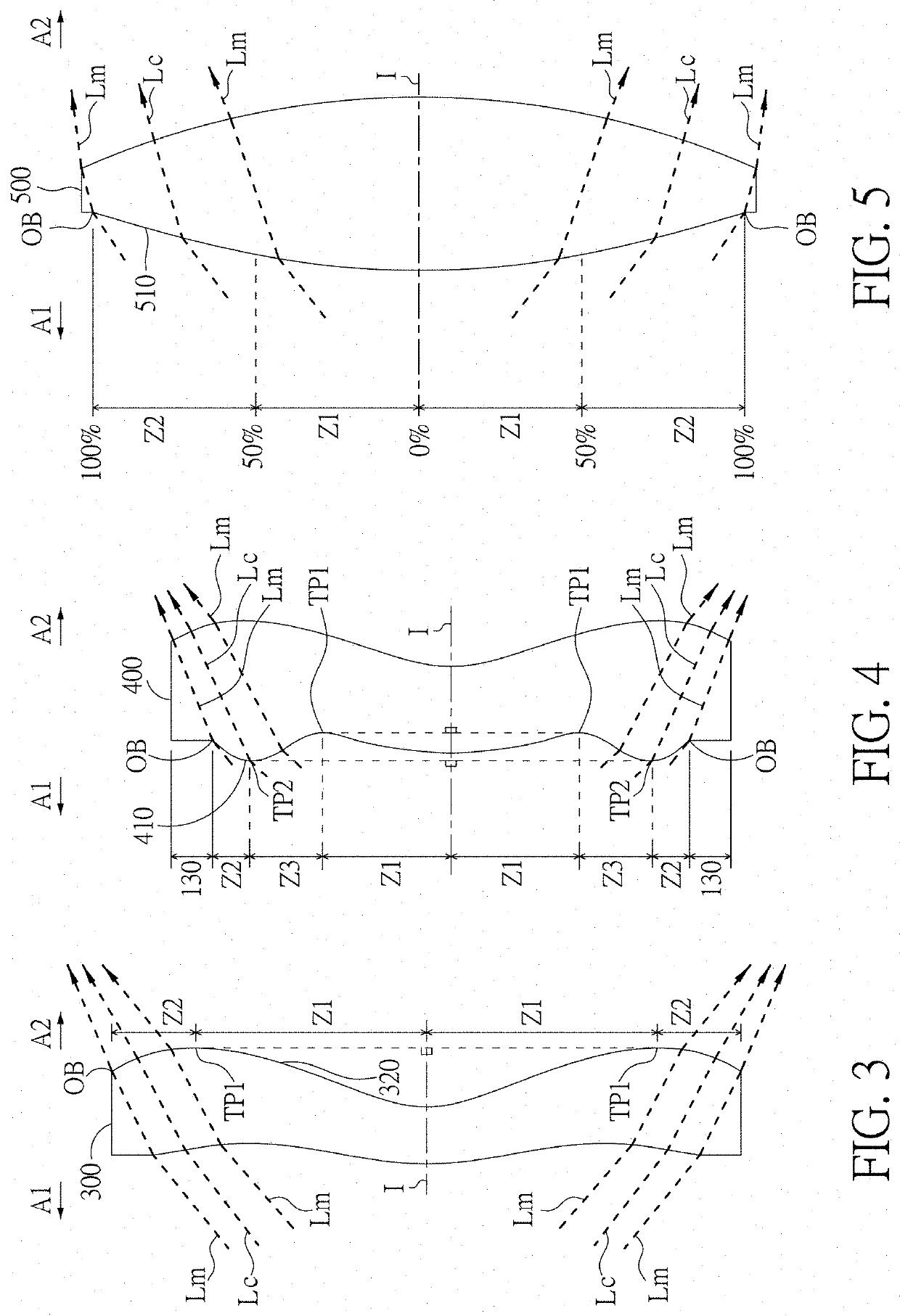

InactiveUS20180067283A1Large field of viewPreferable and stable optical image qualityOptical filtersOphthalmologyOptical axis

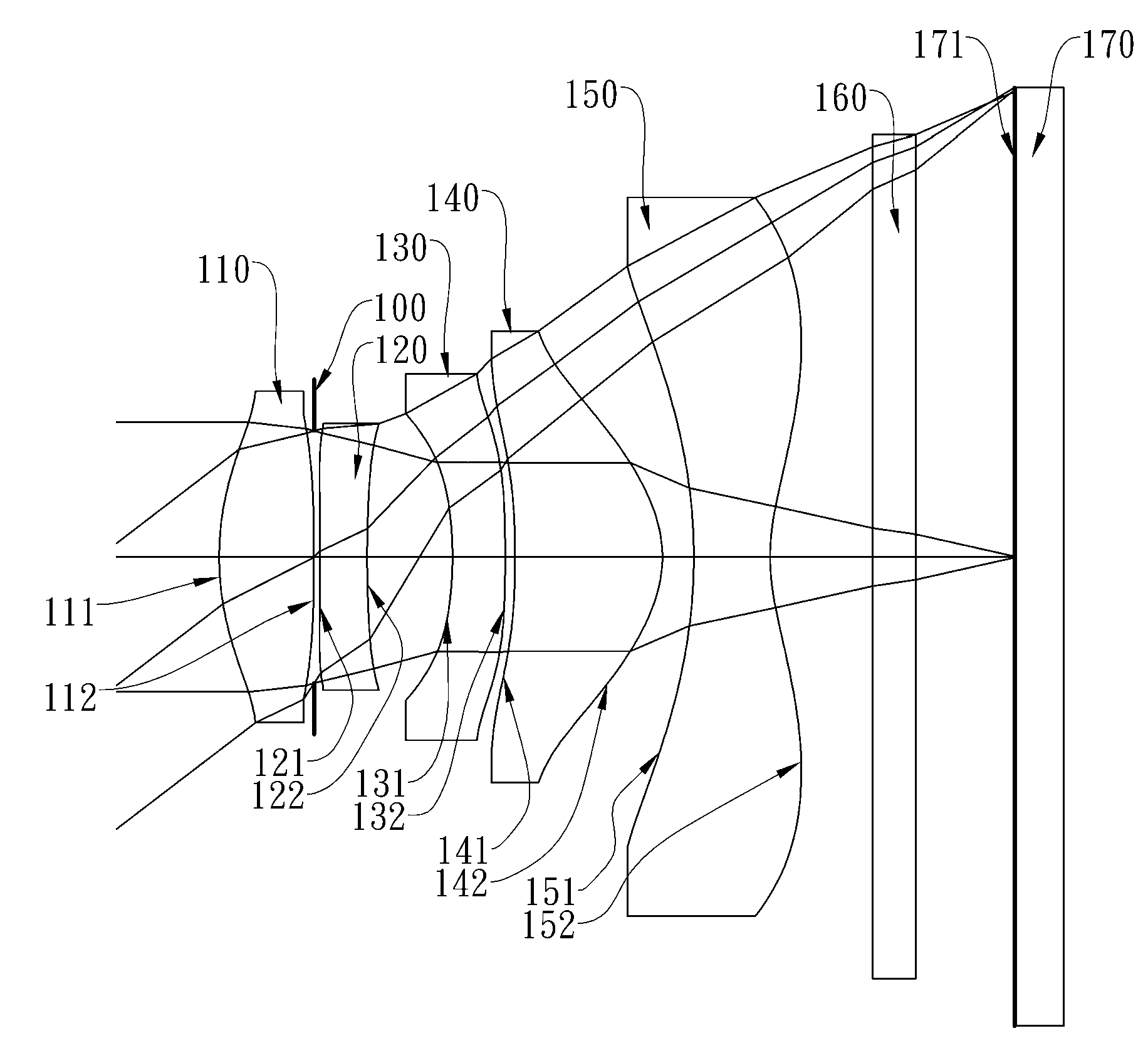

An optical imaging lens including an aperture stop, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element arranged in sequence from an object side to an image side along an optical axis is provided. Each lens element includes an object-side surface and an image-side surface. The material of the first lens element is plastic. The object-side surface of the second lens element has a concave portion in a vicinity of the optical axis. The image-side surface of the second lens element has a concave portion in a vicinity of a periphery of the second lens element. The object-side surface of the third lens element has a concave portion in a vicinity of a periphery of the third lens element. The image-side surface of the third lens element has a concave portion in a vicinity of the optical axis. The fourth lens element has positive refractive power. The image-side surface of the fifth lens element has a convex portion in a vicinity of the optical axis. The material of the sixth lens element is plastic.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

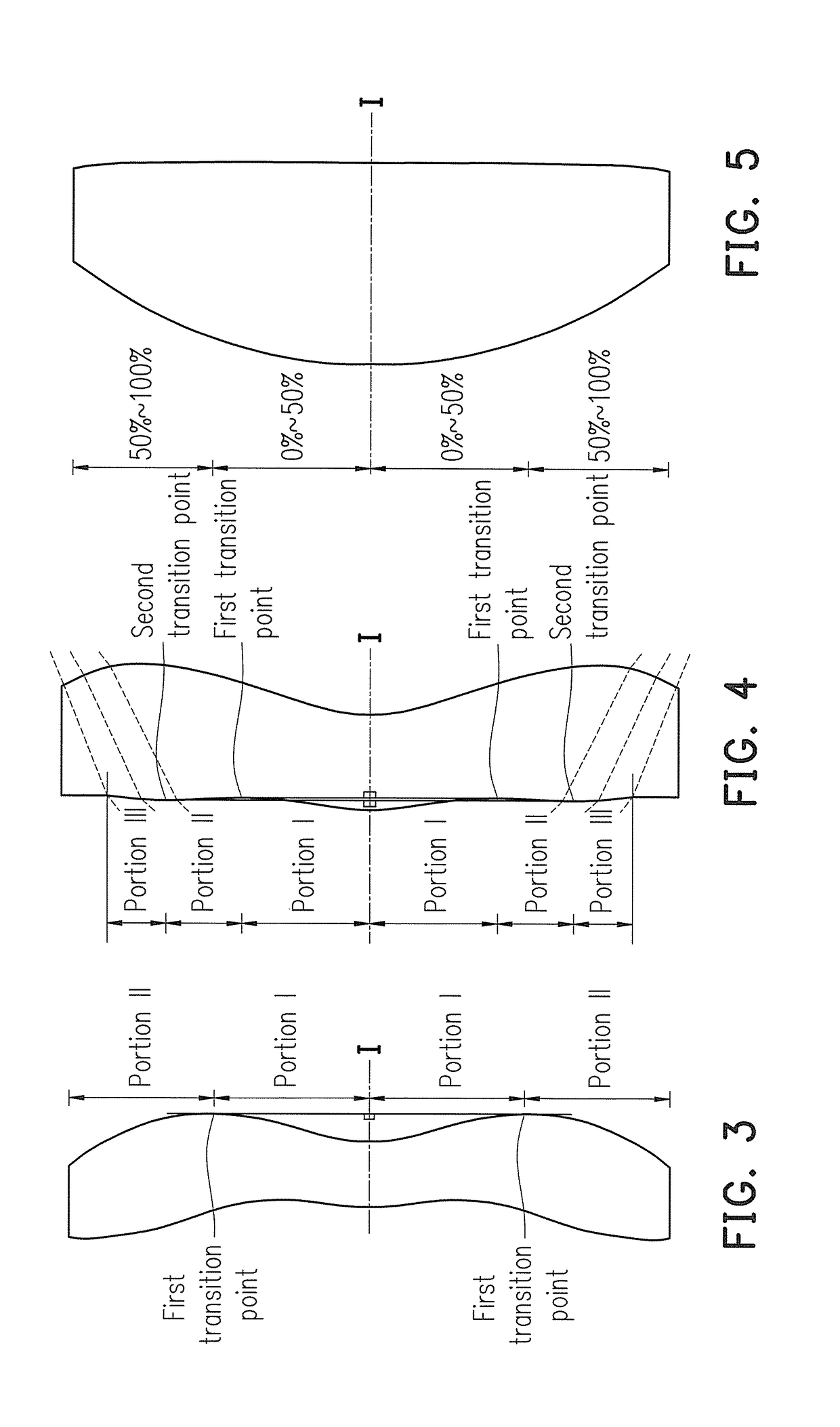

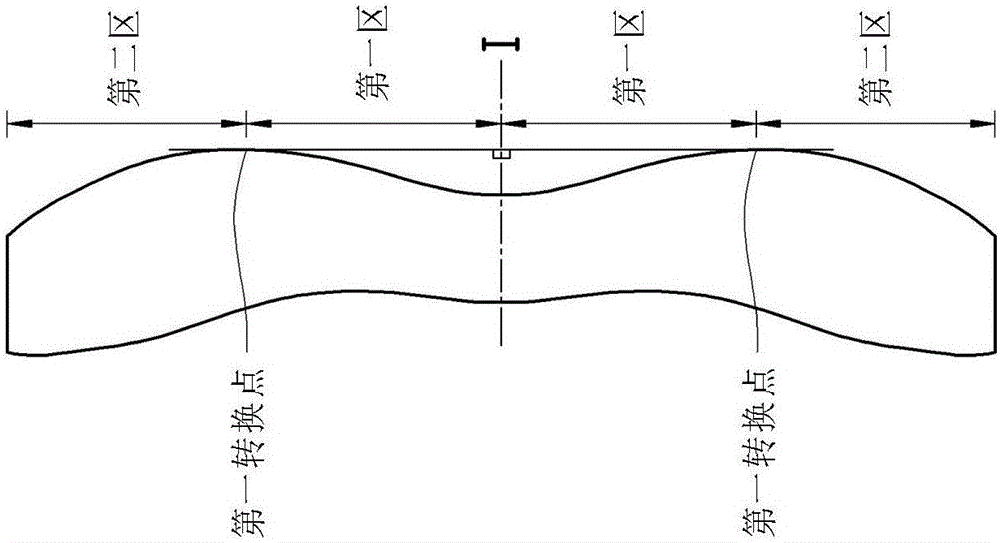

Optical lens set

ActiveUS20180059370A1Shorten system lengthSufficient optical performanceOptical elementsOptical axisPhysics

An optical lens assembly includes a first lens of positive refractive power, a second lens of refractive power, at least one of the object surface and the image surface being aspherical, a fourth lens of refractive power, a fifth lens of a concave object surface near its optical-axis and both the object surface and the image surface being aspherical so that the Abbe number υ4 of the fourth lens, the Abbe number υ5 of the fifth lens, an air gap G12 between the first lens and the second lens, an air gap G23 between the second lens and the third lens, an air gap G45 between the fourth lens and the fifth lens, the second thickness T2 of the second lens, the third thickness T3 of the third lens, the fourth thickness T4 of the fourth lens, and the fifth thickness T5 of the fifth lens satisfy 18≦υ4−υ5≦50 and (G12+T2+G23+T3+T4+G45+T5) / G34≦6.3.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

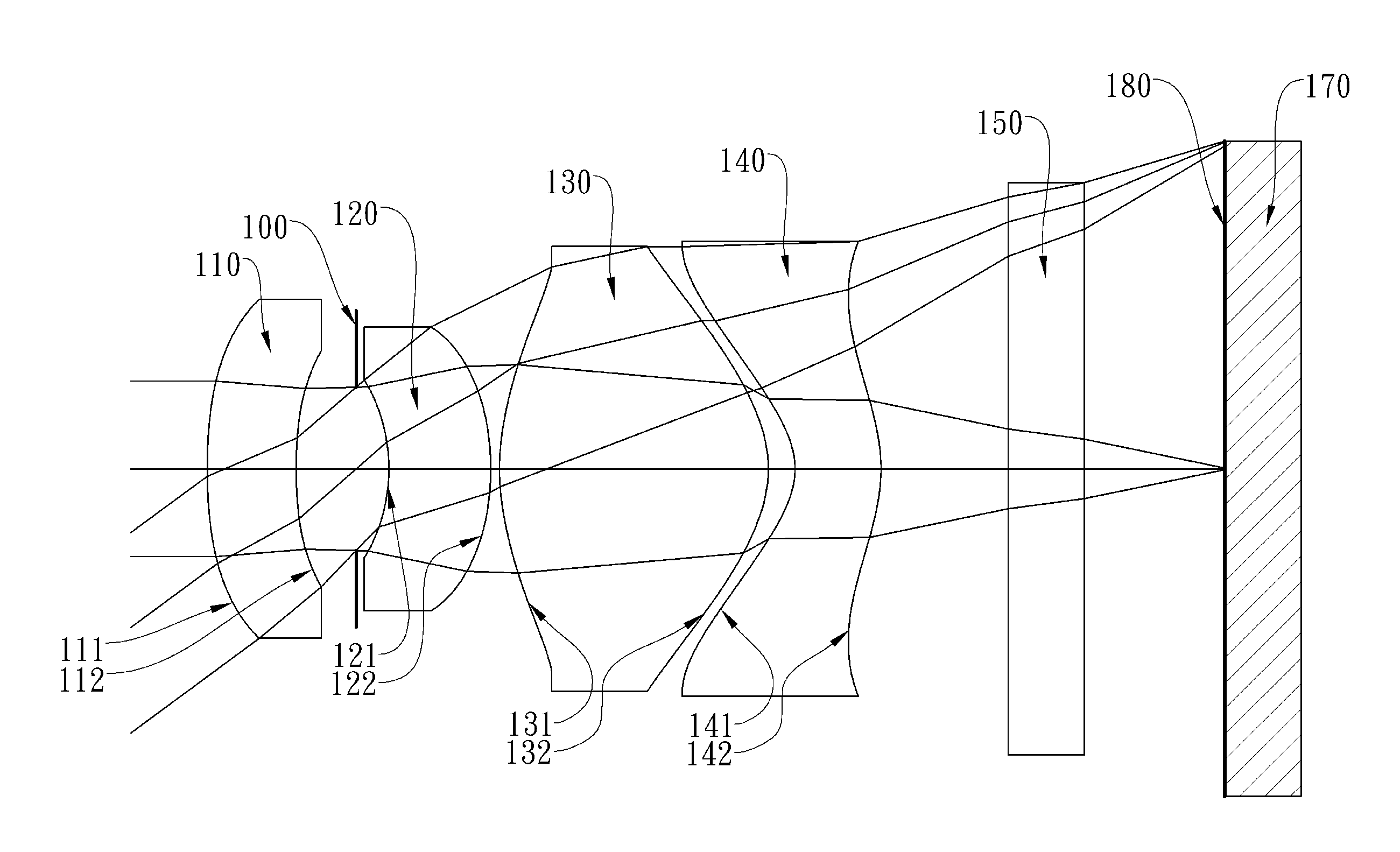

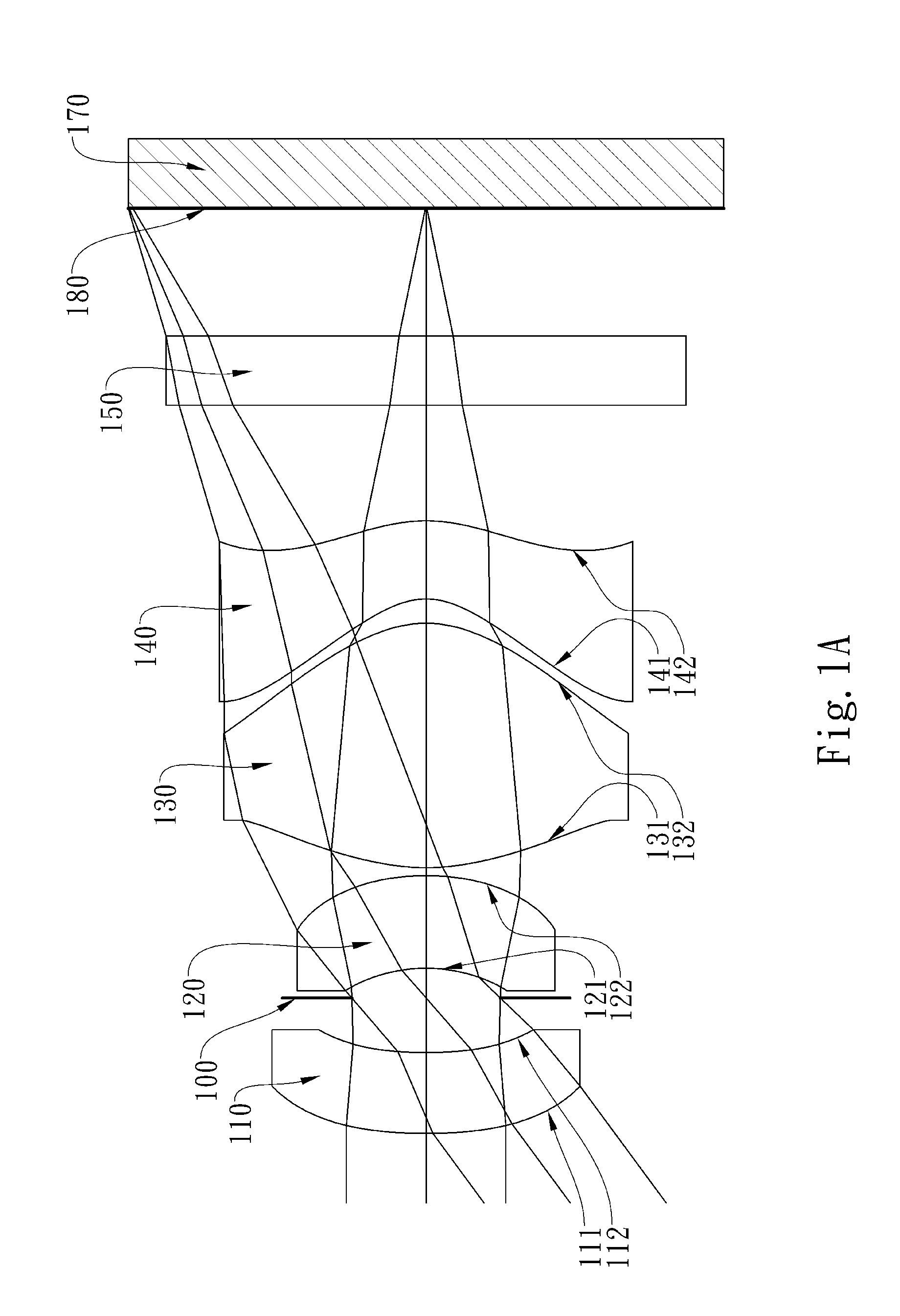

Image capturing optical system

This invention provides an image capturing optical system in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element with both the object-side and image-side surfaces thereof being aspheric, and the fourth lens element is made of plastic; and a fifth lens element with negative refractive power, both the object-side and image-side surfaces thereof being aspheric, at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof, and the fifth lens element is made of plastic. By such arrangement, photosensitivity and total track length of the system can be reduced, and better image quality can be obtained.

Owner:LARGAN PRECISION

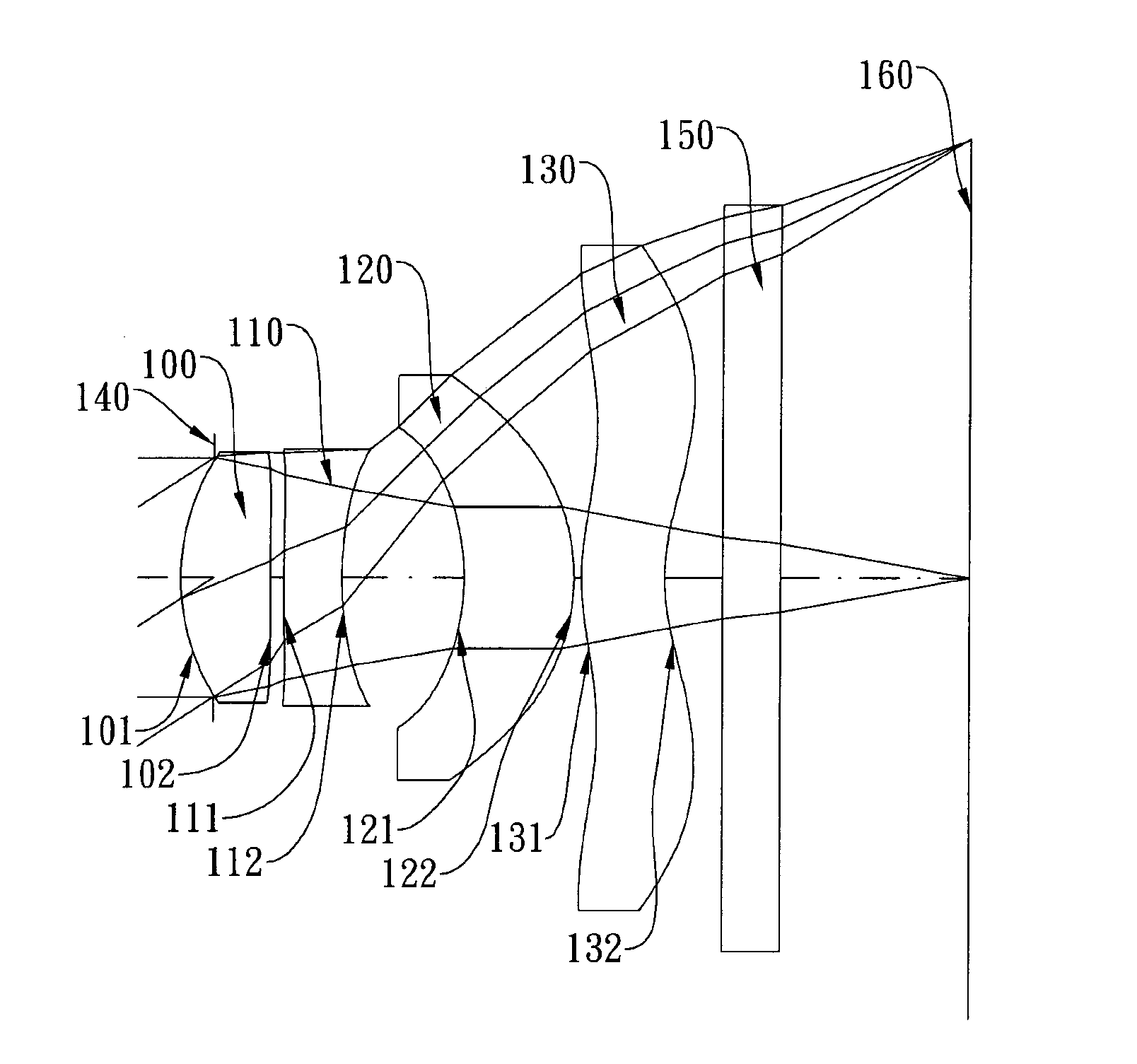

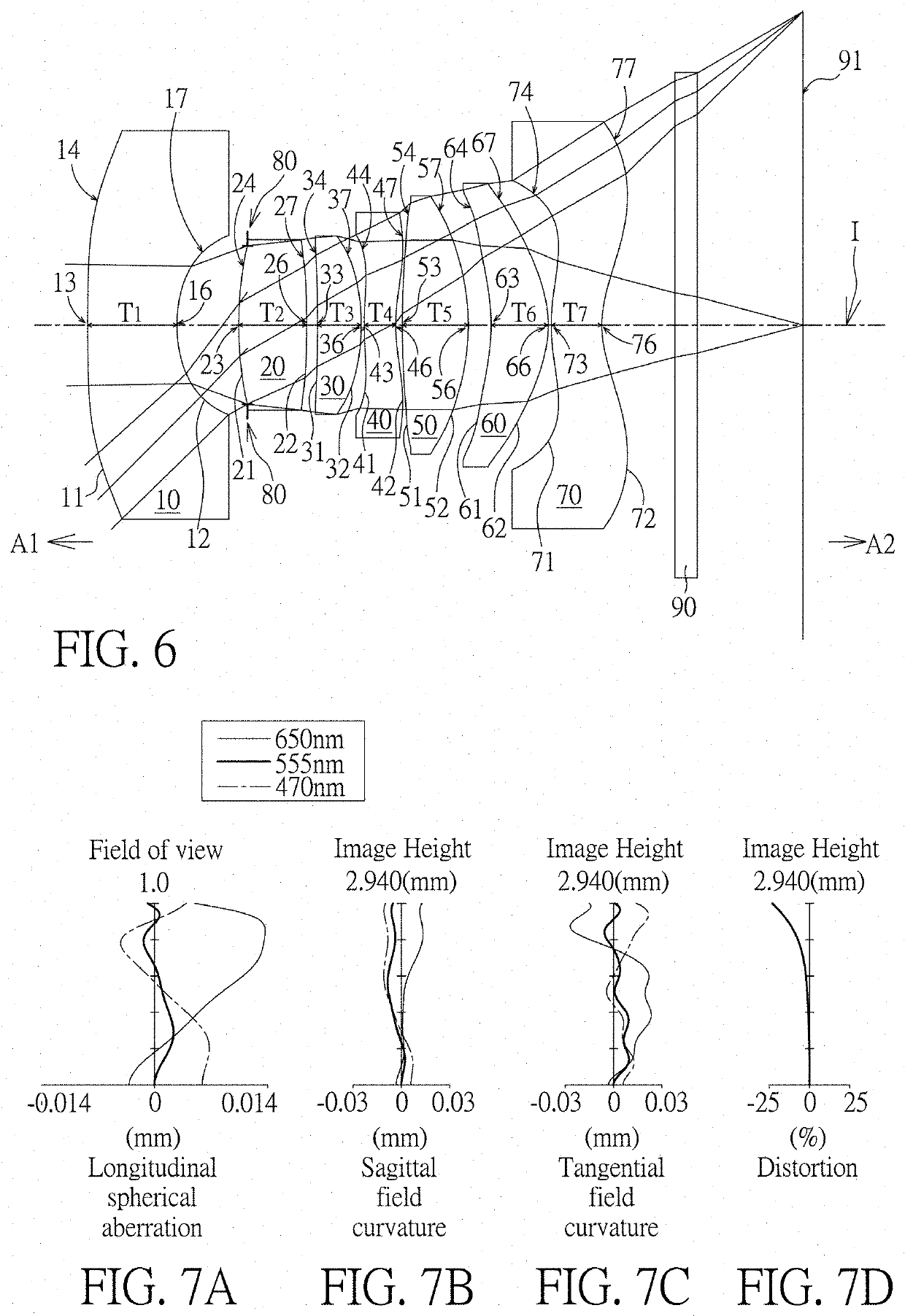

Optical lens system

ActiveUS20130208365A1Improve sensitivity of sensorSufficient back focal lengthLensOptical imagingFocal length

This invention provides an optical lens system in order from an object side to an image side comprising: a first lens element having a convex object-side surface; a negative second lens element having a concave object-side surface and a convex image-side surface; a positive third lens element having a convex object-side surface and a convex image-side surface; a plastic negative fourth lens element having a concave object-side surface and a convex image-side surface, with both the object-side and image-side surfaces thereof being aspheric. By such arrangement, the incident angle of off-axis light projected onto the sensor can be suppressed for improving the sensitivity of the sensor effectively. Also, a sufficient back focal length can be retained for disposing other optical elements (e.g., an IR-pass filter), and thereby the system can be more suitable for the infrared aspect of optical imaging systems.

Owner:LARGAN PRECISION

Optical image capturing lens system

This invention provides an optical image capturing lens system comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element; and a fifth lens element with negative refractive power, at least one of the object-side and image-side surfaces thereof being aspheric, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein the system at least has one front stop and one rear stop; which are positioned between an imaged object and the third lens element as well as between the third lens element and the fifth lens element, respectively. By such arrangement, photosensitivity and total track length of the system can be reduced, and the aberration and astigmatism of the system can be effectively corrected. Moreover, the focusing performance thereof can be improved.

Owner:LARGAN PRECISION

Imaging lens assembly

ActiveUS20110075271A1Reduce sensitivitySmall sizeTelevision system detailsColor television detailsConvex sideImaging lens

This invention provides an imaging lens assembly comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens with negative refractive power having a concave object-side surface; a third lens with positive refractive power having a convex image-side surface, at least one of both surfaces thereof being aspheric; and a fourth lens with negative refractive power having a convex object-side surface and a concave image-side surface on which at least one inflection point is formed; wherein there are four lenses with refractive power, an on-axis spacing between an aperture stop and an electronic sensor provided therein is SL, an on-axis spacing between the object-side surface of the first lens and the electronic sensor is TTL, they satisfy the relation: 0.75<SL / TTL<0.90.

Owner:LARGAN PRECISION

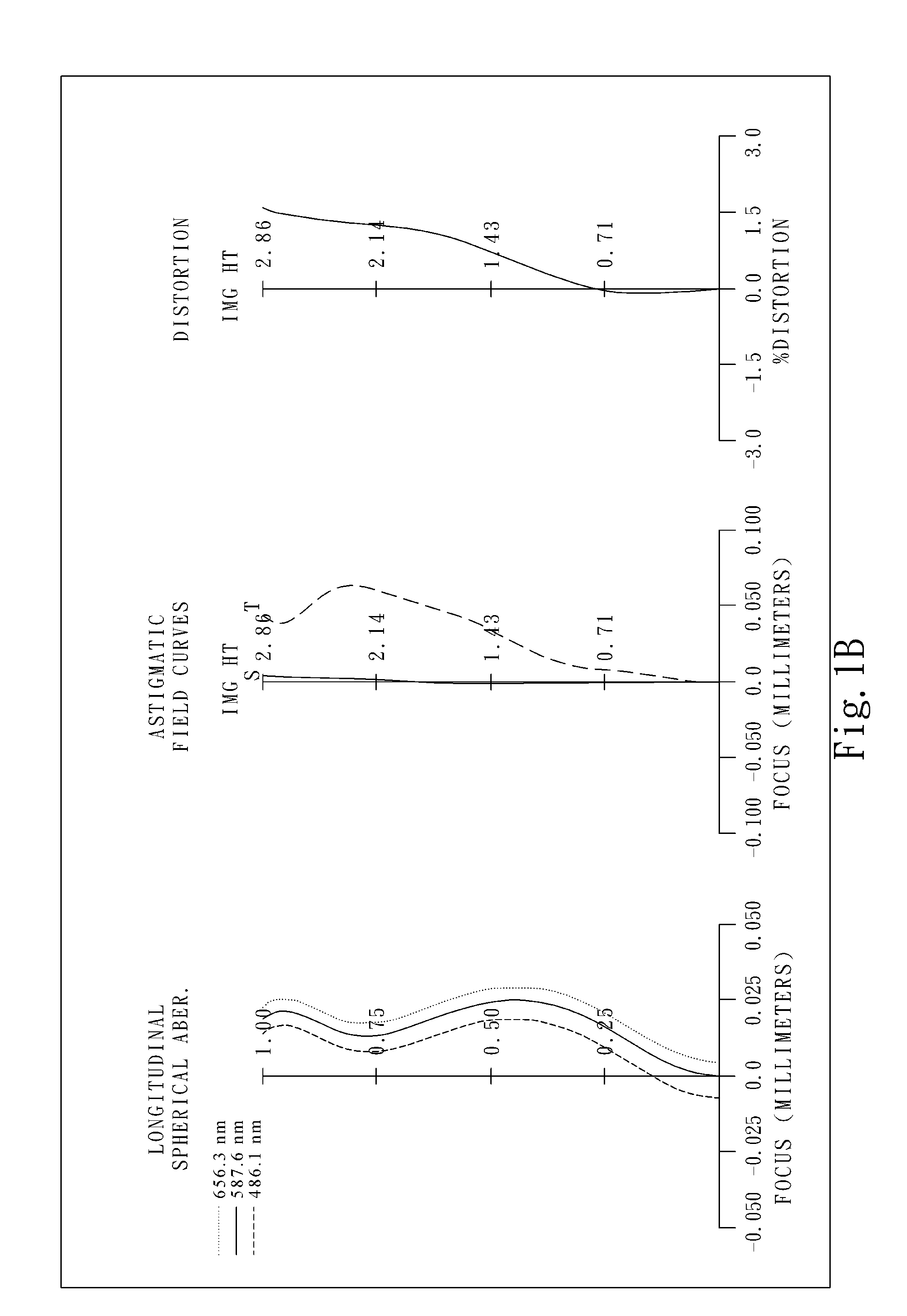

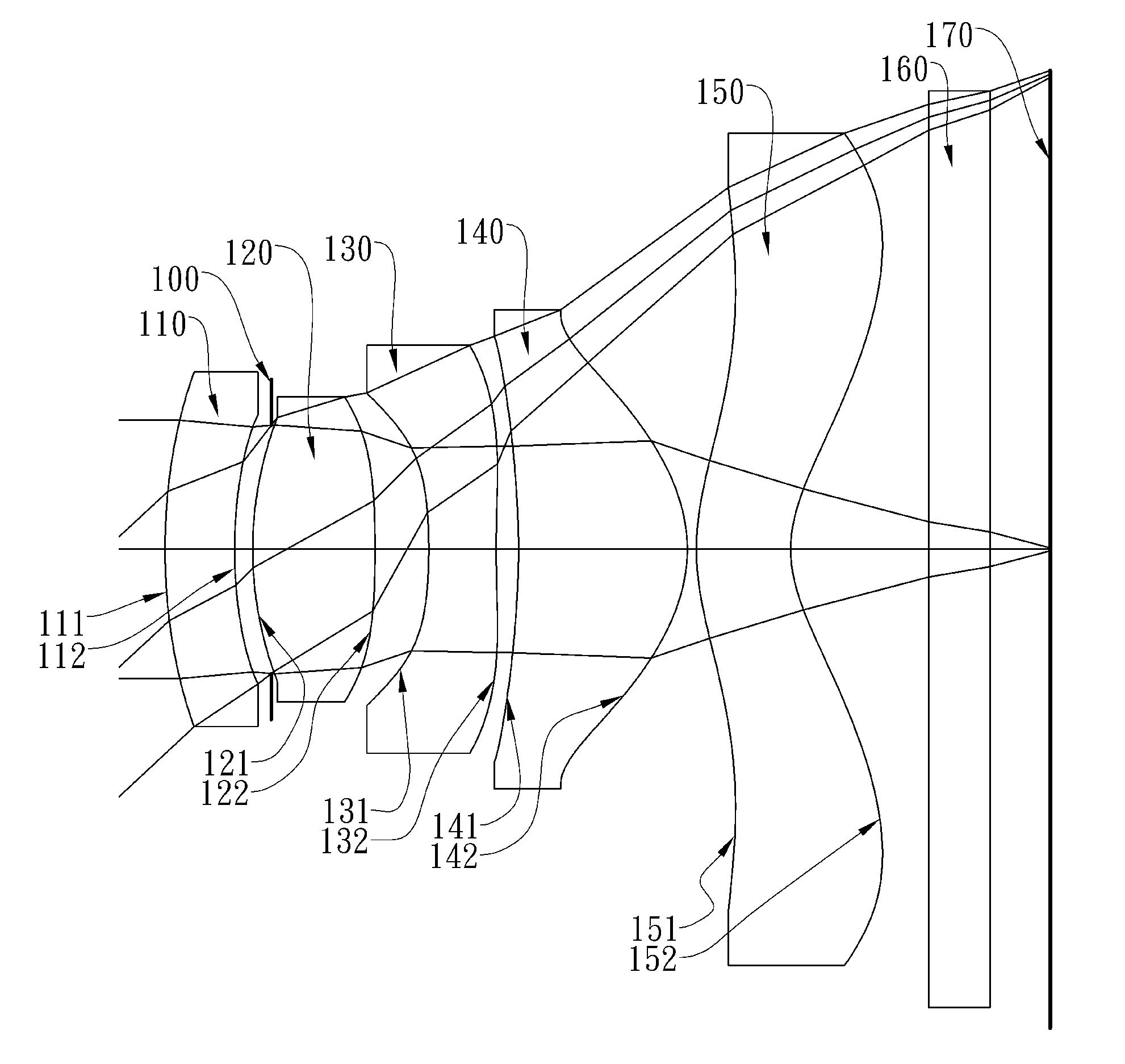

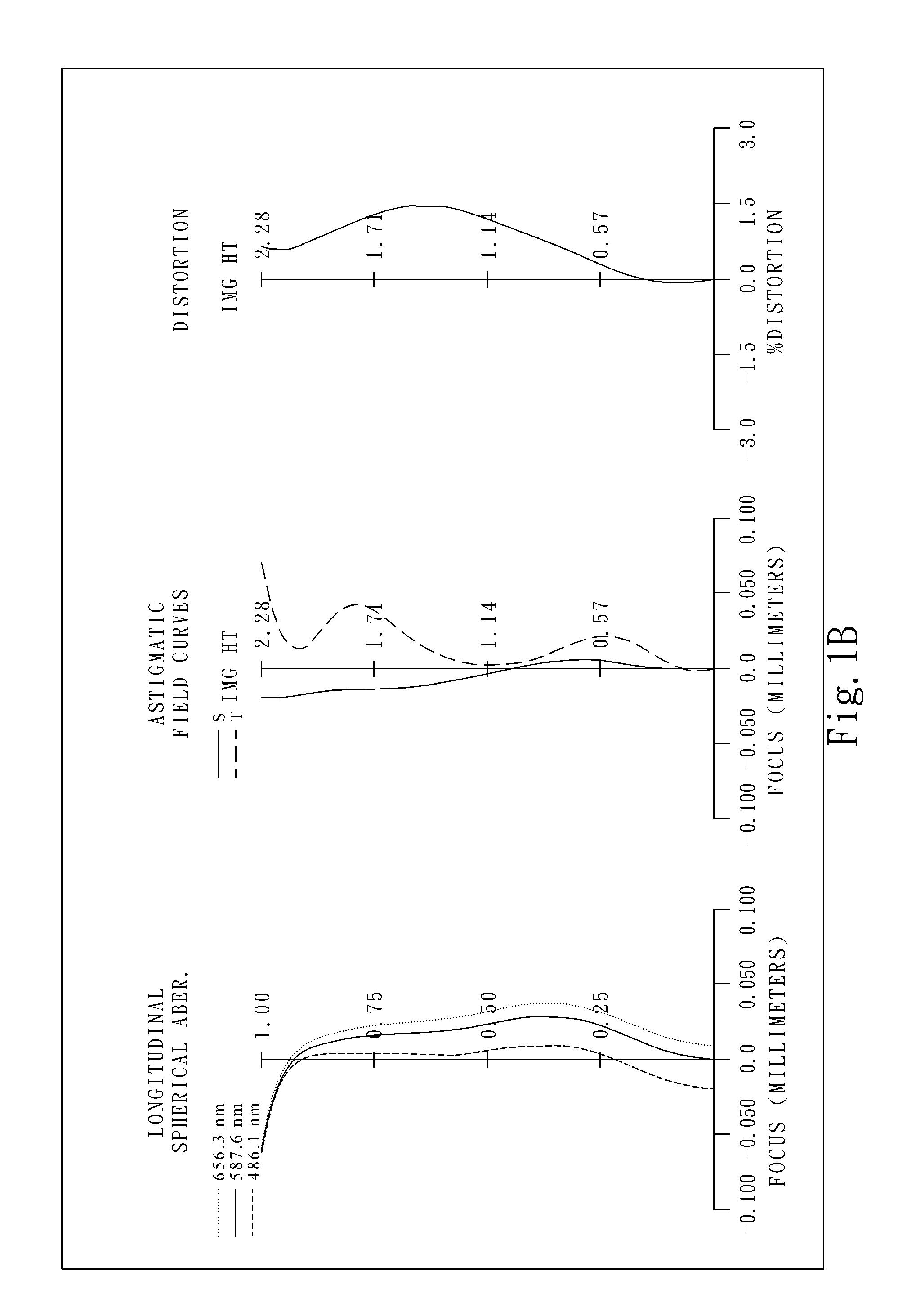

Optical imaging lens

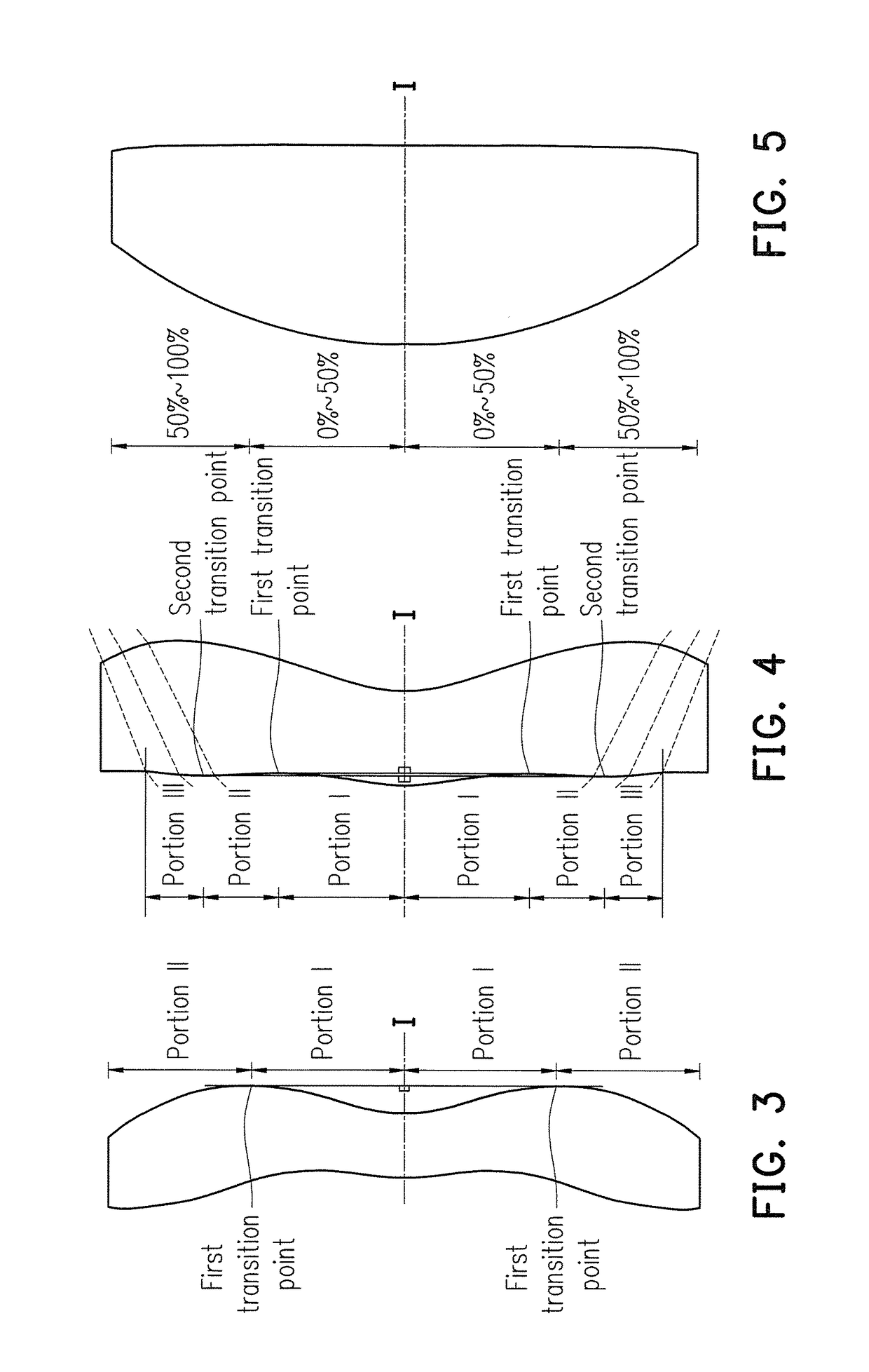

ActiveUS20170269329A1Good optical performanceShorten lens lengthOptical elementsCamera lensOptical axis

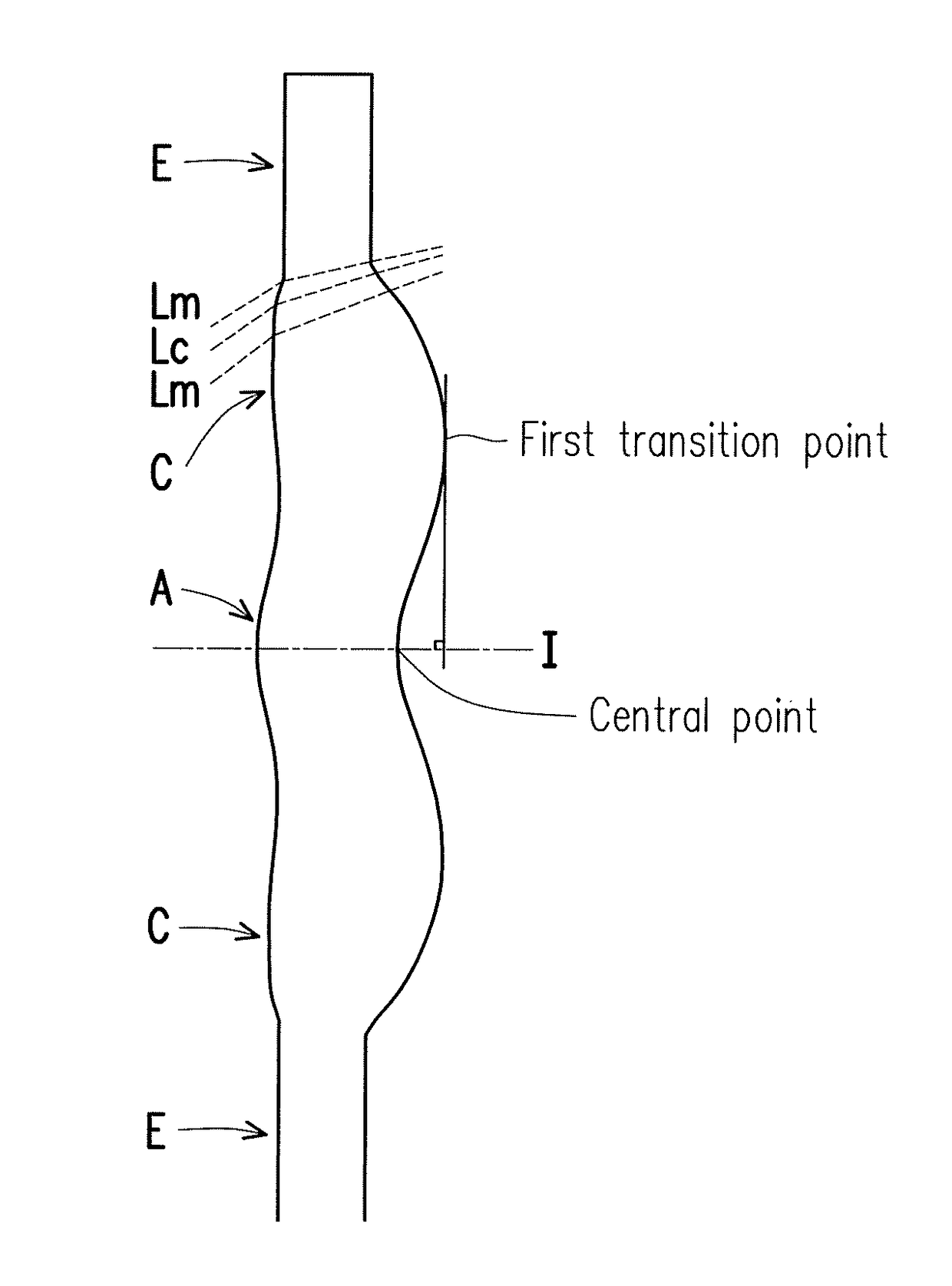

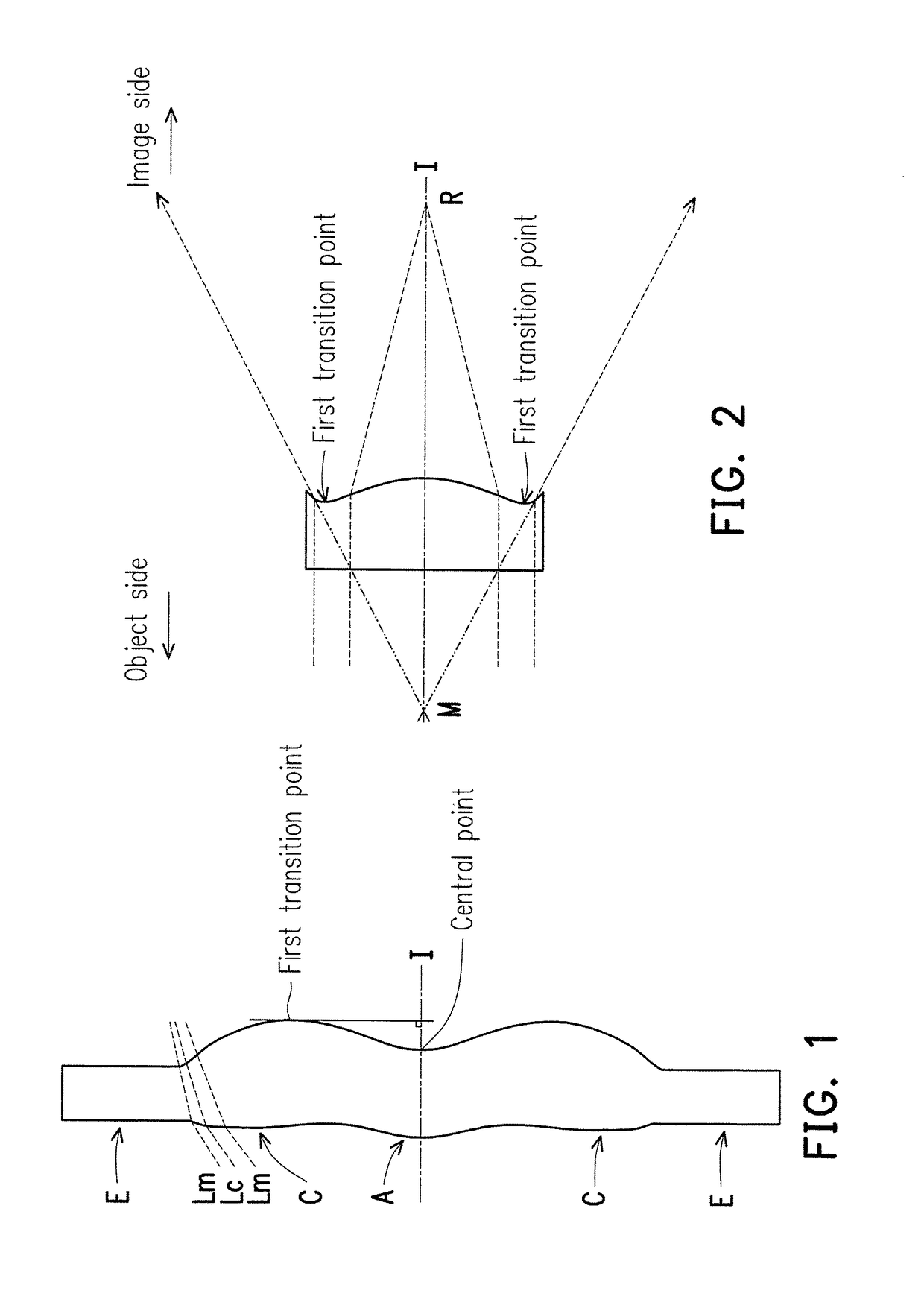

An optical imaging lens includes first, second, third, and fourth lens elements arranged in order from an object side to an image side along an optical axis. Each lens element has an object-side surface and an image-side surface. The first lens element has positive refracting power. The object-side surface of the first lens element has a convex portion in a vicinity of the optical axis and a convex portion in a vicinity of a periphery. The second lens element has negative refracting power. The object-side surface of the third lens element has a concave portion in a vicinity of a periphery. The image-side surface of the fourth lens element has a convex portion in a vicinity of a periphery.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Image capturing optical lens system

This invention provides an image capturing optical lens system in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with negative refractive power having at least one of the object-side and image-side surfaces thereof being aspheric; a fourth lens element having at least one of the object-side and image-side surfaces thereof being aspheric; a fifth lens element having a concave image-side surface, both the object-side and image-side surfaces thereof being aspheric, at least one inflection point is formed on at least one of the object-side surface and the image-side surface thereof, and the fifth lens element is made of plastic. By such arrangement, photosensitivity and total track length of the system can be reduced, and the aberration and astigmatism of the system can be effectively corrected. Moreover, high image resolution can be obtained.

Owner:LARGAN PRECISION

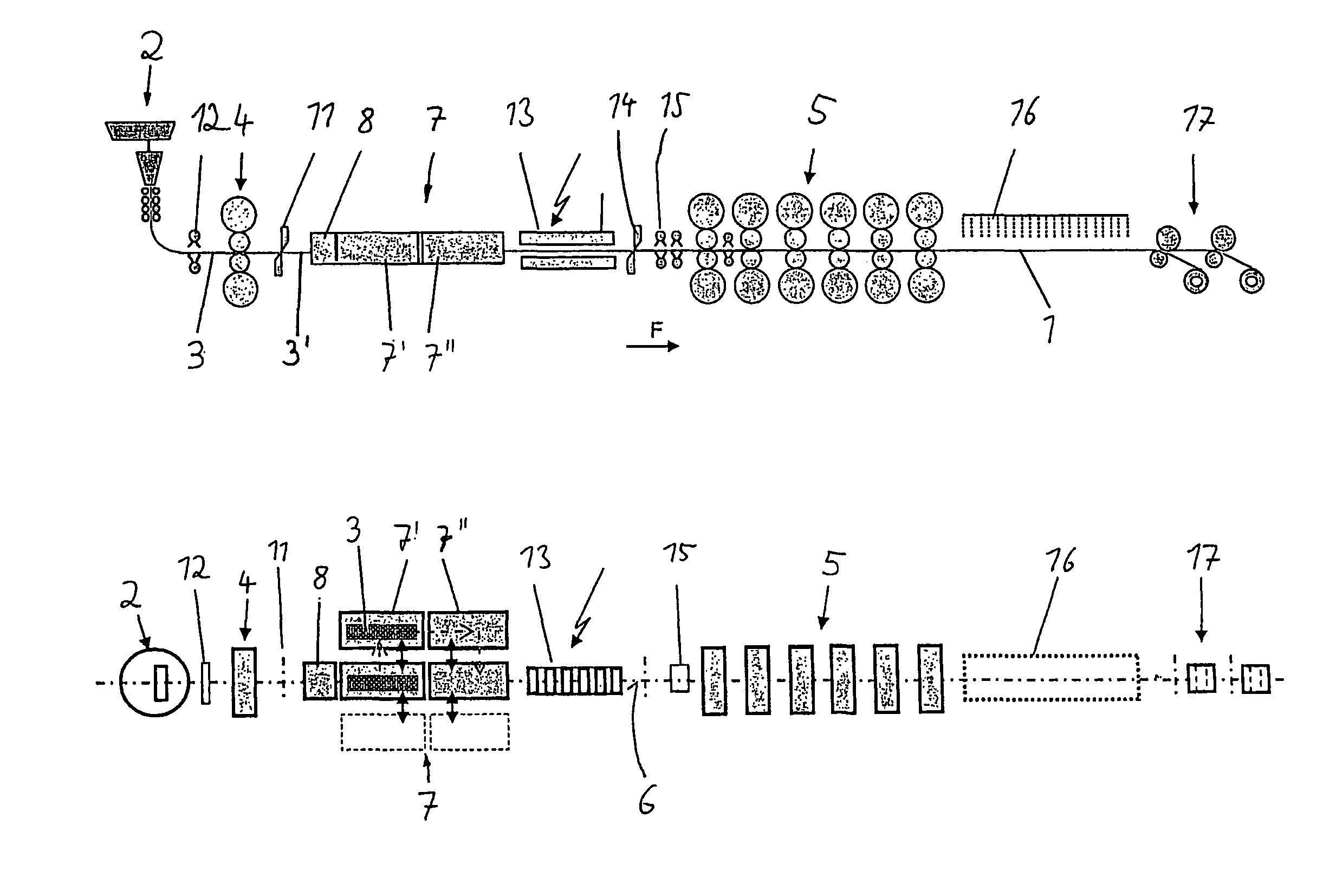

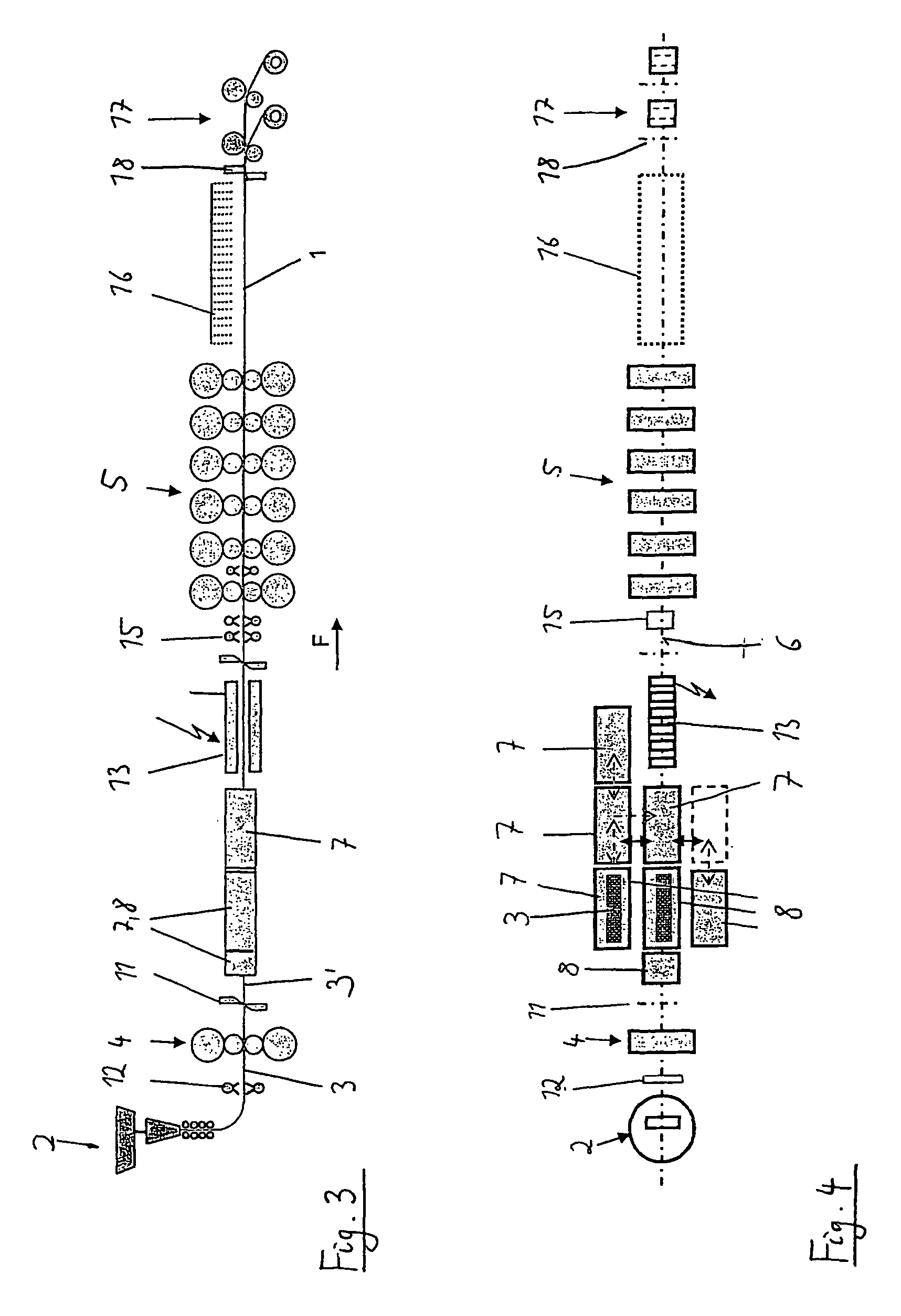

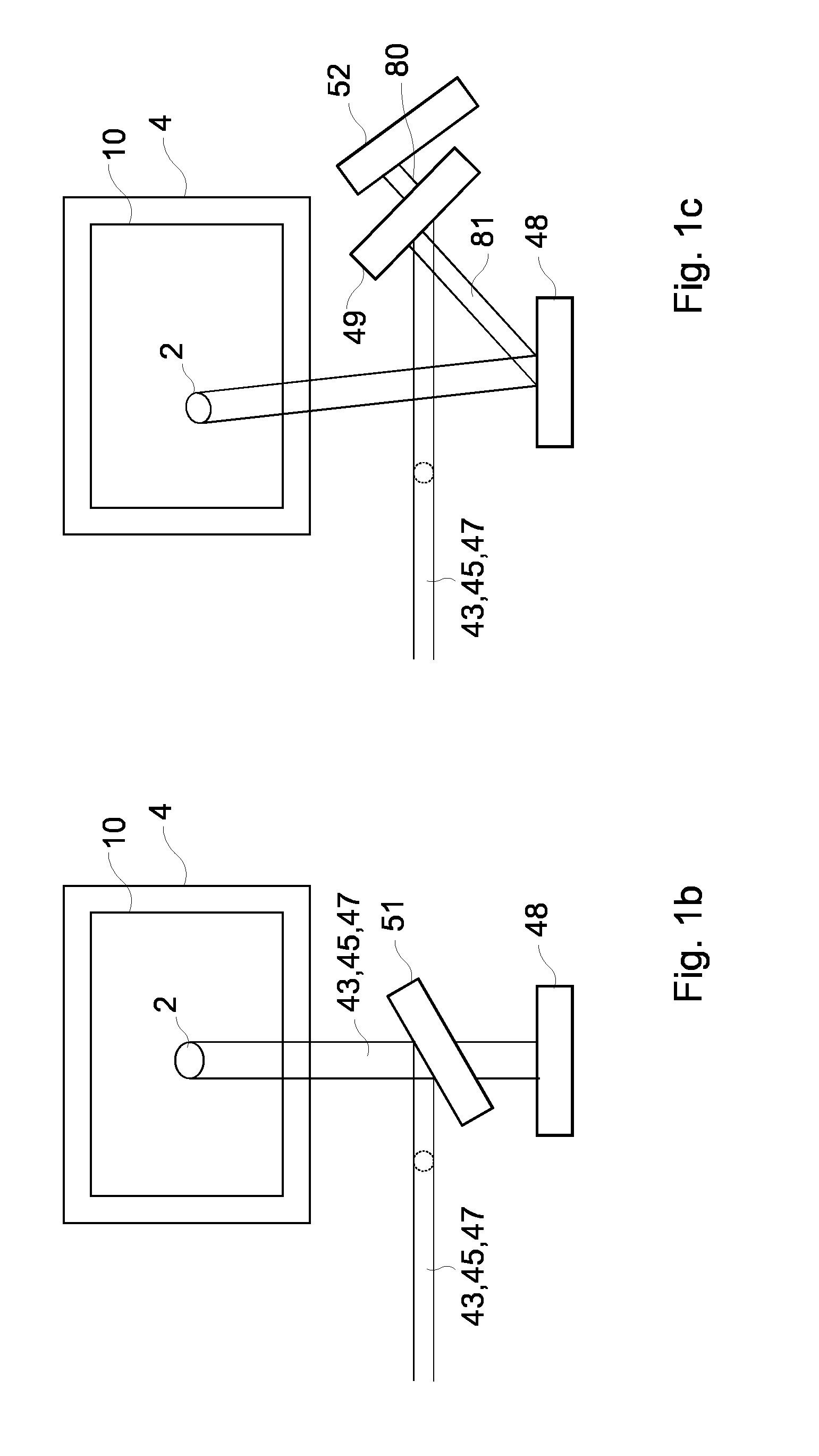

Method and device for manufacturing a metal strip by means of continuous casting and rolling

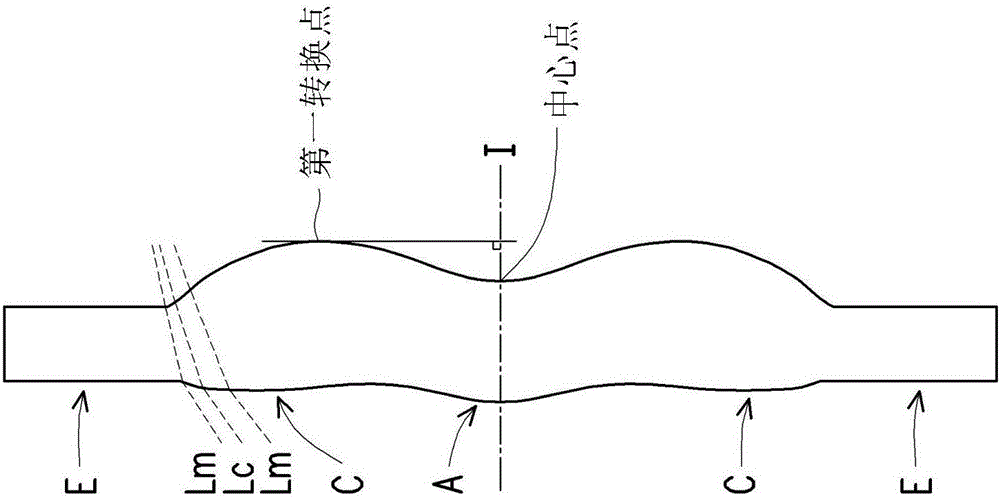

InactiveUS8011418B2Shorten system lengthLower investment costsCasting plantsMetal rolling stand detailsSteel beltOperation mode

A method of manufacturing a metal strip includes casting a slab (3) or preliminary strip (3′) in a casting machine (2) and subsequently rolling the cast slab (3) or preliminary strip (3′) in at least one rolling train (4, 5) in a first operating mode with the at least one rolling train being connected with the casting machine for continuously manufacturing the metal strip, and in a second operating mode removing the cast slab (3) or preliminary strip (3′) from the main transport line (6) with a shuttle system arranged between the casting machine (2) and the at least one rolling train (4, 5), storing the removed slab (3) or preliminary strip (3′), and subsequently transporting the removed slab (3) or preliminary strip back into the main transport line, with the removed slab (3) or preliminary strip (3′) being heated to a desired temperature or maintained at a desired temperature prior to the transport back into the main transport line (6) for discontinuously manufacturing the metal strip.

Owner:SMS DEMAG AG

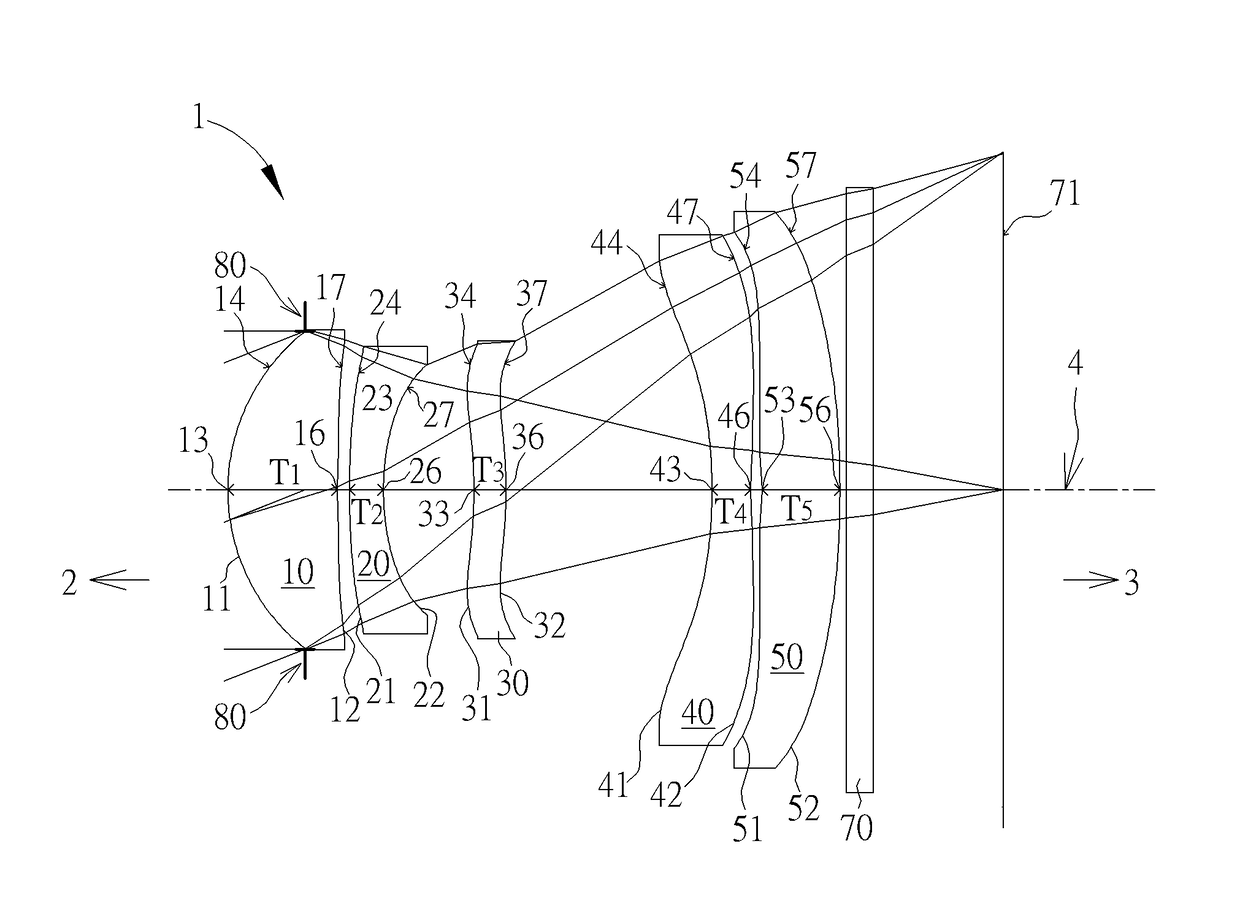

Optical lens assembly

An optical lens assembly includes first, second, third, and fourth lens elements arranged in order from an object side to an image side along an optical axis. Each lens element has an object-side surface and an image-side surface. The object-side surface of the first lens element has a convex portion in a vicinity of a periphery. The second lens element has negative refracting power. The object-side surface of the third lens element has a concave portion in a vicinity of a periphery. The image-side surface of the fourth lens element has a convex portion in a vicinity of a periphery.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Optical imaging lens

InactiveCN106526797AShorten system lengthAberration correctionOptical elementsCamera lensOptical axis

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

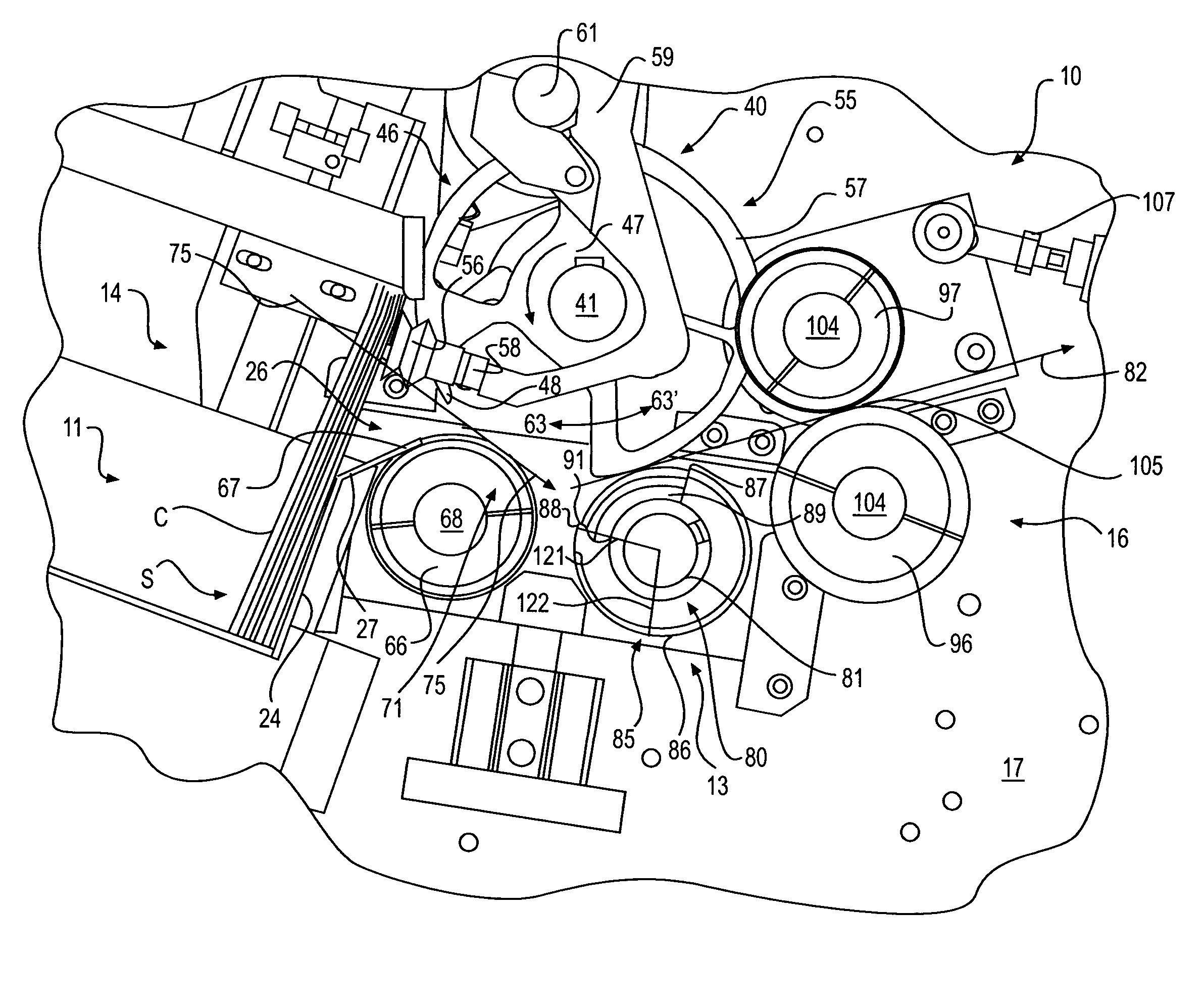

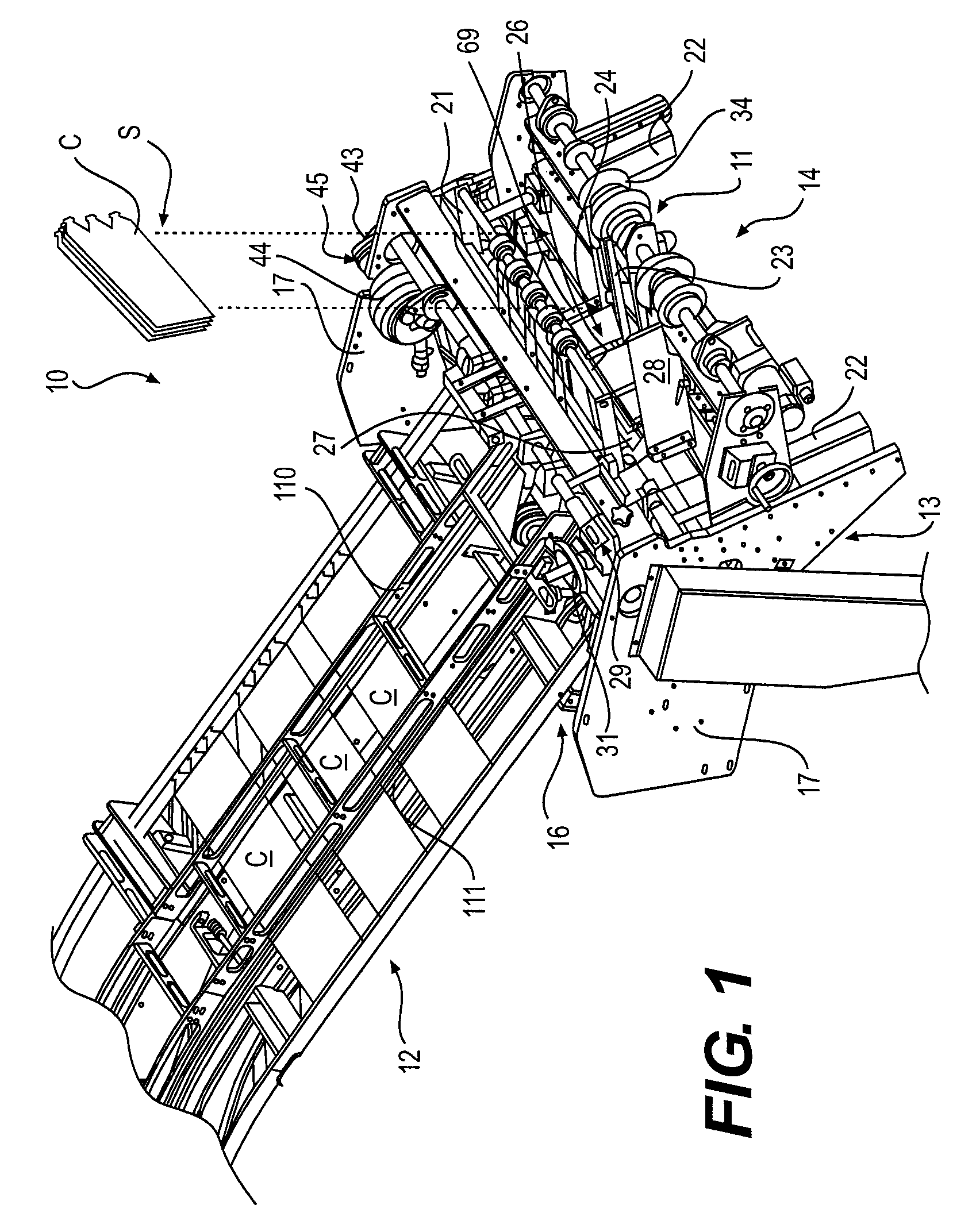

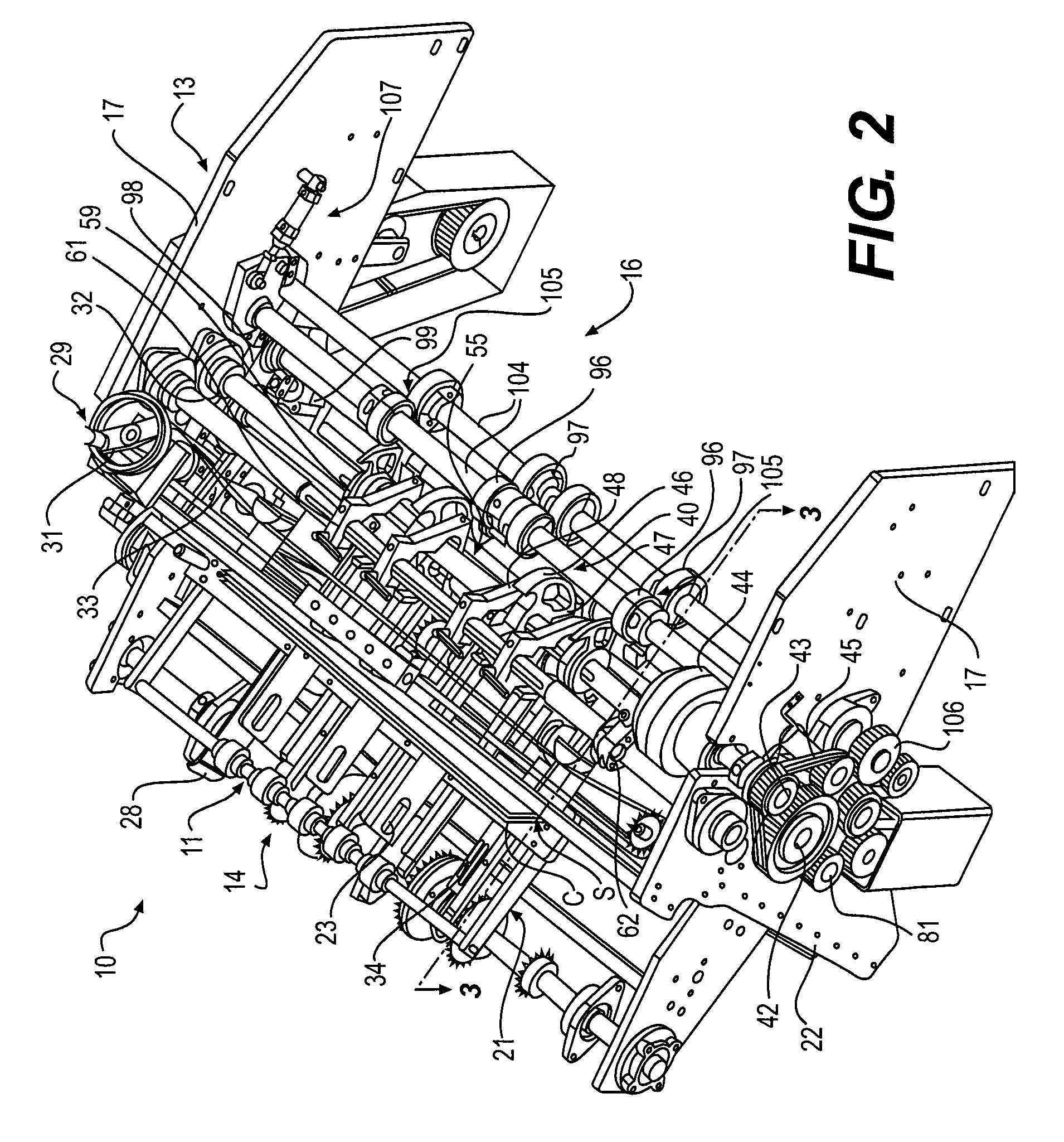

Carton feeding system

ActiveUS8870519B2Shorten system lengthFeeding of the cartons to the carton conveyor can be accomplished more efficientlyPackagingStacking articlesCartonEngineering

A carton feeding system is provided for feeding selected cartons from a stack of cartons contained within a carton magazine to a downstream carton conveyor such as for a product packaging machine. A carton picking device removes a selected carton from the stack of cartons within the magazine, after which the carton is engaged between a carton engaging segment of the primary segment wheel and a draw roller, which pulls the carton from the magazine and feeds the carton along a first path of travel. Thereafter, a secondary segment wheel engages and redirects a leading portion of the carton toward a second path of travel. The carton then is fed along its second path of travel toward engagement between a pair of downstream nip rolls that feed the carton into the downstream carton conveyor.

Owner:GRAPHIC PACKAGING INT

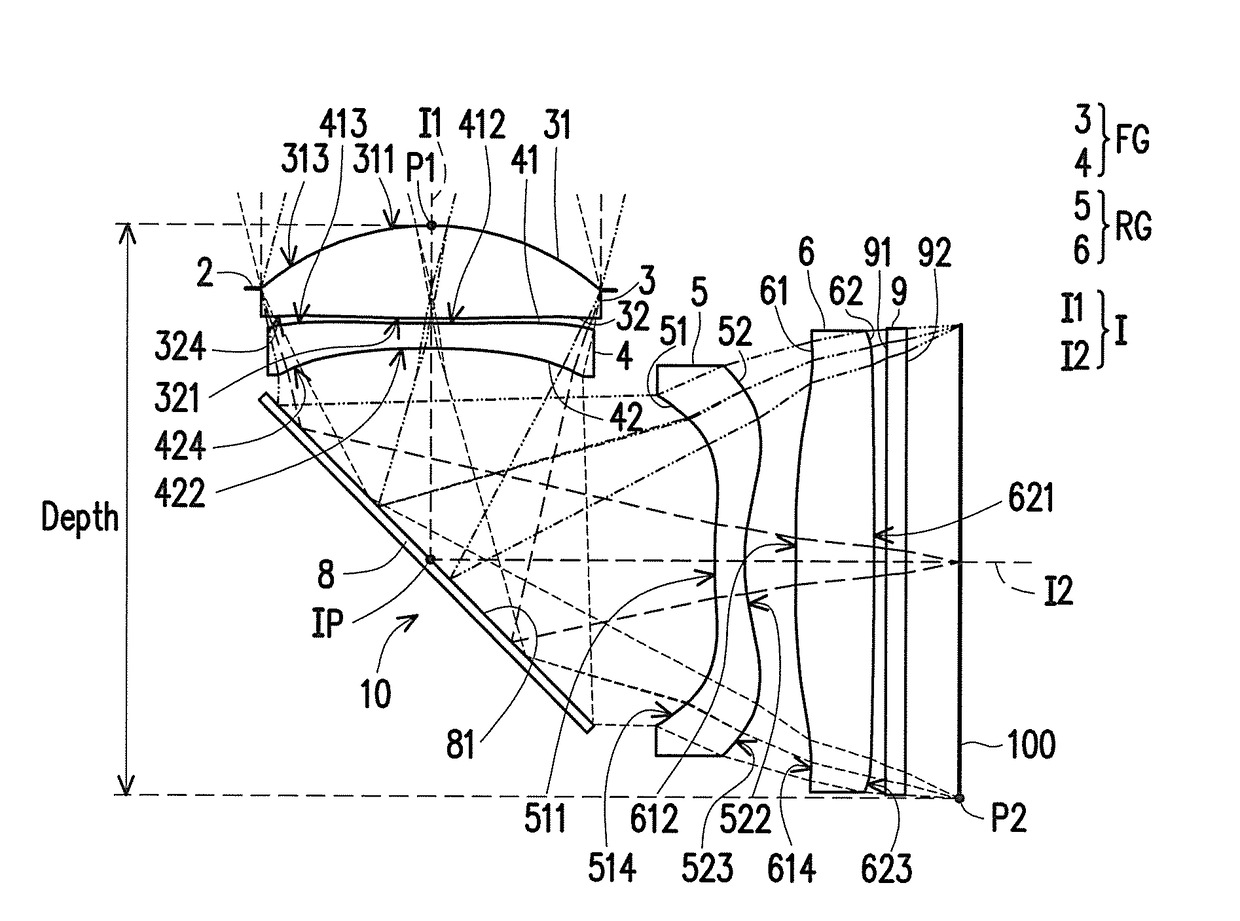

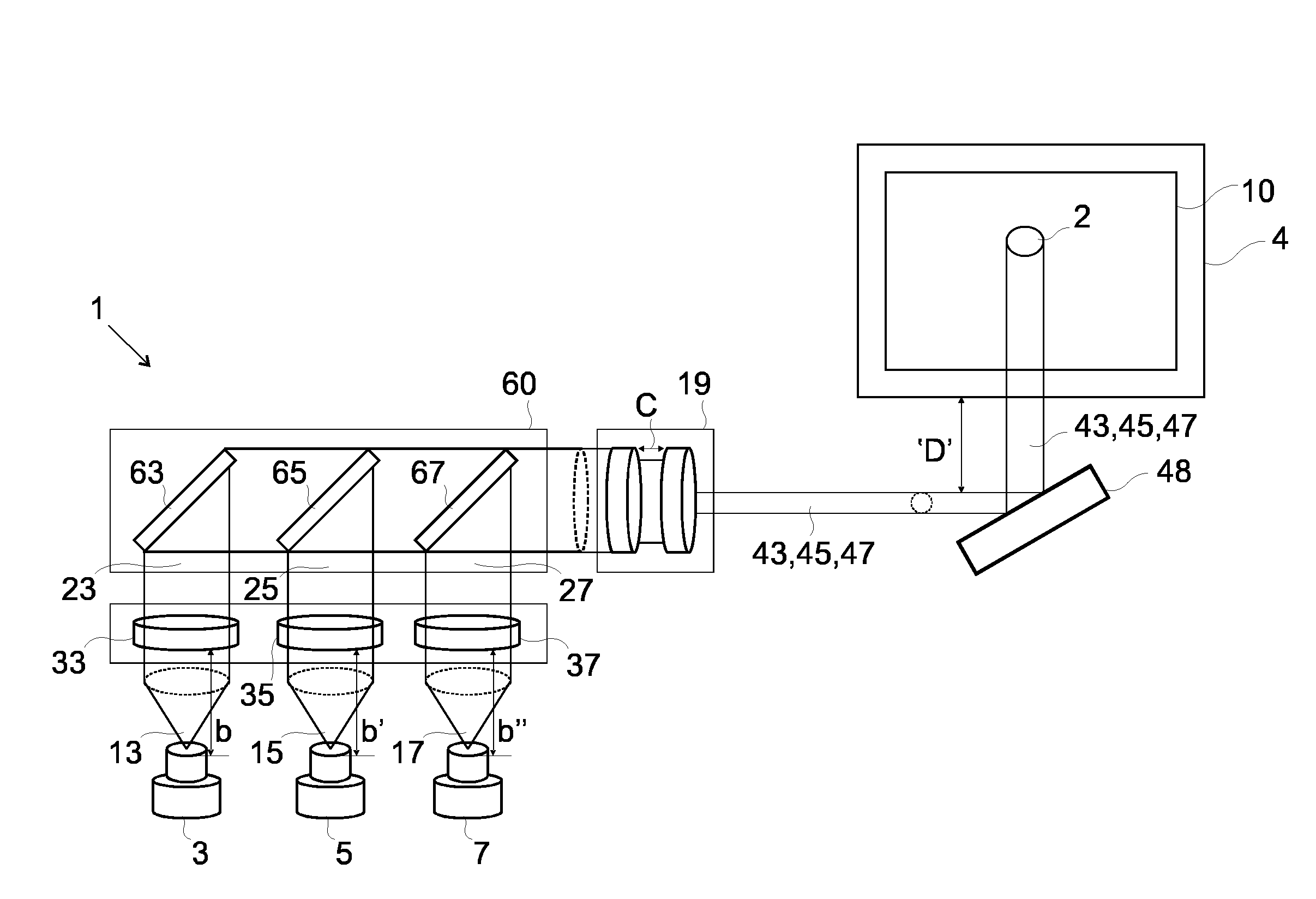

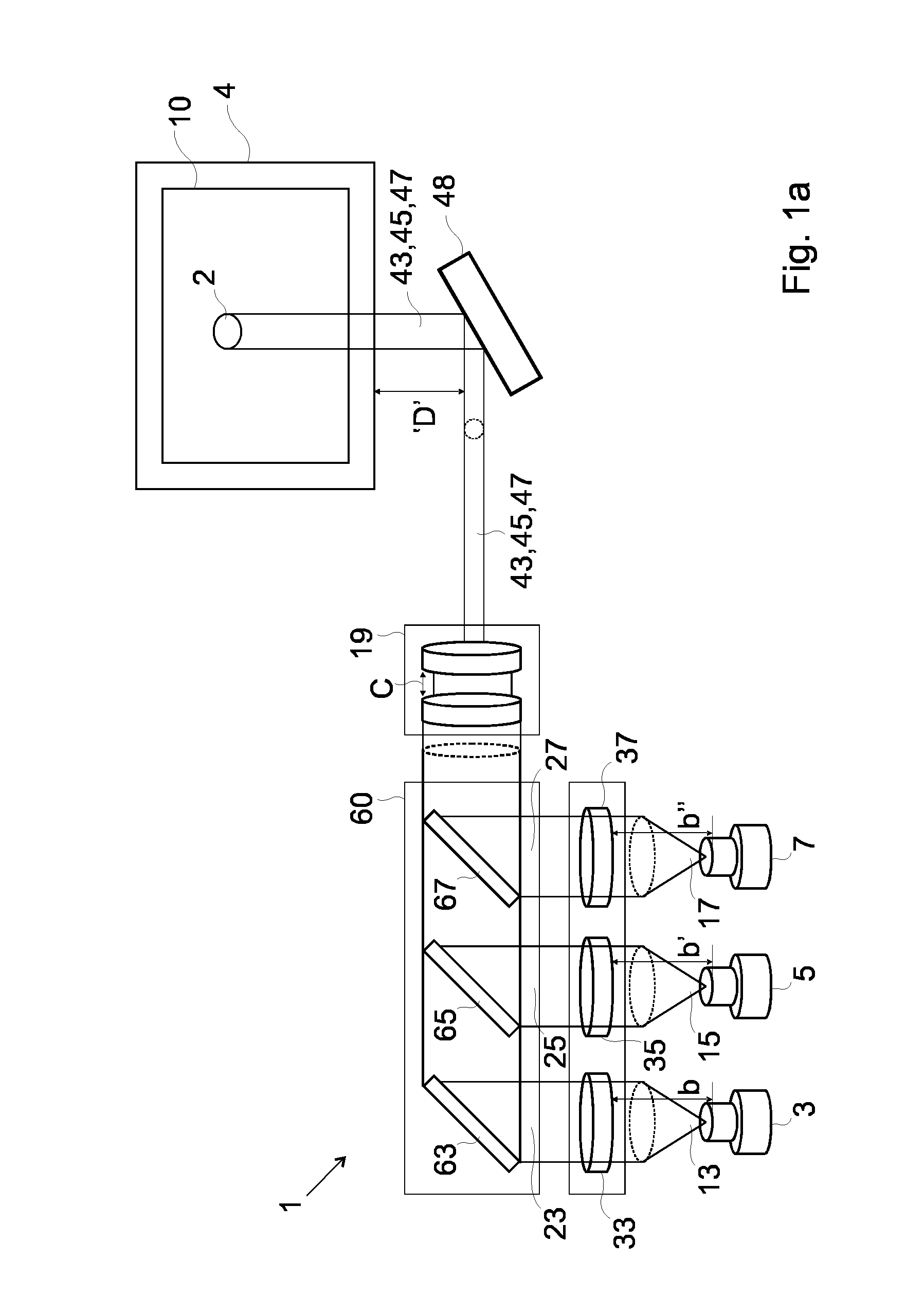

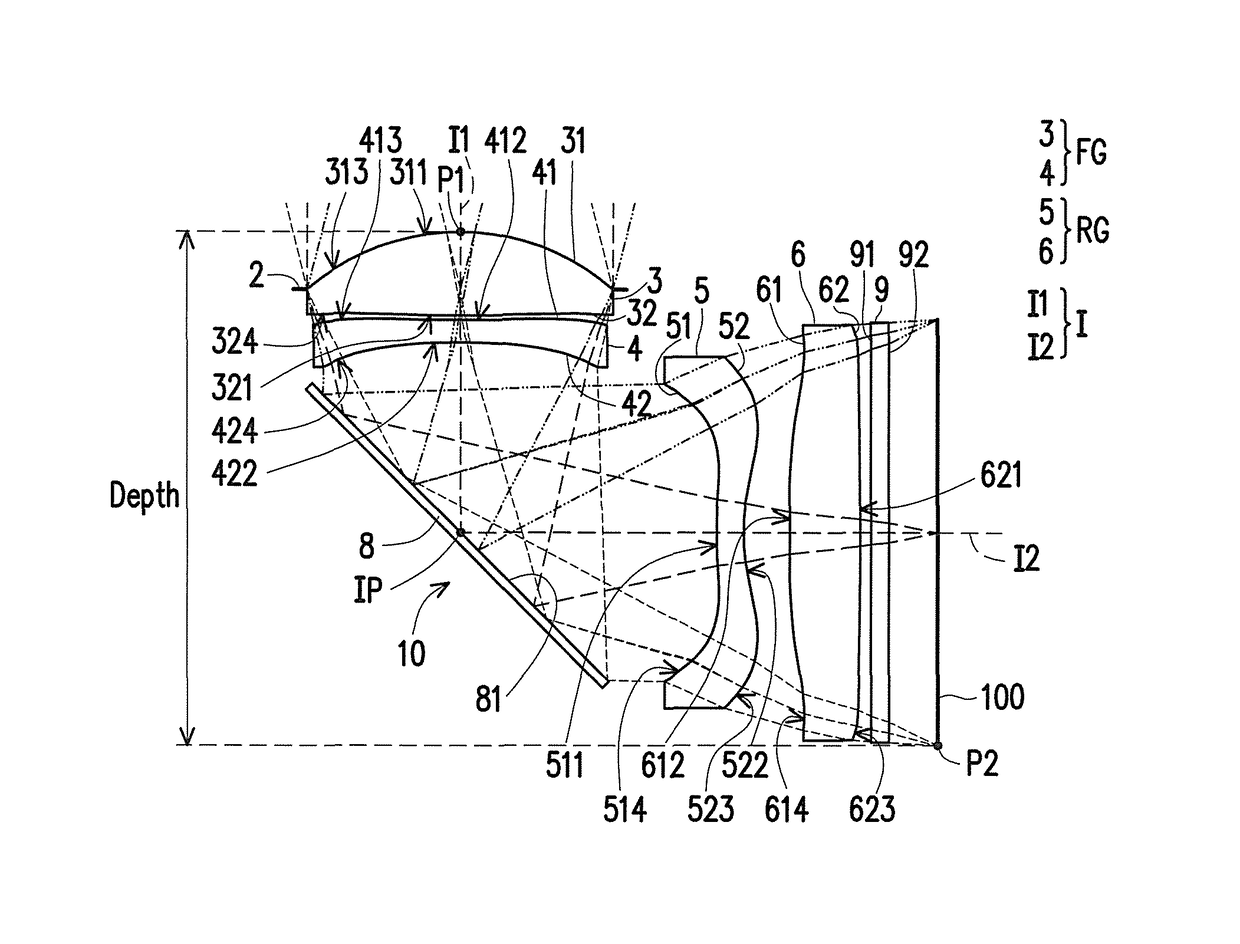

Projection device

InactiveUS20150286121A1Shorten system lengthAvoid excessive lightLine/current collector detailsProjectorsRegulators (device)Light source

A projection device comprising, a red light source, a green light source, and a blue light source which can emit red, green and blue light respectively, a beam combiner which is configured such that it can combine light beams; a means for collimating the light emitted from the red, green and blue light sources to provide red, green and blue collimated light beams, an optical modifier means, which is arranged such that the optical modifier means can receive the red, green and blue collimated light beams, and wherein the optical modifier means is configured to modify cross sectional dimensions of the red, green and blue collimated light beams to provide red, green and blue projection beams each of which has a circular cross section, and wherein the optical modifier means is configured, and the distances between the light sources and means for collimating are set, such that the dimensions of the circular cross sections of the red, green and blue projection beams are equal at a predetermined distance from the projection device such that the spot sizes of each of the red, green and blue projection beams are equal or have predefined sport sizes at the predetermined distance from the projection device; MEMS mirror which is configured such that it can oscillate about at least one oscillation axis to scan the red, green and blue projection beams across a projection screen which is positioned at the predetermined distance from the projection device.

Owner:GOOGLE LLC

Image capturing optical lens system

Owner:LARGAN PRECISION

Image capturing lens system

This invention provides an image capturing lens system in order from an object side to an image side comprising four non-cemented lens elements with refractive power: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power having a concave image-side surface; a plastic third lens element having a concave object-side surface and a convex image-side surface, both the object-side and image-side surfaces thereof being aspheric; and a plastic fourth lens element with negative refractive power having a concave image-side surface, both the object-side and image-side surfaces thereof being aspheric, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein the image capturing lens system comprises a stop positioned between the first lens element and the second lens element.

Owner:LARGAN PRECISION

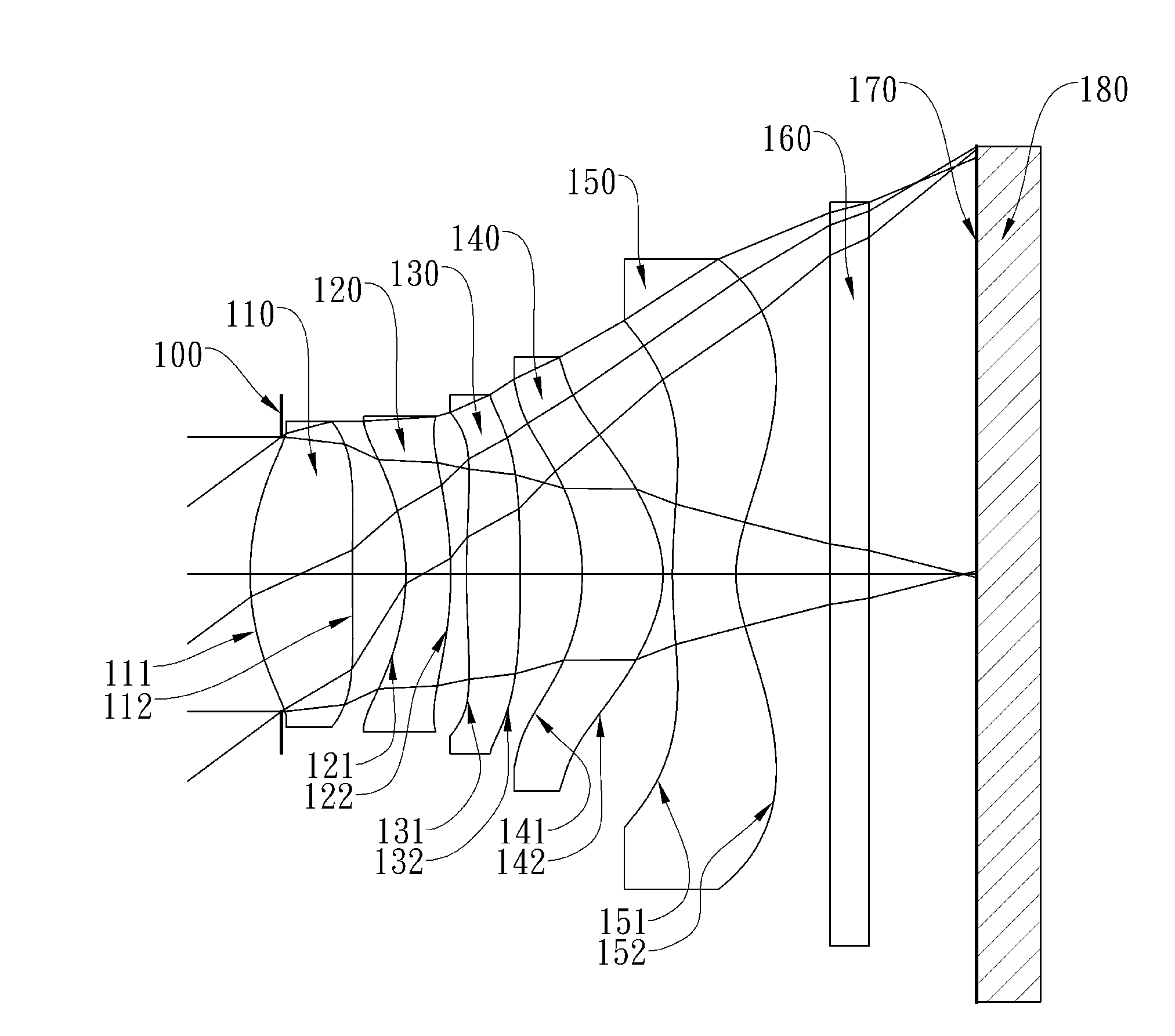

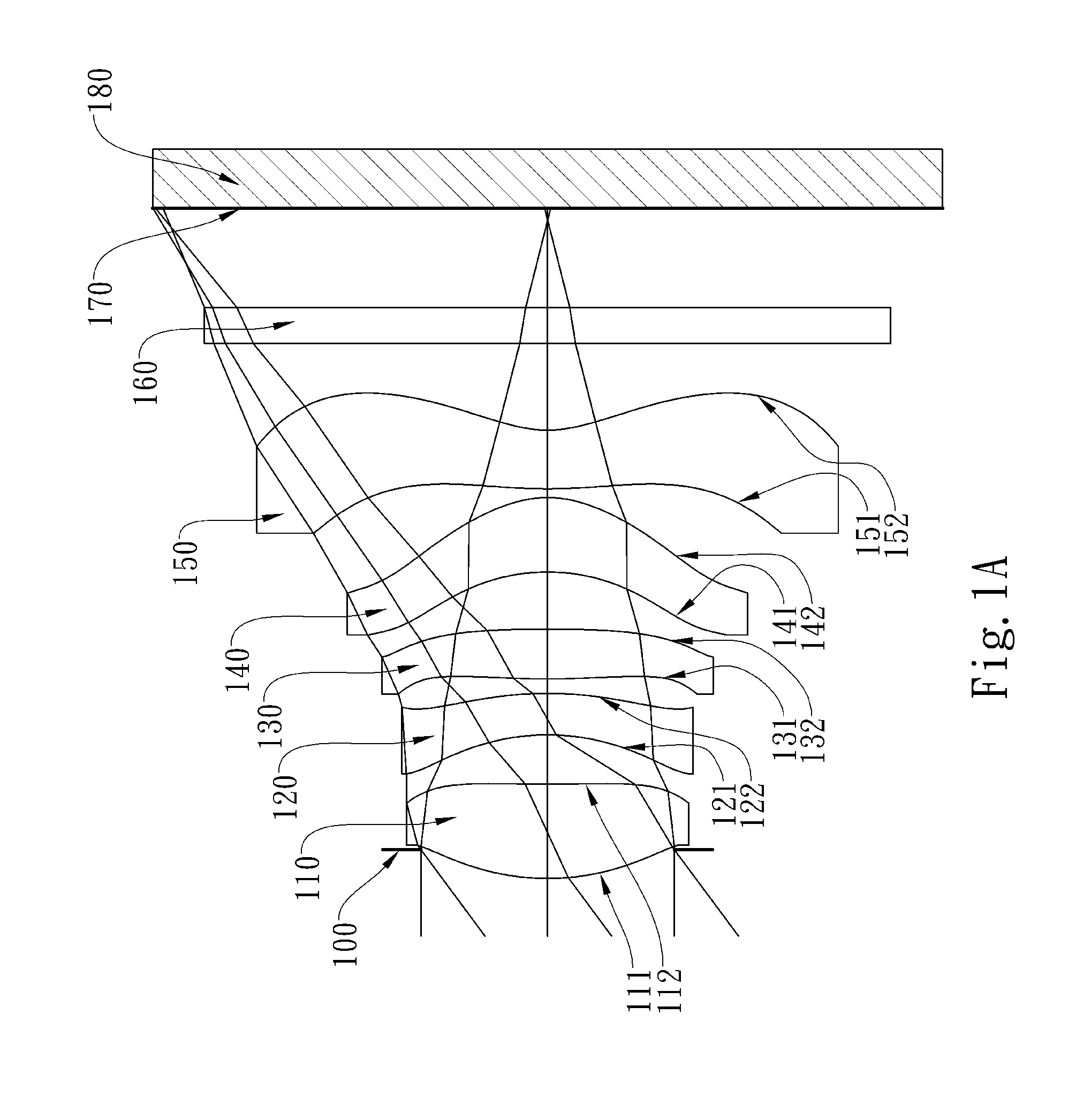

Optical imaging lens

ActiveUS20190204557A1Improve image qualityShorten lens lengthOptical elementsCamera lensOptical axis

An optical imaging lens includes a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element, a seventh lens element, and an eighth lens element from an object side to an image side in order along an optical axis. The first lens element to the eighth lens element each include an object-side surface facing the object side and an image-side surface facing the image side. The second lens element has negative refracting power. The optical axis region of the image-side surface of the third lens element is concave. The optical axis region of the object-side surface of the fourth lens element is concave. The periphery region of the image-side surface of the fourth lens element is convex. The periphery region of the object-side surface of the sixth lens element is concave.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Optical lens system

This invention provides an optical lens system comprising: a first lens element with negative refractive power having a convex object-side surface; a second lens element with negative refractive power having a concave object-side surface and a convex image-side surface; a third lens element with positive refractive power; a plastic fourth lens element with negative refractive power having a concave object-side surface and a convex image-side surface, with both the object-side and image-side surfaces thereof being aspheric, and having at least one inflection point positioned on at least one of the object-side and image-side surfaces thereof; wherein the number of lens elements with refractive power is limited to four. By such arrangement, especially by the first and the second lens elements with negative refractive power, the system has sufficient back focal length for arranging required optical elements, and thereby is suitable for various applications.

Owner:LARGAN PRECISION

Optical imaging lens

ActiveUS20200003992A1Shorten system lengthEnsure qualityOptical elementsOphthalmologyImaging quality

An optical imaging lens includes a first lens element to a seventh lens element. The first lens element, the fifth lens element and the sixth lens element are made of plastic. The optical axis region of the image-side surface of the second lens element is convex, the optical axis region of the image-side surface of the third lens element is convex, the optical axis region of the object-side surface of the fourth lens element is convex and the optical axis region of the image-side surface of the seventh lens element is concave to satisfy (T5+G56+T6) / (G23+T3+G34+T4+G45)≥1.200 by controlling the surface curvatures of each lens element to enlarge HFOV, to reduce the system length and to have good imaging quality.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Image capturing optical system

Owner:LARGAN PRECISION

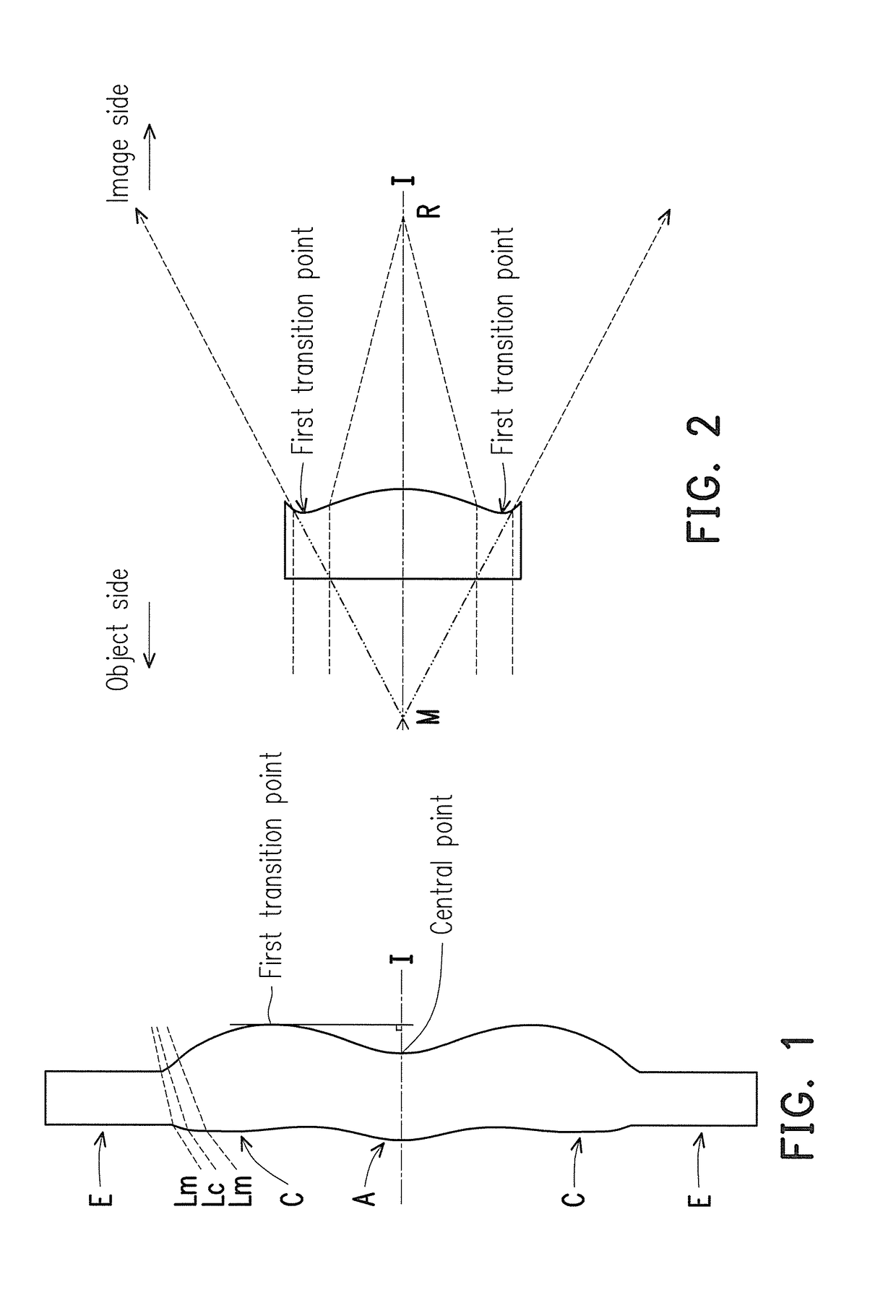

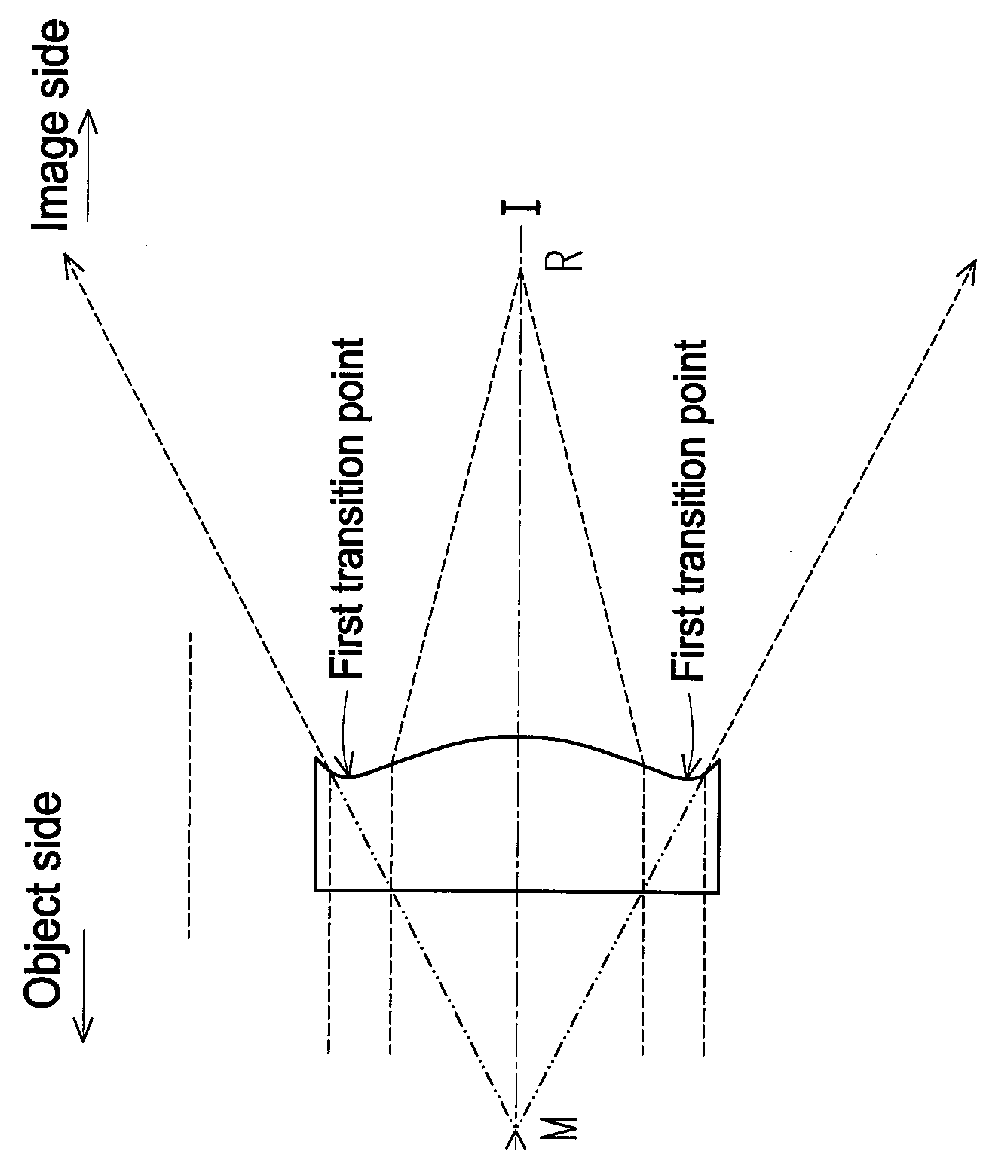

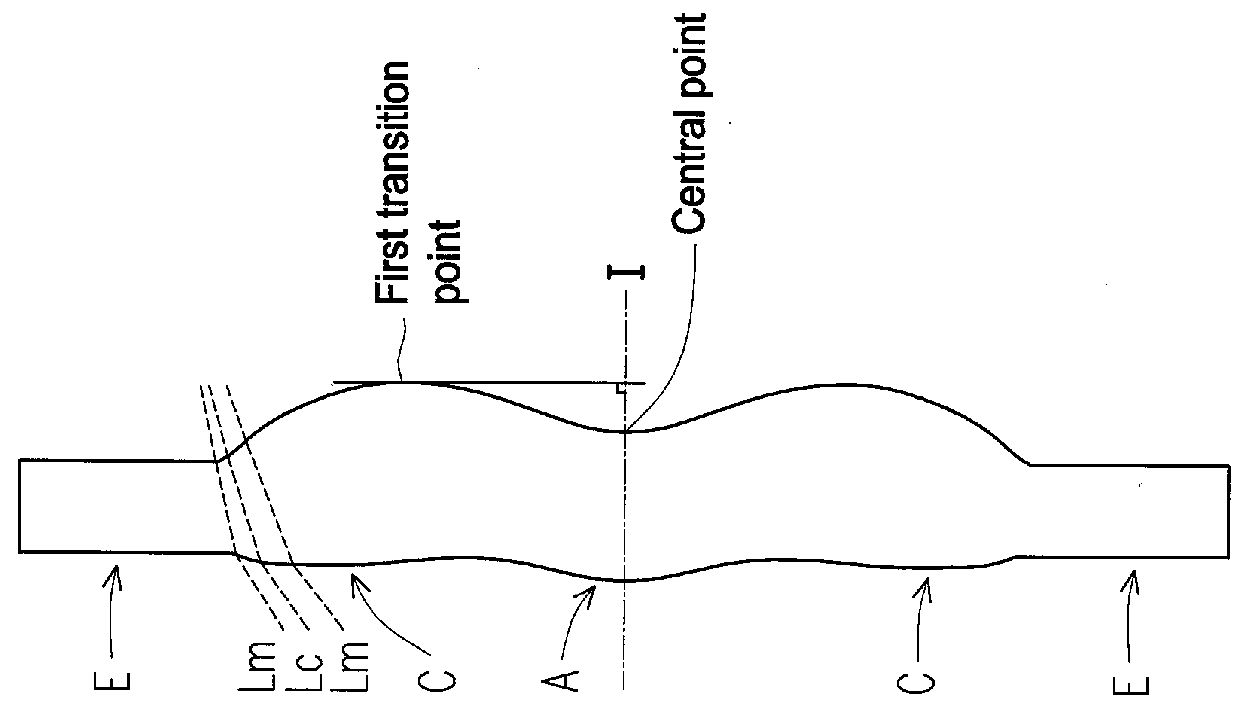

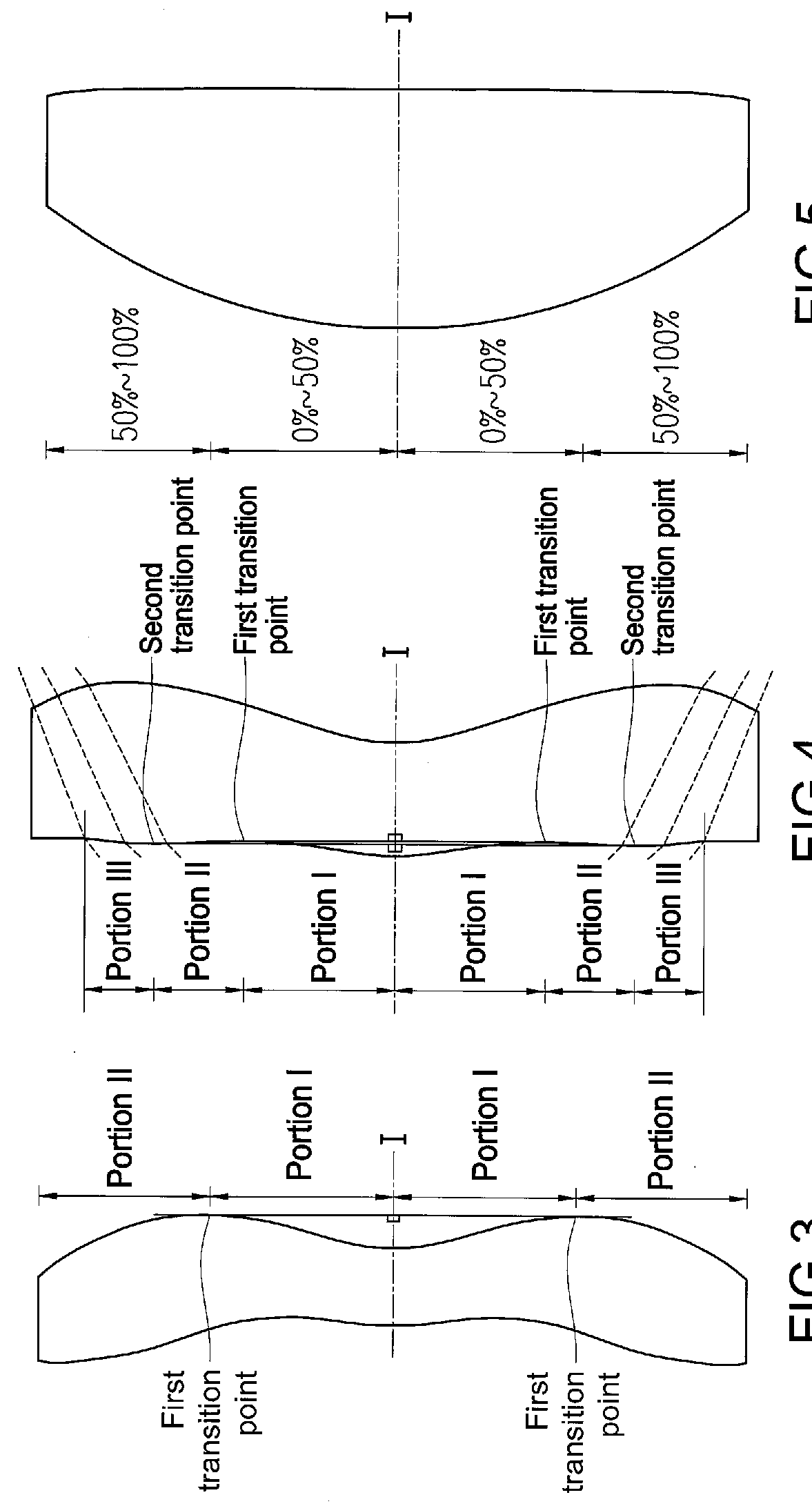

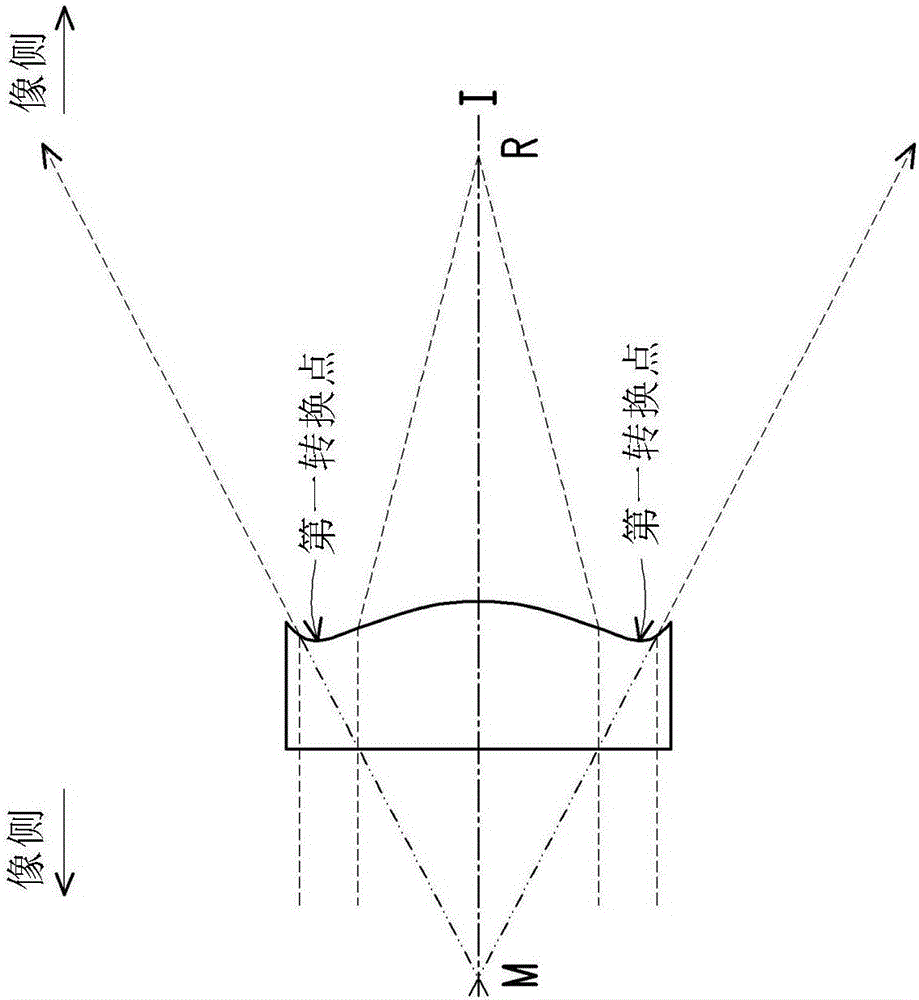

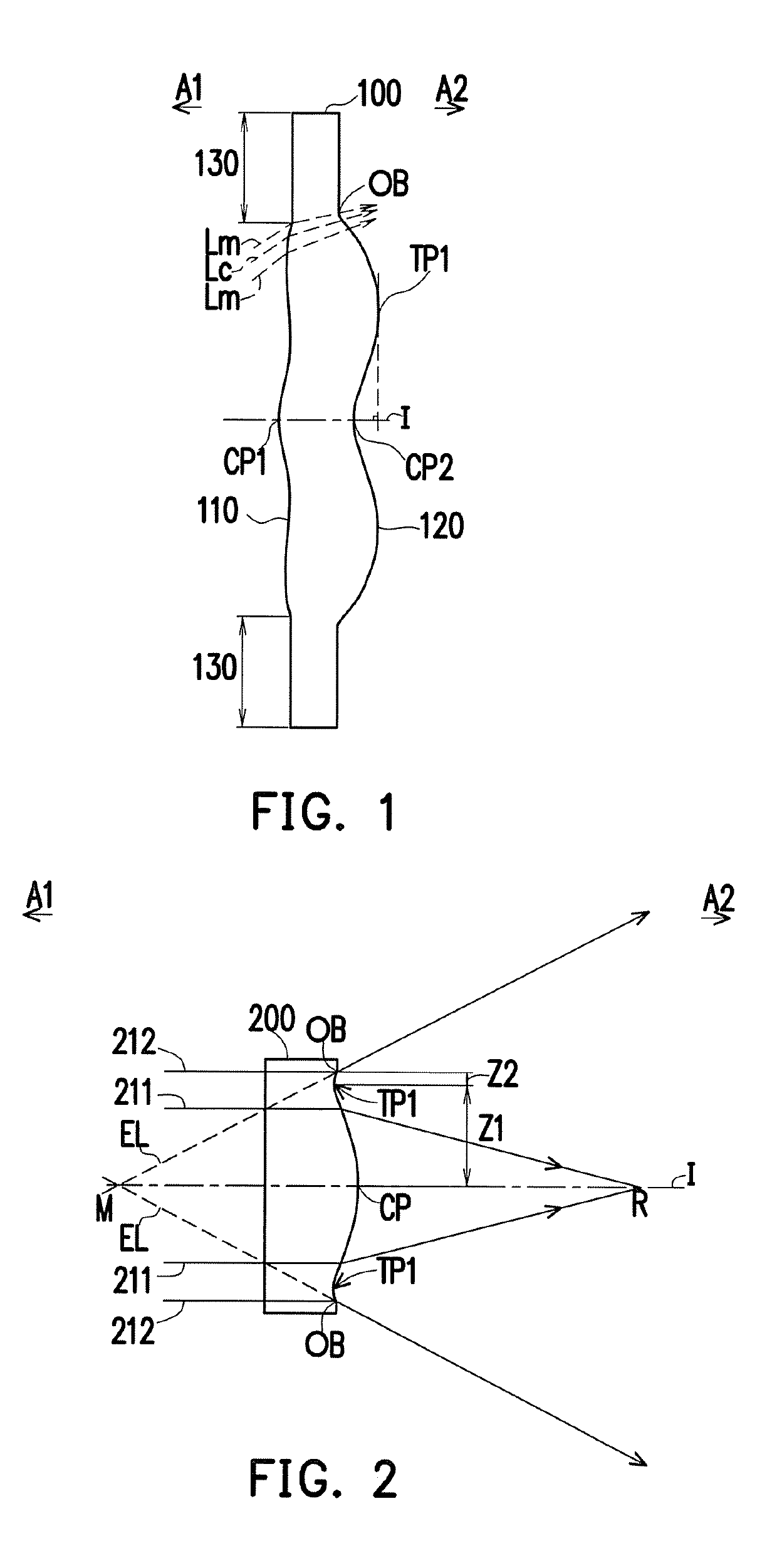

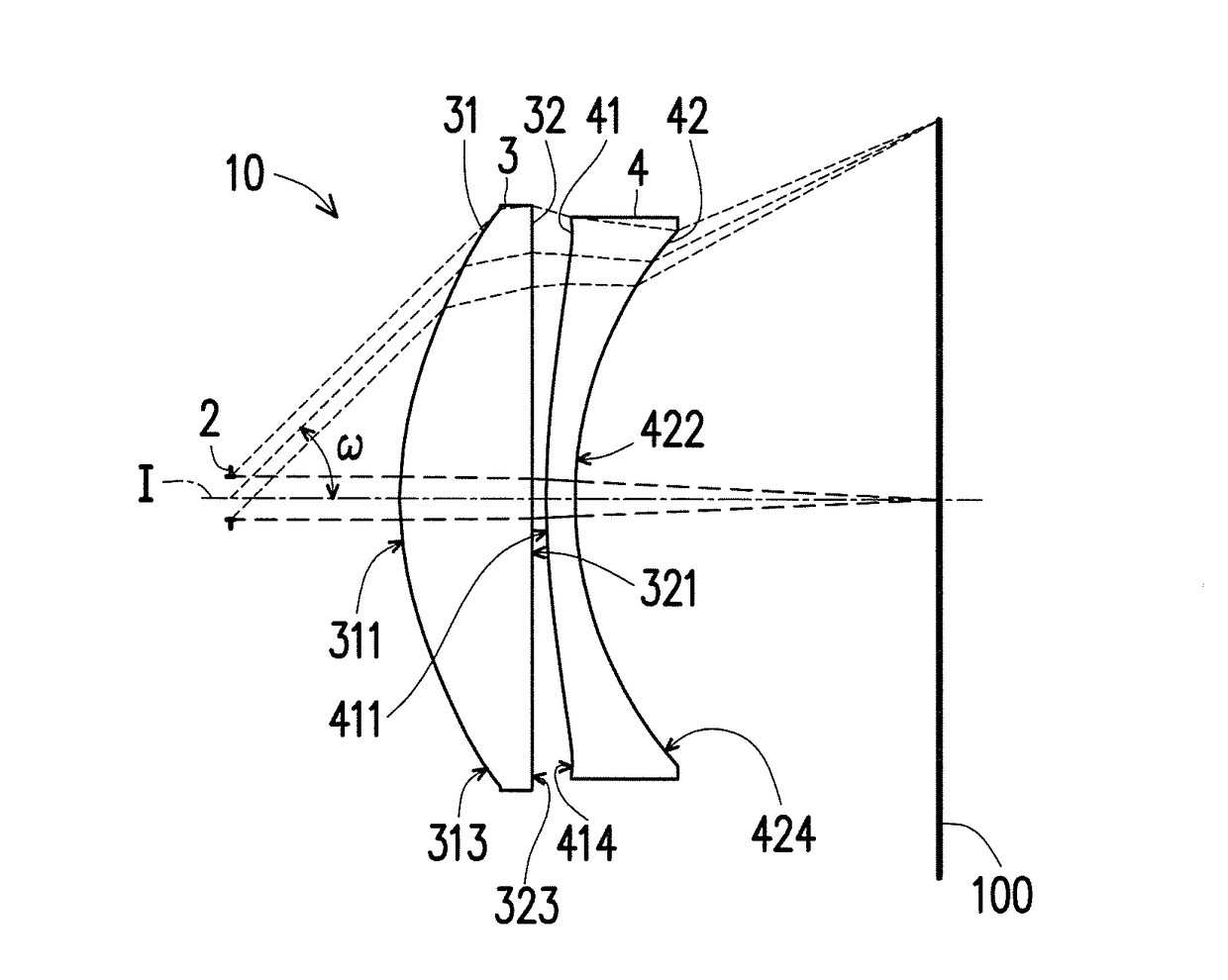

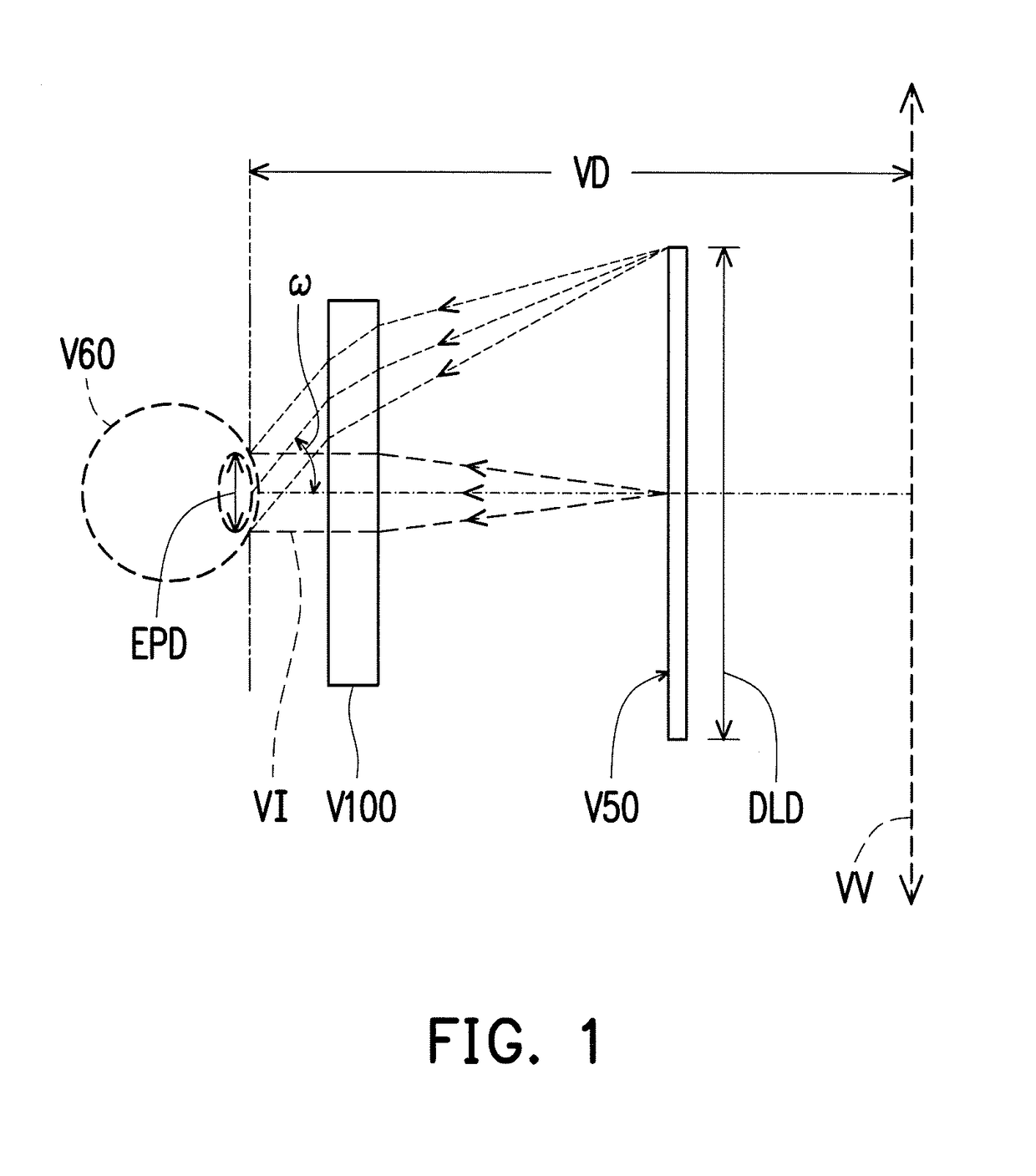

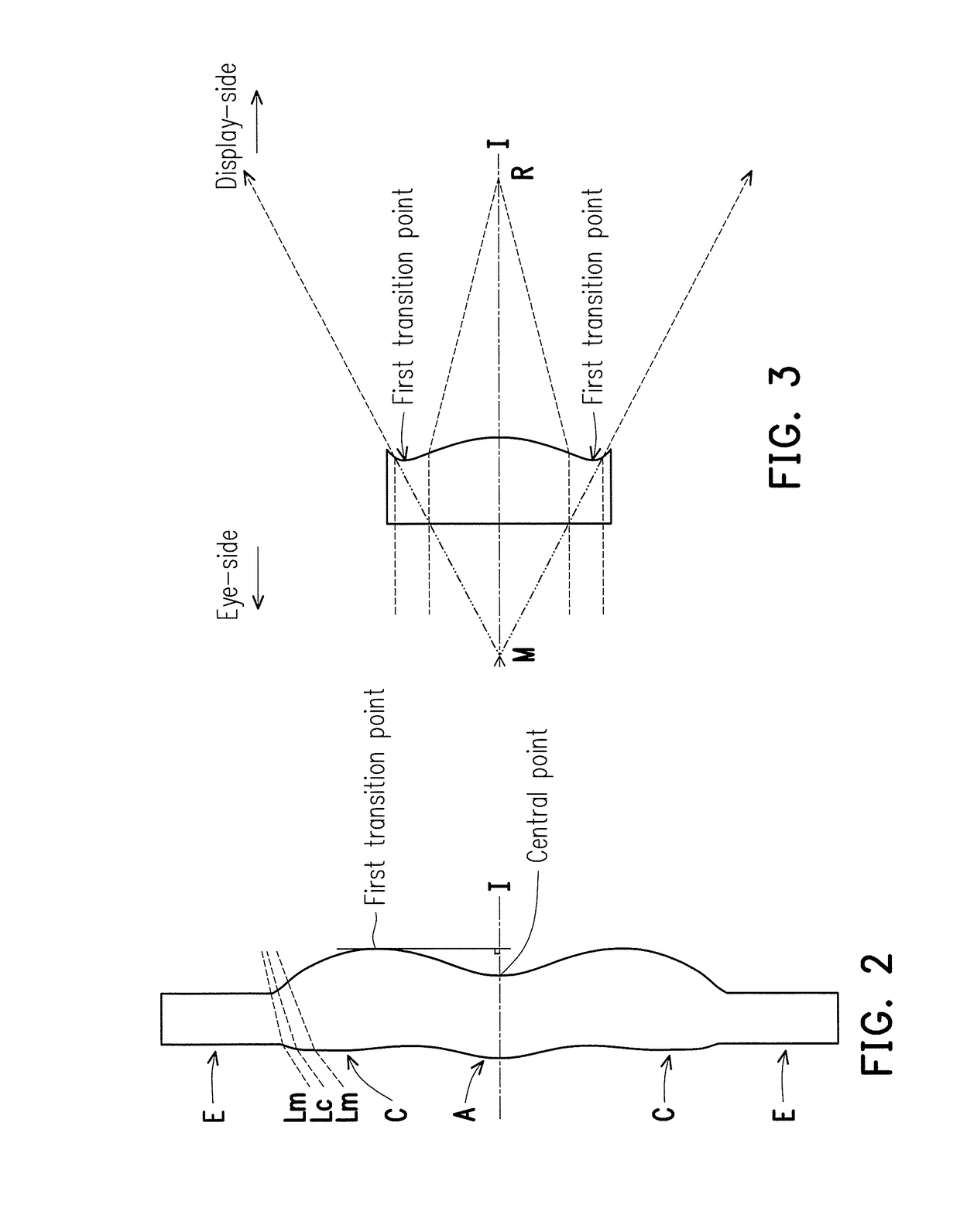

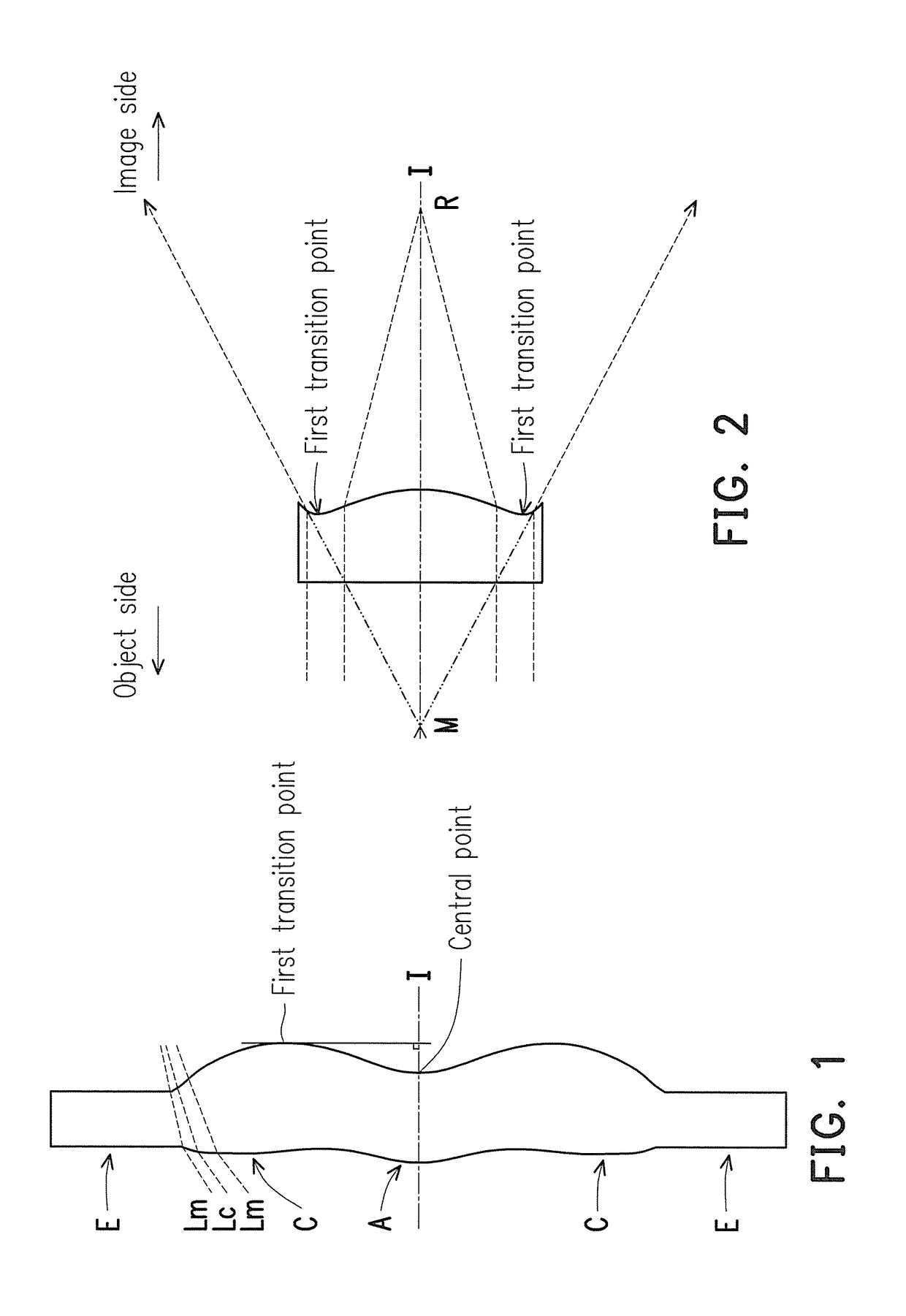

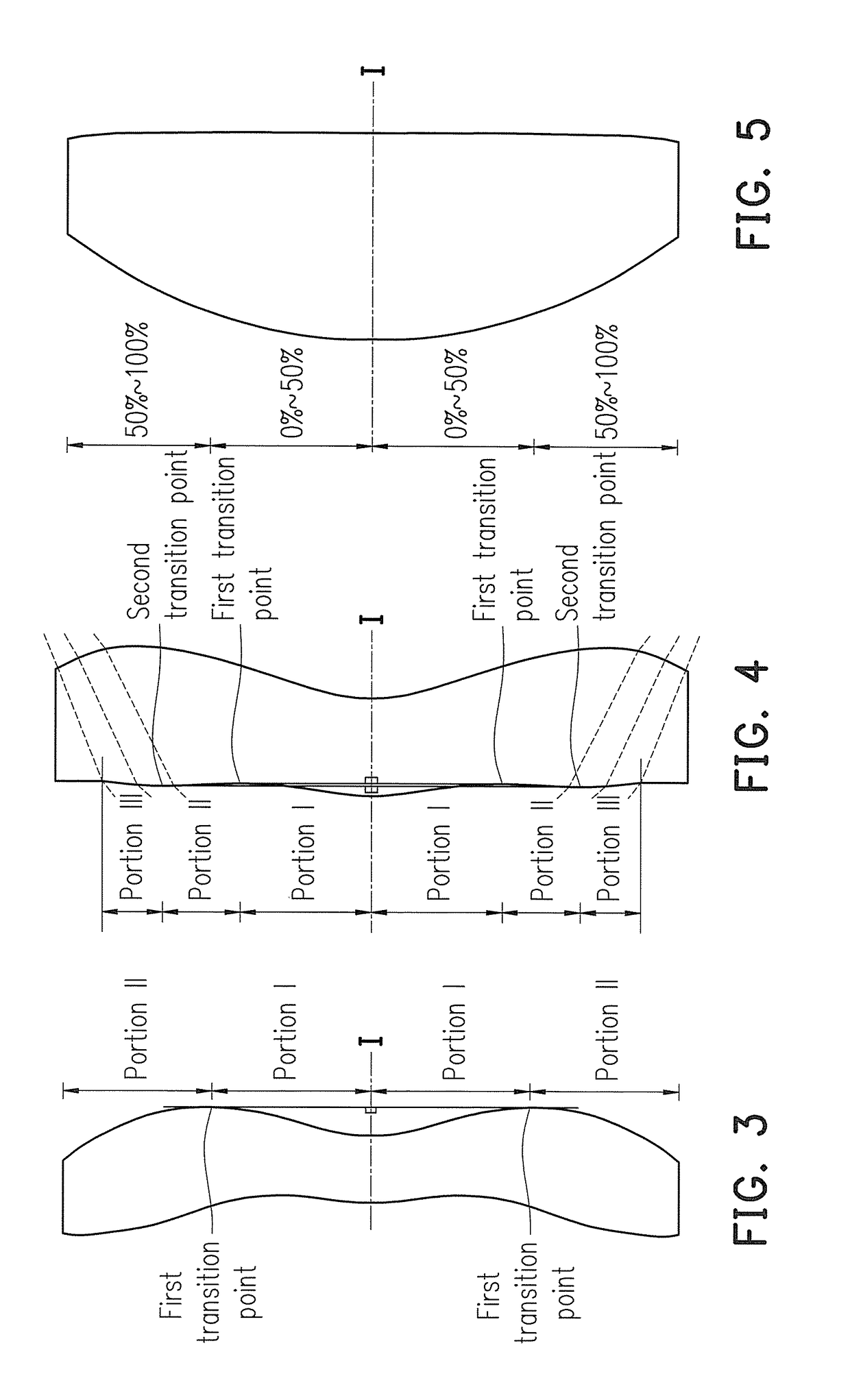

Ocular optical system

ActiveUS20180088313A1Improve image qualityLarge field of viewLensMagnifying glassesEyepieceOptical axis

An ocular optical system includes a first lens element and a second lens element from an eye-side to a display-side in order along an optical axis. The first lens element and the second lens element each include an eye-side surface and a display-side surface. The eye-side surface of the first lens element has a convex portion in a vicinity of the optical axis. The second lens element has negative refracting power. The ocular optical system satisfies 1.5≦|f2 / f1| and 250 millimeters / EFL≦10, wherein f2 is the focal length of the second lens element, fl is the focal length of the first lens element, and EFL is the effective focal length of the ocular optical system.

Owner:GENIUS ELECTRONICS OPTICAL CO LTD

Image capturing lens system

Owner:LARGAN PRECISION

Image lens system

Owner:LARGAN PRECISION

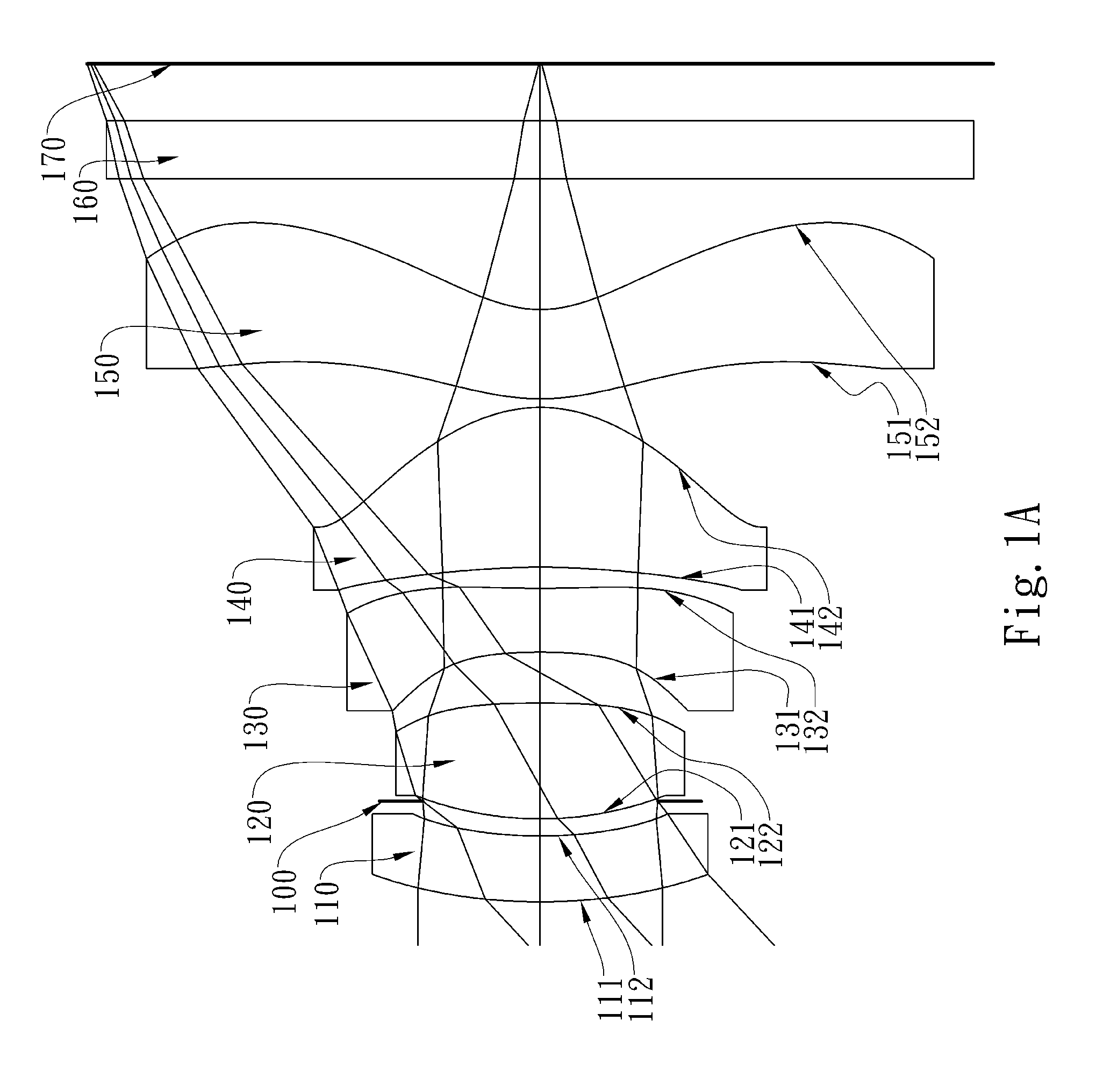

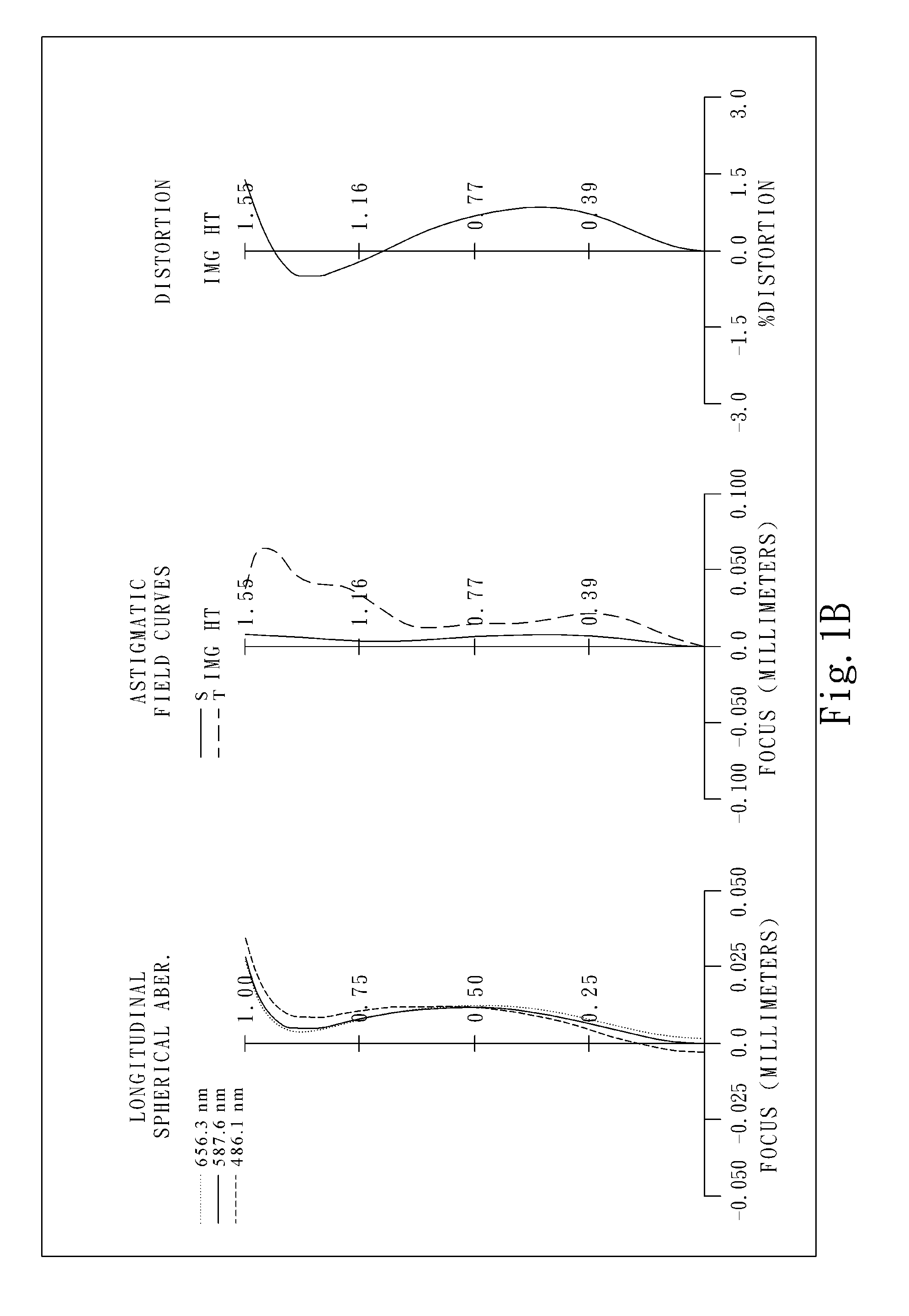

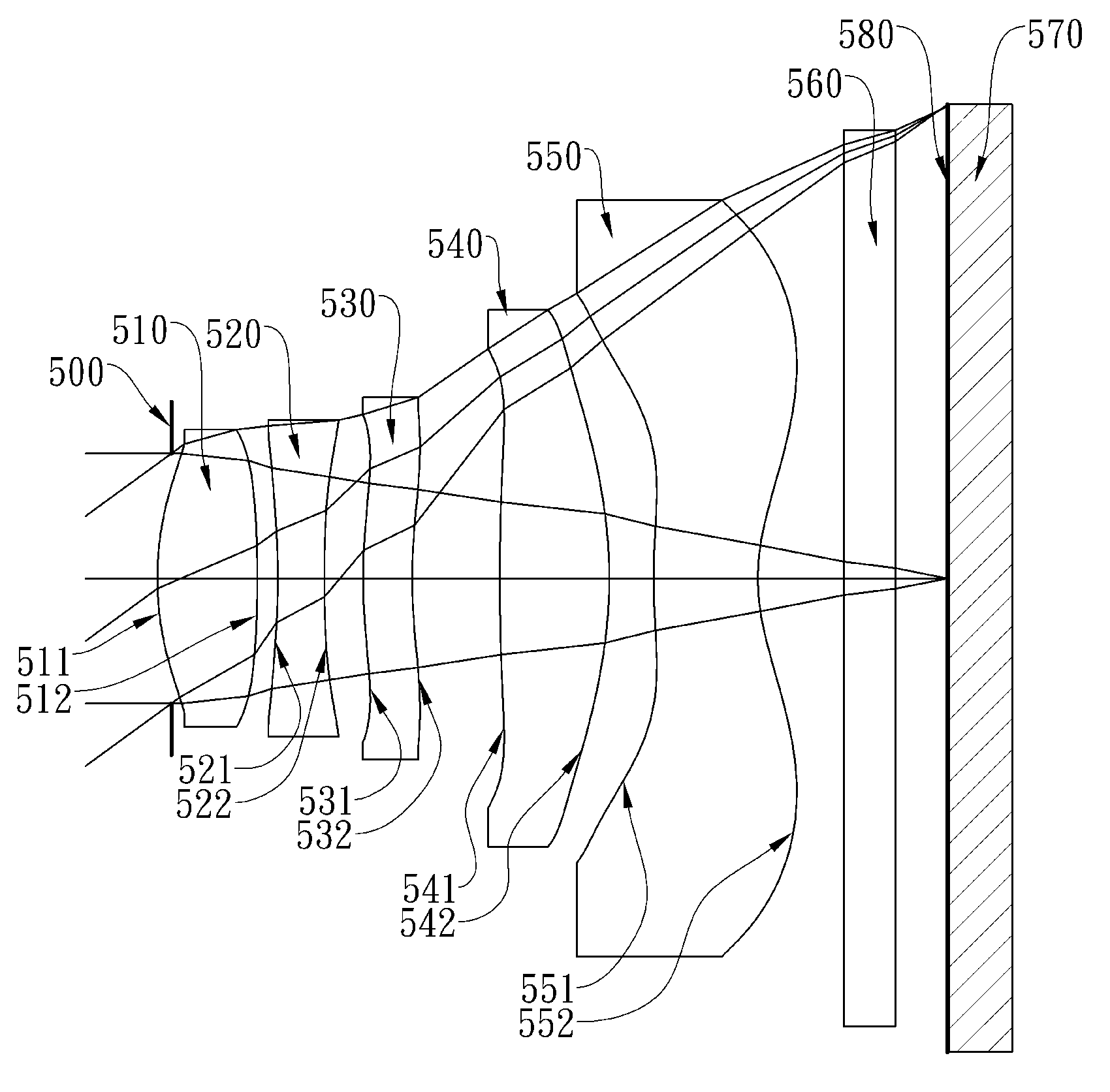

Optical imaging lens

ActiveUS9897780B1Good optical performanceShorten system lengthOptical elementsCamera lensOptical axis

An optical imaging lens includes a first lens element, a second lens element, a third lens element, and a fourth lens element from an object side to an image side in order along an optical axis. The first lens element to the fourth lens element each include an object-side surface and an image-side surface. The first lens element has positive refracting power. The second lens element has negative refracting power. At least one of the object-side surface and the image-side surface of the third lens element is an aspheric surface. At least one of the object-side surface and the image-side surface of the fourth lens element is an aspheric surface. A maximum distance between the image-side surface of the first lens element and the object-side surface of the second lens element in a direction parallel to the optical axis is less than 0.2 mm.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Optical lens set

ActiveUS20180059371A1Shorten system lengthSufficient optical performanceOptical filtersCamera lensOptical axis

An optical lens assembly includes a first lens of a concave image surface near its periphery, a second lens of a plastic material, a third lens of a concave object surface near the optical-axis and a concave image surface near its periphery, a fourth lens of a concave object surface near the optical-axis, a fifth lens of a concave object surface near its periphery and a convex image surface near the optical-axis.

Owner:GENIUS ELECTRONICS OPTICAL XIAMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com