Electrical connectors and electrical connector assemblies

An electrical connector and connector technology, applied in the direction of two-part connection device, connection, circuit, etc., can solve the problems of low height of electrical connectors, damage strength, workability of fitting reliability, difficult terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in all the drawings for describing the embodiments, the same members are given the same reference numerals in principle, and repeated description thereof will be omitted. In addition, in the following embodiments, when referring to the number of elements (including number, numerical value, amount, range, etc.), except for the case where it is particularly clearly stated and the case where it is clearly limited to a specific number in principle, etc. , is not limited to this specific number, and may be above or below a specific number.

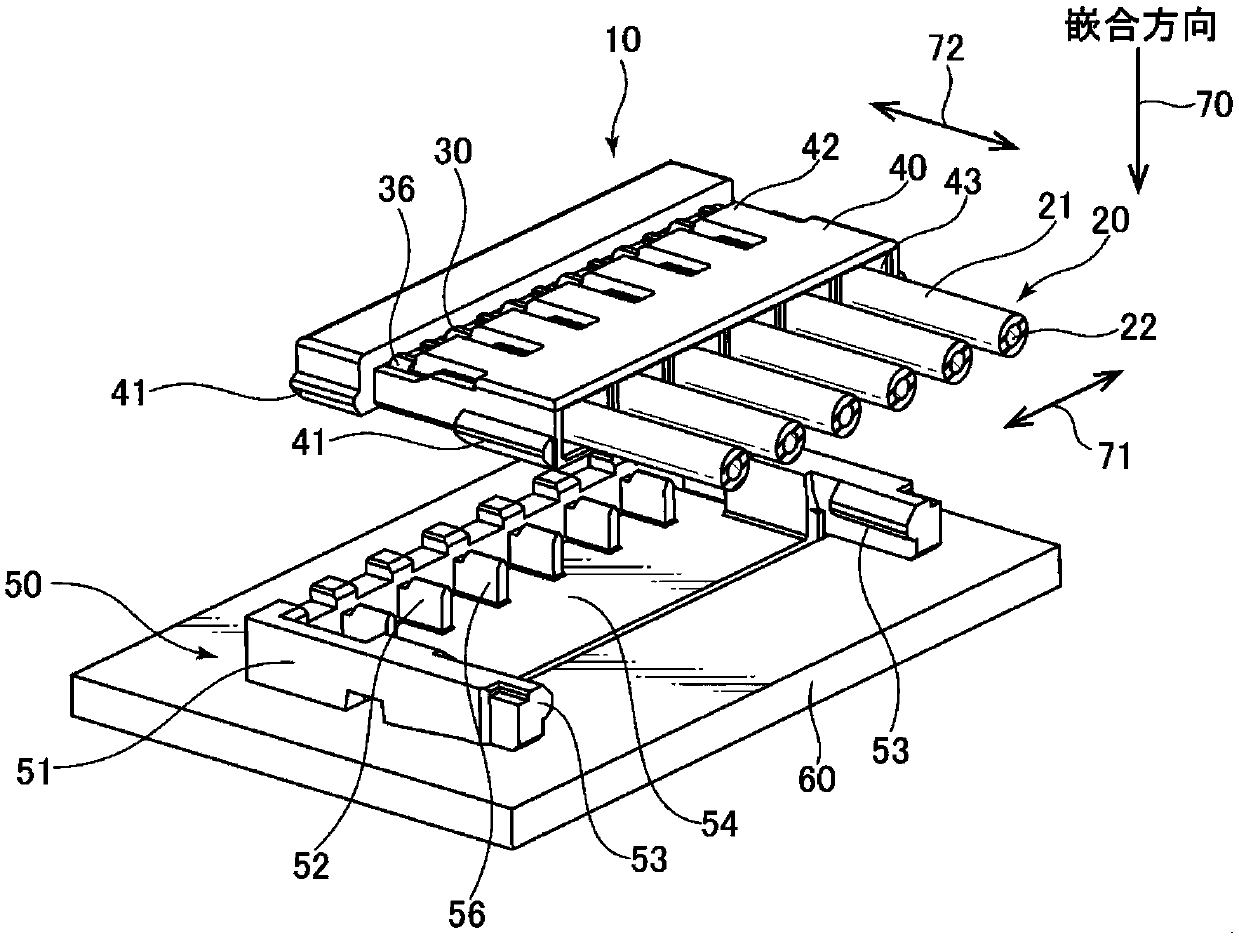

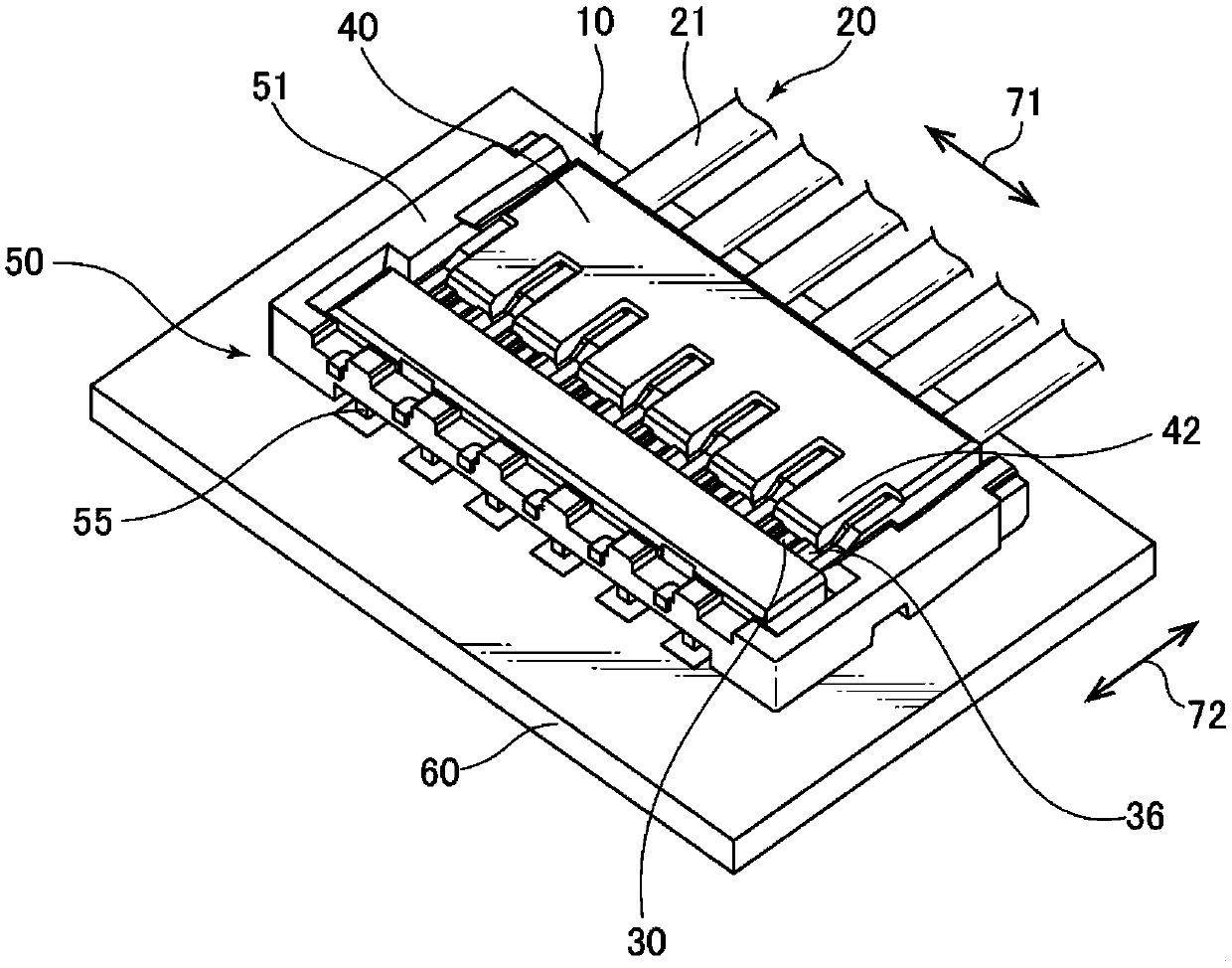

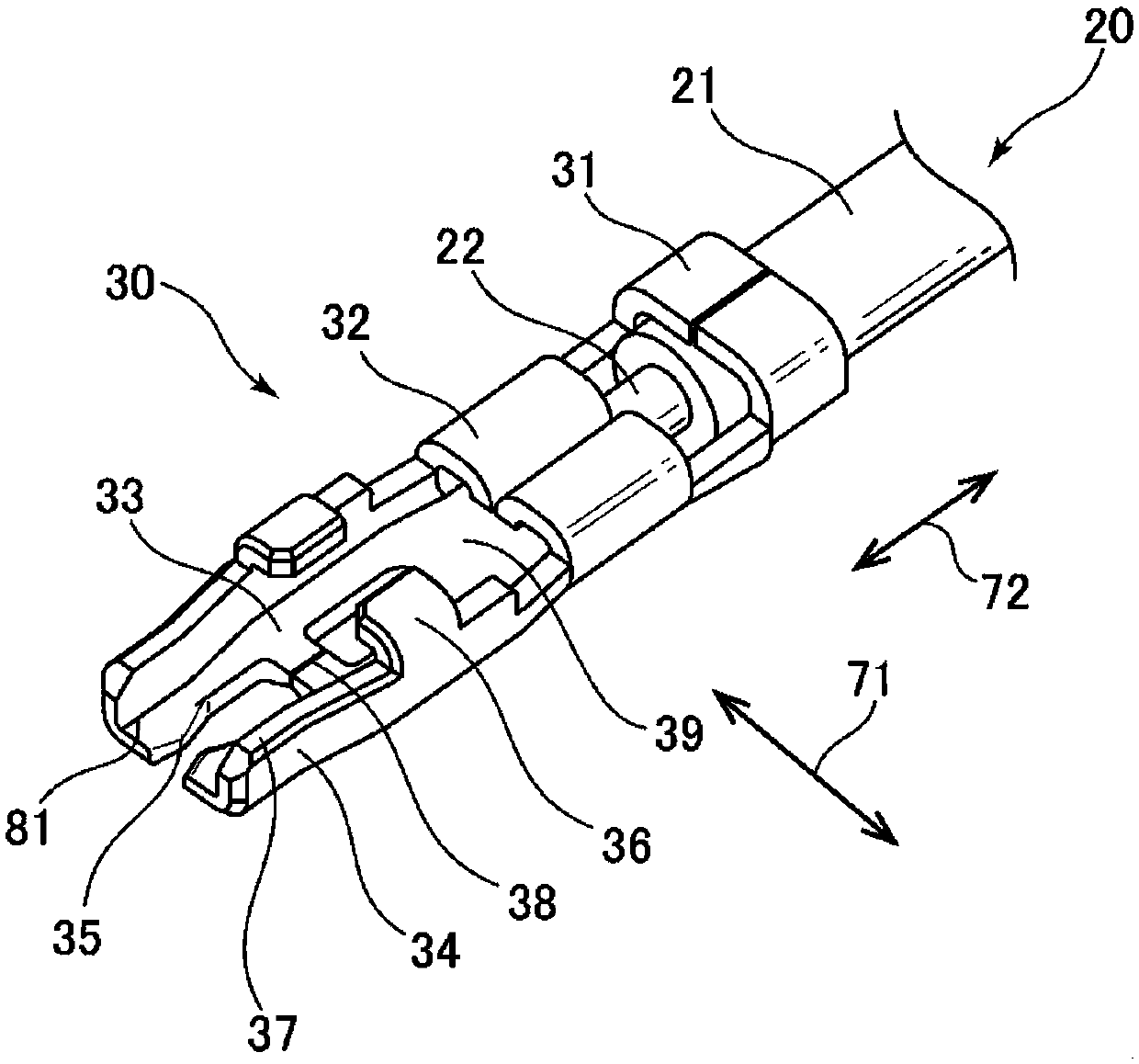

[0057] figure 1 It is a perspective view showing the appearance before fitting of the cable-side connector and the board-side connector according to one embodiment of the present invention. figure 2 It is a perspective view showing the external appearance after fitting of the cable-side connector and the board-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com