Direct push plate flow regulating damping cylinder for intelligent knee joint

A flow regulation and knee joint technology, applied in the field of hydraulic damping cylinder, can solve the problems of difficult processing, increased power consumption, large volume and weight, etc., to avoid failure to work, reduce complexity, and achieve continuous damping adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

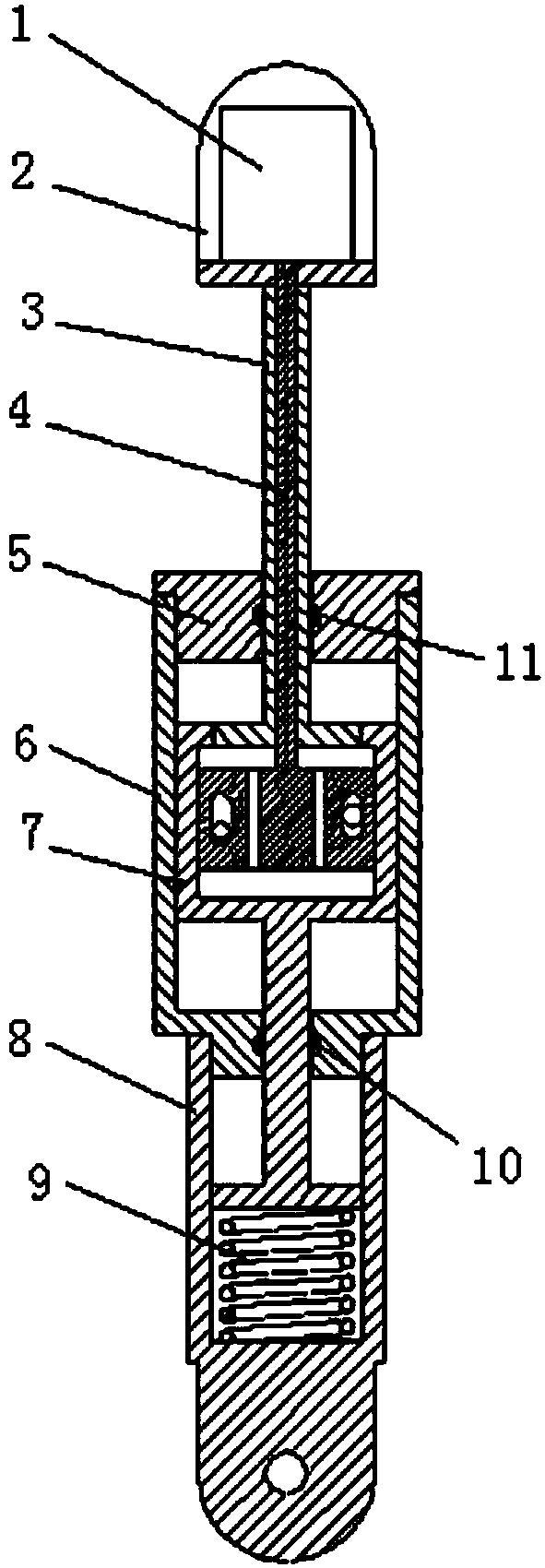

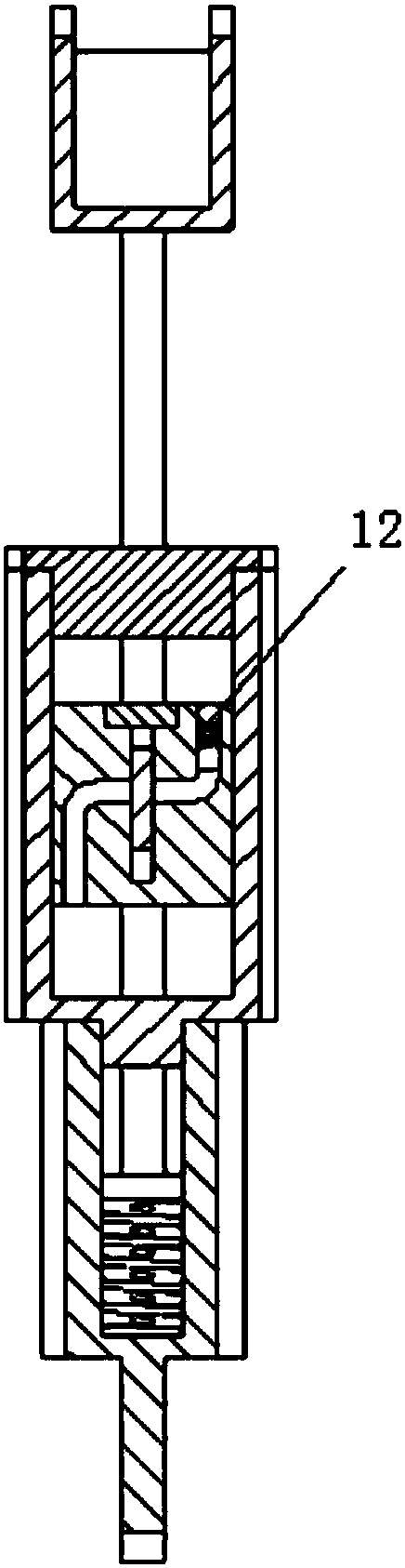

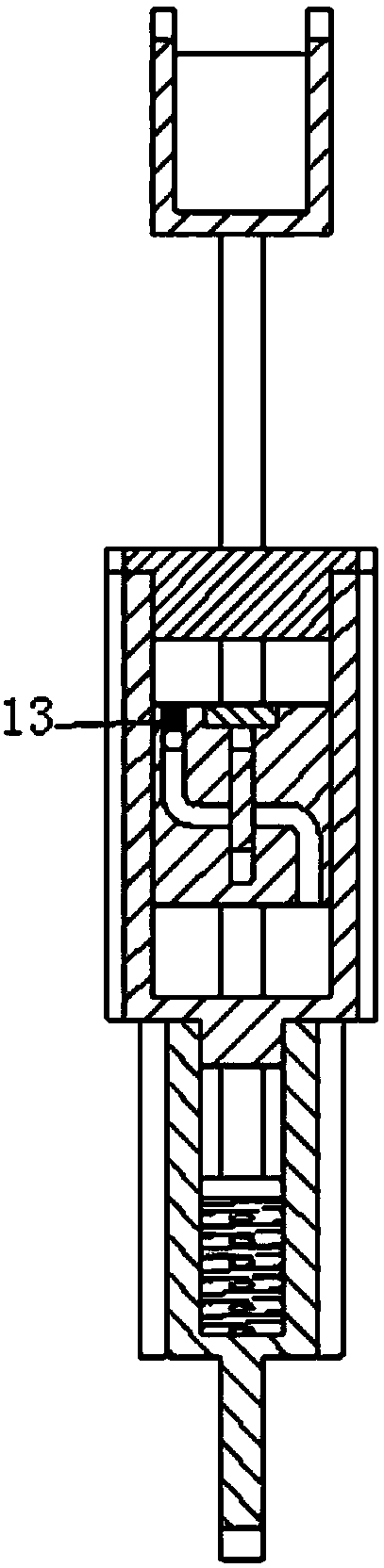

[0021] Such as Figure 1 to Figure 3 As shown, a direct-push plate type flow regulating damping cylinder for intelligent knee joints provided by the present invention includes a linear motor 1, a motor bracket 2, a hollow piston rod 3, a plate valve body 4, a hydraulic cylinder upper cover 5, and a hydraulic cylinder Cylinder body 6, hollow piston block 7, spring case 8, extension spring 9, seal ring A10, seal ring B11, check valve A12, check valve B13.

[0022] One end of the hydraulic cylinder block 6 is fixedly connected to the upper cover 5 by threads, and the other end is fixedly connected to the spring shell 8 by threads. The spring shell 8 is placed with a stretching spring 9, and the hydraulic cylinder block 6 is equipped with a hollow piston block 7 and a hollow piston block 7. One end is connected to the extension spring 9 through the piston rod, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com