A device and method for preparing superfine fiber bundles by melt blown method

A technology of ultra-fine fiber and melt-blown method, which is applied in the field of fiber manufacturing, can solve the problems of low strength, inability to use alone, and inability to use the properties of fiber bundles, etc., to achieve the effect of improving fiber strength and avoiding bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

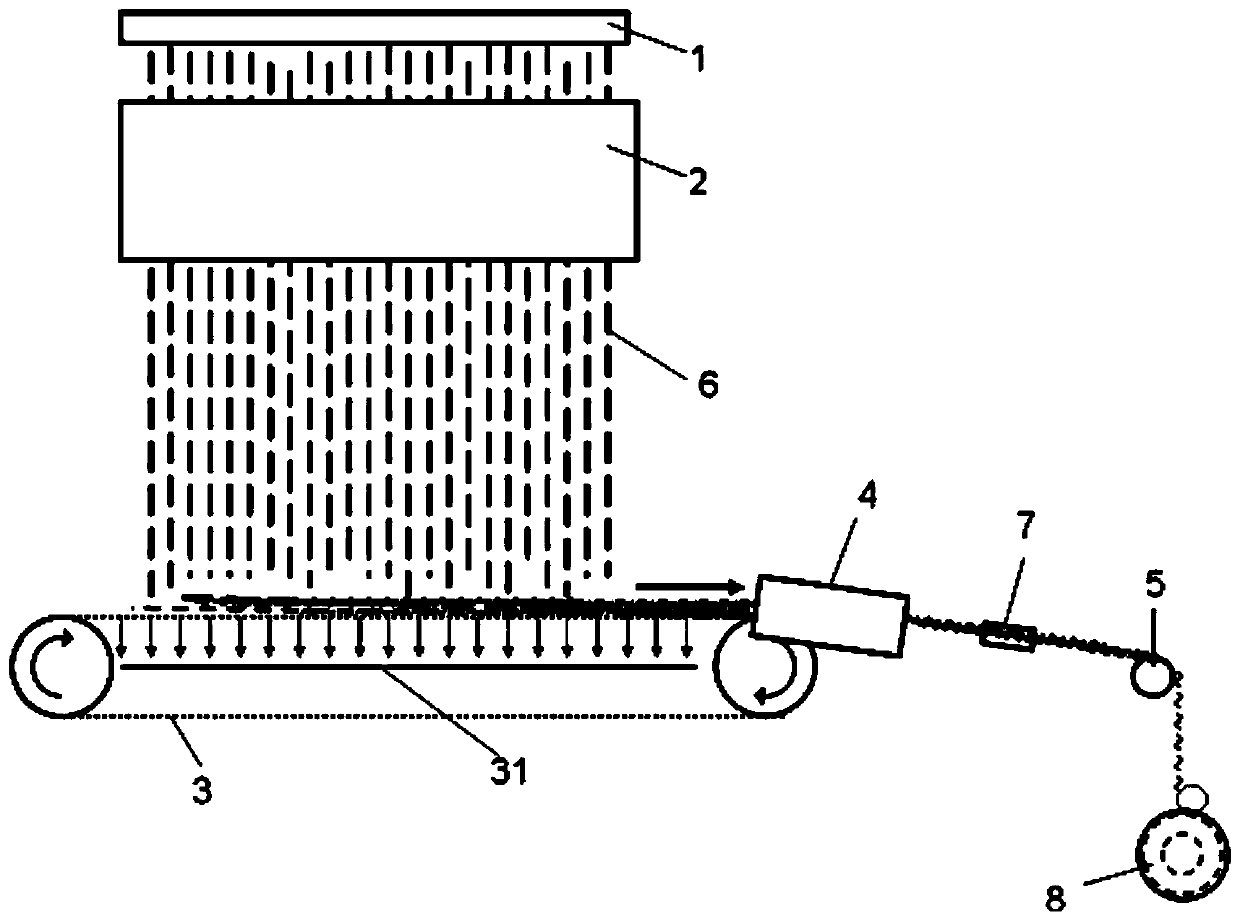

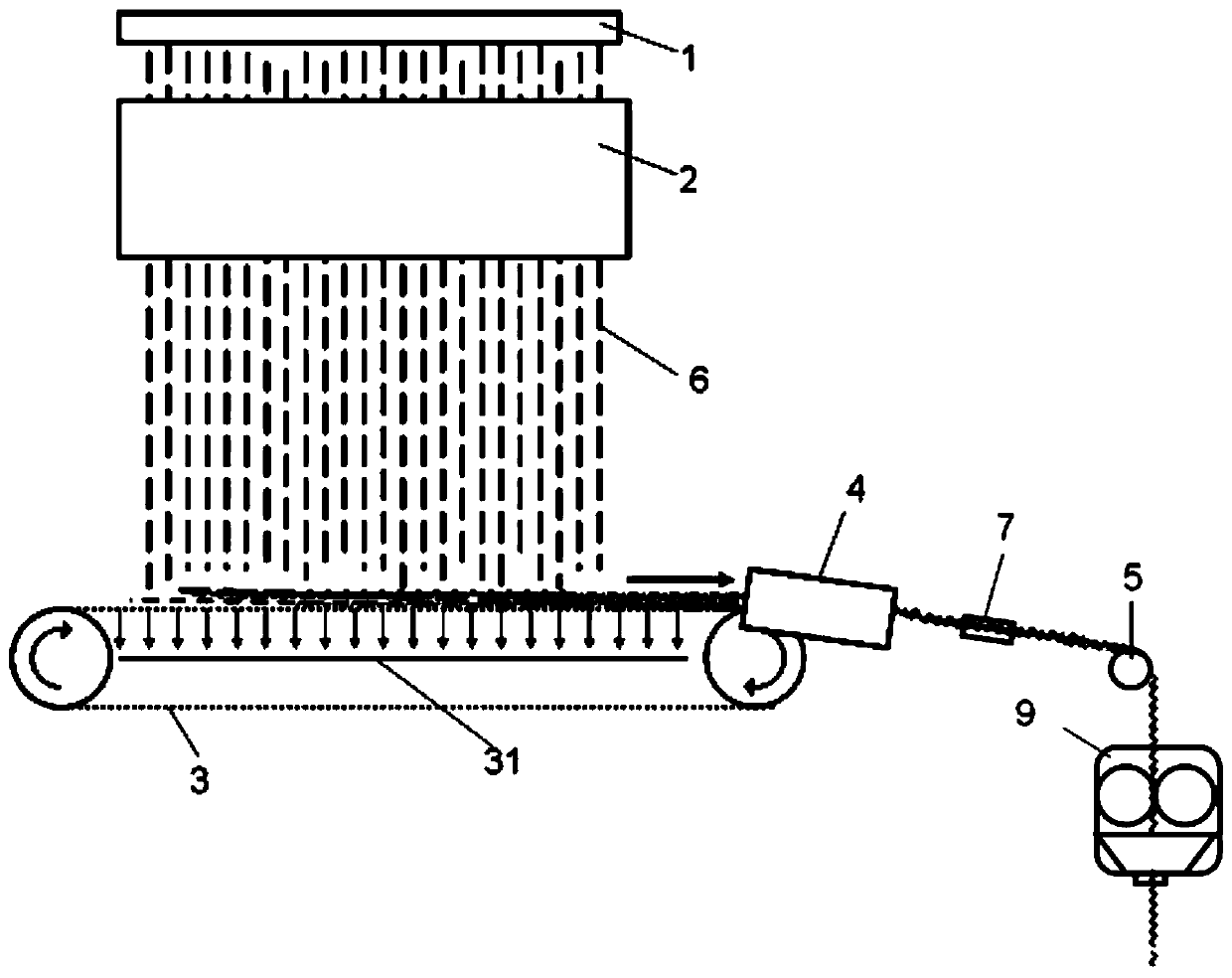

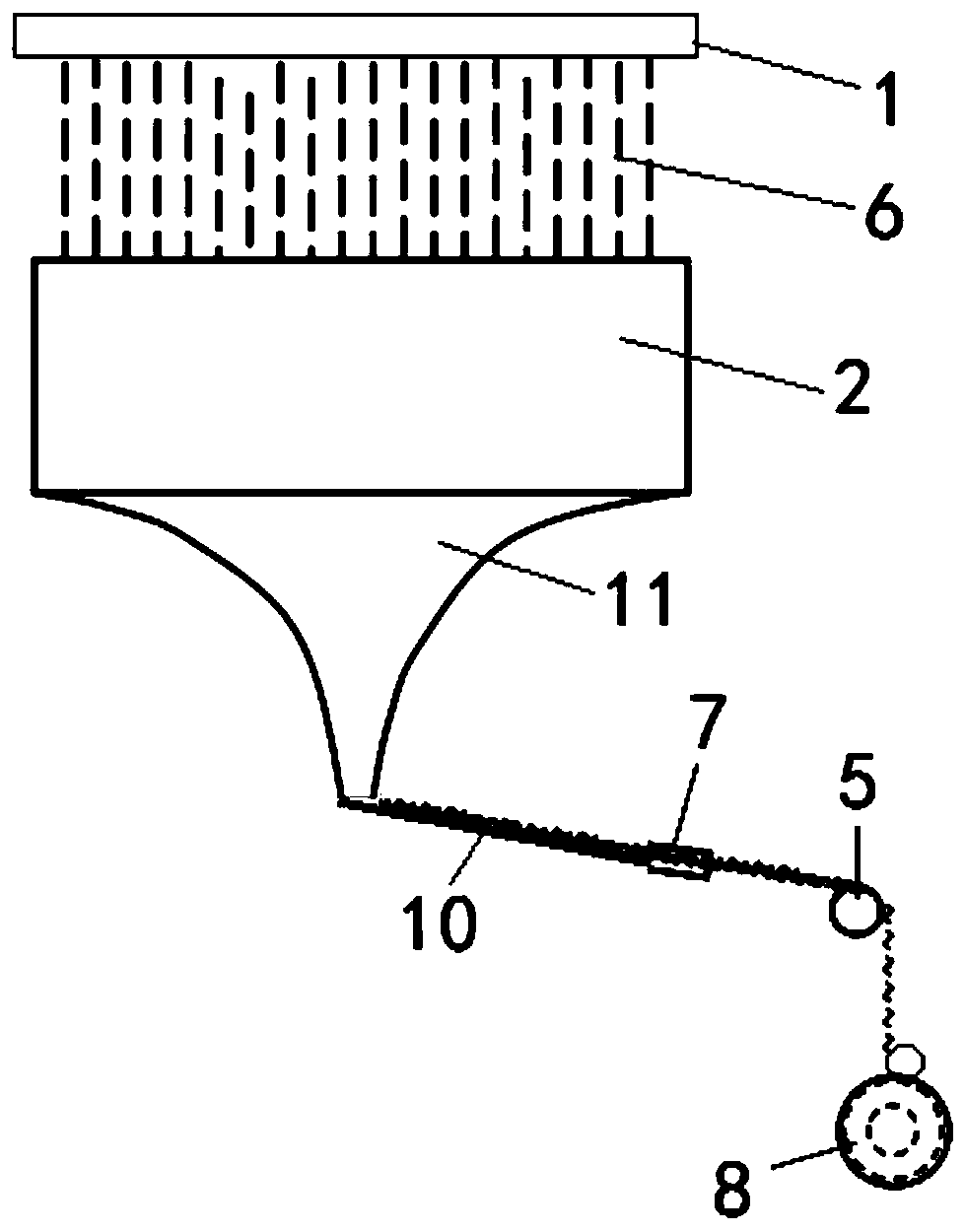

[0075] A device for preparing superfine fiber bundles by melt blown method. The hopper of the melt blown device is connected to the screw extruder pipe, the metering pump is connected to the screw extruder and the melt blown die head, and the hot air is distributed on both sides of the spinneret hole, cooling When the clustering device adopts the first embodiment, the cold air box 2 is set under the spinneret of the melt blown die head, the screen receiving device 3 is below the cold side blowing, and the bell-mouth cluster is placed horizontally on the screen at a certain angle to travel direction, the screen receiving device 3 is driven along the width direction of the meltblown device 1 from the end far away from the horn-mouth clusterer to the end close to the horn-mouth clusterer, and the microfiber bundles are further bundled by the horn-mouth clusterer sent to the collection unit. When the cooling and clustering device adopts the second embodiment, the cold air box 2 is...

Embodiment 2

[0078] A device for preparing superfine fiber bundles by melt blown method. The hopper of the melt blown device is connected to the screw extruder pipe, the metering pump is connected to the screw extruder and the melt blown die head, and the hot air is distributed on both sides of the spinneret hole, cooling When the clustering device adopts the first embodiment, the cold air box 2 is set under the spinneret of the melt blown die head, the screen receiving device 3 is below the cold side blowing, and the bell-mouth cluster is placed horizontally on the screen at a certain angle to travel direction, the screen receiving device 3 is driven along the width direction of the meltblown device 1 from the end far away from the horn-mouth clusterer to the end close to the horn-mouth clusterer, and the microfiber bundles are further bundled by the horn-mouth clusterer sent to the collection unit. When the cooling and clustering device adopts the second embodiment, the cold air box 2 is...

Embodiment 3

[0081] A device for preparing superfine fiber bundles by melt blown method. The hopper of the melt blown device is connected to the screw extruder pipe, the metering pump is connected to the screw extruder and the melt blown die head, and the hot air is distributed on both sides of the spinneret hole, cooling When the clustering device adopts the first embodiment, the cold air box 2 is set under the spinneret of the melt blown die head, the screen receiving device 3 is below the cold side blowing, and the bell-mouth cluster is placed horizontally on the screen at a certain angle to travel direction, the screen receiving device 3 is driven along the width direction of the meltblown device 1 from the end far away from the horn-mouth clusterer to the end close to the horn-mouth clusterer, and the microfiber bundles are further bundled by the horn-mouth clusterer sent to the collection unit. When the cooling and clustering device adopts the second embodiment, the cold air box 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com