A kind of negative ion melt-blown superfine fiber cigarette filter material and preparation method thereof

A technology of ultra-fine fibers and negative ions, which is applied in the fields of e-liquid filter elements, fiber chemical characteristics, tobacco, etc., can solve the problems of low filtration efficiency of cigarette filter materials, and achieve the effects of enhancing human immunity, improving filtering effects, and increasing fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for negative ion melt-blown ultra-fine fiber cigarette filter material, specifically comprising the following steps:

[0030] Step S1, uniformly mixing 94-99 parts by weight of polypropylene material and 1-6 parts by weight of nano-tourmaline masterbatch to obtain a mixture;

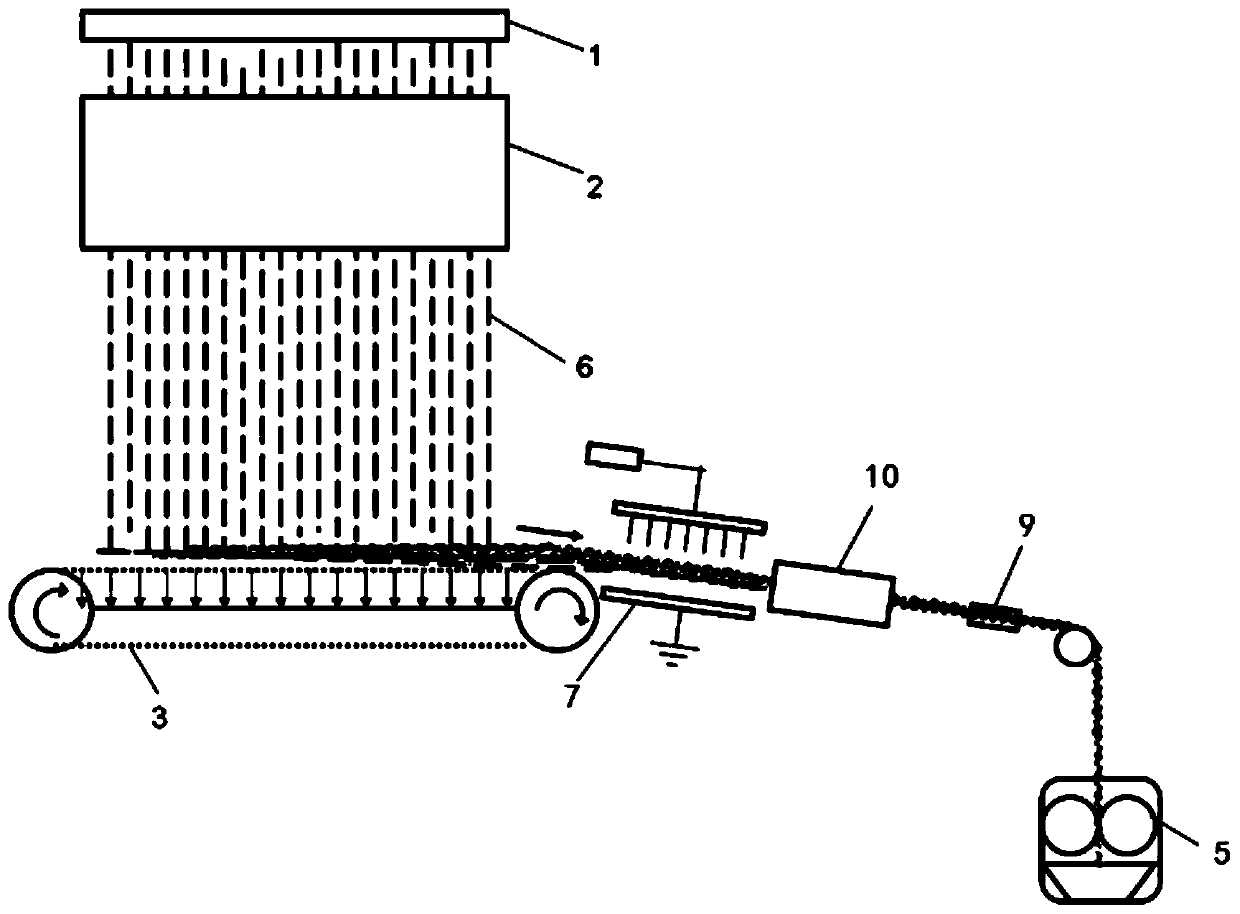

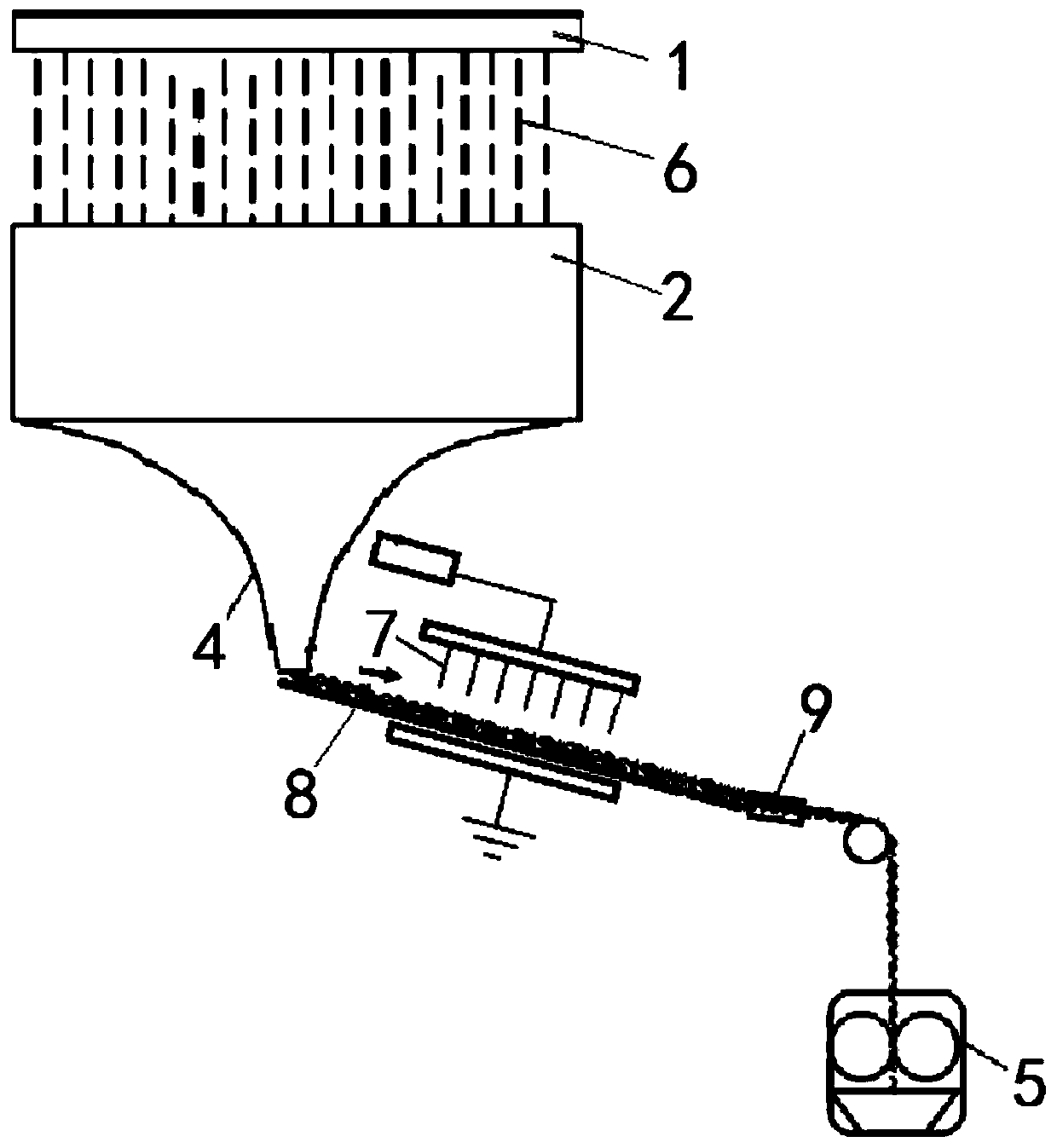

[0031] Step S2, the melt-blown device 1 prepares melt-blown ultrafine fibers 6 using the mixture;

[0032] Step S3, the cooling and bundling device cools and bundles the melt-blown ultrafine fibers 6 ejected from the melt-blown device 1;

[0033] Step S4, the collection device 5 performs electret treatment and collection on the melt-blown ultrafine fibers 6 to obtain the electret ultrafine fiber cigarette filter material.

[0034] The nano tourmaline master batch in the step S1 is made by mixing nano-scale tourmaline material and polypropylene material, and the content of tourmaline is 20-40% of the mass of the nano tourmaline master batch.

[0035] In the first embodiment o...

Embodiment 1

[0053] A method for negative ion melt-blown superfine fiber cigarette filter material, comprising the following steps:

[0054] Step S1, crushing the tourmaline into nanoscale and mixing it with polypropylene slices to make nano-tourmaline masterbatch, the content of tourmaline in the nano-tourmaline masterbatch is 20% of the mass of tourmaline masterbatch;

[0055] Step S2, taking 96 parts by weight of polypropylene pellets and 4 parts by weight of nano-tourmaline masterbatch and mixing them uniformly to obtain a mixture;

[0056] Step S3, set the temperature of the four regions of the preparation device for negative ion melt-blown ultra-fine fiber cigarette filter material at 260°C, 260°C, 270°C, and 270°C, and feed the mixture obtained in step S2 into the screw extruder The silo is used to form the melt through the screw melting extruder;

[0057] Step S4, the melt is sprayed out through the spinneret after passing the metering pump, and drawn under 220°C and 0.4MPa hot ai...

Embodiment 2

[0062] Step S1, crushing the tourmaline into nanoscale and mixing it with polypropylene slices to make nano tourmaline master batches, the content of tourmaline in the nano tourmaline master batches is 30% of the mass of the tourmaline master batches;

[0063] Step S2, taking 95 parts by weight of polypropylene pellets and 5 parts by weight of nano-tourmaline masterbatch and mixing them uniformly to obtain a mixture;

[0064] Step S3, set the temperature of the four regions of the negative ion melt-blown ultra-fine fiber cigarette filter material preparation device at 260°C, 260°C, 270°C, and 270°C, and feed the mixture obtained in step S2 into the screw extruder. bin, forming a melt through a screw melting extruder;

[0065] Step S4, the melt is sprayed out through the spinneret after the metering pump, and drawn under 220°C and 0.4MPa hot air to obtain melt-blown ultra-fine fibers. After the melt-blown ultra-fine fibers are cooled, they are bundled with a curtain collection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com