Material-sorting and color-recognizing device for plug-in robot

A technology of color recognition and robotics, applied in sorting and other directions, can solve the problem that workpieces of different colors cannot be picked and placed in different positions, the color identification of workpieces to be sorted cannot be distinguished, and the size and color of objects to be sorted are not the same and other problems, to achieve the effect of simple structure, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

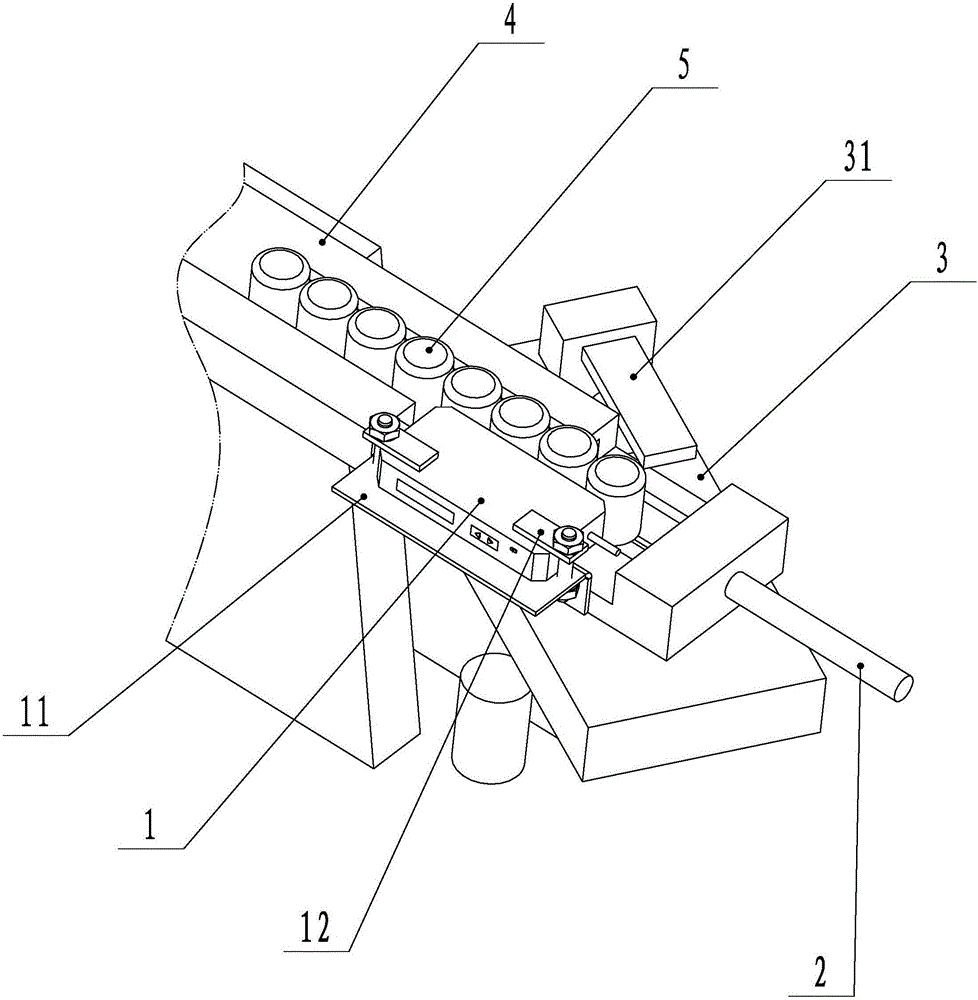

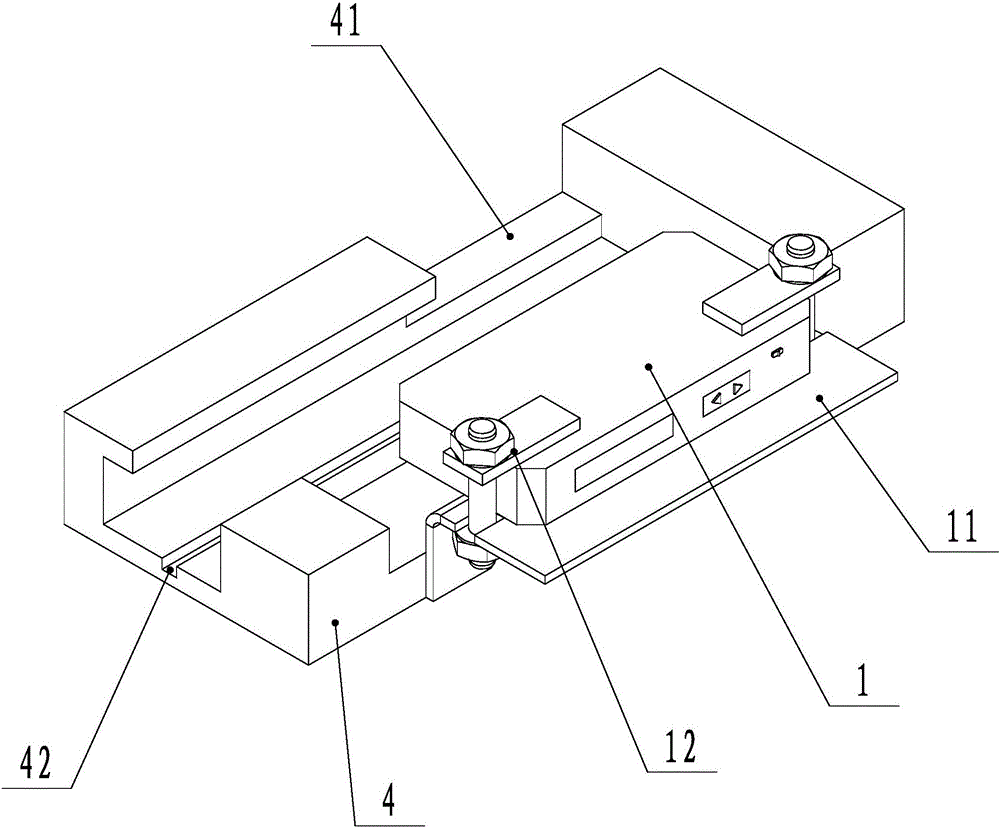

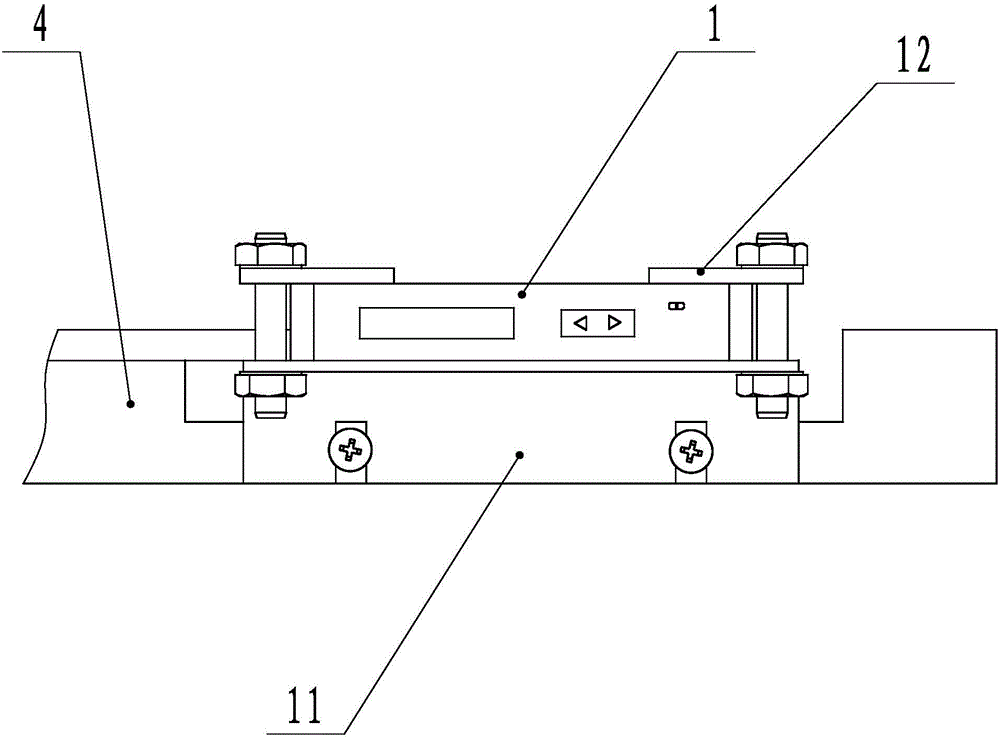

[0020] refer to Figure 1 to Figure 5 , a plug-in robot material sorting color recognition device, including a guide rail 4 installed and connected to the outlet of the vibrating plate mechanism, the component 5 slides along the guide rail 4 after coming out of the vibrating plate mechanism, and the end of the guide rail 4 is provided with a position sensor 2. One side of the position sensor 2 is provided with a color recognition sensor 1, and the other side is provided with a clamping mechanism 3. The position sensor 2, the color recognition sensor 1 and the clamping mechanism 3 are respectively connected to the control system. The position sensor 2. When sensing the approach of component 5, a signal is sent to the control system. The control system controls the clamping mechanism 3 to clamp the component 5 close to the color recognition sensor 1. The color recognition sensor 1 recognizes the color of the component 5 and feeds back to the control system. The control system acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com