Axis-split type paper money thickness-measuring mechanism

A split-axis, thickness measurement technology, applied in the mechanical field, can solve problems such as difficulty in ensuring measurement accuracy, low thickness measurement accuracy, limited manufacturing accuracy, etc., and achieve good dust removal effect and high thickness measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

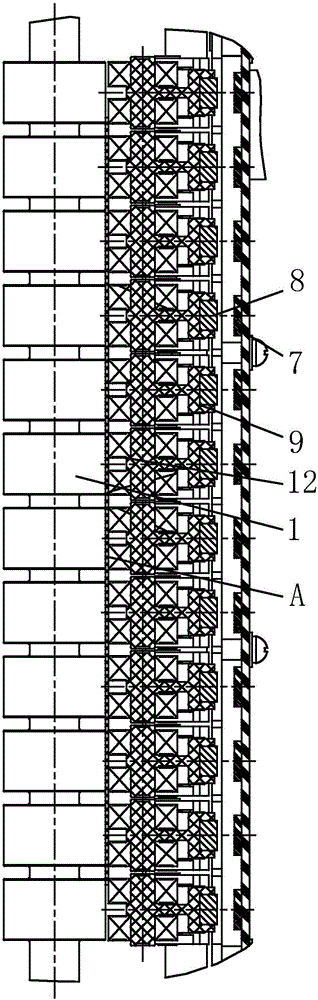

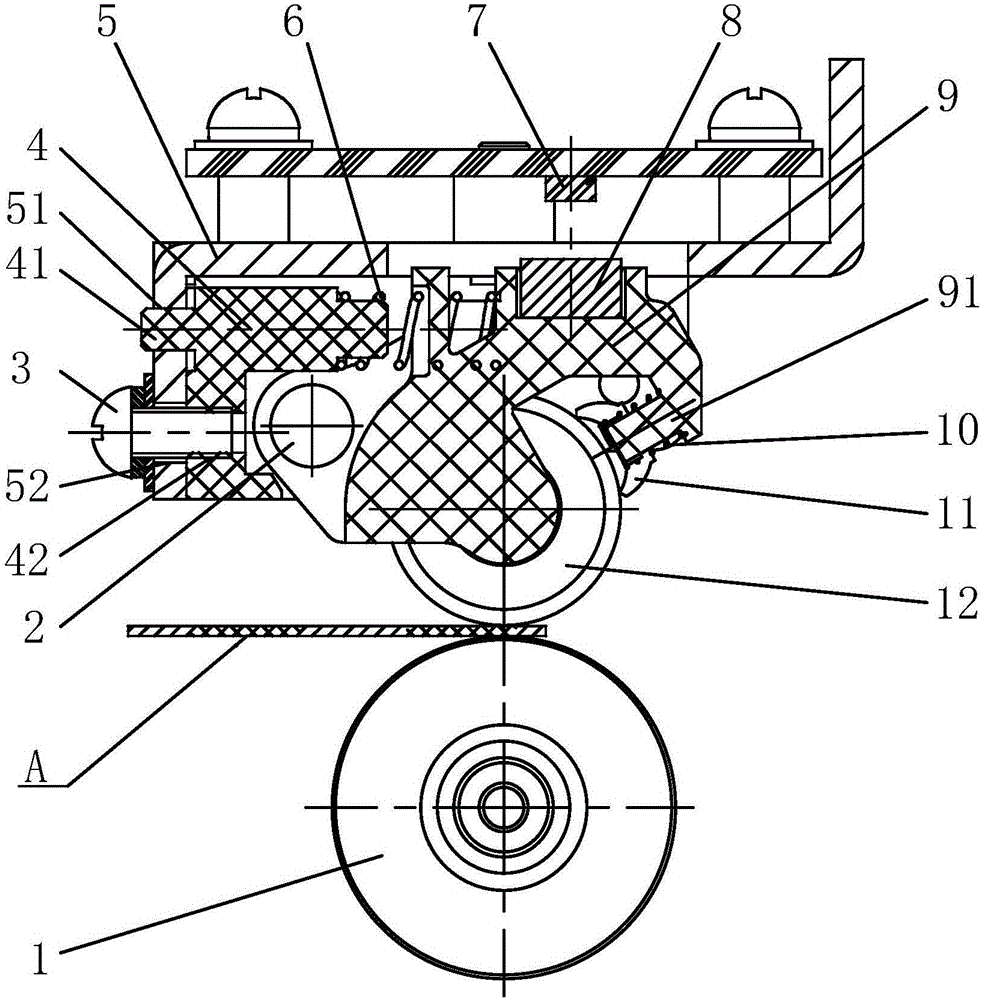

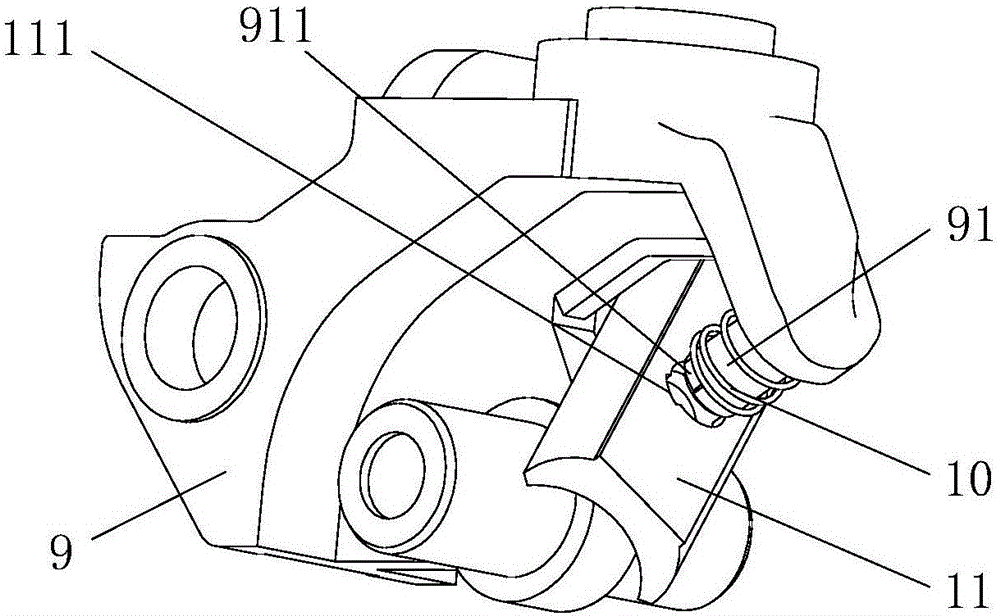

[0025] Such as figure 1 , figure 2 , image 3 The illustrated embodiment is a shaft-splitting banknote thickness measuring mechanism, which is used to measure the thickness of thin objects such as banknotes to be tested, and provide thickness change data for judgment. The thickness measuring mechanism includes a thickness measuring frame 5 arranged horizontally in the width direction, and 12 rocker arm seats 4 are arranged side by side along the thickness direction on the thickness measuring frame, and each rocker arm seat is provided with a rocker arm shaft in the width direction 2. The direction of the rocker shaft is horizontal. The 12 rocking arms 9 are sleeved on the rocking arm seat by the rocking arm rotating shafts rotating one by one. The outer free end of each rocking arm is all equipped with roller 12, and roller is the double whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com