Reaction kettle cleaned with circulating water

A technology of circulating water and reaction kettle, which is applied in chemical/physical/physical-chemical stationary reactors, cleaning hollow objects, cleaning methods and utensils, etc. The effect of improving cleaning quality and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

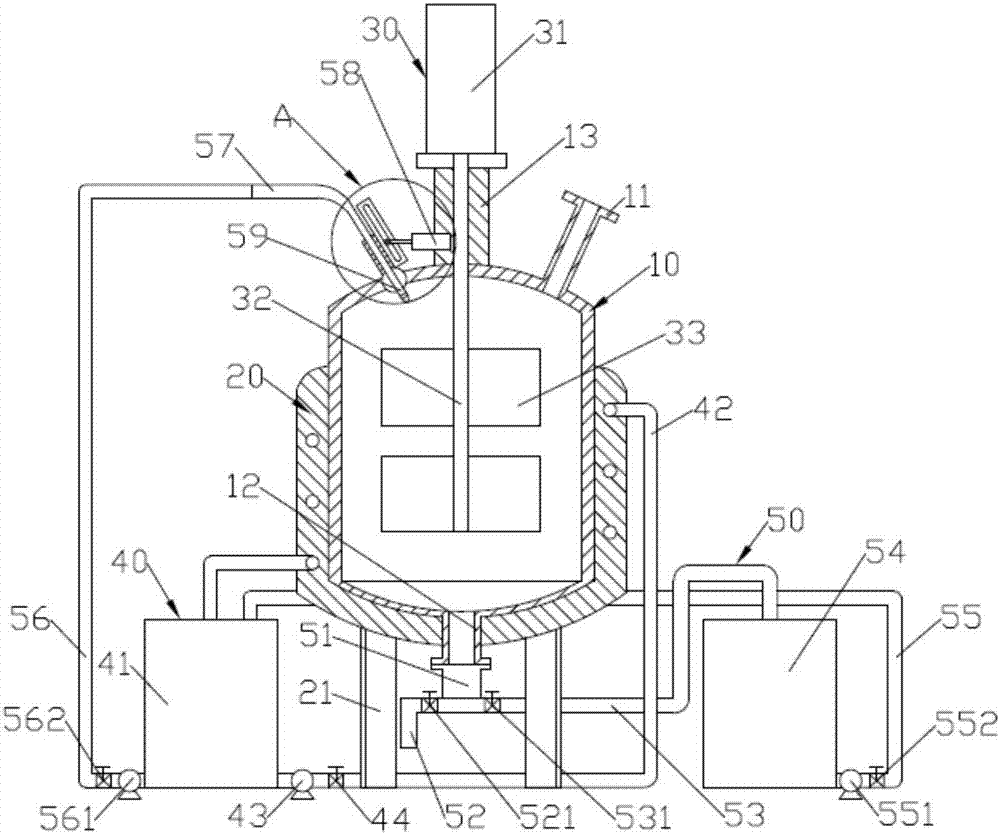

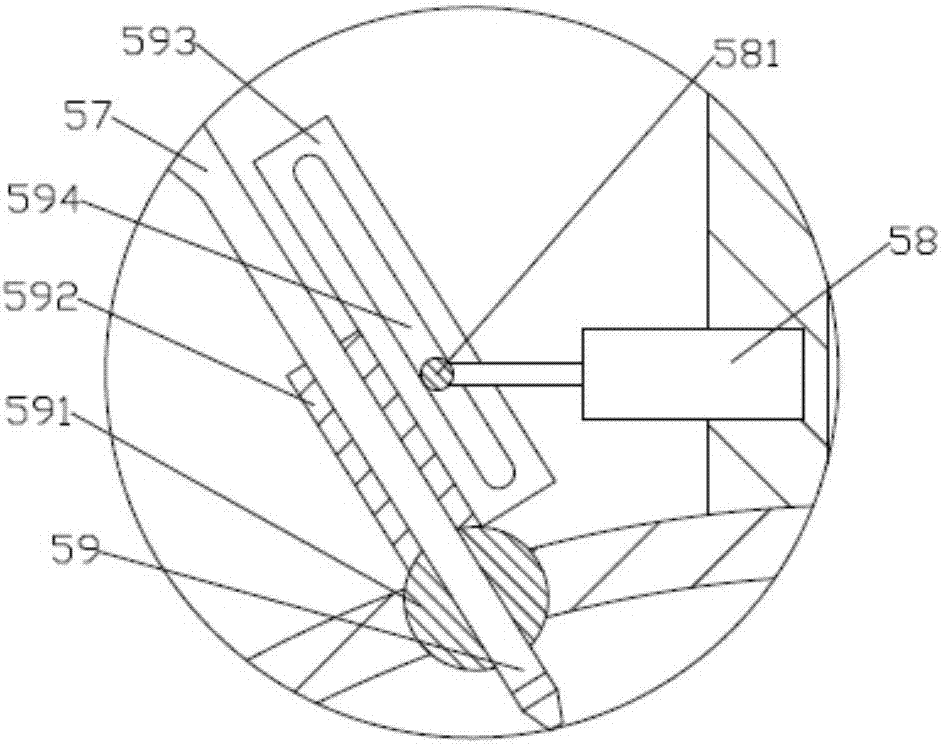

[0014] Such as figure 1 , figure 2 As shown, a reaction kettle for circulating water cleaning includes an inner cylinder 10, a jacket 20, a stirring device 30, a circulating water heating device 40 and a circulating water cleaning device 50; the jacket 20 is installed on the lower part of the outer surface of the inner cylinder 10 The bottom of the jacket 20 is fixed with some supporting feet 21; the stirring device 30 includes a stirring motor 31, a stirring rod 32 and some stirring blade groups 33; the top of the inner cylinder 10 is provided with a motor support seat 13; the top right side of the inner cylinder 10 A feed pipe 11 inclined downward is provided; a discharge pipe 12 is provided at the center of the bottom of the inner cylinder 10; the stirring motor 31 is installed on the motor support base 13 and is set downward; the stirring rod 32 is fixed on the bottom of the stirring motor 31 On the output shaft and inserted downwards into the inner cylinder 10; several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com