Opposite inserting type air pipe joint and mounting method thereof

A technology for air duct joints and air ducts, applied in mechanical equipment, couplings, etc., can solve the problems of easy air leakage, easy fracture, low strength, etc., achieve good sealing effect, reduce the risk of air leakage, connect simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

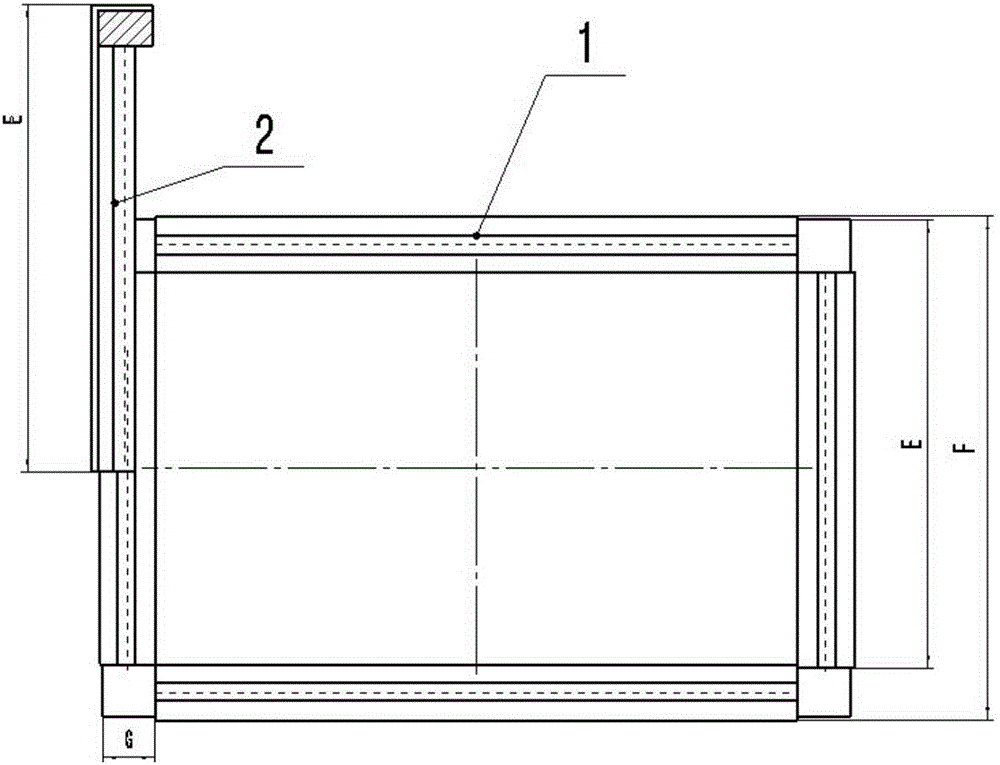

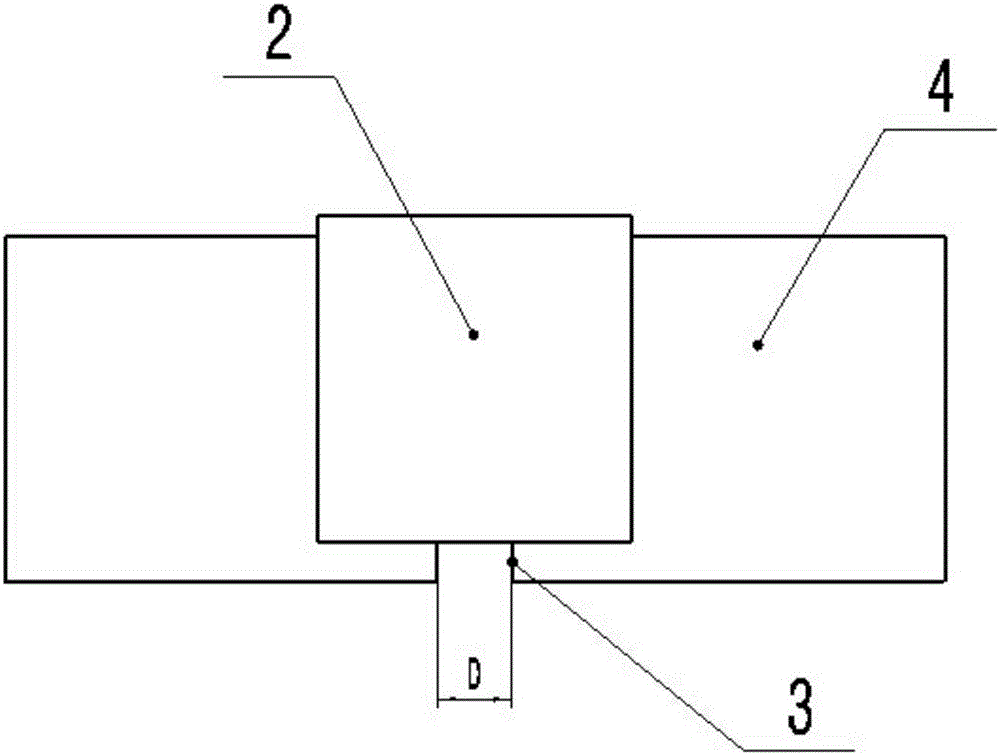

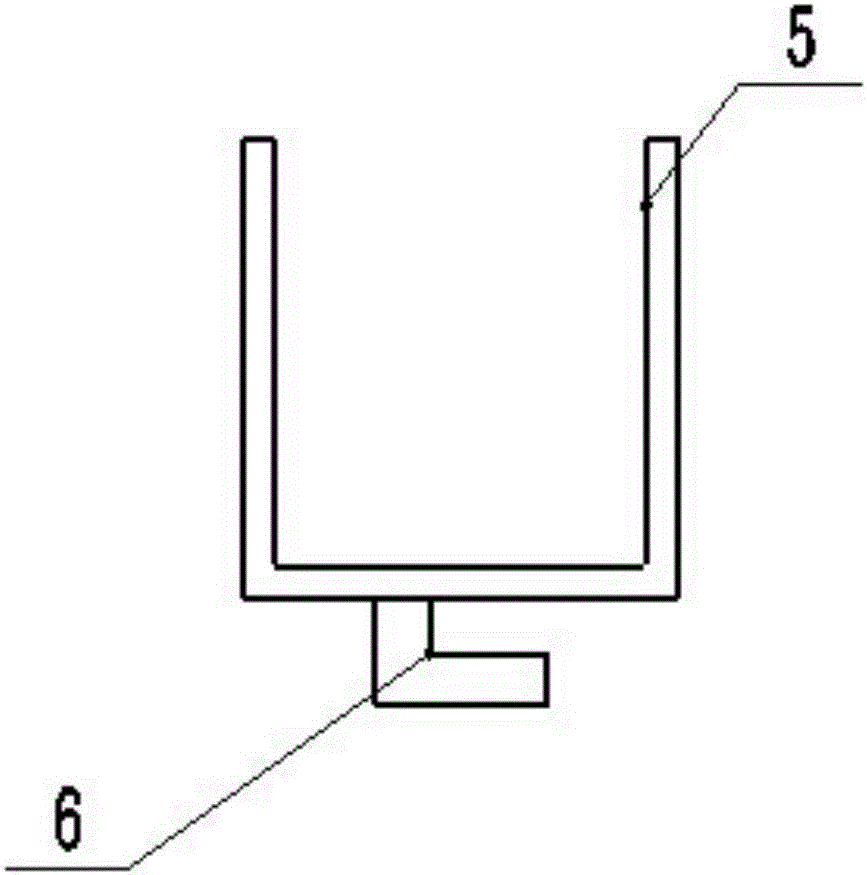

[0031] Such as Figure 1-6 As shown, a plug-in air pipe joint of the present invention includes a strip-shaped female buckle 1 and an L-shaped male buckle 2, such as image 3 As shown, one side of the bar-shaped female buckle 1 is provided with a U-shaped groove 5 stuck on the side plate 4 of the air duct end 3, and the other side of the strip-shaped female buckle 1 is provided with a Figure 4-6 As shown, the L-shaped chuck 6 docked with the L-shaped male buckle 2, the outer layer of the L-shaped male buckle 2 is an L-shaped supporting plate 7, and a sealing block 8 is arranged in the right angle of the L-shaped supporting plate 7, and the L-shaped The inner surface of the strip plate 9 of the supporting plate 7 is provided with a double-hook chuck 10 which cooperates with the L-shaped chuck 6 and engages with each other.

[0032] Such as Figure 4-6 As shown, the width B of the L-shaped pallet 7 is greater than or equal to four times the width A of the double-hook chuck 10...

Embodiment 2

[0040] Such as Figure 1-6 As shown, a plug-in air pipe joint installation method includes steps:

[0041] Step 1) According to the four unilateral lengths (F-2G) of the square air duct end 3, intercept the bar-shaped female buckle 1 of the same length; also intercept the length E of the matching L-shaped male buckle 2;

[0042] Step 2) Put the intercepted strip female buckle 2 through the U-shaped groove 5 and glue it on the side plate 4 of the air duct end 3, and then use rivets for riveting;

[0043] Step 3) Butt the two air duct ends 3 with the strip female buckle 1 installed with each other;

[0044] Step 4) Then insert the double-hook clamp head 10 of the L-shaped male buckle 2 into the L-shaped clamp head 6 of the strip-shaped female buckle 1 on the two air duct ends 3, and apply glue on the sealing block 8, and insert the L-shaped male buckle The buckle 2 is fully inserted, and then the remaining single-sided side panels 4 on the air duct end 3 are connected in turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com