Object deformation measurement method in high-temperature environment

A measurement method and high-temperature environment technology, which is applied in the field of materials science and optical experiments, can solve the problems that the deformation area cannot be taken into account, the price of narrow-band filters is high, and it is not suitable for large-scale promotion and use, so as to eliminate the excessive difference in surface brightness and fill Effect of vacancies on deformation measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

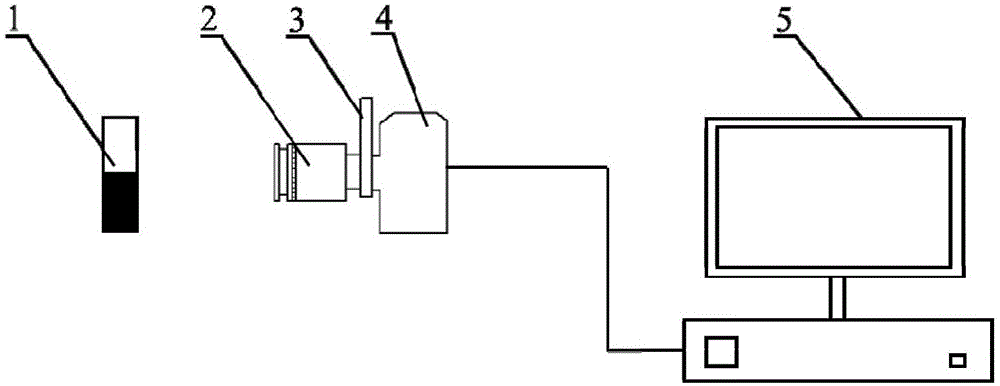

[0022] figure 1 It is a schematic structural diagram of an object deformation measuring device in a high temperature environment, and the device includes a lens 2 , a filter group 3 for automatically adjusting attenuation rate, a camera 4 and a computer 5 .

[0023] First, aim the lens 2 at the measured object 1, and adjust the focal length of the lens 2 to make the measured object 1 clearly image.

[0024] Then manually adjust the attenuation rate of the filter group 3 to the minimum, adjust the aperture of the lens 2 and the exposure time of the camera 4 to ensure that the brightness of the image formed by the darkest part of the surface of the measured object 1 is moderate.

[0025] At the beginning of the test, the camera collects an image at the initial attenuation rate, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com