Audio test unit for microphones of wearable electronics

An audio test device and audio test technology, applied in the direction of electrical components, etc., can solve the problems of complex audio test steps and inability to perform automatic tests, and achieve the effect of strong adjustability and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The PCBA microphone and audio calibration used in the past has disadvantages such as the inability to perform automatic testing, and the audio testing steps are complicated (after the speaker is installed, the standard microphone is used for testing and calibration).

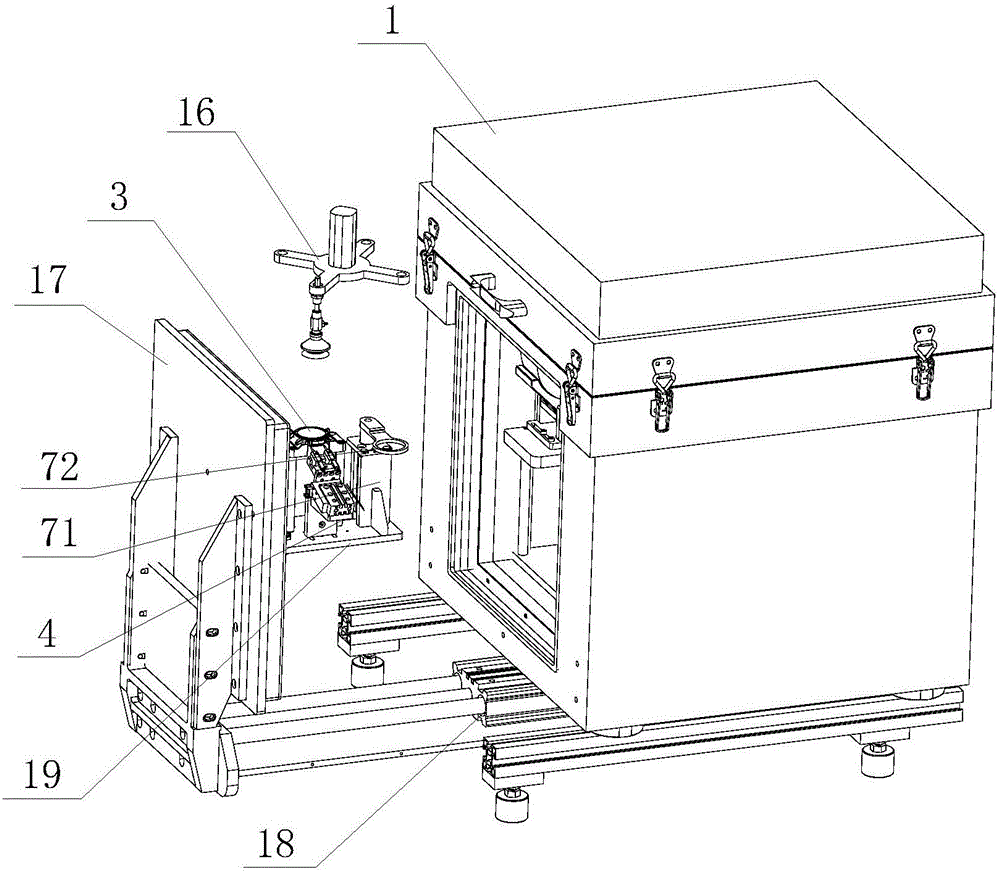

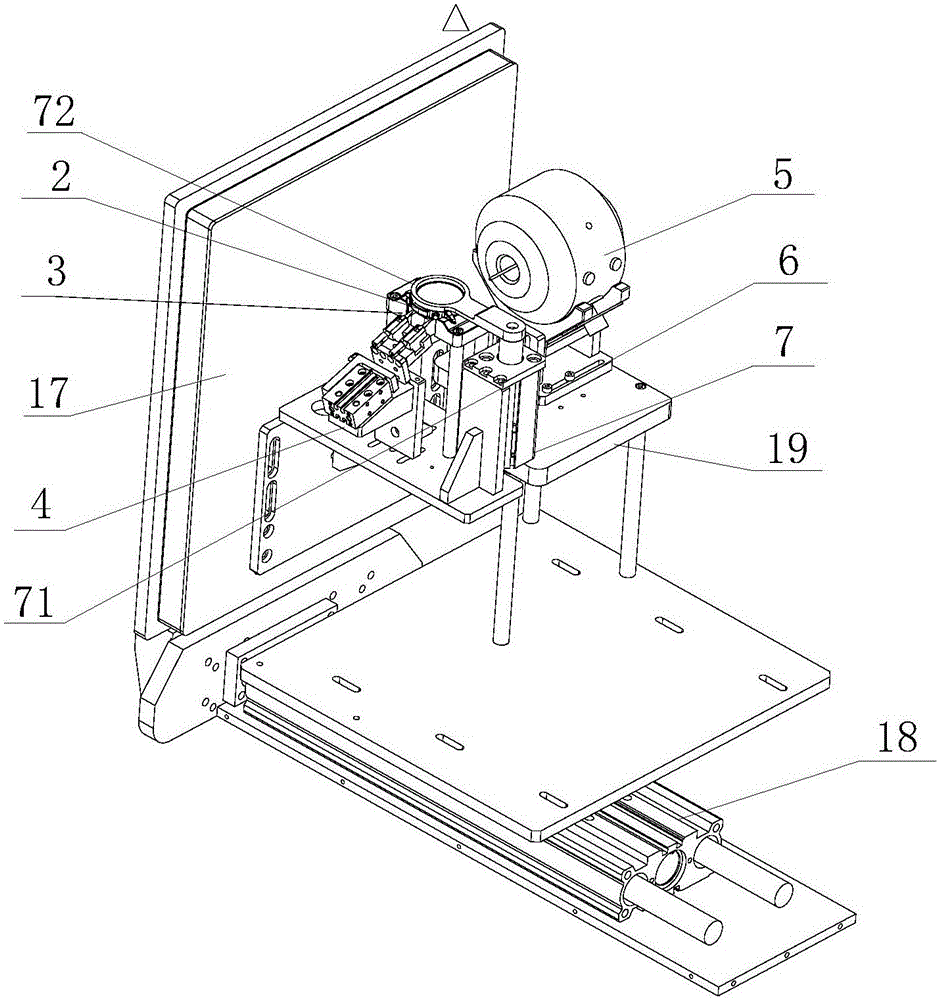

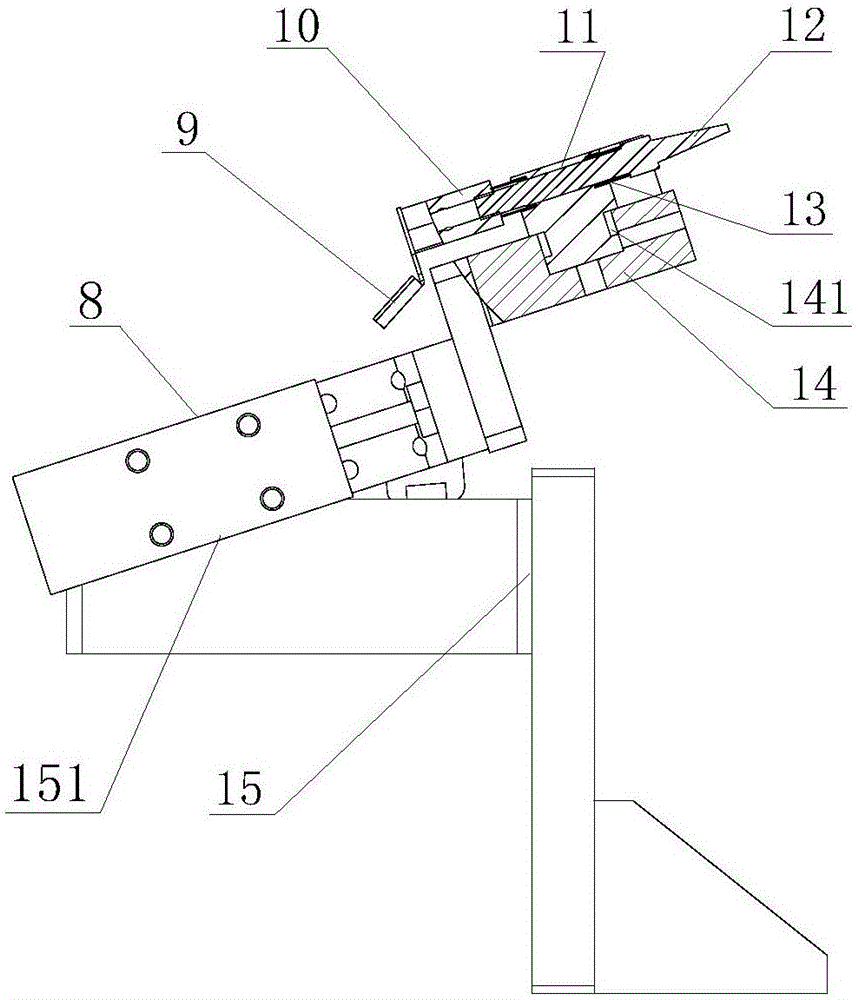

[0028] The design concept of the present invention is: for the PCBA microphone and audio calibration used in the past, there is no automatic test and the audio test steps are complicated. The present invention locks the electronic product on the product positioning module through the product pressing module. area, and then enter the shielding box. In the shielded field environment, the audio test of the microphone of the electronic product is carried out through the audio test communication module, and the reliability of the audio of the product microphone is judged by the returned signal value. The audio test uses the change of the voltage signal when the sound card is sounding to judge the audio perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com