Cold-heat conversion chicken feet skin removing method

A technology of cold and heat conversion and chicken feet, which is applied in poultry peeling, poultry cleaning/disinfection, slaughtering, etc., can solve the problems of uneven stress on chicken feet, residual scales, and many bacteria in chicken feet, and achieve the goal of reducing bacteria Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

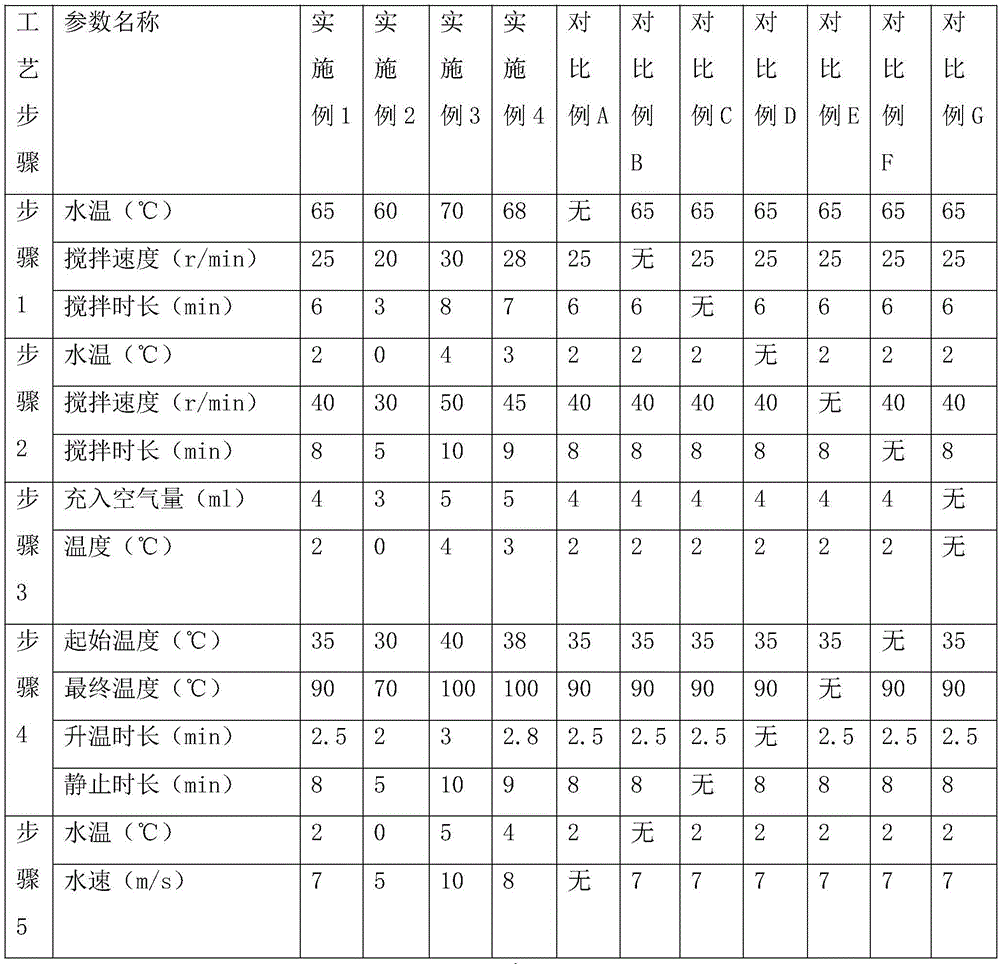

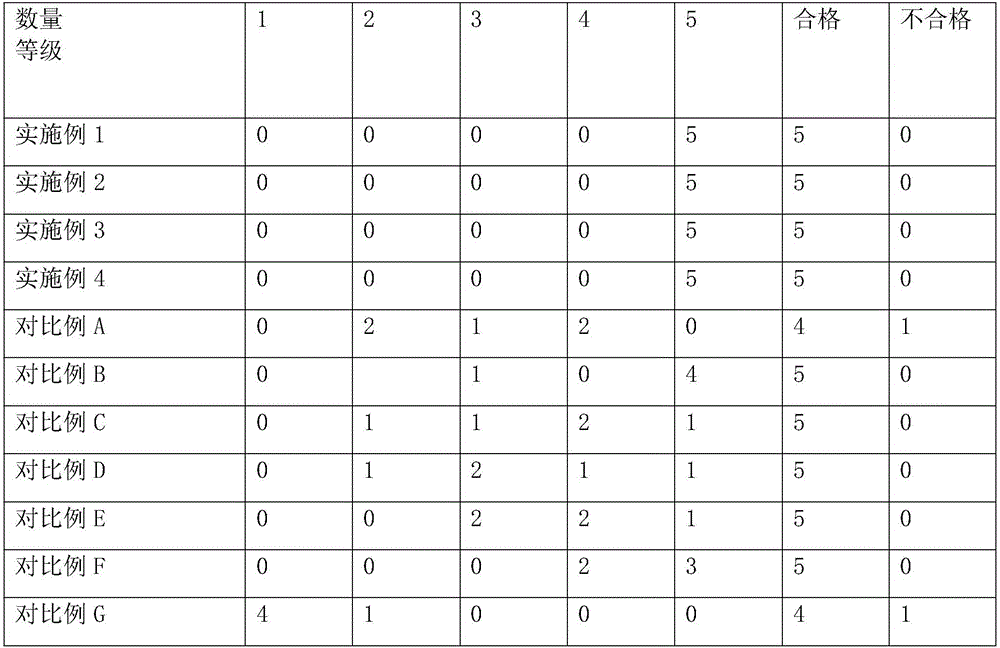

[0031] Embodiment 2 Compared with Embodiment 1, the parameters of each operation are all correspondingly reduced, and the whole peeling process has no impact.

Embodiment 3

[0032] Embodiment 3 Compared with Embodiment 1, the parameters of each operation are correspondingly increased, which can effectively completely remove the scales on the chicken feet, and effectively reduce the amount of bacteria.

Embodiment 4

[0033] In Example 4, compared with Example 1, the mass parts between the components are correspondingly increased, and there is basically no influence on the entire matrix.

[0034] Compared with Example 1, comparative example A does not control the scalding water temperature, which easily leads to too high or too low water temperature, which causes the scales to be fully separated from the chicken feet, which has a great influence on the steps after step 1; The water speed is not limited, and it is easy to cause many scales on the chicken feet.

[0035] Compared with Example 1, comparative example B does not limit the stirring speed in step 1, which easily leads to uneven heating of chicken feet, resulting in uneven separation of scales and chicken feet; and the water temperature in step 5 is not adjusted. If limited, the meat quality of the chicken feet will become less chewy.

[0036] Compared with Example 1, Comparative Example C does not limit the stirring time in step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com