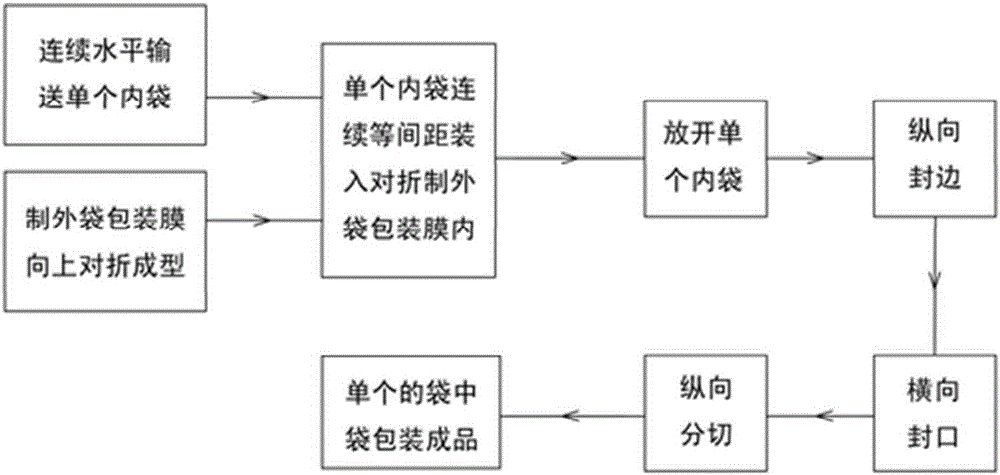

Bag in bag high-speed packaging method and device thereof

A bag-in-bag, packaging film technology, applied in the directions of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of low production efficiency and slow packaging speed, and achieve the effects of reasonable structure, improved production efficiency, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

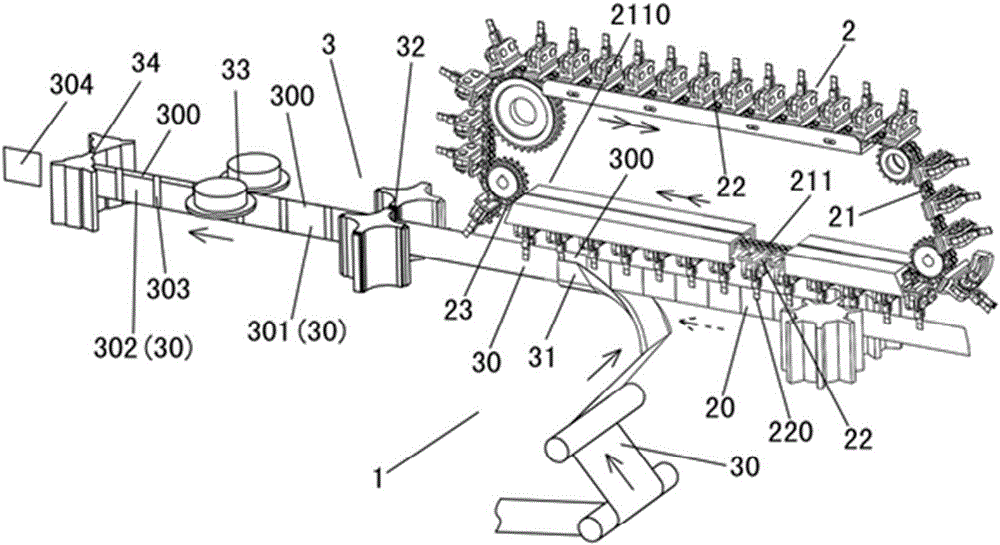

[0062] Such as figure 2 and image 3 As shown, the bag-in-bag high-speed packaging device in this preferred embodiment is characterized in that it includes a frame 1 and a single inner bag continuous horizontal conveying mechanism 2 and a horizontal outer bag making mechanism 3 respectively arranged on the frame 1;

[0063] The above-mentioned single inner bag continuous horizontal conveying mechanism 2 includes an annular conveying member 21, a bag clip 22 and an opening and lifting clip track 23;

[0064] The above-mentioned annular conveying member 21 is vertically arranged;

[0065] The above-mentioned annular conveying member 21 is rotatably mounted on the frame 1;

[0066] The above-mentioned circular conveying part 21 has a linear conveying part 211, and the above-mentioned linear conveying part 211 is located on the lower part of the circular conveying part 21;

[0067] The above-mentioned bag clips 22 are fixedly installed on the annular conveying member 21 at equ...

Embodiment 2

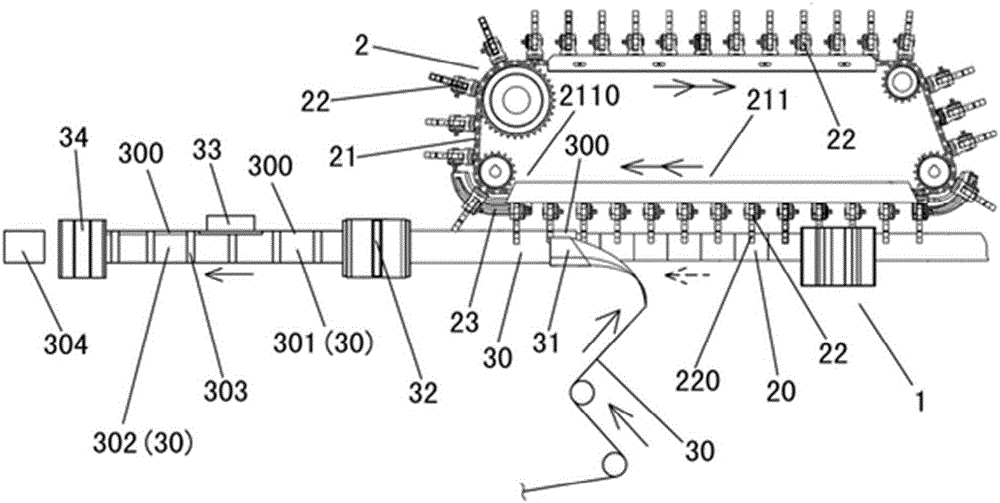

[0087] The shape, structure or combination thereof of preferred embodiment 2 is substantially the same as that of preferred embodiment 1, structure or combination thereof, the difference between the two lies in:

[0088] Such as Figure 4 and Figure 5 As shown, the circular conveying member 21 in the preferred embodiment 2 is arranged horizontally; at the same time, the opening and lifting track 23 extends forward with a lifting track 230 .

[0089] The working process and working principle of the preferred embodiment 2 are basically the same as those of the preferred embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com