Double-layer binding tape forming device

A forming device and double-layer technology, which is applied in the direction of textiles and papermaking, cloth feeding mechanism, sewing equipment, etc., can solve the problems of time-consuming, laborious, difficult to control and cumbersome production process, and achieve the goal of preventing mutual interference, smooth appearance and avoiding mistakes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

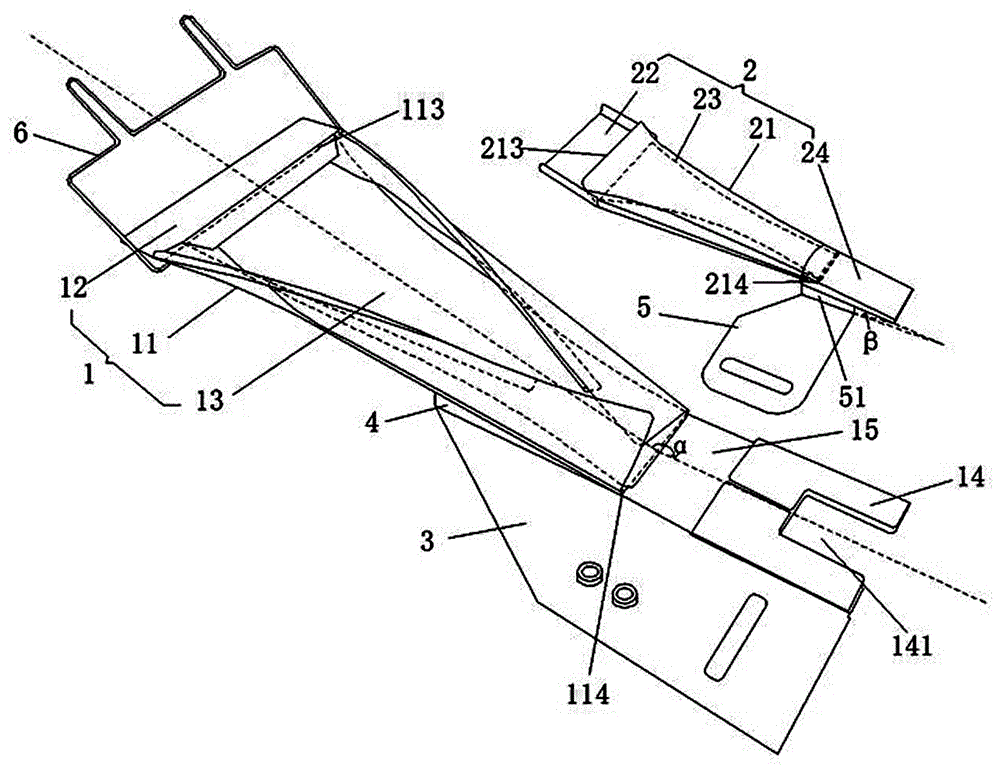

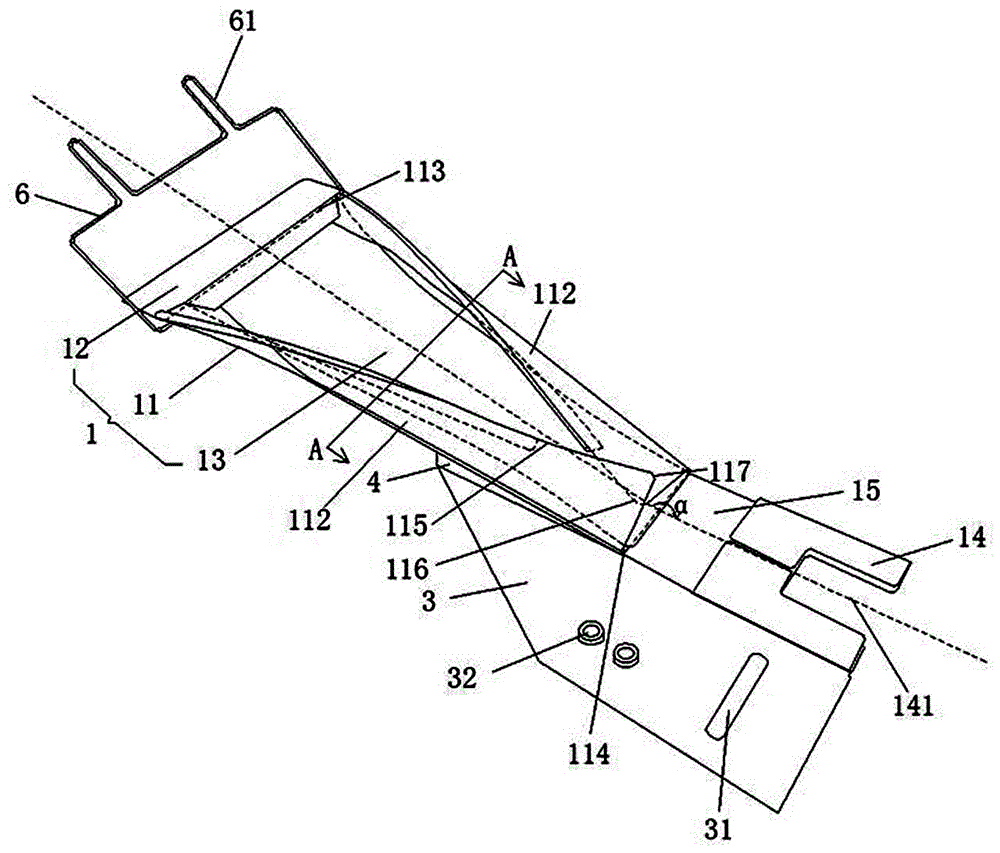

[0023] The invention discloses a double-layer bundle forming device, which comprises: a first pulling cylinder 1, a second pulling cylinder 2, a fixing plate 3, a supporting plate 4, a first connecting plate 5 and a bracket 6, the fixing plate 3 Fixed on the workbench of the sewing machine, the first puller 1 is fixed on the fixed plate 3, the support plate 4 is vertically installed on the fixed plate 3, and the top of the support plate 4 is supported on the bottom of the first puller 2 , the first connecting plate 5 is fixedly mounted on the fixing plate 3 , and the second pulling tube 2 is welded to one end of the first connecting plate 5 and suspended above the first pulling tube 1 . The bracket 6 is welded on the first cloth inlet 113 of the first pulling cylinder 1 .

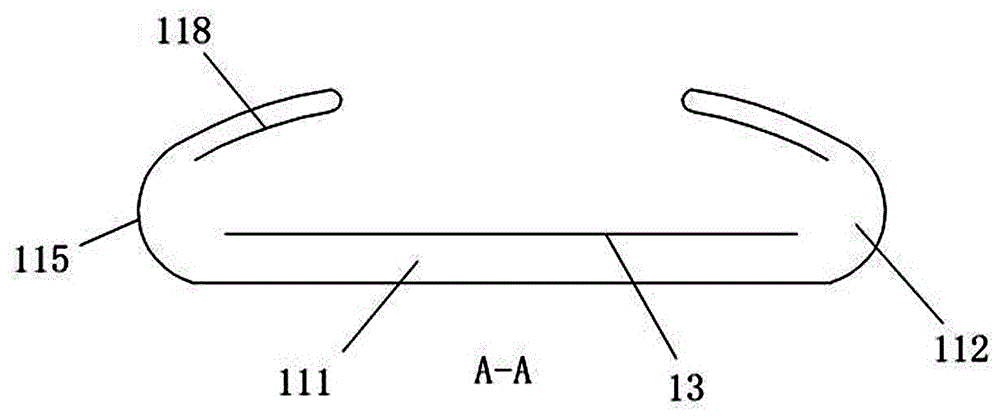

[0024] The first pulling cylinder 1 includes: a first fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com