A compressor shaft and a compressor having the same

A compressor and spindle technology, applied in the field of compressors, can solve the problems of unstable back pressure, fluctuation of back pressure, and inability to provide sufficient back pressure oil, so as to achieve no back pressure fluctuation, guarantee back pressure, and sufficient back pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

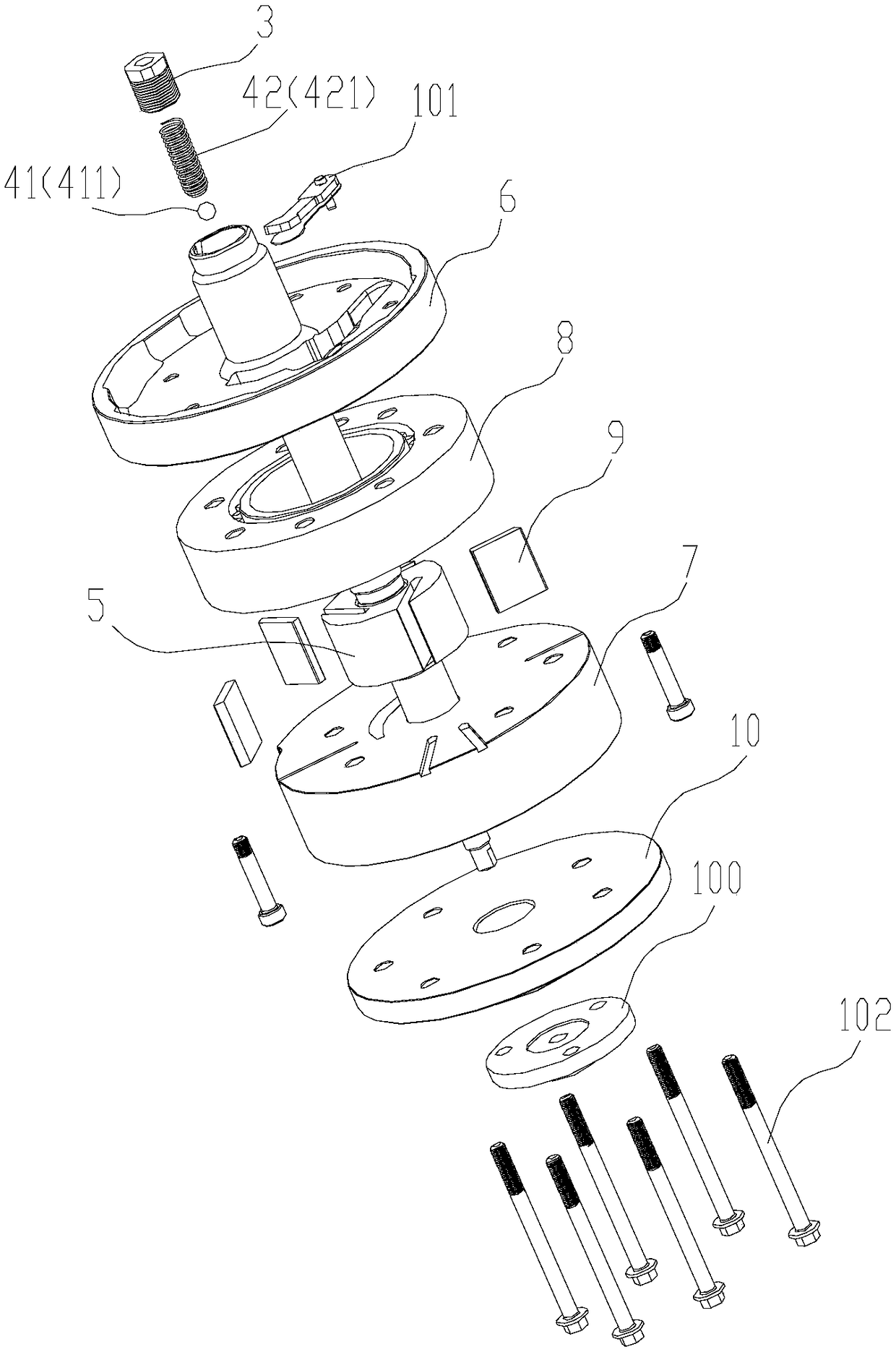

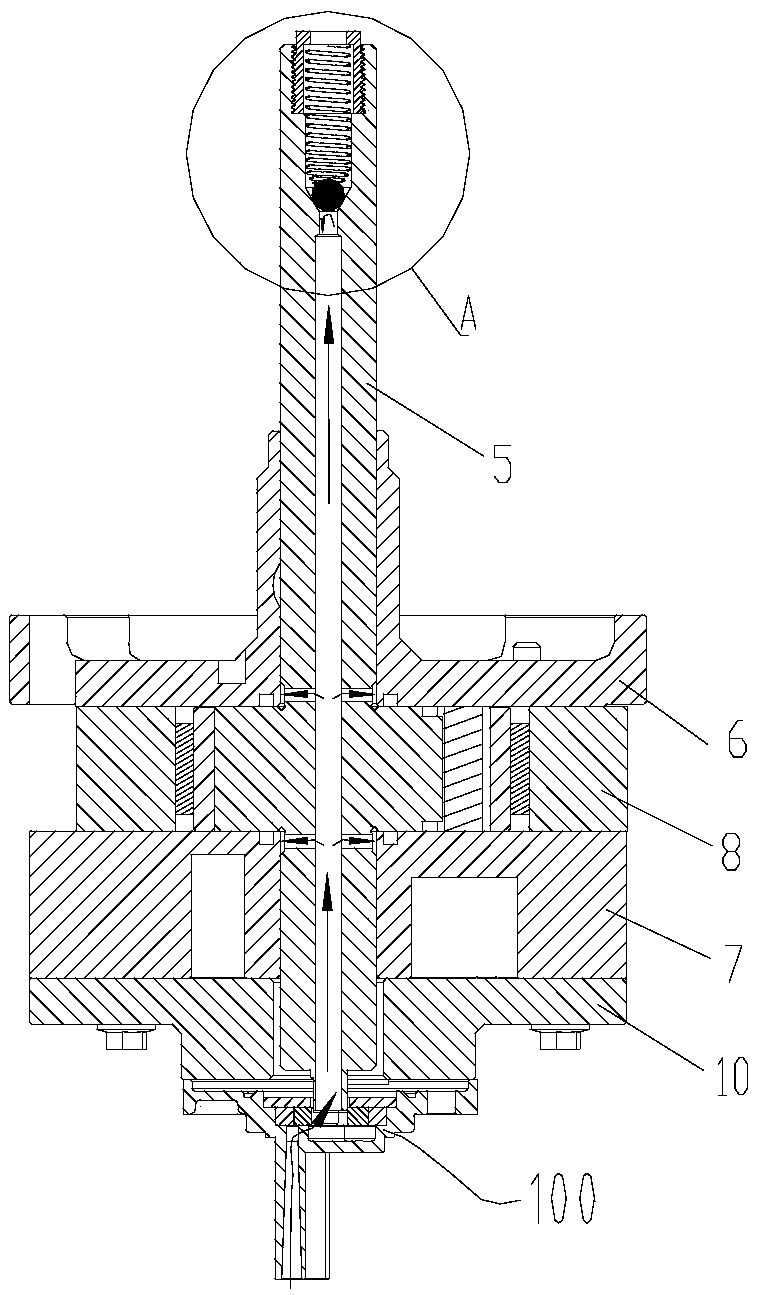

[0038] Such as Figure 1-8c As shown, the present invention provides a compressor main shaft, which includes a main shaft center hole 1 that is opened in the axial direction and can allow back pressure oil to flow through, and communicates with the main shaft center hole 1 in the radial direction. The main shaft radial oil hole 2, the main shaft radial oil hole 2 is used to deliver the oil out of the main shaft 5 to provide the required back pressure and lubrication;

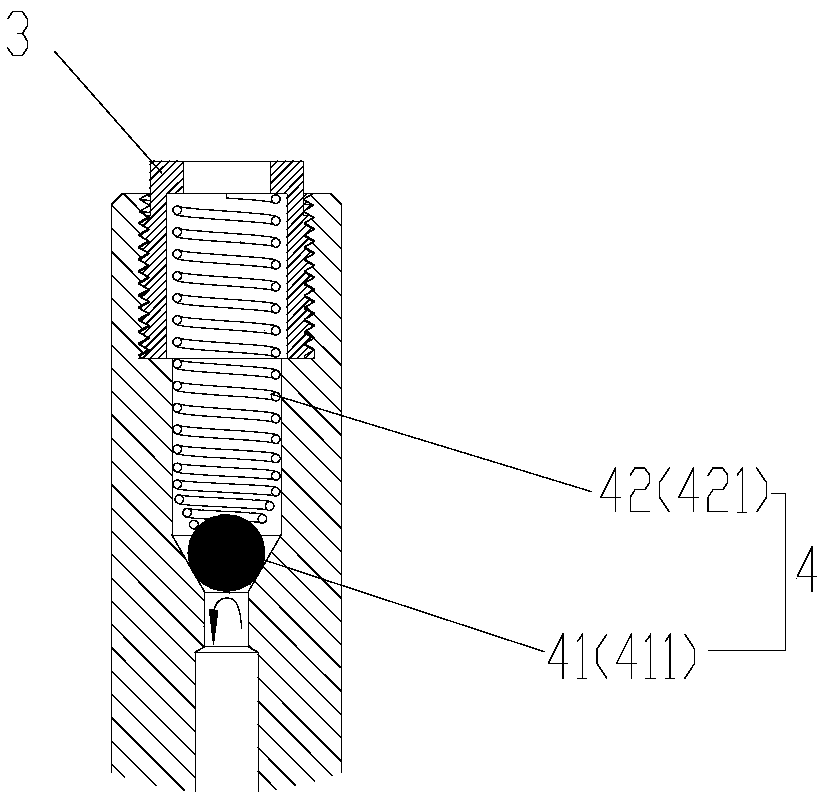

[0039] An oil plug 3 is arranged on the upper part of the spindle center hole 1, and a valve assembly 4 is also arranged in the spindle center hole 1 between the oil plug 3 and the spindle radial oil hole 2 , the upper end of the valve assembly 4 is connected to the oil plug 3;

[0040] The valve assembly is configured such that when the oil pressure in the central hole of the main shaft is greater than the back pressure provided by the valve assembly, the valve assembly opens to allow oil to flow from the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com