Freight car bogie axle box positioning device

A bogie shaft and positioning device technology is applied in the field of parts manufacturing of rail vehicle truck bogies, which can solve the problems of inability to satisfy vibration damping force, poor deflection of heavy vehicles, inability to effectively control the overhead of truck steering, and avoid hot axles. Faults, ensure the safety of railway transportation, and improve the effect of dust-proof and oil-proof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

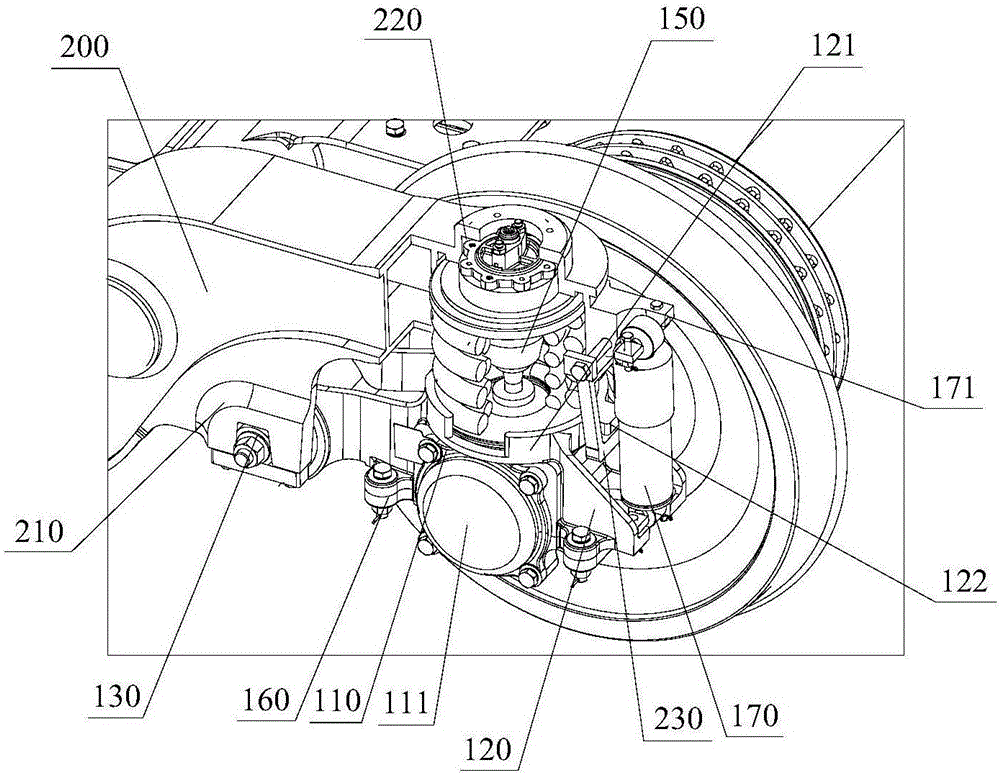

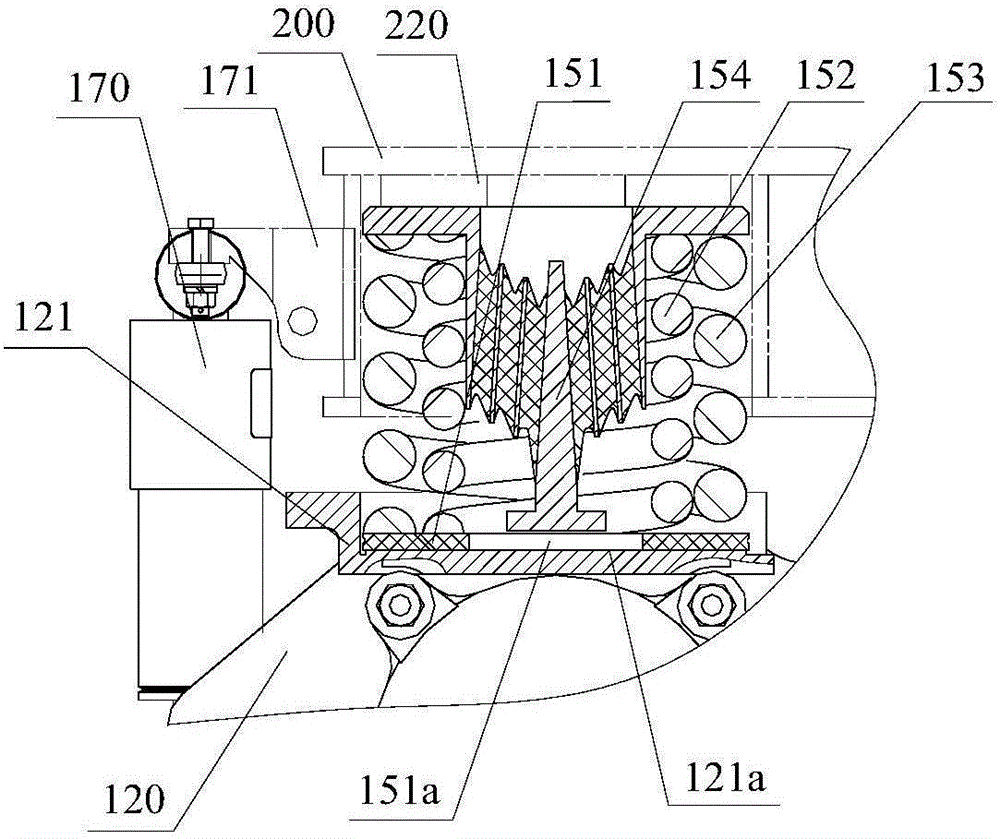

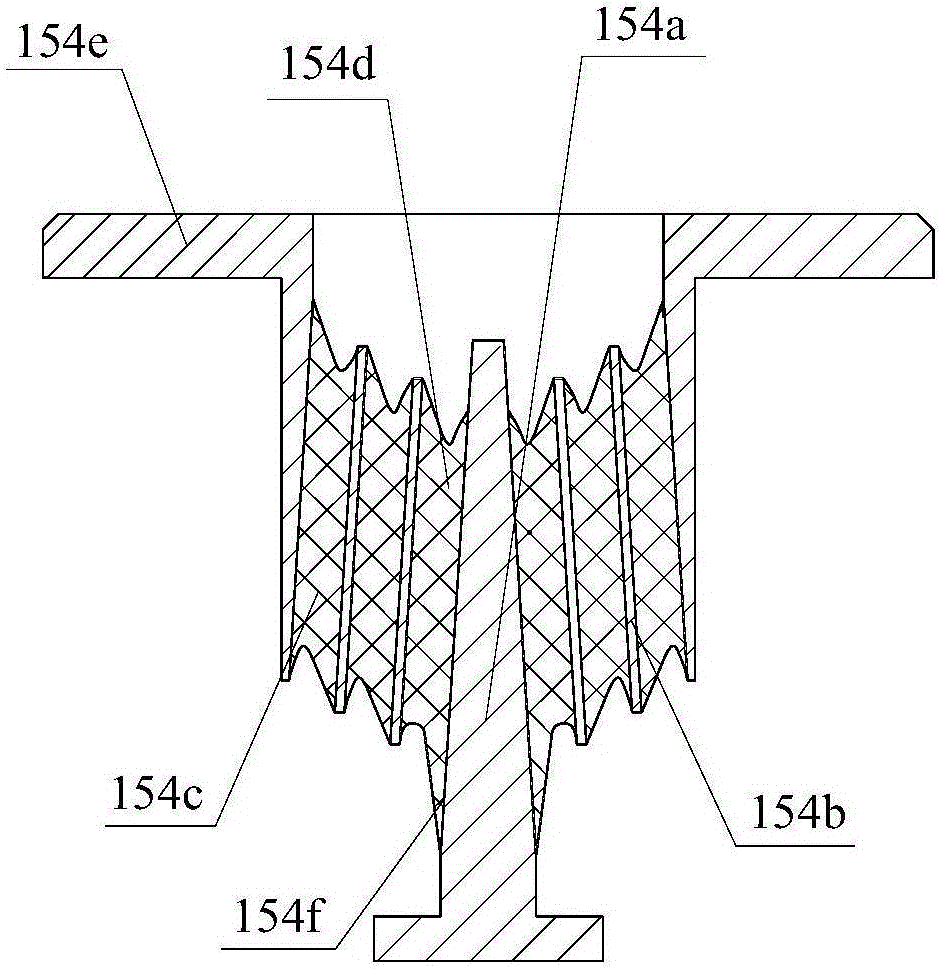

[0028] Such as figure 1 The axlebox positioning device of the truck bogie shown includes the axlebox body 110, the positioning arm 120, the elastic positioning node composition 130, the frame 200, the axlebox elastic suspension system 150, the clamping hoop 160 and the vertical hydraulic shock absorber 170 . The axle box 110 is formed by fixing the bolts after being surrounded by the positioning arm 120 and the clamping hoop 160, combined with Figure 6 As shown, the wheel set bearing 113 is arranged in the cavity 112 of the axle box body 110, and the axle box end cover 111 is installed on the outer end of the cavity 112 of the axle box body 110; figure 2 As shown, the upper top surface of the rotating end of the positioning arm 120 is provided with a bearing platform 121, and the axle box elastic suspension system 150 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com