Ceramic surface treatment method and ceramic shell

A ceramic surface and treatment method technology, applied in the field of ceramic materials, to achieve the effects of eliminating burning marks, reducing costs, and increasing the color range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

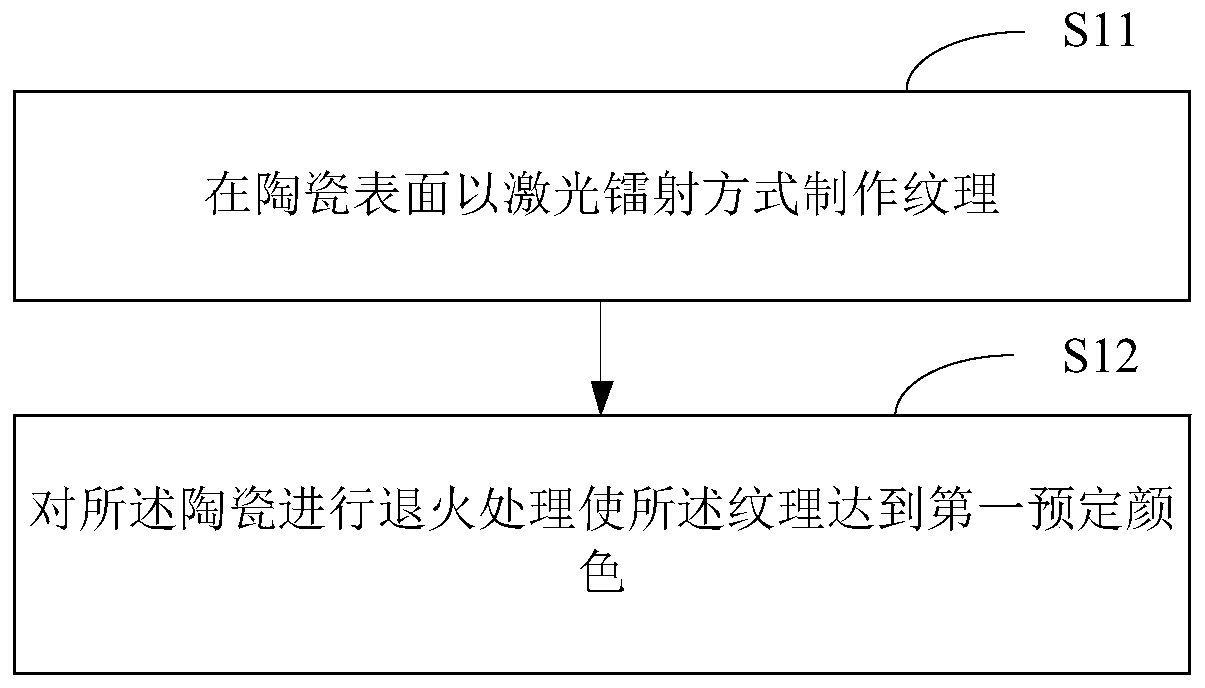

[0032] figure 1 It is a flow chart of a ceramic surface treatment method shown according to an exemplary embodiment, and the method can be applied to ceramic shells and the like. Such as figure 1 As shown, the method includes the following steps.

[0033] In step S11, the texture is made on the surface of the ceramic by means of laser laser. Among them, making textures by laser laser is also called "laser laser engraving" or "laser laser engraving".

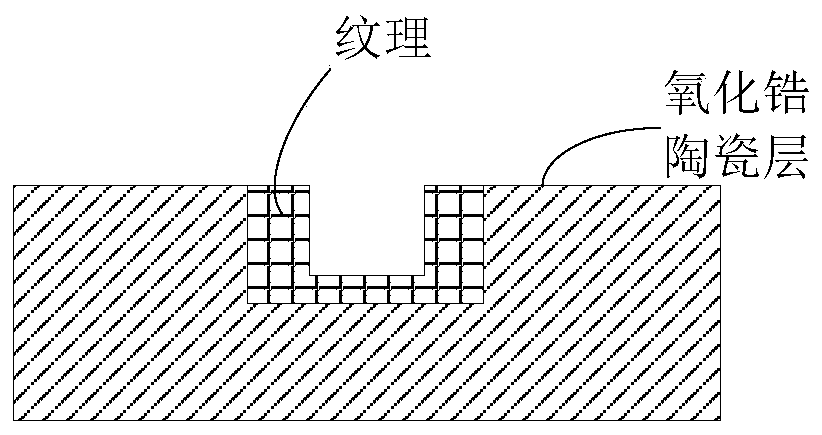

[0034] In a possible implementation manner, the ceramics may be zirconia ceramics, or other suitable ceramic materials with similar properties, which are not limited herein. For ease of understanding, zirconia ceramics are taken as an example for illustration below.

[0035] In a possible implementation manner, the method may further include preparing zirconia ceramics, for example, making powder into zirconia ceramics by means of dry pressing, hot die casting, sintering and the like.

[0036] figure 2 is a schematic diagr...

Embodiment 2

[0060] Figure 12 It is a schematic diagram of a ceramic shell according to an exemplary embodiment. The ceramic shell is surface-treated by the above-mentioned method, as shown in FIG. 11 , the shell can be used for mobile phones or other devices, such , tablets, watches, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com