Passenger car braking beam sleeve-retreating and sleeve-insetting machine

A brake beam and back sleeve technology, which is applied in the direction of manufacturing tools, milling machine equipment details, milling machine equipment, etc., can solve problems affecting driving safety, brake beam cracks, and low work efficiency, so as to ensure the quality of car repair and work smoothly , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

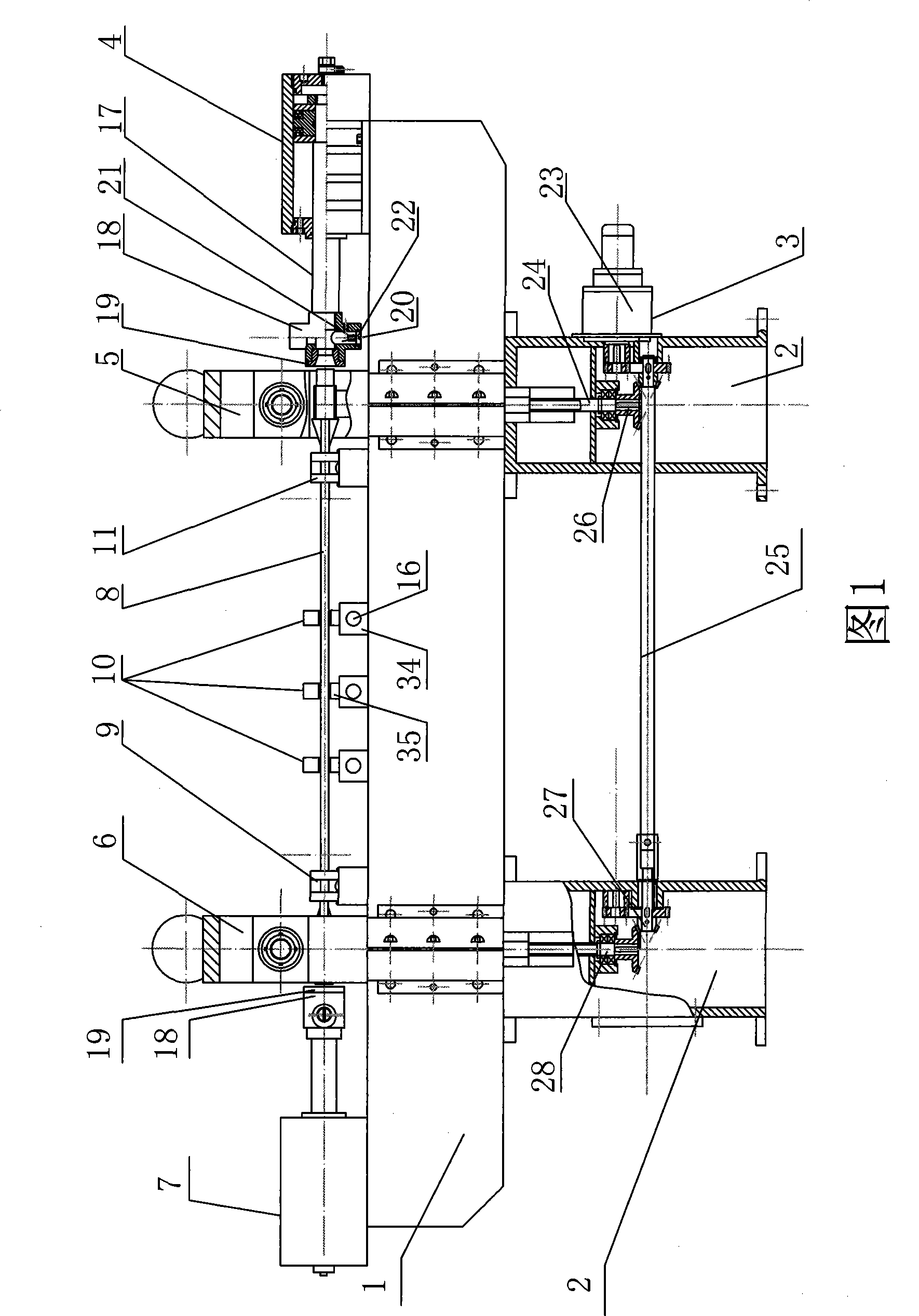

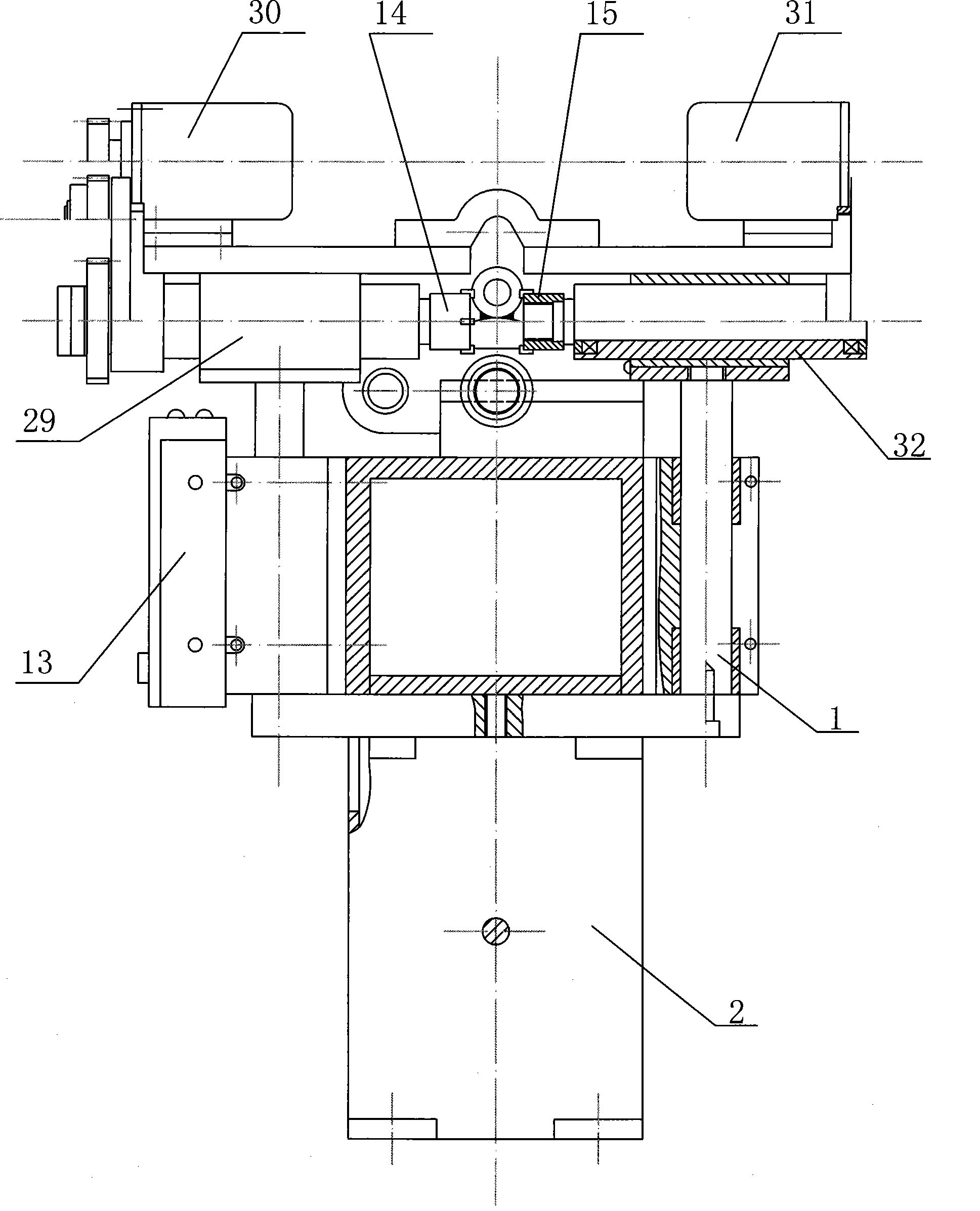

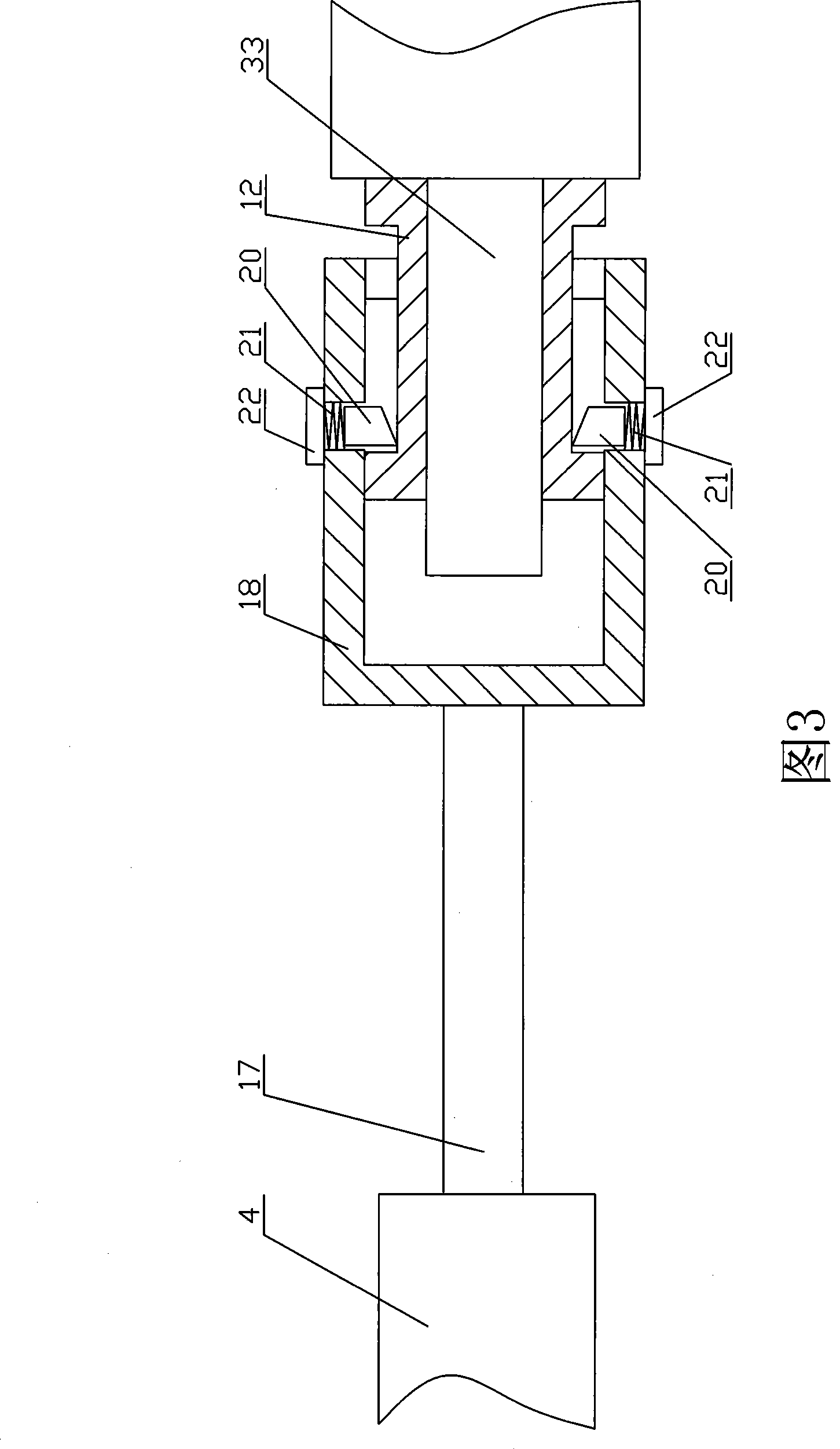

[0021] The specific embodiment of the present invention is as shown in the accompanying drawings; Two supports 2 are housed below the body 1, and a transmission pair is housed in the support 2, and a motor 23 drives the bevel gear pair 26, 27 to make the transmission shaft 24 , 28 rotate and then drive left and right milling cutter holders 29,32 to rise or fall; Left and right milling cutter heads 14,15 are housed on left and right milling cutter holders 29,32. Drive left and right milling head 14,15 rotary cuttings by motor 30,31. Left and right hydraulic cylinders 7, 4 and left and right milling devices 6, 5 are installed on the left and right sides of the working platform of the body 1 respectively. Fixed molds 9, 11 and three clip pushers 10 are respectively housed in the middle of the workbench. When the sleeve is withdrawn, the movable pin 20 in the push head 18 is pressed in by the milled sleeve 12 and the milled sleeve 12 enters the cavity of the push head 18. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com